Abstract

Synchronous fluorescence spectroscopy, a technique that measures both the absorption and the emission properties of a sample in a single measurement, was used for the analysis and classification of intact cereal flours (wheat, corn, rye, buckwheat, rice, and barley). Total synchronous fluorescence spectra recorded in constant wavelength mode show clear differences in the emission spectra of different flours due to variances in intrinsic fluorophore concentrations and their microenvironments. Principal component analysis, cluster analysis, and partial least squares discriminant analysis are used to assess the ability of synchronous fluorescence measurements to differentiate and classify intact samples of different flour types. The flour specimens were obtained directly from a market in Belgrade and had different expiration dates to provide a more representative set of samples. The results of the current analysis suggest that chemometric methods applied on synchronous fluorescence data can discriminate and classify flour types and that the best results are achieved using a combination of synchronous fluorescence measurements at synchronous intervals of 7 and 20 nm. The quality of results, the high speed of measurements, and the avoidance of extensive sample preparation make synchronous fluorescence spectroscopy a promising technique for cereal research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rapid and sensitive analytical technologies for food analysis are needed to respond to the growing public interest in food quality and safety. To make these technologies widely available, they should be relatively inexpensive, easily adapted to on-line monitoring, nondestructive, and, if possible, should not require highly skilled operators. In this context, fluorescence spectroscopy constitutes an interesting sensor technology because several functionally important fluorescent substances are inherent to food systems. These fluorophores include proteins, vitamins, secondary metabolites, toxins, and various types of flavoring compounds and pigments. Fluorescence spectroscopy is able to determine various properties of foods without the use of chemicals and time-consuming sample preparation (Andersen and Mortensen 2008). The potential of fluorescence for use in food research has increased in recent years with the wider application of chemometrics and with technical and optical advances in spectrofluorometry.

Fluorescence spectroscopy offers several inherent advantages for the characterization of food products compared with other spectrophotometric techniques. Fluorometric measurements are 100–1,000 times more sensitive than other methods (Strasburg and Ludescher 1995) and relatively rapid. The fluorescence intensity and spectrum of a molecule often depend strongly on that molecule’s environment. Environmental sensitivity means that fluorescence is able to characterize conformational changes, such as those attributable to the thermal, solvent, or surface denaturation of proteins, as well as the interactions of proteins with other food components (Karoui et al. 2006).

Traditional fluorescence techniques, which rely on single measurements of either emission or excitation spectra, are often inadequate for the analysis of complex systems. In such cases, excitation–emission matrices or total synchronous fluorescence (TSF) techniques may improve the analytic potential of fluorescence measurements (Sikorska et al. 2005).

The synchronous fluorescence (SF) method involves simultaneously scanning both emission and excitation wavelengths while keeping constant the interval between wavelengths, Δλ (constant wavelength mode), or between frequencies, Δν (constant energy mode). The resulting spectra are dependent on both the absorption and the emission properties of the investigated sample and therefore possess more features and give more information relative to traditional measurements (Vo-Dinh 1982). Synchronous scanning generates spectra with decreased bandwidths, reducing in this way the extent of overlap in the spectra of mixtures of fluorescent compounds. Moreover, SF spectra obtained with a small Δλ show an effective lowering of bandwidth resulting in spectral simplification and a consequent reduction in spectral overlap (Rubio et al. 1986). Additional sensitivity enhancement may be obtained by combining SF spectroscopy with derivative spectroscopy (Patra and Mishra 2002; Hur et al. 2010).

Fluorescence measurements are usually carried out using transmission or reflectance techniques. The transmission technique is employed for detecting solution fluorescence, while reflectance techniques have been used primarily for examining the front-surface fluorescence of turbid suspensions or solid materials (Liangand and Lin 2000). This technique measures the fluorescence emitted only from the sample surface, reducing the influence of nonfluorescent disturbances.

Fluorescence spectroscopy is a very practical technology currently in use in the environmental and agricultural field (Zaccone et al. 2009; Cocozza et al. 2011), as well as in the food production one. In particular, total fluorescence and synchronous scanning fluorescence techniques have been used to characterize different food products (Sadecka and Tothova 2007) such as commercially available vegetable oils (Sikorska et al. 2005), to detect quality changes in dairy products (Andersen and Mortensen 2008), and to investigate different dairy products such as milk (Kulmyrzaev et al. 2005), cheese (Herbert et al. 2000; Karoui et al. 2007a), and yogurt (Becker et al. 2003; Christensen et al. 2005). This technique is also useful for the determination of the level of lipid oxidation in foods such as fish and meat (Aubourg 1999; Wold et al. 2002), as well as to classify the botanical and/or geographic origins of honey samples (Karoui et al. 2007b).

Cereals are grown in greater quantities and provide more food energy worldwide than any other type of crop (Zaccone et al. 2010). In some developing countries, cereal constitutes the majority of daily sustenance. Cereal flour is one of the most important foods in many cultures and is the defining ingredient in most breads and pastries. Early applications of fluorescence spectroscopy in cereal food analysis were directed toward the prediction and classification of botanical tissue components of complex wheat flour (Jensen et al. 1982) and rye flour (Kissmeyer-Nielsen et al. 1985) samples. The front-face fluorescence of intact samples was investigated by Zandomeneghi (1999). Using this measurement geometry, fluorescence spectroscopy can discriminate between different species of cereals (Lakowicz 1983). In addition, this technique has been used to determine the relative xanthophyll contents in flours obtained from four breads and five durum wheats (Zandomeneghi et al. 2000), as well as for the measurement of riboflavin in cereal flours (Zandomeneghi et al. 2003). Kamut brand wheat from soft and hard wheat in flours, pasta, and semolina was also differentiated by front-face fluorescence spectroscopy (Karoui et al. 2006). According to published studies, the principal contributions to cereal flour fluorescence are from amino acids, riboflavin, vitamins, and carotenoids (Christensen et al. 2006).

The objective of this work was to investigate the potential of front-face SF spectroscopy coupled with statistical tools for use as a rapid and low-cost technique for the characterization and classification of cereal flours. To make the survey as general as possible, cereal flours (wheat, corn, rye, buckwheat, rice, and barley) were obtained directly from supermarket shelves, from various producers and with different expiration dates. Taking into account the fact that the appropriate selection of synchronous intervals is of high importance for application of synchronous spectroscopy in multicomponent samples (Patra and Mishra 2002), we aimed to find the optimal synchronous intervals for cereal flour classification using standard statistical methods [i.e., principal component analysis (PCA), cluster analysis, and partial least square discriminant analysis (PLS-DA)]. The presented study, to best of our knowledge, is the first investigation of the application of synchronous fluorescence spectroscopy in cereal flour research.

Material and Methods

Fluorescence Spectroscopy

Fluorescence measurements were performed in synchronous scanning mode (constant wavelength) on a Fluorolog-3 Model FL3-221 spectrofluorometer (Horiba JobinYvon) utilizing a 450-W Xenon lamp as the excitation source and an R928 PMT as the detector. Both excitation and emission monochromators used double gratings with dispersions of 2.1 nm/mm (1,200 grooves/mm), blazed at 330 nm for excitation and 500 nm for emission. The front-face accessory (Horiba JobinYvon) provided measurements with 22.5° reflection geometry. Total synchronous fluorescence spectra were recorded in the excitation range from 280 to 580 nm and for synchronous wavelength intervals from 5 to 180 nm. All slits were set at 1 nm, and the acquisition time per one data point was 0.2 s. Spectra were adjusted to compensate for source intensity changes using the signal from a built-in reference photodiode detector.

A total of 39 samples of cereal flours, from different producers and with different times until their expiration dates, were taken from markets and measured using front-face synchronous fluorescence spectroscopy. Various types of cereal flours, including wheat (11 samples), corn (9 samples), rye (6 samples), buckwheat (5 samples), rice (4 samples), and barley (4 samples), were examined. Flour specimens are prepared in a pellet form by gentle pressing.

Statistical Analysis

Exploratory data analysis and classification were performed using principal component analysis, cluster analysis, and partial least square discriminant analysis. All calculations were executed using the Solo (Eigenvector) software package.

PCA is an unsupervised statistical method that transforms a number of possibly correlated variables into a smaller number of uncorrelated variables called principal components. Each principal component is a linear combination of the original variables, and the principal components are orthogonal to each other, so there is no redundant information. The idea behind this method is to represent in an approximate manner a cluster of individuals in a smaller dimensional subspace. To do so, it projects the cluster onto a subspace in such a way that the inertia of the projection is maximal. The first principal component accounts for as much of the variability in the data as possible, and each succeeding component accounts for as much of the remaining variability as possible.

Cluster analysis is a method for unsupervised learning that does not require any prior knowledge about the group membership of the data set. This method uses distances between samples to build clusters and assumes that samples that are close to each other belong to the same group. Distances between the samples can be defined in many ways: for example, Euclidian distance, Mahalanobis distance, Minkowski distance, Manhattan distance, and distances based on PCA scores. Samples in one cluster are assumed to be similar to each other, and samples from different cluster are assumed to be less similar; therefore, every sample is first assumed to be an independent cluster, and then each cluster is connected to the next nearest sample. This process is repeated until all of the clusters are connected. The results of cluster analysis are then presented as a connection dendrogram. Using this approach, one can see how well the samples will group and investigate which groups are more similar and which are more unique.

PLS-DA is a variant of partial least square regression method often used for multivariate calibration, but it can also be used for classification. The output of this method is a threshold for every group that separates one group from all of the others. New data sets or cross-validation can be used for the evaluation of this model. Here, we used the venetian blinds cross-validation method, which selects every s th sample from the data set, repeats that s times, and makes s data splits.

Results and Discussion

Synchronous Fluorescence Spectra of Cereal Flours

Total SF spectra for different types of cereal flours are presented in the form of contour maps in Fig. 1. Emission patterns reflect the specificity of intrinsic fluorophores and their microenvironments in flours. Each contour map is a unique representation of the flour class, i.e., a fluorescence “fingerprint,” with only subtle variances between flours within the same class, and therefore may be used for chemometric flour classification and analysis purposes (Christensen et al. 2006). Even though these patterns look very similar, with exception of pattern obtained with rice sample, they differ in emission band center positions and band intensities. These emission differences arise due to different fluorophore concentrations and molecular environments in flours of different botanical origins.

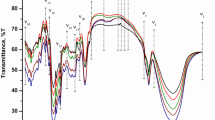

Although TSF spectra record all of the fluorescence emission data for the chosen spectral interval and therefore include all spectral features relevant for classification, the application of this technique to routine analysis is not convenient due to long measurement times and difficulties in producing user-friendly instrumentation for measurements at various synchronous intervals. For these reasons, synchronous spectra were taken at a single synchronous interval and used as data resources for further analysis. Figure 2 shows the wavelength dependence of fluorescence emissions of various types of cereal flours taken with using a synchronous interval of 10 nm as a typical example of synchronous spectra that could be further used for statistical analysis.

In addition to normalization automatically done by the instrument, all synchronous spectra were normalized to have maximum emission intensities of 100 (Ramanujam et al. 1996; Dramićanin et al. 2005; Ebenezar et al. 2010). Compared to normalization against emission of fluorescence standards, which can correct day to day variations in instrument throughput, this procedure is capable to remove influence of different morphologies of samples and possible variations in the sizes of illuminated surfaces. This is important for possible remote sensing applications where samples of different sizes and morphologies should be analyzed. The downside of the procedure is that fewer data are available for statistical analysis.

The difference between the SF spectra of different flours can be clearly observed from three emission band centers (λ 1, λ 2, and λ 3) and intensities (I 1, I 2, and I 3). While the origins of these bands are not important for the process of statistical analysis and flour type classification, it is worth mentioning that the most intense band is due to tryptophan emission, the second band comes mainly from ferulic acid and in some part from other p-hydroxycinnamic acids such as coumaric and caffeic acid (Zandomeneghi et al. 2000; Christensen et al. 2006; Karoui and Dufour 2008). The third band is largely due to the presence of riboflavin (Zandomeneghi et al. 2003) with interference of lutein and xantophyll emissions (Zandomeneghi et al. 2000; Christensen et al. 2006; Karoui and Dufour 2008). Additional fluorescence emission is observed in spectra of rice samples at excitation wavelength of about 480 nm. However, this feature cannot be exploited for classification purposes since other flours show minimal emission around this wavelength. Therefore, in classification process, data from emission at this wavelength would enable easy classification of rice flour samples, but on the cost of classification overlap of other flour types. It is worth pointing out the big differences between rice and other cereals in both TSF and SF spectra (in terms of intensity and complexity). Also, one can observe significant shifts of λ 1 in corn with respect to other cereals and the same behavior of λ 2 in buckwheat. All these differences ease discrimination between cereal flours.

In addition to differences in fluorescence between flours of different botanical origin, the variation of fluorescence properties is also present between samples of the same groups. These “in-group” variances take place due to differences in cereal grains, milling processes, flour moisture, etc. Table 1 lists mean values and standard deviations of fluorescence emission band centers and intensities measured at synchronous intervals of 5, 7, 10, and 20 nm calculated for each investigated flour type. One can easily notice that mean values of parameters differ between sample groups, but the in-group variance prevents their direct usage for classification. However, chemometric methods are capable to exploit very subtle parameter variances for successful classification, as for example as shown by Karoui et al. (2006) in case of the kamut brand detection by classical emission spectroscopy. One should also note that differences of band center positions between flour groups are expressed differently when changing synchronous interval in measurements. In case of tryptophan band position (first emission band), this difference changes from 5.5 nm for Δλ = 20 nm to 12.2 nm for Δλ = 5 nm. In each case boundary values come from corn (lower) and wheat (upper) flours. Similar trend is present with center position of the second emission band. The band position difference changes from 20.5 nm for Δλ = 20 nm to 36.1 nm for Δλ = 5 nm, and here, boundary values come from buckwheat (lower) and rice (upper) flours. An opposite trend is present with the third band. In this case maximal difference in band position is decreasing from 20 nm for Δλ = 20 nm to 16.7 nm for Δλ = 5 nm, where the lower bound is from barley flour and upper bond from corn flour emission.

Data Preprocessing

Before performing any analysis on the data set, the data were preprocessed to ensure data quality and to improve the efficiency and ease of further analysis. Here, preprocessing involved data mean centering and scaling. Mean centering alters the values of matrix columns (λ 1, λ 2, λ 3, I 2, and I 3) in such a way that the mean values of these columns become zero (shifted by column mean value), but the distances between the parameters remain the same. Scaling of the data was performed because of the large discrepancy between parameters intensities (see Table 1). Scaling gives the same statistical weight to all of the parameters, and the standard deviation of these values is then set to one. Scaling is performed by dividing every parameter in the column (which has already been mean centered) by that column’s standard deviation. The preprocessing method, which includes both mean centering and scaling of the data, is often referred to as data autoscaling.

Flour Analysis and Classification Based on Preprocessed Synchronous Fluorescence Data

To examine the ability of synchronous fluorescence analysis to discriminate between different types of cereal flours and to find the best synchronous interval for flour classification, several chemometric methods were applied. The ability to discriminate between flour types was best for synchronous spectra using low values for the synchronous interval, and the results of statistical analysis for each method are summarized below for synchronous values of 5, 7, 10, and 20 nm.

Principal component analysis is applied to selected spectral components, λ 1, λ 2, λ 3, I 2, and I 3, using synchronous spectra obtained with synchronous intervals of 5, 7, 10, or 20 nm. The goal was to investigate the variance between the various types of flour, to determine whether the groups showed different spectral characteristics from each other and to visualize the data.

Figure 3 shows four PCA score plots of different flour classes based on preprocessed synchronous fluorescence data for Δλ = 5, 7, 10, and 20 nm. One can see that groups did show differences in spectral characteristics but that some overlap is also present. On plots for Δλ = 5 and 10 nm, barley, wheat, and rye show some overlap, while other groups are visibly separated. Better separation between groups is observed in plots for Δλ = 7 and 20 nm. In these plots, rye does not overlap with barley or wheat, and wheat likewise does not overlap with barley and rye. The result suggests that data from single SF spectra are not sufficient for quality classification of flours even though clear distinction between some groups is present. In particular, rice, corn and buckwheat are clearly separable with each synchronous interval Δλ, while wheat, rye, and barley overlap.

Based on these findings, we decided to use data from two SF spectra measured with Δλ = 7 and 20 nm to achieve better separation of groups. Figure 4 shows results of PCA applied to those ten parameters (λ 1, λ 2, λ 3, I 2, and I 3 from the both spectra), and it can be unmistakably observed that complete separation between groups was achieved, with the highest separation for rice and corn.

To observe the degree of separation between the groups, we performed cluster analysis using Ward's method, which joins clusters in such a way that the within cluster variance is minimized. Figure 5 presents the results of a cluster analysis for the combined parameters of Δλ = 7 and 20 nm. It can be observed that distances between the groups are significant. Wheat and barley are closer than the other pairs of groups but are still well separated.

The results of the PCA and cluster analyses suggest that it is possible to build a classification model using data from SFS. For this purpose, we utilized the PLS-DA method. Ten classification models were made using parameters for Δλ = 5, 7, 10, and 20 nm, and combinations of Δλ = 5 and 7, 5 and 10, 5 and 20, 7 and 10, 7 and 20, and 10 and 20 nm. Table 2 summarizes the calibration and cross-validation errors of these models. One can see that the classification error based on parameters for synchronous intervals of 7 and 20 nm was the smallest of the models. For this model, 100% correct classification rates were obtained for calibration and cross-validation (Cal. = 0, CV = 0) for four of the flour type groups (buckwheat, corn, rice, and rye). Correct classification rates for the wheat and barley are somewhat lower, 89.2% and 87.5%, and 100% and 87.5%, respectively, for the calibration and cross-validation, but still similar to the best result obtained by Karoui et al. (2006) for flour and semolina classification with conventional fluorescence spectroscopy (86.7% and 87.9%).

Conclusions

Fluorescence spectroscopy is a very practical technology currently in use in many areas of agriculture and food production. When used for food discrimination, classification, and investigation of authenticity, it relies on the fluorescence detection of intrinsic fluorophore composition differences and changes in the microenvironments of these fluorophores. In this context, synchronous fluorescence spectroscopy may be highly beneficial because it characterizes both the absorption and emission properties of the investigated sample, thus providing more supportive data for chemometrics from single spectrum measurements.

Here, our results showed that cereal flours could be discriminated and classified using data obtained with front-face synchronous fluorescence measurements. These measurements were performed on flours obtained directly from market shelves, with different expiration dates and with no sample preparation. With the experimental setup used in this work, the measurement of one synchronous spectrum took less than 1 min. Discrimination and classification were possible for low synchronous intervals of 20 nm or less, and the best results were achieved with a combination of synchronous fluorescence measurements using 7 and 20 nm synchronous intervals.

Even though the fluorescence data obtained here were collected using a standard laboratory device, the data normalization and classification procedure facilitates the application of this method to portable and handheld fluorescence measurement devices. In addition, Liu et al. (2007) recently developed a synchronous fluorescence imaging system that will greatly expand the applicability of synchronous scanning methods.

The sample set investigated in this work served to demonstrate the power and applicability of the presented method. More precise estimations of discrimination and classification errors may be obtained with larger sample sets. However, the current results suggest that synchronous fluorescence measurements have strong potential for further application in flour analysis and also to be basis for more complex investigations such as, for example, characterization of cereal flour mixtures.

References

Andersen CM, Mortensen G (2008) Fluorescence spectroscopy: a rapid tool for analyzing dairy products. J Agric Food Chem 56:720–729

Aubourg SP (1999) Recent advances in assessment of marine lipid oxidation by using fluorescence. J Am Oil Chem Soc 76:409–419

Becker EM, Christensen J, Frederiksen CS, Haugaard VK (2003) Front-face fluorescence spectroscopy and chemometrics in analysis of yogurt: rapid analysis of riboflavin. J Dairy Sci 86:2508–2515

Christensen J, Becker EM, Frederiksen CS (2005) Fluorescence spectroscopy and PARAFAC in the analysis of yogurt. Chemometr Intell Lab Syst 75:201–208

Christensen J, Nørgaard L, Bro R, Engelsen SB (2006) Multivariate autofluorescence of intact food systems. Chem Rev 106:1979–1994

Cocozza C, Parente A, Zaccone C, Mininni C, Santamaria P, Miano T (2011) Chemical, physical and spectroscopic characterization of Posidonia oceanica (L.) Del. residues and their possible recycle. Biomass Bioenerg 35:799–807

Dramićanin T, Dramićanin MD, Jokanović V, Nikolić-Vukosavljević D, Dimitrijević B (2005) Three-dimensional total synchronous luminescence spectroscopy criteria for discrimination between normal and malignant breast tissues. Photochem Photobiol 81:1554–1558

Ebenezar J, Aruna P, Ganesan S (2010) Synchronous fluorescence spectroscopy for the detection and characterization of cervical cancers in vitro. Photochem Photobiol 86:77–86

Herbert S, Mouhous RN, Devaux MF, Riaublanc A, Bouchet B, Gallant DJ, Dufour E (2000) Monitoring the identity and the structure of soft cheeses by fluorescence spectroscopy. Lait 80:621–634

Hur J, Lee B, Lee T, Park D (2010) Estimation of biological oxygen demand and chemical oxygen demand for combined sewer systems using synchronous fluorescence spectra. Sensors 10:2460–2471

Jensen SA, Munck L, Martens H (1982) The botanical constituents of wheat and wheat milling fractions.1. Quantification by autofluorescence. Cereal Chem 59:477–484

Karoui R, Cartaud G, Dufour E (2006) Front face fluorescence spectroscopy as a rapid and nondestructive tool for differentiating various cereal products: a preliminary investigation. J Agric Food Chem 54:2027–2034

Karoui R, Dufour E, De Baerdemaeker J (2007a) Front face fluorescence spectroscopy coupled with chemometric tools for monitoring the oxidation of semi-hard cheeses throughout ripening. Food Chem 101:1305–1314

Karoui R, Dufour E, Bosset JO, De Baerdemaeker J (2007b) The use of front face fluorescence spectroscopy to classify the botanical origin of honey samples produced in Switzerland. Food Chem 101:314–323

Karoui R, Dufour E (2008) Sprectroscopic technique: fluorescence and ultraviolet-visible (UV-VIS) spectroscopy. In: Sun D-W (ed) Modern techniques for food authentication, 1st edn. Academic Press, Burlington, p 201

Kissmeyer-Nielsen A, Jensen SA, Munck L (1985) The botanical composition of rye and rye milling fractions determined by fluorescence spectrometry and amino acid composition. J Cereal Sci 3:181–192

Kulmyrzaev AA, Levieux D, Dufour E (2005) Front-face fluorescence spectroscopy allows the characterization of mild heat treatments applied to milk. Relations with the denaturation of milk proteins. J Agric Food Chem 53:502–507

Lakowicz JR (1983) Principles of fluorescence spectroscopy, 3rd edn. Plenum Press, New York, pp 63–93

Liangand JH, Lin CC (2000) Fluorescence kinetics of soybean flour oxidation. J Am Oil Chem Soc 77:709–713

Liu Q, Chen K, Martin M, Wintenberg A, Lenarduzzi R, Panjehpour M, Overholt BF, Vo-Dinh T (2007) Development of a synchronous fluorescence imaging system and data analysis methods. Opt Express 15:12583–12594

Patra D, Mishra AK (2002) Recent developments in multi-component synchronous fluorescence scan analysis. TrAC 21:787–798

Ramanujam N, Mitchell MF, Mahadevan A, Thomsen S, Staerkel G, Malpica A, Wright T, Atkinson N, Richarads-Kortum R (1996) Cervical precancer detection using a multivariate statistical algorithm based on laser-induced fluorescence spectra at multiple excitation wavelengths. Photochem Photobiol 64:720–735

Rubio S, Gomez-Hens A, Valcarel M (1986) Analytical applications of synchronous fluorescence spectroscopy. Talanta 33:633–640

Sadecka J, Tothova J (2007) Fluorescence spectroscopy and chemometrics in the food classification—a review. Czech J Food Sci 25:159–173

Sikorska E, Gorecki T, Khmelinskii IV, Sikorski M, Kozioł J (2005) Classification of edible oils using synchronous scanning fluorescence spectroscopy. Food Chem 89:217–225

Strasburg GM, Ludescher RD (1995) Theory and application of fluorescence spectroscopy in food research. Trends Food Sci Tech 6:69–75

Vo-Dinh T (1982) Synchronous luminescence spectroscopy: methodology and applicability. Appl Spectrosc 36:576–581

Wold JP, Mielnik M, Pettersen MK, Aaby K, Baardreth P (2002) Rapid assessment of rancidity in complex meat products by front face fluorescence spectroscopy. J Food Sci 67:2397–2404

Zaccone C, D'Orazio V, Shotyk W, Miano TM (2009) Chemical and spectroscopic investigation of porewater and aqueous extracts of corresponding peat samples throughout a bog core (Jura Mountains, Switzerland). J Soils Sediments 9:443–456

Zaccone C, Di Caterina R, Rotunno T, Quinto M (2010) Soil–farming system–food–health: effect of conventional and organic fertilizers on heavy metal (Cd, Cr, Cu, Ni, Pb, Zn) content in semolina samples. Soil Till Res 107:97–105

Zandomeneghi M (1999) Fluorescence of cereal flours. J Agr Food Chem 47:878–882

Zandomeneghi M, Festa C, Carbonaro L (2000) Front-surface absorbance spectra of wheat flour: determination of carotenoids. J Agric Food Chem 48:2216–2221

Zandomeneghi M, Carbonaro L, Calucci L, Pinzino C, Galleschi L, Ghiringhelli S (2003) Direct fluorometric determination of fluorescent substances in powders: the case of riboflavin in cereal flours. J Agric Food Chem 51:2888–2895

Acknowledgments

The authors acknowledge the support of the Serbian Ministry of Education and Science through project no. 45020.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zeković, I., Lenhardt, L., Dramićanin, T. et al. Classification of Intact Cereal Flours by Front-Face Synchronous Fluorescence Spectroscopy. Food Anal. Methods 5, 1205–1213 (2012). https://doi.org/10.1007/s12161-011-9359-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-011-9359-1