Abstract

Analytical chemistry plays a fundamental role in proposing fast and reliable procedures to analyze food samples. Proper selection and introduction of complementary foods during the breastfeeding period and childhood reduce the vulnerability to micronutrient deficiencies. This study aimed to propose a sensitive approach for the promotion of adequate food supplements regarding Cd, Fe, Pb, and Zn content. These metals were determined using flame atomic absorption spectrometry (Fe and Zn) and thermospray flame furnace atomic absorption spectrometry (Cd and Pb). A simple procedure mixing the sample (100 mg) with 0.1 mol/L HCl was proposed. Cadmium and Zn showed suitable results when a bovine liver certified sample (SRM 1577b) was studied, and the Fe content was strongly correlated to the size of the particle. Cadmium and Pb were not found in the food samples studied.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The proposition of analytical methods for food quality control and inspection is an important procedure to ensure proper micronutrient levels. Nutrition of children at school age is of public concern since these minerals are critical to their growth and development (Fraga 2005; Welch and Graham 2005). The levels of metal concentrations must be known to avoid contaminations with toxic metals and overexposure to micronutrients. Thus, in order to develop fast and reliable procedures to analyze the samples, analytical chemistry must be used (Muños-Olivas 2004). Several procedures employing, for example, mineralization with concentrated reagents (HNO3, HCl, H2O2, and HClO4; Oliveira and Braz 2003) can be found in the literature. These procedures involve great sample mass and require both attention of the operator and long completion time (Huie 2002). However, the analytical sequence time can be reduced using a microwave oven, thus leading to an increase in the analytical sampling rate (Oliveira and Braz 2003). In such procedures, it is possible to use concentrated or diluted acids (Nobrega et al. 2007; Soylak et al. 2007).

Additionally, significant analytical results with high frequency and both low contamination and analyte losses can be obtained through the use of diluted acids and extraction procedures (Donati et al. 2006; Rugani et al. 2004).

Vidal et al. (2002), for example, applied diluted HCl for Ca, Cu, and Fe determination in food samples and compared the proposed method with wet digestion. It was observed that the procedure using diluted HCl was faster, simpler, and presented more accurate results. Aleixo et al. (2004) determined Cd and Pb in pig kidney and rice flour samples. The authors mixed the samples with 2.8 mol/L HNO3 using an ultrasound batch and centrifuged the mixture prior to analyte determination.

An important consideration to meet the nutritional requirements of Fe and Zn is related to the food sources, focusing on proper introduction and selection of complementary foods during the breastfeeding period and childhood, in order to reduce vulnerability to micronutrient deficiencies (Bulusu et al. 2007). A number of factors play a role in the introduction and selection of supplementary foods, which include infant maturation, cost, food supply logistics, and safety guidelines. Despite all efforts, composition of school meals do not, in great part, meet the dietary requirements regarding the minerals content (Rogers et al. 2007).

Thus, a sensitive approach for the promotion of adequate supplements during infancy calls for attention as to their nutritional composition, especially when considering that toxic metals content in school meals are not clearly stated.

Experimental

Samples

Six samples of a supplemental recipe were prepared at the Nutrition College of the Pontifical Catholic University of Campinas located in the State of São Paulo, Brazil. The recipe was composed by minced chicken liver, milk, milk cream, salt, chopped onion, and garlic. These components were cooked under atmospheric pressure for 15 min and mixed together with a blender to make a smooth paste that could later be incorporated to children food to enrich it. This supplementation aims to provide the proper amount of Fe, Zn, and vitamins to children food in the Campinas metropolitan area schools. It is important to mention that there is no information concerning heavy metal contamination since toxic compounds can be accumulated in the liver (Fraga 2005). Taking into account that toxic compounds can accumulate in the liver, elucidating whether chicken liver can be a source of metal contaminant in the school meal is an attractive topic. The analyzed samples were the (1) supplement alone, (2) the supplement incorporated to beans, (3) the beans alone, (4) meat and potatoes, (5) meat and sauce, and (6) rice and vegetables. All samples were prepared following standard cooking procedures and then freeze-dried (Flexy-Dry Freeze Dryer, Kinetics Thermal Systems, Stone Ridge, NY, USA).

Equipments

Cadmium, Fe, Pb, and Zn contents were determined using an atomic absorption spectrometer (Spectra AA640, Varian, Mulgrave, Victoria, Australia), equipped with a deuterium lamp for background radiation correction. The determinations were made under the conditions (wavelength, slit, and lamp current) reported in Table 1. In all cases, an oxidizing-air (13.5 L/min) acetylene (2.0 L/min) flame was used. Iron and Zn were determined by using the spectrometer in the conventional flame mode (flame atomic absorption spectrometry [FAAS]), and Cd and Pb were determined by using thermospray flame furnace atomic absorption spectrometry (TS-FF-AAS; Gáspár and Berndt 2000). The TS-FF-AAS main characteristics are depicted in Fig. 1. In this technique, a Ni tube is placed above an air/acetylene flame, and the sample is directly introduced into this tube (see detail in Fig. 1). By using this procedure, total sample introduction, long residence time, and good sensitivity (Pereira-Filho et al. 2002) can be achieved.

For the sample preparation, optimization was achieved by using an ultrasound batch (AquaWave 9374, Barnstead International, Dubuque, IA, USA), a vortex (37600 Mixer, Thermolyne, Dubuque, IA, USA), a centrifuge (Hermle Z200A, Labnet, Edson, NJ, USA), an analytical balance (AS200, Ohaus, São Bernardo do Campo, São Paulo, Brazil), and a microwave oven (Ethos 1, Milestone, Sorisole, Bergamo, Italy).

Reagents and Solutions

All solutions were prepared with distilled and deionized water (Milli-Q Plus, Millipore, Barueri, São Paulo, Brazil). The calibration solutions were prepared after successive dilutions of the stock standard solutions (Merck, Darmstadt, Germany). For Fe and Zn, the concentrations varied from 0.25 to 8 and from 0.2 to 1.5 mg/L, respectively. Due to the expected low Cd and Pb concentrations, the calibration solutions varied from 5 to 25 and from 100 to 500 μg/L, respectively.

Procedure for Metal Extraction

In order to reduce the sample preparation procedures time, an extraction method was studied. In this case, a simple procedure mixing the sample with diluted acids was proposed. In order to maximize the optimization of this extraction a fractional factorial design (Bruns et al. 2006) was developed. Seven variables were taken into account: sample mass (1), acid volume (2), acid concentration (3) acid type (4), mixing type (123), mixing time (124), and filtration (1234). Table 2 shows the experiments performed. A 27 − 3 fractional factorial design was organized, and 16 experiments were made. The mixing type, mixing time, and filtration variables were obtained after combinations 123, 124, and 1234, respectively. All experiments were performed in two levels (normalized in −1 and +1). The sample masses used were 100 (low level normalized in −1) and 200 mg (high level normalized in +1). Hydrochloric acid (normalized in −1) and HNO3 (+1; both from Merck) were tested in order to observe their performance in the extraction procedure. The acid volumes and concentrations tested were 5 (−1) and 10 mL (+1) and 0.1 (−1) and 1 mol/L (+1), respectively. Two mixing devices and time were evaluated: vortex (−1) and ultrasound (+1), at 5 (−1) and 10 min (+1), respectively. The influence of filtration procedure was also tested (−1 with no filtration and +1 with filtration). The experimental conditions were optimized by determining the Zn contents in the lyophilized supplement. These conditions were then used to check the influence of the sample particle size. Three particle sizes were investigated: 106, 212, and 600 μm, and only the rice and vegetables (sample 6—see “Samples”) sample was tested. This sample was manually milled and then sieved (Bertel, Caieiras, São Paulo, Brazil).

Microwave-assisted digestions were carried out using a 250-mg sample, 2 mL concentrated HNO3 and 1 mL H2O2 (30%, w/v) to compare to the optimized extraction conditions previously described. The heating program used was as follows: 1 min, 250 W (step 1); 1 min, 0 W (step 2); 3 min, 250 W (step 3); 5 min, 400 W (step 4); 7.5 min, 800 W (step 5), and 10 min, 0 W (step 6 for ventilation). This microwave program was adapted from Gouveia et al. (2001).

Procedure for Metals Determination using TS-FF-AAS

In the TS-FF-AAS technique, some variables must be evaluated in order to obtain suitable results and high sensitivity. The main variables were sample volume, carrier flow rate, metal tube atomizer composition, and carrier type. As described in the extraction optimization section, the TS-FF-AAS conditions were also evaluated using a fractional factorial design. Table 3 shows the experiments performed. In this case, the carrier type (123) was obtained combining variables 1 (volume), 2 (flow rate), and 3 (tube). A total of eight (24 − 1) experiments were performed, and a Zn analytical curve (from 25 to 125 μg/L) was recorded in each experiment. In most works, only the signal magnitude (signal area or height) is evaluated. In this work, the ratio (ratio 1) between the regression mean sum of squares and residuals mean sum of squares and the ratio (ratio 2) between the lack of fit mean sum of squares and pure error mean sum of squares were also observed. High ratio 1 and low ratio 2 describe the best work conditions. Other parameters such as slope, coefficient of regression, interception, limits of detection (LOD) and quantification (LOQ), and the relative standard deviation (RSD) of blanks were also evaluated.

Results and Discussion

Optimization of the Metals Extraction

As described in “Procedure for Metal Extraction,” Zn was determined in each experiment. In order to facilitate the data interpretation, these values were normalized, with 100 being the highest value.

Figure 2 shows the probability graphic of the calculated variables contrasts. The highest contrasts were observed for mixing type (−24%), sample mass (−17%), and filtration (−14%). In this case, when the ultrasound was used, a less intensive Zn extraction was observed. In the same way, when a higher mass (200 mg) was used, poor Zn extraction was obtained, probably due to a small interaction between the solid sample and the liquid. In the case of filtration, it could be observed that when the samples were not filtered, more Zn was extracted due to the possible particles introduction into the flame zone and consequently into the optical path of the equipment. In order to avoid manipulation and contamination, centrifuging of the samples was indicated as an alternative for filtration. The other calculated contrast values (mixing time, acid type, concentration, and volume) showed negligible values (ranging from −10% to 6%—see the contrasts between the dotted vertical lines in Fig. 2), thus proving that the use of either HCl or HNO3, for instance, is of minor importance.

Finally, the fixed extraction conditions were 100 mg (sample mass), 5 mL (acid volume), 0.1 mol/L (acid concentration), HCl, vortex, and 5 min (mixing time).

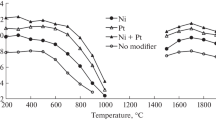

Optimization of the TS-FF-AAS System

When considering the TS-FF-AAS optimization conditions, several parameters were observed. Table 4 shows the most remarkable results. It was observed that for the slope parameter, the use of the Ni tube and a higher sample volume (100 μL) resulted in the highest values (a more sensitive method). Similarly, the lowest LOD and LOQ were obtained using HNO3. Considering the blank RSD, the use of the Ni tube and a higher flow rate (0.6 mL/min) resulted in lower values. When ratios 1 and 2 were observed, more suitable results were obtained using a higher sample volume and Ni tube. Figure 3 shows the contrasts calculated when the slope parameter was observed. By comparing Table 4 and Fig. 3, it was concluded that the best TS-FF-AAS conditions were achieved by using a higher sample volume and the Ni tube. A higher sample volume was not tested in the following experiments in order to avoid a decrease in the sample frequency. The results’ evaluation showed that a high flow rate allows better results; however, during extended-time experiments (approximately 60 min) using real samples, it was observed that the highest flow rate generates a cooling effect in the ceramic capillary tip, decreasing the efficiency of the thermospray formation. Thus, 200 μL sample volume, 99% Ni tube, 0.5 mL/min flow rate, and 0.01% v/v HNO3 as the carrier were the final experimental conditions.

Metal Determination in Food Samples

Cadmium and Pb were determined using TS-FF-AAS. Figure 4 shows some analytical signals for Cd calibration solutions, supplement, and certified sample (Bovine Liver—SRM 1577b). As it can be observed, Cd was not detected in the supplement. On the other hand, by weighing approximately 100 mg of the certified sample and adjusting the final volume to 5 mL, as described in “Optimization of the Metals Extraction,” the theoretical Cd concentration is approximately 10 μg/L. Figure 4 shows good agreement between the theoretical and experimental values, and the analytical frequency was 38 determinations per hour.

The TS-FF-AAS presented suitable detection limits and good repeatability for Cd and Pb determinations. For Cd, the LOD and LOQ were 0.6 and 2.0 μg/L, respectively, the repeatability for certified sample determination was 3.8% (n = 3), and the reproducibility was 7.0% (n = 14). The obtained concentration for Cd in the certified sample was 0.50 ± 0.04 mg/kg using the extraction procedure. This value is in good agreement with the certified value. An unpaired t test (Bruns et al. 2006) was calculated, and no differences between these values were observed within 95% of confidence level.

Considering Pb, the LOD and LOQ were 6.0 and 20 μg/L, respectively. The certified value for Pb is 0.129 ± 0.004 mg/kg in the bovine liver—SRM 1577b; by using the proposed method, Pb was neither found in the certified sample nor in the food samples. During the experimental part in our laboratory, approximately 3,000 determinations were performed (100 h) for Cd and Pb, using the same Ni tube with no observable sensitivity losses. The Ni tube lifetime is up to now unknown.

When considering Zn, the LOD and LOQ were 0.032 and 0.107 mg/L, respectively. This metal was found in all samples, and Table 5 shows the results. The repeatability and reproducibility were 2.0% (n = 3) and 6.0% (n = 19), respectively. The certified Zn concentration in the SRM 1577b is 127 ± 16, and the obtained value in the extraction and mineralization processes were 123 ± 6 (n = 19) and 120 ± 5 mg/kg (n = 3), respectively. The values observed in the extraction and mineralization were compared with the certified one using an unpaired t test, and they were concordant within a level of confidence of 99% and 95%, respectively. For Fe, extraction recovery observed in the certified sample was 69%. In the mineralization, the observed concentration was 168 ± 9 mg/kg (n = 3). This value is in agreement with the certified one (184 ± 15 mg/kg) within a confidence level of 95%. The LOD and LOQ for Fe were 0.10 and 0.34 mg/L, respectively.

Extractions performed using the rice and vegetables sample with different particle sizes (106, 212, and 600 μm) indicate that, for Zn, the size of the particle did not significantly affect the metal removal (22.2 ± 2.8, 22.1 ± 1.5, and 21.8 ± 2.0 mg/kg for sizes 106, 212, and 600 μm, respectively). For Fe, a lower extraction was observed in larger particles (2.3 ± 1.1 and 3.2 ± 1.5 mg/kg for sizes 212 and 600 μm), with a 101.9 ± 5.0 mg/kg extraction in smaller particles (106 μm).

When comparing the values obtained from both digestion (see also Table 5) and extraction methods, Zn exhibited good similarity, whereas Fe showed extraction concentration values lower than the digestion ones (Table 5), except for the beans and supplement sample. After digestion, Pb showed concentration levels lower than LOD (6.0 μg/L). The Cd concentration exhibited a 35% recovery in the certified sample, while the concentrations were lower than LOD (0.6 μg/L) in the other samples. This low recovery observed in the certified sample after mineralization was probably due to the presence of concomitants (mainly macronutrients). The presence of these concomitants was promoted by the use of microwave digestion and concentrated acid.

The proposed extraction method presented suitable results for Cd and Zn. The Fe extraction process is strongly correlated to the size of the particle. Lead was not found in any sample, and the LOD and LOQ values obtained through TS-FF-AAS were extremely low. The supplement has high Fe and Zn concentrations, and the presence of Cd or Pb was not detected. Another advantage of the extraction method with diluted acids is that by using this procedure, few concomitants are verified in the liquid phase and, consequently, less interference is observed during the metal determination. Finally, the total analytical speed (sample preparation plus determination) is eight samples per hour.

References

Aleixo PC, Santos Júnior D, Tomazelli AC, Rufini IA, Berndt H, Krug FJ (2004) Anal Chim Acta 512:329

Bruns RE, Scarminio IS, Barros Neto B (2006) Statistical design—chemometrics. Elsevier, New York

Bulusu S, Laviolette L, Mannar V, Reddy V (2007) Nestle Nutr Workshop Ser Pediatr Progr 60:91

Donati GL, Nascentes CC, Nogueira ARA, Arruda MAZ, Nóbrega JA (2006) Microchem J 82:189

Fraga CG (2005) Mol Aspects Med 26:235

Gáspár A, Berndt H (2000) Spectrochim Acta Part B 55:587

Gouveia ST, Silva FV, Nogueira ARA, Nóbrega JA (2001) Anal Chim Acta 445:269

Huie CW (2002) Anal Bioanal Chem 373:23

Muñoz-Olivas R (2004) Trends Anal Chem 23:203

Nóbrega JA, Nascentes CC, Araújo GCL, Nogueira ARA, Pirola C (2007) Commun Soil Sci Plant Anal 38:2333

Oliveira E, Braz J (2003) Chem Soc 14:174

Pereira-Filho ER, Berndt H, Arruda MAZ (2002) J Anal At Spectrom 17:1308

Rogers IS, Ness AR, Hebditch K, Jones, LR, Emmett PM (2007) Eur J Clin Nutr 61:856

Rugani KS, Semaan FS, Luccas PO, Pereira-Filho ER (2004) Microchem J 78:187

Soylak M, Tuzen M, Souza AS, Korn MGA, Ferreira SLC (2007) J Hazard Mater 149:264

Vidal MT, Pascual-Martí MC, Salvador A, Llabata C (2002) Microchem J 72:211

Welch RM, Graham RD (2005) J Trace Elem Med Biol 18:299

Acknowledgments

The authors are grateful to the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for the fellowship to JADC and to the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) for the financial support (processes 04/01970-4 and 07/04515-4).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Da-Col, J.A., Domene, S.M.A. & Pereira-Filho, E.R. Fast Determination of Cd, Fe, Pb, and Zn in Food using AAS. Food Anal. Methods 2, 110–115 (2009). https://doi.org/10.1007/s12161-008-9041-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-008-9041-4