Abstract

One-pass harvest equipment has been developed to collect corn (Zea mays L.) grain, stover, and cobs that can be used as bioenergy feedstock. Nutrients removed in these feedstocks have soil fertility implication and affect feedstock quality. The study objectives were to quantify nutrient concentrations and potential removal as a function of cutting height, plant organ, and physiological stage. Plant samples were collected in 10-cm increments at seven diverse geographic locations at two maturities and analyzed for multiple elements. At grain harvest, nutrient concentration averaged 5.5 g N kg−1, 0.5 g P kg−1, and 6.2 g K kg−1 in cobs, 7.5 g N kg−1, 1.2 g P kg−1, and 8.7 g K kg−1 in the above-ear stover fraction, and 6.4 g N kg−1, 1.0 g P kg−1, and 10.7 g K kg−1 in the below-ear stover fraction (stover fractions exclude cobs). The average collective cost to replace N, P, and K was $11.66 Mg−1 for cobs, $17.59 Mg−1 for above-ear stover, and $18.11 Mg−1 for below-ear stover. If 3 Mg ha−1 of above-ear stover fraction plus 1 Mg of cobs are harvested, an average N, P, and K replacement cost was estimated at $64 ha−1. Collecting cobs or above-ear stover fraction may provide a higher quality feedstock while removing fewer nutrients compared to whole stover removal. This information will enable producers to balance soil fertility by adjusting fertilizer rates and to sustain soil quality by predicting C removal for different harvest scenarios. It also provides elemental information to the bioenergy industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

An estimated 218 million Mg of dry feedstock per year will be needed to meet the 76 billion liters of second-generation (non-food source) renewable fuels target for 2022 in the USA [8]. Multiple, regionally specific lignocellulosic materials will be used to achieve this goal, but one of the most important in Midwestern USA will be corn (Zea mays L.) stover. Other potential feedstock materials include other crop residues such as wheat (Triticum aestivum L.), dedicated annual and perennial energy crops (e.g., switchgrass (Panicum virgatum L.), sorghum (Sorghum bicolor L.), miscanthus (Miscanthus), or sugarcane (Saccharum officinarum L.) bagasse)), and woody species such as poplar (Poplar ssp.) and pine (Pinus ssp.) [8]. Additional feedstock biomass will be needed to meet demands for producing biopower [6] and bioproducts [29].

Corn stover refers to the aboveground, non-grain plant parts including the cob, leaves, and stalk. Currently, stover is collected primarily using several field operations following corn grain harvest, in which the stover is cut, windrowed, baled, and hauled to a storage site [33]. These operations increase the number trips across the field, often during a time of year when rainfall or snowfall can limit harvest time and create soil conditions that are susceptible to compaction. To reduce the number of field operations and cost of feedstock collection, one-pass harvest equipment that can collect corn grain as well as stover and/or cobs is being developed [34] but is not yet commercially available. Initial one-pass harvest studies have been conducted to assess various harvest scenarios for collecting corn stover and cobs [18, 34]. A study in Iowa concluded that harvesting grain and stover in one-pass with a 40-cm cutting height could save time and fuel and provide higher quality feedstock for ethanol fermentation than a multi-pass baling operation [18]. Another study suggested feedstock fractionation could reduce ethanol production costs by minimizing pretreatment and hydrolysis requirements [10]. For example, husk and cobs released more glucan and produced more ethanol compared to stalk bottoms when using the same pretreatment and hydrolysis treatment even though the stalk contained a comparable amount of glucan [10].

With successful development of one-pass technology for stover harvest, the next critical question is at what height the corn plant should be cut. This is critical because the amount of crop residue that can be harvested in a sustainable manner without degrading soil resources through loss of soil organic carbon (SOC) or erosion varies by location, crop rotation, and tillage practice [26, 38, 39]. The amount of residue that needs to be returned to the field to maintain SOC can exceed that needed to control wind or water erosion [39]. Furthermore, harvesting crop residues removes more mineral nutrients than harvesting only grain [10, 17, 18, 24, 25]. Developing a broad comprehensive dataset on nutrient removal is important because the amounts removed will depend on element concentration, quantity, and type of stover harvested and frequency of removal.

Nutrient concentrations in corn stover vary between upper and lower portions of the stalk [10, 18, 23]. Therefore, cutting height during harvest will impact both average nutrient concentration in the harvested biomass and the quantity of nutrient removed from the field. Nutrient concentrations in cobs may differ from those in stalks [10] because of differences among plant organs. Unfortunately, there are few publications with multiple locations that provide both information on nutrient concentration in harvested biomass and that also differentiate the vertical distribution of nutrients and differences among stover fractions [10, 20]. Literature from animal science focuses on the feed quality of plant material and frequently is based on material collected at physiological maturity or younger [4, 7, 22, 28]. We collected plants both at physiological maturity and at grain harvest to compare nutrient concentration between the two dates. If there is little difference in nutrient concentration, it suggests data from the animal science literature can be directly used for estimating nutrient removal at grain harvest in the stover.

Weather conditions may sometimes force producers to harvest at earlier than desired times. Although corn stover can have high moisture content at earlier harvest dates, wet storage by ensilage is a possible method to store high moisture bioenergy feedstock [33]. Ensiling corn stover can improve harvest timeliness and reduce harvest losses [33], but does not necessarily provide an economic advantage compared to dry storage methods (e.g., bales) [2]. Thus, several locations included more than one plant maturity.

Developing a broad, geographic database with vertical distribution of nutrients has at least three practical applications. First, the quantity of C that is removed not only affects the value of the biomass crop but also the amount of biomass returned to the soil, which functions as food for microorganisms, maintaining soil structure and SOC. Second, inorganic elements such as K, Cl, and Si can negatively affect feedstock quality for both biochemical conversion and thermochemical processing [3]. Third, removal of essential plant nutrients with biomass harvest will affect the amount and type of fertilizer that is required to maintain soil fertility. The replacement value of the nutrients removed with the stover will have a large impact on the fair market value for the feedstock.

Recognizing the applications listed above and other needs associated with the developing biofuel and bioproducts industries, this multi-location project builds on a companion publication quantifying the vertical distribution of corn stover as a function of cutting height, geographic location, and plant maturity [40]. Our specific objectives for this study were to quantify nutrient concentrations and potential nutrient removal as a function of vertical cutting height, plant organ, and physiological growth stage at different geographic locations and for hybrids with varying maturities. The impetus for this study was use of stover as a bioenergy feedstock, but it would be applicable regardless of the reason for stover collection and removal (e.g., for fodder, bedding, or as a biomaterial for construction materials).

Materials and Methods

Experimental Sites

A multi-location experiment was conducted at Ames, IA, USA; Auburn, AL, USA; Fort Collins, CO, USA; Florence, SC, USA; Lincoln, NE, USA; Mandan, ND, USA; Morris, MN, USA; and St. Paul, MN, USA. Each location had at least one site and sampling date, although some had multiple sites, management practices, and/or sampling dates (Table 1). Collectively, these locations represent a wide range of climatic, soil, hybrid, planting date, population densities, and cultural practices [40] associated with corn production throughout the USA.

Sampling Method

Plants were destructively sampled from a 1.0-m2 area at physiological maturity and/or at grain harvest. The corn plants were cut as close to the soil surface as possible. Ears were removed from the husk and dried separately. The height to the base of the grain-containing ear (ear height), height to the node at which the ear shank was attached to the stalk (shank height), and plant height were recorded to the nearest centimeter for each plant. Corn stalks were marked at 10-cm intervals starting at ground level and continuing upward with the top segment being one 10-cm interval above the base of the primary grain-containing ear. All plant material above the top interval was pooled into a single above-ear sample. All plant parts (cob, above-ear, and 10-cm increment samples) were oven-dried at 60°C to a constant weight. Grain was removed from cob prior to determining dry cob weight.

Our rationale for this sampling approach was to mimic a one-pass harvest system that could collect grain and cobs, or grain and stover. A high-cut (18) one-pass treatment would at least collect everything at and above the ear, while a low cut treatment would collect everything above a stubble height of 10 cm. The 10-cm sampling increments were to help interpolate between the low- and high-cut treatments.

Segment samples from multiple plants (within a replication at each site) were pooled to provide sufficient plant material for chemical analysis. Typically, segments were combined from five to ten plants, depending on plant population (Table 1). C and N analyses for all locations were conducted at the ARS-Agroecosystems Research Unit in Lincoln, NE, USA. All the Cl, microwave digestion, and inductively coupled plasma-optical emission spectroscopy (ICP-OES) analyses were done at the ARS-North Central Soil Conservation Research Laboratory in Morris, MN, USA. Total C and total N in the plant tissue were determined by combustion (900°C) with a Carlo Erba combustion analyzer (Thermo Scientific, Waltham, MA, USA). Chloride was extracted by shaking in 0.01 M CaSO4, and the Cl concentration was determined by flow injection analysis using the mercury (II) thiocyanate colorimetric method measured on a Technicon AutoAnalyzer II (ALPKEM, Clackamas, OR, USA) at 480 nm with a minimum detection limit (MDL) of 1 µg mL−1 [13, 35]. All other nutrients were determined by ICP-OES on a Varian Vista-Pro CCD simultaneous ICP-OES (Varian Incorp., Palo Alto, CA, USA) following a concentrated HNO3 acid microwave digestion procedure using a Mars Xpress Microwave Digester (CEM Corp., Mathews, NC, USA) based on USEPA 3051 and USEPA 3051A methods and manufacturer's recommendations [37]. Elements of interest as plant nutrient or as fouling agents had the following MDL in µg mL−1: 0.4, Al; 0.0.007, B; 0.006, Ca; 0.006, Cu; 0.012, Fe; 0.129, K; 0.003, Mg; 0.001, Mn; 0.13, P; 0.175, S; 0.028, Si; and 0.06, Zn, based on HNO3 acid background matrix following the manufacturer's recommendation for this ICO-OES instrument.

Statistical Analysis

This study was designed to primarily provide information on the vertical distribution of nutrient concentrations from plants harvested at physiological maturity and/or just prior to combine harvest at several locations throughout the USA. The study was not designed to delineate causal relationships or to examine differences associated with location, soil resource, management practices, and/or hybrid selection. The multi-location intent was to include a range of hybrids, relative maturities, and climatic conditions, thus providing a general survey of how nutrient concentration varied vertically within corn plants at or approximately 3 weeks after physiological maturity.

A general linear model using SAS software, version 9.1 (SAS Institute, Gary, NC, USA) [32] was used to determine if there were statistically significant differences in nutrient concentration. Stover fraction or segments were treated as random variables, and variability due to location and location-specific factors (e.g., management practice and hybrid) was included in the error term. Mean comparisons of nutrient concentration among three stover fractions (i.e., above-ear without cob, below-ear, and cob) were made using a protected least significant difference (LSD; p ≤ 0.05) [32]. The number of cob observations was used to calculate protected LSDs, which are a conservative approach as there were fewer cob observations than stover observations. Differences among nutrient concentrations in the 10-cm segments below the ear were compared using Bonferroni minimum significant difference (p ≤ 0.05), as there were more than six means [32].

A subset of five locations that was sampled from the same fields and treatments at both physiological and grain harvest was used to determine if nutrient concentration changed between the two sample dates. Cob data was not available from two of the locations. General linear model analysis was run separately for the three stover fractions. Sample time was treated as a random variable, and variability due to location and location-specific factors (e.g., management and hybrid) was included in the error term. Significant differences are reported at p ≤ 0.05.

Additional descriptive statistics (arithmetic means, standard errors, and number of observations) were calculated within locations for all elements for the three corn stover fractions at both sample dates (Supplemental Tables 1–4). At Fort Collins, multiple plants were harvested, but there was only one replication for each maturity, so a standard error for the Fort Collins location was not calculated. At Mandan, there were two replications for each maturity, but plant materials from each replication were insufficient for analysis, so materials from the two replications were pooled. At other sites, there were at least two sampling areas or replications. Standard errors were reported as an indicator of variability.

Results

Stover Fraction Nutrient Concentrations

Stover nutrient concentrations above and below the ear and within the cobs were determined at all locations for at least one and sometimes two sampling dates. At physiological maturity (Table 2), cobs had lower N, K, S, Ca, Cl, and Si concentrations but higher C content than the stover fractions. At grain harvest, the P concentration was also significantly lower in cobs compared to either stover fraction. At both sampling dates, the concentration of Ca in cobs was below the MDL. The concentration of N, S, and Ca in the above-ear stover fraction exceeded that below the ear at physiological maturity. At grain harvest, the above-ear stover fraction had 16% higher N and 21% higher S concentrations than the below-ear stover fraction.

The concentration of C, N, P, K, S, Ca, Cl, and Si in cobs or in the below-ear stover fraction did not change significantly between the two sample dates (data not shown). The concentration did decrease 17% for N, 26% for S, and 32% for Ca between physiological maturity and grain harvest in the above-ear stover fraction (Table 3). The concentration of N, S, and Ca were greater in the above-ear stover compared to the below-ear fraction, while P concentration did differ significantly between the two fractions (Table 2), such that losing above-ear stover would result in harvesting a greater portion of material with lower concentrations of N, S, and Ca.

Vertical Distribution of Nutrient Below the Ear

Comparisons among the 10-cm increment segments collected below the ear were made within a sampling date, as not all locations were able to sample on both dates. Because the difference between sample's dates was not significant in the below-ear stover fraction (data not shown), only the vertical distribution at grain harvest is presented (Figs. 1, 2, and 3). The concentration of N tended to increase in the segments approaching the ear compared to those near the soil (Fig. 1). Fe (Fig. 2) and Al (Fig. 3) had higher concentrations in the bottom 10 cm, which may reflect some soil contamination, despite efforts to avoid such contamination. There were no significant differences in the vertical distribution of any of the other nutrients (Figs. 1, 2, and 3).

Concentrations of C, N, P, K, and Cl assigned to the midpoint of each 10-cm segment below the ear collected at grain harvest. Lines are error bars; number of locations and replication is not constant with height. Note that the x-axis scales vary among nutrients. Error bar at the bottom of the graph represents Bonferroni minimum significant difference (p ≤ 0.05) among segment nutrient concentrations within a maturity, when general linear model indicated significance among segments

Concentration of Ca, Mg, S, Si, and Fe assigned to the midpoint of each 10-cm segment below the ear collected at grain harvest. Lines are error bars; number of locations and replication is not constant with height. Note that the x-axis scales vary among nutrients. Error bar at the bottom of the graph represents Bonferroni minimum significant difference (p ≤ 0.05) among segment nutrient concentrations when general linear model indicated significance among segments

Concentration of Al, Mn, Zn, B, and Cu assigned to the midpoint of each 10-cm segment below the ear collected at grain harvest. Lines are error bars; number of locations and replication is not constant with height. Note that the x-axis scales vary among nutrients. Error bar at the bottom of graph represents Bonferroni minimum significant difference (p ≤ 0.05) among segment nutrient concentrations when general linear model indicated significance among segments

Discussion

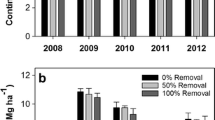

Nutrient Removal and Soil Fertility

Consistent with previous studies [10, 12, 16, 18, 23], nutrient concentrations in this study differed among stover fractions, cutting heights, and plant maturity when sampled (Tables 2 and 3, Figs. 1, 2, and 3). This is important because the amount of N, S, and Ca removed at grain harvest could easily be overestimated if based on concentrations measured at physiological maturity instead of grain harvest, especially if a portion of the plant from above the ear is removed (Table 3). The amount of an element removed from or retained in the field is a function of concentration and biomass harvested (Fig. 4). As the cutting height is lowered, the amount of C and nutrients harvested and removed from the field is increased, and proportionally less is returned to the field. The optimum cutting height depends upon the selection criteria. If the goal is maximum stover harvest, then the lowest cutting height is best. Collection costs per unit of biomass tend to decline at higher removal rates and higher yields [14]. However, if maintaining soil organic C, soil fertility, and preventing erosion are of primary importance, then harvesting only the cob or upper portions of the stalk and cob may be more appropriate (Tables 2 and 3) [15, 40].

It is straightforward to measure nutrient concentration and determine the amount of nutrient removed by harvesting corn stover. However, impacts on soil fertility are more challenging to predict and depend upon the specific nutrient, soil type, spatial variability, and parent material, climate, and crop rotation. Stover has a high C to N ratio (Table 2), and over the short-term, net N-immobilization is expected to occur [36]. As decomposition of the residue progresses, net mineralization should occur [19, 30, 36]. Repeated harvest of crop residue has been demonstrated to reduce N mineralization [21, 31] and decrease beta-glucosaminidiase activity, which is an indicator of N mineralization [11]. Studies in Ohio and in Minnesota both reported that harvesting corn stover can result in less soil organic N than returning stover to the field [5, 9].

Soil fertility is influenced by numerous factors including residue amount, type, and placement interacting with soil temperature, moisture, texture, and fertilizer application [1, 20]. For example, 25 years of stover harvest in New York on a Raynham silt loam significantly reduced soil K and Mg, but only the reduction in K levels was of agronomic consequence [26]. In the same study, repeated stover harvest did not significantly decrease soil concentrations of N, P, Ca, Fe, Mn, Zn, and Al. Another study, which was located in Ohio, showed that 4 years of stover removal reduced available P, K, Mg, and Ca on silty clay loam soils but had very little impact on nutrient availability on clay loam soils [5]. In general, residue removal has the potential to reduce soil fertility levels. The extent of fertility reduction is soil and climate dependent; therefore, producers will need to utilize soil tests and crop scouting to avoid unexpected nutrient deficiencies.

Nutrient Content and Feedstock Quality

The cutting height or fraction harvested impacts feedstock quality for both thermochemical and fermentation platforms. Cobs have lower concentrations of several nutrients (N, P, K, S, and Ca) compared to stover fractions (Table 2). Therefore, they would remove fewer plant nutrients. Low concentrations of N and S in the feedstock reduces the potential for SOx and NOx in the flue gases [41] during thermochemical processing, which must be scrubbed from flue gases. Raising the cutting height from 20 to 70 cm during a one-pass operation reduces the mass of C, N, P, and S harvested about 20% and reduces the amount of Cl by 22%, K by 25%, and Mg and Ca by 29% (Fig. 4). Raising the cutting height disproportionately reduces the amount of elements that are undesirable (Ca, Mg, and K; Fig. 4) in the feedstock relative to the amount of C, which is directly proportional to biomass [40]. Fermentation relies on sugar (or converting cellulose to sugars) to produce liquid fuels like ethanol. Other researchers [10] reported that the amount of recoverable sugars in the stover above the ear exceeded that below the ear, even though the sugar content between the two segments was comparable. The results by Duguid et al. [10] suggest the stover above the ear is a higher quality fermentation feedstock. The lower portion of the stock will be wetter and more likely to have soil contamination [18]. All these factors suggest that the upper portion of the corn stover provides a higher quality feedstock than the lower portion for both thermochemical and fermentation platforms.

Economic Considerations

Nutrient replacement costs were calculated based on 5-year (2005–2009) average prices of $0.64 kg−1 for anhydrous ammonia, $0.55 kg−1 for superphosphate, and $0.49 kg−1 for potash, which corresponds to $0.78 kg−1 elemental N, $2.75 kg−1 elemental P, and $0.96 kg−1 elemental K, respectively [27]. Based on the average N, P, and K concentrations at grain harvest (Table 2) and assuming a cob harvest rate of 1 Mg ha−1, the corresponding removal rate would average 4.5 kg N, 0.3 kg P, and 7.2 kg K per hectare. At these prices and concentration, replacing these macronutrients would cost $11.66 ha−1 (Table 4). The amount of biomass and nutrient removal is a function of cutting height when corn is harvested with a one-pass system. The highest cutting height made with a one-pass system likely would be just below the ear. For the purpose of illustration, assume that a one-pass system at grain harvest collected 3 Mg ha−1 above-ear stover fraction harvested plus 1 Mg of cobs. Based on the cob and above-ear nutrient concentrations, 27.8 kg N, 4.22 kg P, and 32.2 kg K (Table 2) per hectare may be harvested at a corresponding replacement cost of about $64 ha−1 (Table 4). As the harvest rate and or nutrient concentration increases, the cost of nutrient replacement also increases. For example, if an additional 2 Mg ha−1 was harvested of the material below the ear in addition to the cobs and the above-ear stover fraction, the amount of N, P, and K removed could exceed $100 ha−1 (Table 4). Calculation of the minimum payment necessary for biomass harvest to be profitable would need to include nutrient replacement costs: harvest, transportation, and storage costs, as well as any impacts on future crop productivity.

We presented detailed information on the vertical distribution of C and mineral elements in corncobs and stover. This information allows for an estimation of the amount of nutrients removed during stover or cob harvest. It also provides information on the concentration of elements that negatively impact feedstock quality. Harvesting only cobs or cutting just below the ear improves the feedstock quality and reduces the impact of nutrient removal. Because of the relationship between residue removal and its nutrient content, producers harvesting cobs and or stover are advised to utilize soil tests and monitor crops for signs of nutrient deficiency and modify their fertilizer management accordingly. Short- and long-term fertility risks, together with the risks of erosion and loss of SOC, must be considered in making the decisions concerning residue harvest including if, what, and how often to harvest.

Abbreviations

- BON:

-

Bonferroni minimum significant difference

- GLM:

-

General linear model

- ICP-OES:

-

Inductively coupled plasma-optical emission spectroscopy

- LSD:

-

Least significant difference

- MDL:

-

Minimum detection limit

- SOC:

-

Soil organic carbon

References

Andraski TW, Bundy LG (2008) Corn residue and nitrogen source effects on nitrogen availability in no-till corn. Agron J 100:1274–1279

Aristos A, Schechinger T, Birrell SJ, Euken J (2007) Collection, commercial processing, and utilization of corn stover. Final technical report. DOE scientific and technical information. Available via http://www.osti.gov/bridge/product.biblio.jsp?osti_id=917000. doi:10.2172/917000. Cited 29 Jan 2010

Arvelakis S, Koukios EG (2002) Physicochemical upgrading of agroresidues as feedstocks for energy production via thermochemical conversion methods. Biomass Bioe 22:331–348

Bernard JK, West JW, Trammell DS, Cross GH (2004) Influence of corn variety and cutting height on nutritive value of silage fed to lactating dairy cows. J Dairy Sci 87:2172–2176

Blanco-Canqui H, Lal R (2009) Corn stover removal for expanded uses reduces soil fertility and structural stability. Soil Sci Soc Am J 73:418–426

Campbell JE, Lobell DB, Field CB (2009) Greater transportation energy and GHG offsets from bioelectricity than ethanol. Science 324:1055–1057

Cummins DG (1970) Quality and yield of corn plants and component parts when harvested for silage at different maturity stages. Agron J 62:781–784

Biomass Research and Development Board (2008) Increasing feedstock production for biofuels: economic drivers, environmental implications, and the role of research. Biomass Research and Development Board. Available via http://www.brdisolutions.com/Site%20Docs/Increasing%20Feedstock_revised.pdf. Cited 8 Dec 2008

Dolan MS, Clapp CE, Allmaras RR, Baker JM, Molina JAE (2006) Soil organic carbon and nitrogen in a Minnesota soil as related to tillage, residue and nitrogen management. Soil Tillage Res 89:221–231

Duguid KB, Montross MD, Radtke CW, Crofcheck CL, Wendt LM, Shearer SA (2009) Effect of anatomical fractionation on the enzymatic hydrolysis of acid and alkaline pretreated corn stover. Bioresour Technol 100:5189–5195

Ekenler M, Tabatabai MA (2002) Beta-glucosaminidase activity of soils: effect of cropping systems and its relationship to nitrogen mineralization. Biol Fertil Soils 36:367–376

Fageria NK (2004) Dry matter yield and shoot nutrient concentrations of upland rice, common bean, corn, and soybean grown in rotation on an Oxisol. Commun Soil Sci Plant Anal 35:961–974

Gavlak RG, Horneck DA, Miller RO (1994) Soil and plant tissue reference methods for the Western region. Western regional publication. WREP 125. University of Alaska, Fairbanks

Graham RL, Nelson R, Sheehan J, Perlack RD, Wright LL (2007) Current and potential U.S. corn stover supplies. Agron J 99:1–11

Halvorson AD, Johnson JMF (2009) Corn cob characteristics in irrigated central Great Plains studies. Agron J 101:390–399

Hanway JJ (1962) Corn growth and composition in relation to soil fertility: I. Growth of different plant parts and relation between leaf weight and grain yield. Agron J 54:145–148

Heggenstaller AH, Anex RP, Liebman M, Sundberg DN, Gibson LR (2008) Productivity and nutrient dynamics in bioenergy double-cropping systems. Agron J 100:1740–1748

Hoskinson RL, Karlen DL, Birrell SJ, Radtke CW, Wilhelm WW (2007) Engineering, nutrient removal, and feedstock conversion evaluations of four corn stover harvest scenarios. Biomass Bioe 31:126–136

Johnson JMF, Barbour NW, Weyers SL (2007) Chemical composition of crop biomass impacts its decomposition. Soil Sci Soc Am J 71:155–162

Johnson JMF, Papiernik SK, Mikha MM, Spokas K, Tomer MD, Weyers SL (2009) Soil processes and residue harvest management. In: Lal R, Steward B (eds) Carbon management, fuels, and soil quality. Taylor and Francis, LLC, New York, pp 1–44

Kapkiyai JJ, Karanja NK, Qureshi JN, Smithson PC, Woomer PL (1999) Soil organic matter and nutrient dynamics in a Kenyan Nitisol under long-term fertilizer and organic input management. Soil Bio Biochem 31:1773–1782

Kung L Jr, Moulder BM, Mulrooney CM, Teller RS, Schmidt RJ (2008) The effect of silage cutting height on the nutritive value of a normal corn silage hybrid compared with brown midrib corn silage fed to lactating cows. J Dairy Sci 91:1451–1457

Lewis AL, Cox WJ, Cherney JH (2004) Hybrid, maturity, and cutting height interactions on corn forage yield and quality. Agron J 96:267–274

Li BY, Zhou DM, Cang L, Zhang HL, Fan XH, Qin SW (2007) Soil micronutrient availability to crops as affected by long-term inorganic and organic fertilizer applications. Soil Tillage Res 96:166–173

Lindstrom MJ, Gupta SC, Onstad CA, Holt RF, Larson WE (1981) Crop residue removal and tillage—effects of soil erosion and nutrient loss in the Corn Belt. US Department of Agriculture, Ag Info. Bull. No. 442

Moebius-Clune BN, Van Es HM, Idowu OJ, Schindelbeck RR, Moebius-Clune DJ, Wolfe DW et al (2008) Long-term effects of harvesting maize stover and tillage on soil quality. Soil Sci Soc Am J 72:960–969

NASS (2009) Quick stats. USDA National Agricultural Statistic Service, Washington, Available via http://www.nass.usda.gov/. Cited 10 Feb 2010

Neylon JM, Kung L Jr (2003) Effects of cutting height and maturity on the nutritive value of corn silage for lactating cows. J Dairy Sci 86:2163–2169

Ng TK, Busche RM, McDonald CC, Hardy RWF (1983) Production of feedstock chemicals. Science 219:733–740

Paul EA, Clark FE (1996) Soil microbiology and biochemistry. Academic, San Diego

Salinas-Garcia JR, Baez-Gonzalez AD, Tiscareno-Lopez M, Rosales-Robles E (2001) Residue removal and tillage interaction effects on soil properties under rain-fed corn production in central Mexico. Soil Tillage Res 59:67–79

SAS (2002) SAS version 9.1. SAS Institute Inc, Cary

Shinners KJ, Binversie BN, Muck RE, Weimer PJ (2007) Comparison of wet and dry corn stover harvest and storage. Biomass Bioe 31:211–221

Shinners KJ, Boettcher GC, Hoffman DS, Munk JT, Muck RE, Weimer PJ (2009) Single-pass harvest of corn grain and stover: performance of three harvester configurations. Trans ASABE 52:51–60

Technicon (1973) Technicon industrial method AA. ii no. 99-70 w. Sept. 1973. Chloride in water and waste water. Technicon Instrument Corporation, Tarrytown

Tisdall JM, Nelson WL, Beaton JD (1986) Soil fertility and fertilizers. Macmillan Publishing Company, New York

US-EPA (2007) Method 3051a: microwave assisted acid digestion of sediments, sludges, soils, and oils Available via http://www.epa.gov/epawaste/hazard/testmethods/sw846/pdfs/3051a.pdf. Cited 22 Oct 2008

Wilhelm WW, Johnson JMF, Hatfield JL, Voorhees WB, Linden DR (2004) Crop and soil productivity response to corn residue removal: a literature review. Agron J 96:1–17

Wilhelm WW, Johnson JMF, Karlen DL, Lightle DT (2007) Corn stover to sustain soil organic carbon further constrains biomass supply. Agron J 99:1665–1667

Wilhelm WW, Johnson JMF, Lightle D, Barbour NW, Karlen DL, Laird DA et al (2010) Vertical distribution of corn stover dry mass grown at several U.S. locations. BioEnergy Res (in press)

Yu F, Ruan R, Steele P (2008) Consecutive reaction model for the pyrolysis of corn cob. Trans ASABE 51:1023–1028

Acknowledgements

The authors dedicate this publication to Dr. Wally Wilhelm. We thank B. Burmeister for proofreading, but we take full responsibility for any errors. We also thank the reviewers and Dr. Michael Casler for insightful and constructive suggestions for improvements. We acknowledge the efforts of technical and student helpers for sampling and processing plant tissue samples. This work contributes to the USDA-Agricultural Research Service, cross-location–Renewable Energy Assessment Project (REAP). Publication costs were covered by funding from the North Central Regional Sun Grant Center at South Dakota State University through a grant provided by the US Department of Energy Office of Biomass Programs under award number DE-FC36-05GO85041.

Author information

Authors and Affiliations

Corresponding author

Additional information

Wally W. Wilhelm deceased.

The US Department of Agriculture offers its programs to all eligible persons regardless of race, color, age, sex, or national origin and is an equal opportunity employer.

The use of trade, firm, or corporation names in this publication is for the information and convenience of the reader. Such use does not constitute an official endorsement or approval by the US Department of Agriculture or the Agricultural Research Service of any product or service to the exclusion of others that may be suitable.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 218 kb)

Rights and permissions

About this article

Cite this article

Johnson, J.M.F., Wilhelm, W.W., Karlen, D.L. et al. Nutrient Removal as a Function of Corn Stover Cutting Height and Cob Harvest. Bioenerg. Res. 3, 342–352 (2010). https://doi.org/10.1007/s12155-010-9093-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-010-9093-3