Abstract

A key component in the design of every drift tube ion mobility spectrometer (IMS) is the ion shutter which controls the injection of ions into the drift tube. Especially, compact drift tube IMS require very short injection pulses to achieve high resolution and therefore require fast ion shutters. Thus, it is important to find an ion shutter principle that can be readily scaled towards these short injection widths without causing major non-idealities in the injection process, such as drift field inhomogeneities, ion loss and ion discrimination by mobility. In this paper, we compare different ion shutter principles, foremost the Bradbury-Nielsen gate and a field switching design. It is shown through theoretical considerations and field simulations that the Bradbury-Nielsen shutter is more universally applicable and typically less complex for long injections widths but field inhomogeneities associated with its operating principle impede the scaling process. Thus, the currently less used field switching shutters will become the superior principle when very short injection widths are required, as this shutter principle allows for single digit microsecond widths.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ion mobility spectrometers (IMS) are versatile devices for trace gas detection by analyzing the motion of analyte ions through a neutral gas under the influence of an electric field [1]. They offer extremely good limits of detection (LoD) within short measurement times, which has led to their widespread use in the detection of toxic industrial compounds, explosives or chemical warfare agents [2], [3]. However, their mediocre resolution is a major disadvantage in applications which require the separation of more complex gas samples, for example in breath gas analysis [4] or quality control [5]. Thus, improving the resolution of IMS has been an ongoing goal of research groups for the last decades.

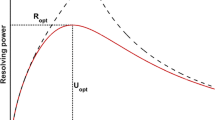

Recently, an analytical model for predicting the influence of instrumental parameters on both the resolution and the signal-to-noise-ratio (SNR) of a drift tube IMS has been published [6]. An increase of the SNR is equivalent to a reduction of the LoD by the same factor, but generally the SNR is more convenient for theoretical calculations. This analytical model includes the initial width of the ion packet, ion loss at the ion shutter, longitudinal diffusion in the drift region, signal averaging as well as distortion and noise created by the transimpedance amplifier. Its main results are given by equations (1) and (2), which can be used to estimate the dependence of a peak’s resolution and signal-to-noise-ratio on different IMS parameters. It is assumed that the IMS is always operated at its resolution-optimal voltage. L D denotes the length of the drift region, while w Inj and w Amp are the contributions to the temporal peak width by ion injection and amplification.

From these equations, two possible ways of constructing high resolution drift tube IMS while maintaining the excellent limits of detection become apparent. First, longer drift tubes improve separation power [7] since resolution grows proportional to L D 2/3, while the effects of the drift length on the signal-to-noise-ratio compensate each other as long as all other parameters are scaled correctly. However, the consequence is of course a larger drift tube, which results in higher system complexity and cost as well as reduced portability. Therefore, improving separation power by increasing the drift tube length is limited, especially due to limitations in manufacturing very long drift tubes. Second, resolution can be improved by reducing the absolute values of the temporal injection width w Inj and the amplifier width w Amp , while keeping w Inj = w Amp . According to equation (2), this will maintain a constant SNR, as it only depends on the match between w Inj and w Amp , while the resolution increases accordingly to equation (1). Thus, it is possible in theory to reach extremely high resolutions in a compact drift tube IMS without sacrificing the excellent limits of detection. In practice however, there are limitations. The two most important issues are discussed in the following. First, as shown in [6], reducing the widths of injection and amplification shifts the IMS to a point of operation which is more susceptible to non-idealities inside the drift tube, such as field inhomogeneities. Therefore, the drift tube geometry needs to be designed more carefully. Second, the analytical model is based in the assumption that increasing the amplifier bandwidth will lead to a proportional increase in noise and that decreasing the initial width of the ion packet will proportionally decrease the amount of ions injected into the drift tube. When non-linear effects cause significant deviations from this linear model, the analytical approximation no longer applies and the signal-to-noise-ratio decreases. This paper concentrates on ion shutter principles that allow very short injection widths for improved separation power.

Ion Shutters for High Resolution Drift Tube IMS

A suitable ion shutter for a high resolution drift tube ion mobility spectrometer needs to generate small ion packets without causing non-idealities. Generally, two main non-idealities exist when operating ion shutters at very short pulse widths. First, most ion shutters create regions in which all ions are discharged while the shutter is closed. After the shutter has been opened, ions will start passing these regions at their drift velocity. However, only the ions which have completely passed the shutter at the end of the injection time will be actually injected into the drift tube, as all other ions will be discharged upon closing the shutter [8]. Therefore, the initial temporal width of the ion packet after injection will not correspond to the shutter timing, since the temporal ion packet width is reduced by the time the ions need to traverse the shutter regions where ions are discharged when the shutter is closed. As the ions travel at their distinctive drift velocity, this so-called cutting width is ion mobility dependent and leads to a discrimination of ions with lower mobilities [9]. When the injection width is reduced, the same cutting width leads to increasing discrimination [10]. Second, the initial spatial expansion of the injected ion cloud decreases proportionally to w Inj 1/3 when the temporal initial width w Inj is reduced in order to achieve higher resolution. This is caused by the fact that the optimum drift voltage and therefore drift velocity just grows proportional to w Inj − 2/3 while the spatial expansion of the ion packet is its temporal width multiplied with the drift velocity. Therefore, a large portion of the ion packet is still very close to the ion shutter at the moment the shutter is being closed. Any inhomogeneities of the drift field caused by the potentials applied to the closed ion shutter therefore increasingly distort the ion cloud and negatively affect resolution. As differences in the experienced drift field lead to differences in the drift time, the injected ion packet increasingly distorts which limits the achievable initial ion packet width [8]. Furthermore, the optical transparency of the shutter, defined as the percentage of the shutter cross section that is not physically blocked, should not be reduced when scaling the ion shutter for smaller injection widths. For example, decreasing the mesh size while keeping the diameter of the shutter grid wires constant reduces the optically transparency. This results in less possible paths for the ions to traverse the shutter when it is open and therefore in an increased ion loss and a reduced signal intensity. As our design goal is to improve IMS resolution without increasing the LODs, optical transparency should be as high as possible.

Bradbury-Nielsen Shutter

The Bradbury-Nielsen ion shutter was first used in electron mobility measurements nearly 80 years ago [11]. Since then, it has been the workhorse of ion mobility spectrometry and is still employed by the majority of today’s devices. It consists of two parallel sets of wires, which are insulated from each other, as shown in Fig. 1.

In the open state, all wires have the same electric potential as shown in the left panel of Fig. 2 and the gate becomes essentially a metal grid which does not inhibit ion motion between the shutter grid wires blocking the ion paths. Figure 2 and all other electric field simulations were computed using the finite element software COMSOL Multiphysics. In the closed state however, opposing electric potentials are applied to the wires. This results in an electric field perpendicular to the drift direction as shown in the right panel of Fig. 2, so that all ions reaching the shutter are discharged. In order to effectively close the Bradbury-Nielsen ion shutter, it is necessary to apply a perpendicular field strength which is about twice as high as the drift field strength [9], [10], [12]. This is an extremely important relationship, as it causes the field shape around the shutter to be independent of the chosen drift voltage, as all potentials at the shutter scale in a linear fashion. Thus, the shape of the electric field needs to be analyzed only with respect to the Bradbury-Nielsen shutter geometry.

One major advantage of the Bradbury-Nielsen shutter for ion mobility spectrometry is its flexibility with respect to the employed ion source since it does not impose any requirements associated with the ion source, such as certain dimensions of the ionization region or electric field strengths inside the ionization region, making it universally applicable for all devices. Furthermore, for long injection widths and low resolutions, electric drift fields and hence the required closing fields are low. Thus, the potential difference which needs to be switched is also small, making the electrical control circuits quite simple. Typically, the measurement parameters result in a voltage difference between the shutter grid wires of just a few tens of volts. This is also an important advantage, as the potentials at the ion shutter are typically referenced to the drift voltage, requiring the switches to be isolated from ground potential. The main disadvantage of the Bradbury-Nielsen shutter is however the perpendicular electric field, which is associated with its operating principle, but also the main cause of both mobility dependent ion discrimination and extensive drift field distortion. The discrimination is mainly caused by the fact that this perpendicular field does not only exist inside the shutter plane, but significantly protrudes from it. The penetration depth of the perpendicular field into the drift region is proportional to the spacing between the shutter grid wires [9], [13], which is shown in Fig. 3. As explained already, all ions present in these areas are discharged when the shutter is closed.

The distortion of the drift field is shown in Fig. 4. Due to the different electric potentials of the shutter grid wires in the closed state, the drift field strength is increased or decreased in the vicinity of the gate. This leads to so-called depletion, dispersion and compression zones [8], in which ions experience different electric fields and therefore drift velocities. This results in significant ion packet distortion and increased injection widths, as it also becomes visible in simulations of the ion motion through the shutter [12], [10].

Field strengths at three closed Bradbury-Nielsen shutters with different geometries. From left to right, the three wire spacings are 1,000 μm, 500 μm and 250 μm. The corresponding diameters are 300 μm, 150 μm and 75 μm. Gray color indicates the nominal drift field strength, while black or white indicate an increase or decrease by 50 % respectively

Both non-idealities, the ion discrimination and ion packet distortion, become more and more pronounced for shorter injection widths, as both the cutting width and the extent of the drift field distortion stay constant and therefore increasingly affect the injection width. As shown in the middle and right panel of Figs. 3 and 4 respectively, both effects can be mitigated by reducing the spacing between the wires and the wire diameter. It is important to note, that just reducing the wire spacing is not a sensible approach, as this would decrease the optical transparency of the gate, leading to increased ion loss and therefore decreased signal intensity. Furthermore, the wire diameter itself also adds to the cutting width.

Thus, the scalability of the Bradbury-Nielsen shutter for very short injection widths comes down to the ability to manufacture shutter grids with tiny wire spacing and diameters while maintaining sufficient precision and reproducibility. Over the past decades, more and more sophisticated winding techniques have been developed, using several special frames to position the different wires [14], [15]. Furthermore, alternative ways to manufacture Bradbury-Nielsen shutters have been tested, for example deep reactive ion etching (DRIE) [16]. However, the relative precision of the manufacturing process always degrades with smaller dimensions, ultimately leading to inhomogeneous wire spacing and diameters and therefore shutter properties across the drift tube cross section. The smallest reported Bradbury-Nielsen shutter applied in a drift tube IMS has a wire spacing of 250 μm with a wire diameter of 75 μm [17]. This corresponds to the rightmost panel in both Figs. 3 and 4. It is obvious that even at such a small structural size, inhomogeneities still persist. Typically, the shortest injection widths achievable with Bradbury-Nielsen shutters are about 50 μs–100 μs, as even shorter widths lead to extremely small ion signals [1], [18], [19]. This is however still too slow to reach a resolution above 100 in a 100 mm long drift tube, as can be calculated with the equations from [19]. Hence, in the following we investigate another ion shutter principle that is suitable for compact high resolution drift tube IMS.

Field Switching Shutter

Another possible shutter design reported by [20] and [21], which never gained wide recognition, is switching the drift field inside the ionization region on and off in order to inject the ions.

Figure 5 shows a possible setup for such a field switching shutter. The drift region and the ionization region are divided by a metal grid kept at a constant potential, named the injection grid. Ions are injected by applying a high voltage difference between the ion source and the injection grid, named the injection voltage. This creates an electric field pushing the ions into the drift region and constitutes the open state of the shutter. As there is now an electric field on both sides of the injection grid, the setup is practically identical to an open Bradbury-Nielsen shutter and therefore can be expected to have similar transmission properties. In the closed state, the potential of the ion source is typically not identical to the potential of the injection grid. Instead a very small voltage with opposite polarity to the injection voltage is applied, called the blocking voltage. The purpose of this voltage is to compensate the field penetration of the drift field into the ionization region, thus keeping the ionization region nearly field-free. This is important since the injection grid does not truly inhibit the ion motion through the shutter in its closed state as compared to the Bradbury-Nielsen shutter. Without this compensation field, ions could be continuously pulled from the ionization region into the drift region, leading to an increased baseline and decreased peak intensities due to less ions being available for injection.

The major advantage of the field switching shutter principle is that the complex multi-potential Bradbury-Nielsen gate has been replaced by a simple metal grid with a uniform potential. This offers three significant improvements. First, since isolated wires are no longer required, the gate can be manufactured from a single metal sheet, leading to both easier manufacturing even at very small dimensions and better mechanical stability due to special grid-type structures being possible. We use a grid with a hexagonal structure as shown in Fig. 6 instead of parallel wires exactly for this reason.

Second, the perpendicular electric field of the Bradbury-Nielsen shutter has been eliminated, vastly reducing the cutting width of the shutter. Only the regions inside the shutter grid where the drift field still penetrates into the ionization region despite the blocking voltage are emptied when the shutter is closed. Third, as the shutter grid has a uniform potential, it creates practically no distortion of the drift field. Hence, the deformations in the ion cloud caused by the closed Bradbury-Nielsen shutter are nearly non-existent in this design. These advantages are shown in Figs. 7 and 8, where the drift field lines and drift field strengths for Bradbury-Nielsen and field switching shutters of the same shutter grid dimensions are compared. It is obvious that the field switching shutter performs much better regarding drift field distortion and cutting width. Furthermore, it also offers additional room for improvement, as a reduction of the injection grid dimensions is feasible due to its sturdier structure compared to the parallel wires of a Bradbury-Nielsen shutter.

It should be noted that even though the simulations show parallel wire models, the field of a grid-type structure in most cut planes would be nearly identical, as it would simply appear as a set of wires crossing this plane as long as the openings in the grid are significantly larger than the wire diameter. Since large openings concur with our goal of achieving high optical transparency, this is a valid assumption. Furthermore, a different shape of the openings can influence the ion flux distribution in the drift area due to the different locations of ion loss, but as long as the wire diameter and therefore the “holes” in the ion plug are sufficiently small, this difference will quickly become eliminated by diffusion.

However, the field switching principle has not only advantages over the Bradbury-Nielsen shutter. The main disadvantage is its limited flexibility concerning the ion source due to possible conflicting requirements imposed by the ion source, such as the ionization depth, and the field switching shutter itself on the design of ionization region. Depending on the ion source and especially the ionization depth a proper length of the ionization region is required to avoid ion generation inside the drift tube, leading to a baseline shift. As the required injection voltage at the source is proportional to the distance between ion source and injection grid, large ionization regions quickly lead to extremely high switching voltages. Therefore, this shutter principle works quite well with low-energy electron sources like Tritium, but is difficult with ion sources like Nickel-63 or UV sources, which have larger ionization depths. Furthermore, ion sources which require an electric field for ionization, such as corona discharge or electrospray ionization sources, cannot be used in conjunction with field switching shutters, as these shutters require a field free ionization region when the shutter is closed. Basically, a lot of the design complexity has been moved to the electronic switching circuit. While the Bradbury-Nielsen shutter has a complex mechanical design, but only needs to switch a few tens of volts, the field switching shutter has a simple mechanical design, but requires a switching voltage of a few hundred volts or even several kilovolts. Designing an electronic circuit which is able to switch high voltages within the desired injection time and can also isolate the drift voltage against ground potential is not a simple task.

Despite the mentioned disadvantages, field switching shutters seem to be much more suitable for compact high resolution drift tubes, as they can be scaled to injection widths in the single digit microsecond range due to less non-idealities at identical shutter grid dimensions. Fig. 9 shows the positive and negative reactant ion peaks measured with a 98 mm long drift tube IMS using a field switching shutter set to an initial width of just 5 μs. With such a short initial width, our drift tube IMS reaches a resolution of 183 and limits of detection in the pptv-range for measurement times of less than a second. The spectra were acquired at a temperature of 25 °C, a pressure of 1,018 mbar and a dew point of −82 °C using a drift voltage of 13 kV.

Other Shutter Principles

In addition to the Bradbury-Nielsen and field-switching shutter various other shutter principles and methods of ion gating exist. Unfortunately, all those principles are not suitable for the design of compact high resolution drift tube IMS, so that we just want to state their most significant drawbacks without describing each shutter principle in detail. For example, Tyndall-Powell designs shows similar effects on ion packet distortion and cutting width as Bradbury-Nielsen shutters, while an increasing distance in drift direction between the two shutter grids further increases the cutting width and therefore ion discrimination by mobility. Shutter principles based on switching the drift field or grid-less shutters cause massive distortion of the drift field, limiting the shutter pulse width. Finally, switchable ion sources tend to suffer from comparably slow switching speeds and are also limited by the fact that the extent of the generated ion packet is directly translated into additional initial width. A detailed description of these shutter principles can be found in [1].

Conclusion

While not as universally applicable as the typically employed Bradbury-Nielsen shutter, the field switching shutter offers superior performance when very short injections widths are required. Due to its operating principle and the simple but robust mechanical design of the shutter, it suffers less from non-idealities, which allows injection ion packet widths in the single digit microsecond range. With such short injection widths, compact high resolution drift tube ion mobility spectrometers offering a resolution of more than 180 at a drift length of less than 10 cm become possible. However, as the field switching shutter is not usable in conjunction with different kinds of ion sources, there is presently no universal answer to the question for the optimum shutter principle.

References

G. A. Eiceman, Z. Karpas and H. H. Hill Jr., Ion Mobility Spectrometry, 3nd Edition, CRC Press, 2013

H. Borsdorf and G. A. Eiceman, Appl. Spectrosc. Rev., pp. 323–375, 2006 (41).

Helko Borsdorf, Thomas Mayer, Mashaalah Zarejousheghani and Gary A. Eiceman, Appl. Spectrosc. Rev., pp. 472–521, 2011 (46).

M. Westhoff, P. Litterst, S. Maddula, B. Bödeker and J. I. Baumbach, Int. J. Ion Mobil. Spec., pp. 139–149, 2011 (14).

N. Budimir, D. J. Weston and C. S. Creaser, Analyst, pp. 34–40, 2007 (132).

A. T. Kirk, M. Allers, P. Cochems, J. Langejuergen and S. Zimmermann, Analyst, pp. 5200–5207, 2013 (138).

C. B. Hariharan, L. Seifert, J. I. Baumbach and W. Vautz, Int. J. Ion Mobil. Spec., pp. 31–38, 2011 (14).

D. Yongzhai, W. Weiguo and L. Haiyang, Anal. Chem., pp. 1725–1731, 2011 (84).

M. Tabrizchi and H. R. Shamlouei, Int. J. Mass Spectrom., pp. 67–72, 2010 (291).

F. K. Tadjimukhamedov, J. Puton, J. A. Stone and G. A. Eiceman, Rev. Sci. Instrum., p. 103103, 2009 (80).

N. E. Bradbury and R. A. Nielsen, Phys. Rev., pp. 388–393, 1936 (49).

J. Puton, A. Knap and S. Boguslaw, Sens. Actuator. B-Chem., pp. 116–121, 2008 (135).

C. W. Stoermer, S. Gilb, J. Friedrich, D. Schooss and M. M. Kappes, Rev. Sci. Instrum., pp. 1661–1664, 1998 (69).

J. R. Kimmel, F. Engelke and R. N. Zare, Rev. Sci. Instrum., pp. 4354–4357, 2001 (72).

O. K. Yoon, I. A. Zuleta, M. D. Robbins, G. K. Barbula and R. N. Zare, J. Am. Soc. Mass. Spec., pp. 1901–1908, 2007 (18).

I. A. Zuleta, G. K. Barbula, M. D. Robbins, O. K. Yoon and R. N. Zare, Anal. Chem., pp. 9160–9165, 2007 (79).

X. Zhang, R. Knochenmuss, W. F. Siems, W. Liu, S. Graf and H. H. Hill Jr., Anal. Chem., pp. 1661–1670, 2014 (86).

W. F. Siems, C. Wu, E. E. Tarver, H. H. Hill Jr., P. R. Larsen and D. G. McMinn, Anal. Chem., pp. 4195–4201, 1994 (66).

A. B. Kanu, M. M. Gribb and H. H. Hill Jr., Anal. Chem., pp. 6610–6619, 2008 (80).

Jenkins A (1993) US Patent 5:200,614

J. W. Leonhardt, W. Rohrbeck and H. Bensch, Int. J. Ion Mobil. Spec., pp. 43–49, 2000 (1)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kirk, A.T., Zimmermann, S. Bradbury-Nielsen vs. Field switching shutters for high resolution drift tube ion mobility spectrometers. Int. J. Ion Mobil. Spec. 17, 131–137 (2014). https://doi.org/10.1007/s12127-014-0153-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12127-014-0153-9