Abstract

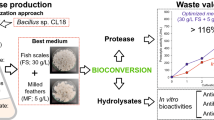

Fish processing industries generate large quantities of fish scales as processing waste, if not treated leading to environmental pollution. Fish scales are hard to degrade, hence cause difficulty in waste management. In this context present study was made to utilize fish scales as substrate for the production of alkaline protease by Bacillus altitudinis GVC11 and subsequently amino acid rich aqua hydrolyzate. B. altitudinis GVC11 efficiently utilized five types of fish scales as substrates and produced maximum alkaline protease using Labeo rohita (28,150 U/mL) followed by Catla catla (23,320 U/mL) at 48 h and Cyprinus carpio (17,146 U/mL) Mugil cephalus (18,917 U/mL), Cirrhinus mrigala (12,430 U/mL) at 72 h. The HPLC analysis of protein hydrolyzate obtained after fermentation was enriched in essential amino acids, leucine, isoleucine, phenylalanine, lysine and non-essential amino acids, tyrosine, arginine and cysteine which can be used as animal feed supplement and organic fertilizer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Global production of fish is growing steadily at 2–3% per annum in recent times with its increasing food supply demand. Fish production is 167 and 171 million tons in 2014 and 2015 respectively by wild fishing and aquaculture [1]. Fish processing industries and fish markets generate huge quantities of underutilized waste during the processing which include viscera, heads, skins, fins, scales, bone frames and tails [2, 3]. Part of these wastes like viscera, heads, tails, bone frame and skins are rich sources of protein which can be converted into useful products (fish meal, fish silage, fish protein concentrate etc.) if properly utilized [4]. Majority of the fish wastes are discarded without significant utilization. This results not only in environmental pollution but also in loss of value added byproducts inside the waste. It also reduces the levels of dissolved oxygen in water and generates toxic products during decomposition, contaminating aquatic habitats and threatening a variety of biodiversity resources [5]. Fish processing wastes like scales, bones and skin constitute up to 30% [6]. Only fish scales constitute approximately 2% of fish body weight and generated in huge quantities [7]. Fish scales are composed of a surface layer containing hydroxyapatite, calcium carbonate and a deeper layer made up of mostly collagen type I. Elements like Ca, Mg, P, Na, S are also present in minute concentrations [6, 8]. Increasingly stringent pollution control measures have forced sea food processors to opt for byproduct recovery schemes, therefore getting rid of fish scales gained importance. Collagen from such fish scales is often used in hydrolyzate form, i.e., protein hydrolyzate and collagen peptide. Such peptides are used in functional foods, as food additives and cosmetics applications due to their physical properties, tight structure and thermal stability. Scientists have focused on the recovery of collagen from fish scales and skins. The recovered collagen is used in cosmetic, biomedical, pharmaceutical and food industries [9]. Protein hydrolyzate released during microbial fermentation of fish scales is rich in essential amino acids, therefore can be used as supplement in animal feed. Enzymatic digestion using protease seems to be the best way for preparing protein hydrolyzate and collagen peptide from fish scales due to its better efficiency and environment friendliness [5].

Alkaline proteases have wide variety of applications in different industries such as detergent, pharma, leather, silk, waste management, photographic and dairy [10]. Proteases are one of the three largest groups of industrial enzymes which share up to 60% of total world enzyme market [11]. Approximately 30–40% of production cost for industrially important enzymes is estimated to derive from the cost of growth medium [12]. Industries producing alkaline proteases by microorganisms focused on new search for cheaper methods to enhance the protease production and decrease the market price [13]. Hence there is a need to reduce the production cost of the enzyme by utilizing wastes generated from different sources such as aqua, agricultural and industries as substrates. In addition to cost effective production of enzyme, wastes used as substrates are also converted into value added products [14]. The present work reports the effective utilization of fish scales as potential substrates by Bacillus altitudinis GVC11 for production of alkaline protease and the fermented broth containing amino acids projected to be used as nutritional supplements and organic fertilizer.

Materials and Methods

Collection and Processing of Fish Scales

Five types fish scales (Labeo rohita, Catla catla, Cyprinus carpio, Mugil cephalus and Cirrhinus mrigala) were collected from local fish market (Hyderabad, India) and washed thrice with tap water, dried and used as substrate without further processing.

Analysis of Nitrogen Content

Nitrogen content of fish scales was determined by micro-Kjeldahl method as per AOAC method [15].

Microorganism and Source

Bacillus altitudinis GVC11, culture isolated from slaughter house waste dumping soil, identified and maintained in the lab was used for alkaline protease production [16]. The chemicals and reagents used in the study were of reputed make purchased from local suppliers.

Enzyme Production

Alkaline protease production was carried out in 250 mL conical flasks containing 100 mL mineral salts medium (MSM) with five types of fish scales as substrate each in varied concentrations (0.5, 1, 1.5, 2 and 2.5%). Flasks were inoculated with 2% (v/v) actively growing broth culture of B. altitudinis GVC11 (containing 108 cells/mL) and incubated at 37 °C, 200 rpm in a rotary shaker. MSM is composed of (g/L): (NH4)2SO4 1, K2HPO4 6, KH2PO4 3, MgSO4.7H2O 0.01, CaCl2.2H2O 0.05, MnSO4.2H2O 0.01, FeSO4.7H2O 0.0001, ZnSO4.7H2O 0.001, tri-sodium citrate 10, dextrose 1, Na2CO3 10 and pH 10 (Hi-Media) [16]. All the experiments were carried out in triplicates thrice on different occasions and values presented are mean of the same.

Alkaline Protease Extraction and Assay

The fermented broth was centrifuged at 15,000 rpm for 15 min at 4 °C and supernatant was used as enzyme source. Alkaline protease activity was determined with alkali soluble casein as substrate according to the method described previously [16]. One unit (U) of alkaline protease is defined as the amount of enzyme which releases l μg tyrosine per minute under standard assay conditions.

Analysis of Free Amino Acids by HPLC

The fish scales fermented broth of B. altitudinis GVC11 was analyzed and quantified for free amino acids by HPLC. Amino acids were first derivatized using phenyl isothiocyanate (PITC) (Sigma Aldrich), to form phenyl thio carbamoyl (PTC) derivatives. Therefore, pre-column derivatization of amino acids with PITC followed by a reversed phase HPLC separation with UV detection at 254 nm was used to analyze the amino acid composition. The obtained amino acid derivatives were separated on 5 μm, 250 × 4.6 mm TC-C18 column (Agilent) by using gradient elution with 0.1 mol/L, pH 6.5 acetate buffer solution-acetonitrile (93:7, v/v) as mobile phase A and acetonitrile–water (4:1,v/v) as mobile phase B. Flow rate maintained was 0.9 mL/min [17].

Results and Discussion

Fish scales are one of the wastes generated from the fish processing industries and fish markets in huge quantities during the processing [3, 18]. They are very hard to degrade, if not disposed properly leads to environment pollution and waste management difficulties. Fish scales are rich source of organic nitrogen and protein (Table 1), hence they can be utilized as substrates for growth of microorganisms and enzyme production. Recent studies have focused to exploit these wastes for the production of higher value added products [18]. In the present study, five types of fish scales were used as substrate by B. altitudinis GVC11 for production of alkaline protease in MSM. Maximum alkaline protease production of 28,150 and 23,320 U/mL was obtained with L. rohita and C. catla fish scales respectively, using 0.5% of each as substrate at 48 h (Table 1; Fig. 1). Reports on production of alkaline protease with fish scales as substrate are scanty. Pan et al. [5] studied production of extra cellular alkaline protease by a bacterium Vogesella sp. using tilapia fish scale powder as substrate. It was reported that under optimized conditions 21,600 U/mL of enzyme production was obtained. Comparatively GVC11 produced higher enzyme yield (28,150 U/mL) than Vogesella sp. with fish scales as substrate (Table 1; Fig. 1). The substrate used for enzyme production by Vogesella sp.7307-1 was powdered form of tilapia fish scale whereas in the present study, fish scales not subjected to any pretreatment, which further reduces production cost significantly. GVC11 also produced significant alkaline protease with other types of fish scales such as C. carpio, C. mrigala and M. cephalus as substrate (Table 1). Maximum alkaline protease production using C. carpio and M. cephalus fish scales was observed to be 17,146 and 18,917 U/mL at 1 and 1.5% of substrate respectively at 72 h (Table 1; Fig. 1). Using C. mrigala fish scales, 12,430 U/mL of alkaline protease production was observed at 48 h with 2% of substrate (Table 1; Fig. 1). Statistical analysis observed that standard deviation was not significant. Till now there are no reports available on alkaline protease production with Catla catla, Cyprinus carpio, Cirrhinus mrigala and Mugil cephalus fish scales as substrate, though significant quantities of such fish scales generated as waste particularly in Indian context.

Amino Acid Composition of Fish Scale Protein Hydrolyzate

Fish scales are rich source of proteins used as substrate in the present study (Table 1). Growth of B. altitudinis GVC11 in fermentation medium with L. rohita and C. catla fish scales as substrate resulted in their complete degradation and the fermented broth was analyzed for the presence of free amino acids, in addition to alkaline protease produced. L. rohita and C. catla fish scale protein hydrolyzate was rich in essential amino acids. The fermented protein hydrolyzate of L. rohita fish scale was found to have essential amino acids like leucine (307.22 nMol), phenyl alanine (39.84 nMol), isoleucine (39.37 nMol), lysine (24.59 nMol), valine (16.36 nMol), methionine (11.77 nMol), and arginine (10.82 nMol). In addition to the above, non-essential amino acid cysteine (6.68 nMol) and non-standards amino acids, carnosine (22.89 nMol) anserine (15.69 nMol), 3-met histidine (19.97 nMol), and ornithine (18.50 nMol) were also observed to be present in significant quantities (Table 2). C. catla fish scale protein hydrolyzate was found to have essential amino acids like, leucine (159.34 nMol), phenyl alanine (20.14 nMol), isoleucine (25.29 nMol), lysine (5.99 nMol), valine (14.69 nMol), methionine (12.33 nMol) and tryptophan (2.42 nMol). In addition to the above, non-essential amino acids, tyrosine (5.15 nMol), arginine (0.46 nMol), cysteine (2.81 nMol) and non-standard amino acids like, anserine (8.05 nMol) and ornithine (2.04 nMol) were also observed to be in significant quantities (Table 2). It was found that both L. rohita and C. catla fish scale protein hydrolyzates were rich in essential amino acids which can be used as feed supplement for animals or as organic fertilizer. Ctenopharyngodon idella fish scales protein hydrolyzate was found to be rich in non-essential amino acids, glycine and proline as reported by Zhang et al. [19]. Also Zhang et al. [20] showed that fresh water carp fish scale hydrolyzate was rich in glycine followed by proline and alanine. In the present study, L. rohita and C. catla fish scale protein hydrolyzates were rich in essential amino acids than the earlier reports which is a significant observation.

Conclusion

Present study reports the use of fish scale waste as substrate for maximum production of alkaline protease by alkaliphilic B. altitudinis GVC11. Fish scales generated as waste in fish processing, if used as substrate for alkaline protease production will reduce cost of production medium by replacing conventional substrates. Use of fish scales as substrate not only reduces the waste concentration but also gives a remedy for environmental pollution caused by them. In addition to enzyme, protein hydrolyzate obtained after fermentation were rich in essential amino acids, which can be used as animal feed supplement and also as organic fertilizer for improved crop production.

References

FAO (2016) Food outlook, biannual report on global food markets. In: Food and agriculture organization of the United Nations, pp 60–66

Rahmi M, Faid M, EiYachioui M, Berny EH, Fakir M, Ouhssine M (2008) Protein rich ingredients from fish waste for sheep feeding. Afr J Microbiol 2:73–77

Esakkiraj P, Maruthiah T, Nawas PMA, Immanuel G, Palavesam A (2013) Solid state protease production by Bacillus thuringiensis AP-CMST using trash fish meal as substrate. J Pure Appl Microbiol 7:1–8

Jayathilakan P, Sultana K, Radhakrishna K, Bawa KS (2012) Utilization of byproducts and waste materials from meat, poultry and fish processing industries: a review. J Food Sci Technol 49:278–293. doi:10.1007/s13197-011-0290-7

Pan MH, Tsai ML, Chen WM, Hwang A, Pan BS, Hwang YR, Kuo JM (2010) Purification and characterization of a fish scale-degrading enzyme from a newly identified Vogesella sp. J Agric Food Chem 58:12541–12546. doi:10.1021/jf1034042

Basu B, Ajit KB (2005) Production of protein rich organic fertilizer from fish scale by Aspergillus mutant AB100-A media optimization study. J Sci Ind Res 64:293–298. doi:10.1007/s11274-007-9492-6

Matmaroh K, Benjakul B, Prodpran T, Encarnacion AB, Kishimura H (2011) Characteristics of acid soluble collagen and pepsin soluble collagen from scale of spotted golden goatfish (Parupeneus heptacanthus). Food Chem 129:1179–1186. doi:10.1016/j.foodchem.2011.05.099

Pati F, Adhikari B, Dhara S (2010) Isolation and characterization of fish scale collagen of higher thermal stability. Biores Technol 101:3737–3742. doi:10.1016/j.biortech.2009.12.133

Mahboob S (2015) Isolation and characterization of collagen from fish waste material-skin, scales and fins of Catla catla and Cirrhinus mrigala. J Food Sci Technol 52:4296–4305. doi:10.1007/s13197-014-1520-6

Kasana RC, Salwan R, Yadav SK (2011) Microbial proteases: detection, production, and genetic improvement. Crit Rev Microbiol 37:262–276. doi:10.3109/1040841X.2011.577029

Sanatan PT, Lomate PR, Giri AP, Hivrale VK (2013) Characterization of a chemostable serine alkaline protease from Periplaneta americana. BMC Biochem 14:1–9. doi:10.1186/1471-2091-14-32

Souissi N, Ellouz-Triki Y, Bougatef A, Blibech M, Nasri M (2008) Preparation and use of media for protease producing bacterial strains based on by-products from Cuttlefish (Sepia officinalis) and wastewaters from marine-products processing factories. Microbiol Res 163:473–480. doi:10.1016/j.micres.2006.07.013

Mukherjee AK, Adhikari H, Rai SK (2008) Production of alkaline protease by a thermophilic Bacillus subtilis under solid-state fermentation SSF condition using Imperata cylindrica grass and potato peel as low-cost medium: characterization and application of enzyme in detergent formulation. Biochem Eng J 39:353–361. doi:10.1016/j.bej.2007.09.017

Srividya S, Mala M (2011) Influence of process parameters on the production of detergent compatible alkaline protease by a newly isolated Bacillus sp. Y. Turk J Biol 35:177–182. doi:10.3906/biy-0906-47

AOAC (2009) Protein (crude) determination in animal feed: copper catalyst Kjeldahl method 984.13, 15th edn. Official methods of analysis of AOAC International, Gaithersburg

Vijay Kumar E, Srijana M, Kiran Kumar K, Harikrishna N, Reddy Gopal (2011) A novel serine alkaline protease from Bacillus altitudinis GVC11and its application as a dehairing agent. Bioprocess Biosyst Eng 34:403–409. doi:10.1007/s00449-010-0483-x

Shi Z, Li H, Li Z, Hu J, Zhang H (2013) Pre-column derivatization RP-HPLC determination of amino acids in Asparagi radix before and after heating process. In: Proceedings of 15 international conference on agricultural and natural resources engineering. 24–25 Dec 2013. pp 351–356

Rebah FB, Miled N (2013) Fish processing wastes for microbial enzyme production: a review. 3 Biotech 3:255–265. doi:10.1007/s13205-012-0099-8

Zhang F, Wang Z, Shiying X (2009) Macroporous resin purification of grass carp fish (Ctenopharyngodon idella) scale peptides with in vitro angiotensin-I converting enzyme (ACE) inhibitory ability. Food Chem 117:387–392. doi:10.1016/j.foodchem.2009.04.015

Zhang F, Wang A, Li Z, He S, Shao L (2011) Preparation and characterization of collagen from fresh water fish scales. Food Nutr Sci 2:818–823. doi:10.4236/fns.2011.28112

Acknowledgements

Authors thank the DBT- ISLARE for financial support to carry out this work and fellowship to HK.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest for this article.

Rights and permissions

About this article

Cite this article

Harikrishna, N., Mahalakshmi, S., Kiran Kumar, K. et al. Fish Scales as Potential Substrate for Production of Alkaline Protease and Amino Acid Rich Aqua Hydrolyzate by Bacillus altitudinis GVC11. Indian J Microbiol 57, 339–343 (2017). https://doi.org/10.1007/s12088-017-0664-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-017-0664-2