Abstract

In the era of industrialization, environmentalists are more concerned with the environment and so are continuously interested in investigating organizational factors that can facilitate the transition towards sustainability. This research systematically investigates the impact of the supply chain partner’s collaborative approach towards green practices on a firm’s sustainability performance. Stakeholder and coordination theories are used to underpin the study. A structural equation modeling technique is adopted to analyze data collected from 126 green supply chain professionals working at various manufacturing firms operating in Pakistan using a survey questionnaire. The results indicate significant and positive impacts of institution pressure and customer monitoring on the adoption of green supply chain management (GSCM) practices by organizations. This study also explains that organizational GSCM practices, external GSCM practices and performance measures have positive and significant relationships. These findings reveal that it is important for managers to address external GSCM pressures by adopting green practices and being a focal firm should undertake GSCM initiatives in collaboration with their suppliers and customers to achieve a holistic impact which ultimately leads to betterment in overall sustainability performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Businesses exist to offer solutions, grow and make a profit. However, in the quest of offering these solutions which lead to their growth and profitability, they tend to neglect the environmental impact their operations create and the economic implications that come along (Kusi-Sarpong et al. 2015; Kusi-Sarpong et al. 2018; Khan et al. 2019a; Najmi et al. 2019). The environmental impact of business operations has received less attention until the 1990s where supply chain operations started considering the effects of business operations on the environment (Sarkis 1999). One of the major considerations was the concept of green supply chain management (Kusi-Sarpong et al. 2016; Sarkis 1999; Sarkis and Weinrach 2001; Sarkis and Cordeiro 2001). Green supply chain considers the impact on the environment with regard to sourcing of raw materials, product composition, manufacturing and delivery to the final consumer as well as product life cycle (Bajaj et al. 2016; Bai et al. 2017; Beamon 1999; Kusi-Sarpong et al. 2016; Sarkis 2003).

Organizations react to environmental pressures exerted by different stakeholders based on their distinct norms, rules or institutions, conventionally manufacturers bear the regulatory pressures from government and due to these regulatory pressures they adopted reactive internal green supply chain management practices (Zhu et al. 2016). Institutional pressure is an important driver and positively affects the adoption of green supply chain management practices in organizations (Yang 2017). Due to stern regulations and likely competitive benefits, manufacturers have adopted assorted green practices (Govindan et al. 2014; Mathiyazhagan et al. 2014). Furthermore, institutional pressures influence organizations to pursue green supply chain management practices (Vanalle et al. 2017). Institutional theory has been used to explain the adoption of environmental management initiatives and green supply chain practices by organizations (Zhu et al. 2013). Stakeholders such as customers, suppliers, and competitors may wield pressure on manufacturers to adopt environmental management practices due to increased public awareness and ongoing damage to the environment (Zhu et al. 2012).

Previous literature highlights the fact that environmental pressure from stakeholders has increased considerable attention due to the awareness of customers (Jabbour et al., 2017). Stakeholder theory has an important role to play in implementing green supply chain initiatives as a result of customer pressures (Chavez et al. 2016). External pressures play a compelling role in the adoption of internal green supply chain initiatives (Adebanjo et al. 2016). Awareness of environmental fallout of manufacturing and production processes become a global phenomenon and it does not only exert pressure on organizations in developed economies but also firms operating in emerging economies in Asia (Geng et al. 2017). Pressures exerted by different stakeholders become the motivating factor for companies to implement environmentally friendly practices (Zhang and Yang 2016). There is a need to emphasize beyond internal boundaries on external players in the supply chain to respond to growing environmental apprehensions of various stakeholders (Laari et al. 2016).

Organizations could get involved directly or indirectly to enhance the environmental practices of supply chain members either by using an arm’s length approach or by investing in resources and internalizing the activities in supply chains (Vachon and Klassen 2006). To use a holistic and integrative approach, organizations first have to adhere to environmental concerns as a strategic course of direction. This then leads it to design such processes, products, and environment-friendly services and then to propagate this approach to all levels of the organization and among supply chain partners (Green Jr et al. 2012a). Dimensions of internal green supply chain management include the upstream and downstream green supply chain. These have to be linked with an external green supply chain to include both customers and suppliers (Yu et al., 2014).

Organizations are now accepting environmental management as a strategic imperative with the prospect of an indelible impact on organizational performance (Diabat and Govindan 2011). Internal green supply chain practices and external green collaborations help organizations to achieve green performance (Yang 2017). Practicing the green supply chain leads to benefits like reduced waste, reduced hazardous air emissions, increased energy efficacy, reduced fuel consumption and less water wastage (Bajaj et al. 2016).

Previous studies have shown inconclusive results which states that there is no significant effect of green practices found on financial performance (Zhang and Yang 2016), mixed results were reported for effect of external and internal green practices on environmental, financial and operational performance (Zailani et al. 2012; Lee et al. 2012; Lai and Wong 2012; Green Jr et al. 2012a; Ahmed et al. 2018; Vachon and Klassen 2008; Golicic and Smith 2013) and no support was found for green supply chain practices on operational performance (Vanalle et al. 2017; Zhu et al. 2007). These mixed results warrant additional detailed holistic investigation to further clarify these relationships between green practices and performance measures (Geng et al. 2017). This study focuses on the Pakistan manufacturing industry to investigate this relationship to help contribute to the closing up of this literature gap and confusion.

This study targets Pakistan and its manufacturing industry due to its recent and potential growth. Pakistan is seen as an expeditiously developing country and as one of the next eleven countries along with BRICS that has high potential to stand with the world’s largest economies in the twenty-first century (www.kcci.com.pk). On a worldwide scale, Pakistan’s enormous economic potential has been acknowledged as per the Price Water House Coopers report of 2017. Pakistan is envisaged to become the world’s 20th largest economy by 2030 and will become the 16th largest economy of the world by 2050 (Hussain 2017). There are several prestigious and reputable international publishers like Bloomberg and Economist etc. which have also acknowledged Pakistan’s impressive economic growth over the last four years (www.finance.gov.pk). The manufacturing sector in Pakistan is the backbone of the economy and it is the second-largest segment of the economy making 13.5% of GDP. Additionally, the manufacturing sector is the largest employment generator in the economy of Pakistan. The manufacturing sector further subdivided into large scale manufacturing which is 80% of the total sector and 10.7% of GDP whereas the small scale manufacturing sector is 13.7% of the total manufacturing sector and constitutes 1.8% to GDP. Overall, the manufacturing sector has had study growth. There was an impressive growth of 5.3% in the 2017 financial year as against 3.7% in the previous year (www.finance.gov.pk). This study draws empirical information from the large scale Pakistan manufacturing companies as studies have shown that the size of organizations affects their environmental performance (see e.g. Pagell et al. 2004). Pakistan is the fifth most densely populated country in the world having its impact on the pollution index. Pakistan manufacturing companies though are flourishing but lack the necessary direction and support for gaining much more insight to drive and improve environmental performance (Zubair et al. 2017). This is mainly due to a trust deficit, unwillingness to invest in environmental management and mostly due to ignorance among the partners. Pakistan’s context of this study will enrich the literature, as this will be the first study in a holistic and integrated manner to examine the external pressures for adopting green supply chain practices and its relationship with various performance measures directly and indirectly.

The objective of this paper is as follows:

-

1.

To develop a framework to understand the motivation and pressures behind GSCM implementation.

-

2.

To understand the effect of collaborations of different stake-holders to improve operational and financial performance.

-

3.

To explore the factors which contribute to improving the environmental performance of a firm.

Theses objective posits following research questions

-

RQ 1.

What are the driving forces of implementing GSCM in an organization?

-

RQ 2.

What are the interconnections among the key stakeholder to get better operational and financial performance?

-

RQ 3.

What are the impact of GSCM and collaborative practices on the environmental performance of the firm?

The rest of the paper is organized in the following manner. Section 2 discusses the theoretical background underpinning the study and hypotheses, and the methodology adopted in the study is presented in Section 3. Results and Data analysis presented in Section 4, and the conclusion is given in Section 5.

2 Theoretical background and hypotheses

It is pertinent to mention that theory always explains the raison d’etre of a phenomenon. The theory is used in research to build a framework for the phenomenon under study and the basic purpose of a theory is to establish, define and elaborate the interconnection among the constructs being researched. The research could be designed to contribute to multiple theoretical viewpoints. It is therefore important for the researches which are interdisciplinary to be considered by theoretical perspectives of other domains for better understanding (Amundson 1998). In the absence of institutional pressure, stakeholder’s pressure alone cannot make companies assign resources for environmental management practices (Vanalle et al. 2017).

2.1 Stakeholder theory

The stakeholder theory is a theory for managing the organization which contains diverse parties or members both internal and external that may impact by business entities like employees, suppliers, customers, and other institutions. This theory advocates morals and values in managing an organization such as the conservation of environment or initiatives like a sustainable supply chain (Jones 1995). Stakeholder theory proposes stakeholders who can affect an organization from achieving its objectives or could get affected by the achievement of an organization’s objectives (Mitchell et al. 1997). It further extends the stakeholder concept and says that it could be an individual or group on which an organization is dependent on its continued survival (Freeman and Reed 1983). Stakeholder theory proposes that organizations produce externalities that affect stakeholders and in return stakeholders exert pressure on organizations to minimize the adverse influences and increase the positive impacts. External environmental concerns from various stakeholders are deemed to be internalized through these stakeholder pressures within and between supply chain members (Sarkis et al. 2010). Stakeholder analysis for GSCM advocates that not all GSCM practices are beneficial for generating a competitive edge for the firms. There are quite many directions and developments in stakeholder theory but the basic principle says that there are external and internal groups which influence organizational practices (Sarkis et al. 2010)

2.2 Coordination theory

An organization can be divided into three general constituents i.e. actors, goals and resources. The coordination theory is defined as a body of principles about how the activities of separate actors can be coordinated in a systematic way to achieve any goal. Coordination theory can both draw upon and contribute to work in many different fields including economics, sociology and organization theory (Malone and Crowston 1990 and Malone 1988). Coordination theory refers to how coordination could occur in diverse systems and that coordination is managing dependencies between activities to achieve a holistic objective (Malone and Crowston 1994). Crowston (1998) argues that the coordination theory is still in the phase of development regarding the mechanism of prevailing coordination in extended kinds of systems. He further stresses the point that actors in a system are challenged with coordination difficulties which are resulted due to dependencies in the organization that limits the efficiency and effectiveness of process performance. Zhu et al. (2012) used a coordination theory-based approach in their research and suggested that the coordination of external and internal GSCM practices has resulted in a more satisfying performance in the overall supply chain. Research extends the GSCM theory development by incorporating a coordination theory standpoint in GSCM research. The coordination theory argues that enterprises should integrate activities along their supply chain. Moreover, it claims that the coordination of organizational activities like as internal and external dimensions of management practices will result in better performance outcomes in the supply chain.

The green supply chain contributes to intertwine and integrate environment factor into production, engineering, and logistics (Sarkis 2006). In a coordinated supply chain focal firm is the decision-maker and through a network of relationships, superior performance is achieved on shared goals (Shah et al. 2008). There are limited researches that examine the internal and external coordination mechanisms holistically between intra-organizational and inter-organizational networks. In the absence of internal cooperation mechanisms inside the organization, the goal of superior performance achievement through external cooperation with supply chain partners can never be materialized. To address this issue coordination theory proposes that manufacturing companies have to streamline, align and coordinate internal and external activities to perform well, additionally to research in the new emergent field of green supply chain management stretching it beyond the technological domain will be fruitful (Zhu et al. 2012). After the extensive literature review following variables are selected within the context of theories.

Institutional pressures

Chinese government-imposed environmental regulations and policies on manufacturers to promote GSCM and other corporate environmental practices primarily to increase exports and to attract foreign investment (Zhu, Sarkis, and Geng, 2005). Institutional pressures are one of the most important factors that encourage companies to adopt internal GSCM and the same influences the automotive suppliers to pursue GSCM practices (Vanalle et al. 2017). Firms have to adhere to institutional pressures that are exerted by external stakeholders on the firms.

Customer monitoring

Customers have an important role in the implementation of internal GSCM practices by manufacturers (Laari et al. 2016). Firms adopt certifications (ISO 14001 or EMAS etc) as the result of the environmental monitoring of customers (Vachon, 2007). Customers are one of the most important stakeholders as firms are dependent on them for their survival and they most importantly influence the organizations to adopt a certain set of strategies.

IGSCM

Internal green supply chain management is defined as the environmental management practices steered within an organization. Coordination among all functional departments along with the entire supply chain is the most important factor to implement these practices successfully (Rao and Holt 2005; Vachon and Klassen 2006; Zhu et al. 2008a; Zhu et al. 2008b). Internal GSCM involves practices such as ISO 14001 certification, an environmental audit of departments, eco-labeling of products manufactured, green procurement system, reduction of greenhouse emissions, green product compliance data (Chien and Shih 2007; Yu et al. 2014a). Internal green supply chain management practices are exercised to curb the externalities and negative impacts of a firm to comply with stakeholder’s pressures.

Supplier monitoring

environmental performance is dependent upon effective and successful ecological monitoring which provides information necessary for the implementation of green sustainability programs throughout the entire supply chain (Green Jr et al. 2012b). Firms are now increasingly tending towards managing their supplier’s environmental performance to make sure that the products delivered are ecofriendly and made through green raw materials (Rao and Holt 2005). Supplier monitoring shows the coordination between customers and suppliers in the context of internal and external green supply chain practices which also covers the aspect of external groups influencing the organization’s practices.

Customer collaboration

Suppliers and buyers need collaborative efforts to achieve environmental sustainability (Tachizawa et al. 2015). Collaboration among customers and suppliers is critical in the context of GSCM (Woo et al. 2016). By collaborating with customers shared a goal of achieving green practices in a coordinated supply chain is materialized.

Supplier collaboration

Green suppliers are critical for establishing a green supply chain strategy and improved green performance (Woo et al. 2016). In a green supply, chain suppliers contribute to attaining environmental sustainability by using green raw materials and adhering to green programs (Yang et al., 2011). In an integrated green supply chain, a focal firm influences others to achieve shared goals.

Environmental performance

Manufacturing firms can curb down hazardous air emissions, water, and solid wastage and reduced consumption of toxic materials (Zhu et al. 2008a). Lack of coordination in external green practices will weaken the environmental performance in manufacturing firms (Zhu et al. 2012). Upon external pressure of stakeholder’s environmental performance is to reduce the negative impact of externalities which firm produces.

Financial performance

A firm’s financial performance is indicated by a reduction in wastages and reworks, improved productivity, increased return on assets (Fullerton et al. 2014). Green efforts improve the green and financial performance in a coordinated supply chain (Yang et al. 2011). Customer collaboration in combination with internal green practices is the most effective way to enhance financial performance (Laari et al. 2016).

Operational performance

Increased demand of customers in environmental sustainability manufacturers required to adopt green practices which leads to operational performance improvement and will be a source of high-level customer satisfaction (Chavez et al. 2016). A proactive environmental management approach results in an improvement in the operational performance of a firm (Vachon and Klassen 2008). Internal environmental management activities and collaboration with both suppliers and customers will result in enhance and improved operational performance in terms of delivery, flexibility, cost and quality (Yu et al. 2014b).

2.3 Hypotheses development

2.3.1 Institutional pressures and IGSCM

Organizations are operating in an environment where they have to face, counter and comply with multiple forces and pressures arising from various sources. Regulatory pressures exerted by the government are critical to comply with firms by adopting reactive internal environmental management practices (Zhu et al. 2012). Firms usually dedicate the resources for implementing comprehensive environmental practices in the presence of strong institutional pressures (Vanalle et al. 2017). Institutional pressures from the important stakeholders as per stakeholder theory helps an organization to improve the compliance while transforming their conventional operations into environment-friendly (Sarkis et al. 2010; Ahmed et al. 2019a). Organizations face the threat of legal action and penalties in case they failed to comply with environmental regulations (Sarkis et.al, 2010). In the light of stake-holder’s theory, coercive or legitimate power is usually displayed by the institutions and external stake-holder possess to make the focal company comply with the environmental-friendly practices (Ahmed et al. 2019a; Khan et al. 2019b).

Various researchers empirically tested the impact of institutional pressures on organizations to adopt internal environmental and green practices found the relationship positive and significant (Zhu et al. 2013; Yang 2017; Vanalle et al. 2017; Mohanty and Prakash 2014).

Based on the above research findings and empirical results we propose our first hypothesis as follows:

-

H1: Institutional pressures has a significant association with internal green supply chain practices.

Stakeholders are sometimes classified into two categories namely primary and secondary. Primary stakeholders are customers, suppliers, employees and investors and secondary stakeholders are media and other special interest groups (Clarkson 1995). Stakeholder pressures are a great source of motivation for organizations to adopt green and environmental management practices (Buysse and Verbeke 2003). The organization’s decision to implement environmental management practices is affected by stakeholders like customers and clients (Sarkis et al. 2010). Customer’s demand from their suppliers to implement proactive environmental practices (Zhu and Sarkis 2004).

Monitoring is defined as a system that makes sure that suppliers are abiding by certain environmental commitments and to take corrective measures if required (De Giovanni and Vinzi 2014). It also involves other activities that involve the collection, evaluation, assessment and analysis of supplier information, supplier’s environmental management and incoming products (Lee 2008). Thus coordinated effort in line with the coordination theory by a customer to monitor the effective actions taken by the focal firm to enhance eco-friendly practices could be helpful to serve the cause. Laari et al. (2016) empirically examined the impact of customer monitoring on the implementation of internal green practices and found this relationship significant and positive. This notion is also supported by Klassen and Vachon (2003) where they found that there is a positive and significant relationship between customer-initiated evaluation and level of investments in environmental technologies. Giovanni and Vinzi (De Giovanni and Vinzi 2014) also studied the effect of monitoring practices on suppliers GSCM practices and found that there is a positive and significant impact of monitoring practice on firms GSCM practices. Since the customer is an important stakeholder as per stakeholder’s theory therefore, based on the above discussion we propose the hypothesis as follows:

-

H2: Environmental monitoring by the customer has a significant association with internal GSCM practices.

2.3.2 IGSCM and firm performance

Diabat and Govindan (2011) state that there is an increasing tendency among organizations to embrace the fact that environmental management is of vital importance and have a long-term effect on organizational performance. Geng et al. (2017) found in their meta-analysis that green supply chain practices lead to enhanced environmental, economic and operational performance. Initiatives to implement environmental management tend to improve environmental performance, financial performance and competitive advantage (Rao and Holt 2005). As a part of the system thinking approach and coordination theory, Zhu et al. (2012) advocate that coordination of external and internal GSCM practices has resulted in a more satisfying performance in the overall supply chain.

de Sousa Jabbour et al. (2017) examined the influence of GSC practices on environmental performance and found that there was a strong and significant relationship among them. These results were supported by another study conducted by Laari et al. (2016). Lee et al. (2012); Lai and Wong (2012); and Yu et al. (2014a) conducted a study and found that the effect of internal green practices is positive and significant with operational performance. Chien and Shih (2007); Huang et al. (2017); Zailani et al. (2012); and Ali et al. (2017) examined the green supply chain practices and found that they are significantly associated with financial performance. Therefore, we postulate our hypothesis as follows:

-

H3 (a): Implementation of internal GSCM practices has a significant association with the operational performance

-

H3 (b): Implementation of internal GSCM practices has a significant association with the environmental performance

-

H3 (c): Implementation of internal GSCM practices has a significant association with the financial performance

2.3.3 IGSCM instigates external Green practices

There is a need to shift from the arm’s length approach to a more collaborative and cooperative approach between customer and supply chain to yield better results from environmental management (Preuss 2005). Green supply chain integration logistically and technologically is linked with the monitoring and collaboration of primary suppliers and customers (Vachon and Klassen 2006). To achieve external green collaboration within the supply chain network a firm must pursue internal green practices. According to the coordination theory, it requires coordinated efforts of a different set of people or functions within the system to achieve a goal (Malone 1988).

An empirical study by Zhu et al. (2013) and Khan and Qianli (2017) suggests that supply chain functional eco-friendly practices both internal and external are significantly and positively correlated. Similarly, Laari et al. (2016) also found internal GSCM practices significantly affecting customer collaboration, supplier collaboration, and monitoring. Though both suppliers and customers have an integral role as per stakeholder theory however coordination and collaboration among them will eventually complement the GSCM (Zhu and Sarkis 2004). Hence, we postulate our hypothesis as follows:

-

H4 (a): Internal green practices have a significant association with the environmental monitoring of suppliers

-

H4 (b): Internal green practices have a significant association with environmental collaboration with suppliers

-

H4 (c): Internal green practices have a significant association with environmental collaboration with customers

2.3.4 Influence of environmental performance on financial performance

Organizations adopt green practices in the quest to achieve environmental performance which also affects other performance measures like operations and finance as these all measures are interlinked in an organization. Optimization in internal functional performance has always been an outcome of coordinated efforts among the internal and external stakeholders. Attaining excellence in one measure certainly affects other measures as well. This will be the greatest motivation for an organization that in a quest to achieve environmental performance, also attain operational and financial performance hence more profitability. This notion was supported by Green Jr et al. (2012b) and Hubbard (2009) as their study shows that environmental performance is significantly and positively associated with financial and operational performance in manufacturing concerns based in the US. Yang et al. (2010) study show that environmental performance has a positive effect on operational performance in manufacturing firms. Fullerton et al. (2014); Yu et al. (2014a) supported the notion that operational performance has a significant impact on financial performance. Hence, we propose our hypothesis as follows:

-

H5 (a): Environmental performance has a significant association with the operational performance

-

H5 (b): Environmental performance has a significant association with financial performance

-

H5 (c): Operational performance has a significant association with financial performance

2.3.5 Influence of environmental collaboration on firm performance

Vachon and Klassen (2008) researched to analyze the environmental collaboration of a firm with its suppliers and customers and found that it has a positive and significant impact on operational performance. Yu et al. (2014b) also supported this in their study where they found GSCM with suppliers and customers are significantly and positively related to operational performance. In past studies, collaborations are an outcome of well-coordinated effort among the partners (Ahmed et al. 2019a). For creating a high level of synergies and collaboration, it is required to bring all the key stakeholders on the same page. Woo et al. (2016) found that environmental collaboration is significantly associated with financial performance. This was also complemented by Corsten and Felde (2005) where they found the effect of supplier collaboration positive and significant with firm financial performance. Tachizawa et al. (2015) and Gimenez et al. (2012) state in their test results that supplier monitoring is significantly related to supplier collaboration and supplier collaboration is significantly associated with environmental performance in the Spanish context.

Green Jr et al. (2012b) studied environmental collaboration and monitoring impact on organizational performance where they found that environmental monitoring has a significant relationship with environmental performance. De Giovanni (2012) also supported this in his study where he established that external environmental management is significantly associated with environmental performance. Laari et al. (2016) study revealed that supplier monitoring is significantly associated with supplier collaboration and environmental performance while environmental collaboration with customers positively and significantly associated with financial performance. Since the performance cannot be improved without having the coordination among the stakeholders (Zhu et al., 2010; Zhu and Sarkis 2004, therefore as per coordination and stakeholder theory we establish our hypothesis as follows:

-

H6 (a): Environmental collaboration with customers has a significant association with environmental performance

-

H6 (b): Environmental collaboration with customers has a significant association with operational performance

-

H6 (c): Environmental collaboration with customers has a significant association with financial performance

-

H6 (d): Environmental collaboration with suppliers has a significant association with operational performance

-

H6 (e): Environmental collaboration with suppliers has a significant association with environmental performance

-

H6 (f): Environmental monitoring of suppliers has a significant association with environmental performance

-

H6 (g): Environmental monitoring of suppliers has a significant association with environmental collaboration with suppliers

-

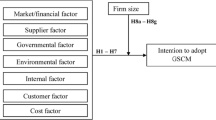

H6 (h): Environmental collaboration with suppliers has a significant association with financial performance. The aforementioned hypothesized relationships are summarized in Fig.1.

3 Research methodology

The main purpose of this paper is to analyze the effect of institutional and stakeholder pressures on the adoption of green supply chain practices by manufacturing firms and how they propagate this pressure further upstream and downstream to their supply chain partners and the result of these green practices on their performance measures. The research approach used in this study is a quantitative approach to identify and analyze the effects and relationships between variables used.

3.1 Research design

In this study, we will use a correlational research design to check the relationships among the constructs by using statistical analysis. Correlational research design commonly used by researchers to analyze the relationship between the dependent and independent constructs. Here in this research, we observe the relationship among institutional pressures and stakeholder pressures with internal green supply chain practices, the relationship among internal green supply chain practices with supplier collaboration, supplier monitoring, customer collaboration, financial performance, environmental performance and operational performance by the correlational method.

3.2 Population, sampling and sampling technique

Since the study focuses on environmental (green) supply chain management in the Pakistan manufacturing industry, the research population included all Pakistani manufacturing companies who were inactive operations at the time of the study. Precisely, the present study aims to analyze the impact of environmental collaboration on a firm’s sustainable performance, therefore data from the companies engaged in environmental initiatives can be considered valid since they are in a better position to respond to the aforementioned hypotheses. On the other hand, possible responses from the companies not participating in any environmental programs cannot anticipate the effects on performance outcomes. Therefore, as a way of sampling, we focused on companies that are ISO 14001 certified to ensure the accuracy and generalizability of results. Moreover, these companies were selected because they were viewed as organizations involved in programs that are in line with the subject under consideration (Zhu and Sarkis 2004). There were 343 ISO 14001 certified companies in Pakistan in 2018 when this study was conducted (ISO Survey 2016, “Laurent Charlet”, para.3).

Respondents for this study were selected through a purposive sampling technique, a non-probability sampling method and included supply chain managers holding the position of executive, senior officers, assistant managers, managers, general managers or directors in the ISO 14001 certified companies. Moreover, with the help of the business directory of Pakistan, the contact details of ISO 14001 certified companies were identified. The companies were then approached by mailing the survey questionnaire through online google-forms. During the process of data collection, several reminders were also given to the non-responding companies which lead to the data of 126.

3.3 Sample size and data collection

The sampling and sampling techniques resulted in a collection of 126 usable data from the target population, who worked as supply chain practitioners from ISO 14001 certified manufacturing companies in Pakistan. The survey questionnaire was used as a data collection instrument -composed of 58 items to measure performance outcomes. All questions were answered using a 5-point Likert scale. Details of the constructs adapted and their sources can be found in Table 1. Details of the demographics of respondents are tabularized in Table 2.

3.4 Issue of Endogeneity

Guide Jr and Ketokivi (2015) highlights the issue of causality in empirical research settings involving cross-sectional data. The issue of causality refers to a scenario where endogenous constructs in a research model also affect the exogenous construct accordingly. Therefore, as employed in the studies by Dubey et al., (Dubey et al. 2018; Dubey et al. 2019) and Ahmed et al. (2019b), nonlinear bivariate causality direction ratio (NLBCDR) was computed. According to Kock (2018), the threshold value of NLBCDR is >0.7, which is found in the present study as 0.974.

4 Results and data analysis

4.1 Overview

In this section, a detailed data analysis of the collected data in the study was completed. The objective is to analyze the pressures and influences on a focal firm internal green supply chain practices and internal green practices effect on performance measures along with upstream and downstream of a supply chain. Independent variables in this study includes institutional pressures (IP) and customer monitoring (CM) whereas internal green supply chain practices (IGSCM), customer collaboration (CC), supplier collaboration (SC), supplier monitoring (SM), financial performance (FP), operational performance (OP) and environmental performance (EP) are dependent variables.

4.1.1 Use of PLS-SEM

The structural equation modeling (SEM) technique is used as it is highly precise (Hair et al. 2010). SEM uses different types of models to show the relationship between observed variables and to provide a quantitative test of the theoretical model (Schumacker and Lomax 2010). PLS-SEM has proven over the years to be more appropriate in dealing with complex models with a considerably high number of indicators, constructs or relationships (Barclay et al. 1995; Garthwaite 1994). In this research, PLS is used due to its predictive power and capability to handle complex models. This technique is suitable for small sample sizes and complex models (Hair Jr et al. 2014; Peng and Lai 2012). In addition to this, technically PLS-SEM algorithm examines the measurement model employing partial regression and structural model by ordinary least square separately which helps PLS-SEM to estimate better, comparing to other types of SEM, in a scenario having the small sample size and complex models (Hair et al. 2019). Moreover, according to Reinartz et al. (2009), employing CB-SEM resulted in abnormal outcomes in small-sized non-normal data, whereas PLS-SEM is found to be consistent in terms of robustness in similar scenarios (Sarstedt et al. 2016). Data analysis is performed by using Smart PLS software as it is deemed the most powerful SEM tool (Ringle et al. 2005; Chin 1998).

4.2 Measurement, outer model

In this section reliability and construct validity of our research model are analyzed through discriminant validity, convergent validity and content validity details are mentioned in the below sections.

4.2.1 Content validity

The content validity of measurement items was assessed by using composite reliability. Values should be greater than 0.7 to be adequate (Nunnally and Bernstein 1994; Fornell and Larcker 1981). Items that have higher loading on other constructs were removed. Results are mentioned in Table 3 where all the items have loaded more than 0.7, which indicate strong, factor loadings.

4.2.2 Convergent validity

To ensure convergent validity, it is required to confirm that construct items that are theoretically related to each other must be related to each other after the data analysis. We can ensure this by using three types of methods namely factor loadings, composite reliability and average variance extracted (Hair et al. 2010). In the factor loading section, we consider the factors relevant which are highly loaded i.e. equal to or more than 0.7 and statistically significant. In the second step, we see composite reliability which indicates how consistently the items seek to specify the latent constructs (Hair et al. 2010). Values which are ideally accepted for composite reliability is 0.7 (Hair et al. 2010; Fornell and Larcker 1981). It is evident in Table 4 that composite reliability values are ranging from 0.883 to 0.944 which are quite above the recommended and prescribed values.

In the third step, we will check the average variance extracted, it is defined as a level of common variance between the indicators of the latent construct (Hair et al. 1998). The value of the average variance extracted ideally be more than 0.5 (Fornell and Larcker 1981; Hair et al. 2010). It is quite evident from Table 4 that our values of average variance extracted are between 0.579 to 0.807 which are according to the prescribed level. Hence from all three methods checked convergent validity has been established.

4.2.3 Discriminant validity

In this section, we discuss discriminant validity which is the measure to check how a set of measurement items differentiate a variable from other variables in a research model. In other words, the measures which are should not be related to each other are in actual do not found to be linked with each other after data analysis conducted. In order to make sure the discriminant validity square root of the average variance extracted is analyzed with correlations between the constructs of research (Chin, 2010; Fornell and Larcker 1981). We can see from Table 5 that diagonal line values are greater than other values in their respective rows and columns that establish the discriminant validity. Another way to confirm discriminant validity is the heterotrait-monotrait ratio of correlations (HTMT) estimates which should not be more than 0.85 (Henseler et al. 2015). Value in Table 6 shows that they are well below 0.85 hence establishing the discriminant validity.

4.3 Structural model and hypothesis testing

As we have checked and established the goodness of fit for the outer model in the previous section now we will scrutinize the standardized path coefficients to test the postulated relationships established in this study. Software used for this purpose is SmartPls 3.2.4 (Ringle, Wende and Becker, 2015). To check the statistical significance of path coefficients, the bootstrapping technique is used in this research (Chin 1998; Tenenhaus and Vinzi 2005; Haenlein and Kaplan 2004; Efron and Tibshirani 1986). Results of path analysis are summarized in Fig. 2.

4.3.1 Predictive relevance of the model

The predictive power of factors is examined via R square and Q square (Cross-Validated Redundancy). The value of R square higher than 26% is deemed significant (Cohen 1988). In Table 7 we can see that 47.5% of internal green supply chain (IGSCM) is explained by customer monitoring and institutional pressures; 43.5% of customer collaboration is explained by internal green supply chain management; 51.4% of supplier monitoring is explained by internal green supply chain management; 43.2% of supplier collaboration is explained by supplier monitoring and internal green supply chain management; 57% of operational performance is defined by internal green supply chain management along with supplier collaboration. Environmental performance and customer collaboration; 48.8% of environmental performance is defined by internal green supply chain management along with customer collaboration. Supplier monitoring and supplier collaboration; 46.4% of financial performance is defined by customer collaboration, environmental performance, supplier collaboration, and internal green supply chain management. These results indicate that the factors used in this study are highly predictive.

The second method to check the model’s predictive quality is cross-validated redundancy measure which is also called Q square (Hair et al. 2012; Geisser 1974; Stone 1974). Cross-validated redundancy measure is tested by blindfolding technique in SmartPLS with omissions distances at 5. This method is customized to estimate the parameters by not including some of the data and handling them as missing values (Fararah and Al-Swidi 2013). Q square values greater than 0 shows that the model has predictive significance. In Table 7 we can also see the Q square values for customer collaboration is 0.266, for environmental performance its value is 0.276, for financial performance its value is 0.323, for internal green supply chain management its value is 0.290, for operational performance its value is 0.307, for supplier collaboration its value is 0.244 and for supplier monitoring its value is 0.332. All these values confirm that model fitness is good and the model has good prediction quality.

5 Conclusion

5.1 Summary and theoretical implications

The main emphasis of this paper is to evaluate what triggers the internal green supply chain management practices in manufacturing firms operating in Pakistan. This research takes a holistic approach to assess the impact of internal green supply chain practices by including upstream and downstream channels of a focal firm and fills the gap identified by Tachizawa et al. (2015) and Dai et al. (2017). Further, it also fills the gap identified by Geng et al. (2017) and Vanalle et al. (2017) by conducting this research in less explored emerging Asian economies. Our research addresses the call from Geng et al. (2017) to examine green supply chain management from a theoretical lens. The results validate the stakeholder theory whereas the coordination theory is also supported to a great extent. It is observed that customer monitoring and institutional pressures have a positive and significant effect on internal green supply chain practices. It shows that green practices are triggered by stakeholder and regulatory pressures. This finding is in line with Chavez et al. (2016); Yang (2017); Lee (2008); Vanalle et al. (2017); Laari et al. (2016) which concluded that close monitoring of customers’ demand and expectations and mechanism to have updated customers’ information results in improvement in internal processes and accordingly green practices. As internal green supply chain practices triggered off by customer monitoring and institutional pressures their impact is found positive on customer collaboration and supplier monitoring. These results show that internal green practices are closely linked with customer collaboration and supplier monitoring in the downstream and upstream respectively. These significant results are in line with Laari et al. (2016). Interestingly internal green practices have no significant impact on supplier collaboration. Our results show that in the context of Pakistan supplier monitoring is a more appropriate and significant approach to implement and propagate green practices in upstream of the supply chain than collaboration with a supplier. This may be due to the implementation of green practices that are in the infancy stage in Pakistan which makes the monitoring approach more effective. Internal green supply chain management practices are positively and significantly impacting environmental and operational performance. This authenticates the work of (Chien and Shih (2007); Li et al. (2016); De Giovanni (2012); Huang et al. (2017); Yu et al. (2014a) which also endorsed that by improving IGSCM organizations can improve their operational efficiencies by reducing wastes and in result it impacts positively on environmental performance. Results indicate a positive and significant relationship between internal green supply chain management practices, environmental and operational performance but IGSCM has no significant impact on financial performance, as internal green practices implementation does incur a cost. It is plausible that results found no significant relationship between them. Laari et al. (2016) also found no significant relationship between internal green supply chain management and financial performance.

On the downstream side, it is observed that collaborating with customers results in a positive impact on operational, environmental and financial performance. These results substantiate the work of (Corsten and Felde (2005); Chavez et al. (2016); Tachiwaza et al., (2015); Yang et al. (2011) whose studies are aligned with this finding of present study and that is customer collaboration and frequent interactions along with firms’ capabilities to absorb customers’ opinion and work closely with them often reap better operational, environmental and financial performances. It is noted that the effect of environmental performance is complementary to operational performance which is in line with the work of (Green Jr et al. 2012a) but has no effect on financial performance. Laari et al. (2016) also found no impact of environmental performance on financial performance in their research. Operational performance is relating to financial performance and has a significant impact on it which compliments the work of Fullerton et al. (2014). It also fulfills the call of Laari et al. (2016) to examine the effect of internal green supply chain management on operational performance and operational performance impact on financial performance. As internal green supply chain management has a complementary effect on supplier monitoring. Consequently, supplier monitoring has a positive and significant effect on supplier collaboration which authenticates the work of Tachizawa et al. (2015) and also has a cogent effect on environmental performance which validates the work of Green Jr et al. (2012b). It was postulated that supplier collaboration has a positive effect on operational performance, environmental performance and financial performance. But it was found that supplier collaboration has no effect on operational performance which was also the case in the research by Hollos et al. (2012). Supplier collaboration also does not affect environmental performance. Laari et al. (2016) also found no support for supplier collaboration’s significant impact on environmental performance, while it has a significant effect on financial performance which substantiates the work of Corsten and Felde (2005). Overall results indicate that Pakistani manufacturing firms find supplier monitoring a preferred and effective approach than supplier collaboration to implement green practices and to achieve environmental performance.

5.2 Theoretical implications

This study provides three theoretical contributions to enhance the literature of green supply chain management. First, most of the results of this study are found to be consistent with the previous researches which are performed to explain or explore the coordinated efforts of various stake-holders having different research model for instance (Ahmed et al. 2018; Ahmed et al. 2019a; Hollos et al. (2012) and Zhu et al. (2013) Laari et al. (2016). Lee et al. (2012); Lai and Wong (2011); and Yu et al. (2014a). This consistency in results enhances the rigor in the use of stake-holder aligned with system/coordinated theory in GSCM. Second, studies before this limit the smaller frameworks that are good to keep the focus of the study on a specific area but this study uses the comprehensive research model to understand the holistic behavior of supply chain members in achieving the common goal of improving environmental and economic performance. Third, this research provides a framework explains the contributions of stakeholders and then its impact on firm performance. This may be helpful to academicians and researchers to further extend their research on similar lines. Thus through the outcome of this research, it is evident that institutional and stakeholder pressures are effective in persuading companies to adopt green practices. While systematic coordination in the shape of collaboration and monitoring enhances the firm green performance.

5.3 Managerial implications

It is evident from the findings of this study that institutional and stakeholder pressures are effective in persuading companies to adopt green practices. There is a need for government and other stakeholders to increase their magnitude of pressure on firms operating in Pakistan to make them comply with this external pressure and adopt green supply chain management practices for the betterment of the environment. To respond and comply with external pressures to adopt green supply chain management, focal firms have to collaborate with its customers and monitor its suppliers to further transfer the pressure in the supply chain to achieve the wholesome effect. Internal green supply chain management has an impact on supplier collaboration but through supplier monitoring. On performance measures, internal green supply chain management has a positive effect on operational and environmental performances which means the stronger the internal green practices, the better these two performance measures will be. This is a morale booster for managers in manufacturing firms in Pakistan that by making your supply chain greener your firm will achieve excellence in environmental and operational performance. On the contrary internal green supply chain management not improving the financial performance which is understandable as green environmental practices do cause an increase in short term costs but in the long run, they will achieve financial competitiveness (Woo et al. 2016). Another important dimension in performance measure is that collaborating with a buying firm will achieve excellence in all three performance measures i.e. environmental performance, financial performance, and operational performance. While collaborating with suppliers gets good financial performance. It is also pertinent to note that supplier monitoring which is the effective approach in Pakistani context has a complementary effect on environmental performance, therefore, it is highly recommended for managers in Pakistani manufacturing firms to adopt supplier monitoring as their focal approach (Laari et al. 2016).

5.4 Limitation of the study & future research directions

Even though this study makes considerable contributions to theory and practices, but more researches are required in a similar direction to have an in-depth understanding of the phenomenon. For future studies in this area may focus on the specific industry or sector like pharmaceutical, automobile, textile, etc. to be more specific in providing policy implications. Institutional pressure can further be broken down into factors like normative, coercive, and mimetic pressures which may provide further insights. This study is conducted in the context of Pakistani manufacturing industries with a small sample size which limits the generalizability of the results. Moreover, the present study employs data from ISO 14001 certified companies only, therefore study having non-certified companies may generate different results. Finally, testing the mediating relationship among variables will be useful to comprehend the indirect effects of the variable.

References

Adebanjo D, Teh PL, Ahmed PK (2016) The impact of external pressure and sustainable management practices on manufacturing performance and environmental outcomes. Int J Oper Prod Manag 36(9):995–1013

Ahmed W, Ahmed W, Najmi A (2018) Developing and analyzing framework for understanding the effects of GSCM on green and economic performance: perspective of a developing country. Management of Environmental Quality: An International Journal 29(4):740–758

Ahmed W, Najmi A, Arif M, Younus M (2019a). Exploring firm performance by institutional pressures driven green supply chain management practices. Smart and Sustainable Built Environment (forthcoming)

Ahmed W, Najmi A, Khan F, Aziz H (2019b). Developing and analyzing framework to manage resources in humanitarian logistics. Journal of Humanitarian Logistics and Supply Chain Management (Forthcoming)

Ali A, Bentley Y, Cao G, Habib F (2017) Green supply chain management–food for thought? Int J Log Res Appl 20(1):22–38

Amundson SD (1998) Relationships between theory-driven empirical research in operations management and other disciplines. J Oper Manag 16(4):341–359

Bai C, Kusi-Sarpong S, Sarkis J (2017) An implementation path for green information technology systems in the Ghanaian mining industry. J Clean Prod 164:1105–1123

Bajaj PS, Bansod SV, Paul ID (2016) A review on the Green supply chain management (GSCM) practices, implementation and study of different framework to get the area of research in GSCM. In Techno-Societal 2016, International Conference on Advanced Technologies for Societal Applications (pp. 193-199). Springer, Cham

Barclay D, Higgins C, Thompson R (1995) The partial least squares (pls) approach to casual modeling: personal computer adoption Ans use as an illustration

Beamon BM (1999) Designing the green supply chain. Logist Inf Manag 12(4):332–342

Buysse K, Verbeke A (2003) Proactive environmental strategies: a stakeholder management perspective. Strateg Manag J 24(5):453–470

Chavez R, Yu W, Feng M, Wiengarten F (2016) The effect of customer-centric Green supply chain management on operational performance and customer satisfaction. Bus Strateg Environ 25(3):205–220

Chien MK, Shih LH (2007) An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational performances. International Journal of Environmental Science and Technology:(IJEST), 4(3), 383

Chin WW (1998) Commentary: issues and opinion on structural equation modeling

Chin, W. W. (2010). How to write up and report PLS analyses. In Handbook of partial least squares (pp. 655-690). Springer, Berlin, Heidelberg.

Clarkson ME (1995) A stakeholder framework for analyzing and evaluating corporate social performance. Acad Manag Rev 20(1):92–117

Cohen J (1988) Statistical power analysis for the behavioral sciences 2nd edn

Corsten D, Felde J (2005) Exploring the performance effects of key-supplier collaboration: an empirical investigation into Swiss buyer-supplier relationships. International Journal of Physical Distribution & Logistics Management 35(6):445–461

Dai J, Cantor DE, Montabon FL (2017) Examining corporate environmental proactivity and operational performance: a strategy-structure-capabilities-performance perspective within a green context. Int J Prod Econ 193:272–280

De Giovanni P (2012) Do internal and external environmental management contribute to the triple bottom line? Int J Oper Prod Manag 32(3):265–290

De Giovanni P, Vinzi VE (2014) The benefits of a monitoring strategy for firms subject to the emissions trading system. Transp Res Part D: Transp Environ 33:220–233

de Sousa Jabbour ABL, Vazquez-Brust D, Jabbour CJC, Latan H (2017) Green supply chain practices and environmental performance in Brazil: survey, case studies, and implications for B2B. Ind Mark Manag 66:13–28

Diabat A, Govindan K (2011) An analysis of the drivers affecting the implementation of green supply chain management. Resour Conserv Recycl 55(6):659–667

Dimmaggio P, Powell W (1983) The iron cage revisited: institutional isomorphism and collective rationality in organizational fields. Am Sociol Rev 48(2):147–160

Dubey R, Gunasekaran A, Childe SJ (2018) Big data analytics capability in supply chain agility: the moderating effect of organizational flexibility. Manag Decis

Dubey R, Gunasekaran A, Childe SJ, Roubaud D, Wamba SF, Giannakis M, Foropon C (2019) Big data analytics and organizational culture as complements to swift trust and collaborative performance in the humanitarian supply chain. Int J Prod Econ 210:120–136

Efron B, Tibshirani R (1986) Bootstrap methods for standard errors, confidence intervals, and other measures of statistical accuracy. Stat Sci:54–75

Hair F Jr, Sarstedt M, Hopkins L, Kuppelwieser VG (2014) Partial least squares structural equation modeling (PLS-SEM) an emerging tool in business research. Eur Bus Rev 26(2):106–121

Fararah FS, Al-Swidi AK (2013) The role of the perceived benefits on the relationship between service quality and customer satisfaction: a study on the Islamic microfinance and SMEs in Yemen using PLS approach. Asian Soc Sci 9(10):18

Fornell C, Larcker DF (1981) Evaluating structural equation models with unobservable variables and measurement error. J Mark Res:39–50

Freeman RE, Reed DL (1983) Stockholders and stakeholders: a new perspective on corporate governance. Calif Manag Rev 25(3):88–106

Fullerton RR, Kennedy FA, Widener SK (2014) Lean manufacturing and firm performance: the incremental contribution of lean management accounting practices. J Oper Manag 32(7–8):414–428

Garthwaite PH (1994) An interpretation of partial least squares. J Am Stat Assoc 89(425):122–127

Geisser S (1974) A predictive approach to the random effect model. Biometrika 61(1):101–107

Geng R, Mansouri SA, Aktas E (2017) The relationship between green supply chain management and performance: a meta-analysis of empirical evidences in Asian emerging economies. Int J Prod Econ 183:245–258

Gimenez C, Sierra V, Rodon J (2012) Sustainable operations: their impact on the triple bottom line. Int J Prod Econ 140(1):149–159

Golicic SL, Smith CD (2013) A meta-analysis of environmentally sustainable supply chain management practices and firm performance. J Supply Chain Manag 49(2):78–95

Govindan K, Kaliyan M, Kannan D, Haq AN (2014) Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int J Prod Econ 147:555–568

Green KW Jr, Zelbst PJ, Bhadauria VS, Meacham J (2012a) Do environmental collaboration and monitoring enhance organizational performance? Ind Manag Data Syst 112(2):186–205

Green KW Jr, Zelbst PJ, Meacham J, Bhadauria VS (2012b) Green supply chain management practices: impact on performance. Supply Chain Management: An International Journal 17(3):290–305

Guide Jr, V. D. R., & Ketokivi, M. (2015). Notes from the editors: redefining some methodological criteria for the journal⋆. Journal of Operations Management, 37(1), v-viii

Haenlein M, Kaplan AM (2004) A beginner's guide to partial least squares analysis. Underst Stat 3(4):283–297

Hair, J. F., Black, W. C., Babin, B. J., Anderson, R. E., & Tatham, R. L. (1998). Multivariate data analysis (Vol. 5, No. 3, pp. 207–219). Upper Saddle River, NJ: Prentice hall

Hair JF, Risher JJ, Sarstedt M, Ringle CM (2019) When to use and how to report the results of PLS-SEM. Eur Bus Rev 31(1):2–24

Hair JF, Sarstedt M, Ringle CM, Mena JA (2012) An assessment of the use of partial least squares structural equation modeling in marketing research. J Acad Mark Sci 40(3):414–433

Hair JF, Black WC, Babin BJ, Anderson RE (2010) Multivariate data analysis: a global perspective, 7th edn. Pearson, Upper Saddle River

Henseler J, Ringle CM, Sarstedt M (2015) A new criterion for assessing discriminant validity in variance-based structural equation modeling. J Acad Mark Sci 43(1):115–135

Hollos D, Blome C, Foerstl K (2012) Does sustainable supplier co-operation affect performance? Examining implications for the triple bottom line. Int J Prod Res 50(11):2968–2986

Huang YC, Huang CH, Yang ML (2017) Drivers of green supply chain initiatives and performance: evidence from the electrical and electronics industries in Taiwan. International Journal of Physical Distribution & Logistics Management 47(9):796–819

Hubbard G (2009) Measuring organizational performance: beyond the triple bottom line. Bus Strateg Environ 18(3):177–191

Hussain D(2017). Pakistan could become 16th largest economy by 2050: PWC. DAWN. Retrieved from https://www.dawn.com/news/1313636

ISO Survey (2016). Retrieved January 02, 2018, from https://www.iso.org/the-iso-survey.html

Jones TM (1995) Instrumental stakeholder theory: a synthesis of ethics and economics. Acad Manag Rev 20(2):404–437

Khan F, Ahmed W, Najmi A (2019a) Understanding consumers’ behavior intentions towards dealing with the plastic waste: perspective of a developing country. Resour Conserv Recycl 142:49–58

Khan F, Ahmed W, Najmi A, Younus M (2019b) Managing plastic waste disposal by assessing consumers’ recycling behavior: the case of a densely populated developing country. Environmental Science and Pollution Research, 1-13

Khan SAR, Qianli D (2017) Impact of green supply chain management practices on firms’ performance: an empirical study from the perspective of Pakistan. Environ Sci Pollut Res 24(20):16829–16844

Klassen RD, Vachon S (2003) Collaboration and evaluation in the supply chain: the impact on plant-level environmental investment. Prod Oper Manag 12(3):336–352

Kock N (2018) WarpPLS user manual: version 6.0. ScriptWarp Systems: Laredo, TX, USA

Kusi-Sarpong S, Bai C, Sarkis J, Wang X (2015) Green supply chain practices evaluation in the mining industry using a joint rough sets and fuzzy TOPSIS methodology. Resources Policy 46:86–100

Kusi-Sarpong S, Gupta H, Sarkis J (2018) A supply chain sustainability innovation framework and evaluation methodology. International Journal of Production Research, 1-19

Kusi-Sarpong S, Sarkis J, Wang X (2016) Assessing green supply chain practices in the Ghanaian mining industry: a framework and evaluation. Int J Prod Econ 181:325–341

Laari S, Töyli J, Solakivi T, Ojala L (2016) Firm performance and customer-driven green supply chain management. J Clean Prod 112:1960–1970

Lai KH, Wong CW (2012) Green logistics management and performance: some empirical evidence from Chinese manufacturing exporters. Omega 40(3):267–282

Lee SM, Tae Kim S, Choi D (2012) Green supply chain management and organizational performance. Ind Manag Data Syst 112(8):1148–1180

Lee SY (2008) Drivers for the participation of small and medium-sized suppliers in green supply chain initiatives. Supply Chain Management: An International Journal 13(3):185–198

Li S, Jayaraman V, Paulraj A, Shang KC (2016) Proactive environmental strategies and performance: role of green supply chain processes and green product design in the Chinese high-tech industry. Int J Prod Res 54(7):2136–2151

Malone TW (1988) What is coordination theory?

Malone TW, Crowston K (1990) What is coordination theory and how can it help design cooperative work systems?. In Proceedings of the 1990 ACM conference on Computer-supported cooperative work (pp. 357-370). ACM

Malone TW, Crowston K (1994) The interdisciplinary study of coordination. ACM Computing Surveys (CSUR) 26(1):87–119

Mathiyazhagan K, Govindan K, Noorul Haq A (2014) Pressure analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int J Prod Res 52(1):188–202

Mitchell RK, Agle BR, Wood DJ (1997) Toward a theory of stakeholder identification and salience: defining the principle of who and what really counts. Acad Manag Rev 22(4):853–886

Mohanty RP, Prakash A (2014) Green supply chain management practices in India: an empirical study. Production Planning & Control 25(16):1322–1337

Najmi A, Kanapathy K, Aziz AA (2019) Prioritising factors influencing consumers' reversing intention of e-waste using analytic hierarchy process. International Journal of Electronic Customer Relationship Management 12(1):58–74

Nunnally JC, Bernstein IH (1994) The theory of measurement error. Psychom Theory:209–247

Pagell M, Yang CL, Krumwiede DW, Sheu C (2004) Does the competitive environment influence the efficacy of investments in environmental management? J Supply Chain Manag 40(2):30–39

Peng DX, Lai F (2012) Using partial least squares in operations management research: a practical guideline and summary of past research. J Oper Manag 30(6):467–480

Preuss L (2005) Rhetoric and reality of corporate greening: a view from the supply chain management function. Bus Strateg Environ 14(2):123–139

Rao P, Holt D (2005) Do green supply chains lead to competitiveness and economic performance? Int J Oper Prod Manag 25(9):898–916

Reinartz W, Haenlein M, Henseler J (2009) An empirical comparison of the efficacy of covariance-based and variance-based SEM. Int J Res Mark 26(4):332–344

Ringle, C. M., Wende, S., & Will, A. (2005). SmartPLS 2.0. Hamburg

Sarkis J (1999) A methodological framework for evaluating environmentally conscious manufacturing programs. Comput Ind Eng 36(4):793–810

Sarkis J (2003) A strategic decision framework for green supply chain management. J Clean Prod 11(4):397–409

Sarkis J (2006). Greening the supply chain. Springer Science & Business Media

Sarkis J, Cordeiro JJ (2001) An empirical evaluation of environmental efficiencies and firm performance: pollution prevention versus end-of-pipe practice. Eur J Oper Res 135(1):102–113

Sarkis J, Weinrach J (2001) Using data envelopment analysis to evaluate environmentally conscious waste treatment technology. J Clean Prod 9(5):417–427

Sarkis J, Gonzalez-Torre P, Adenso-Diaz B (2010) Stakeholder pressure and the adoption of environmental practices: the mediating effect of training. J Oper Manag 28(2):163–176

Sarstedt M, Hair JF, Ringle CM, Thiele KO, Gudergan SP (2016) Estimation issues with PLS and CBSEM: where the bias lies! J Bus Res 69(10):3998–4010

Schumacker RE, Lomax RG (2010) A beginner’s guide to structural equation modeling (3rd Ed). Taylor & Francis Group, New York

Shah R, Goldstein SM, Unger BT, Henry TD (2008) Explaining anomalous high performance in a health care supply chain. Decis Sci 39(4):759–789

Stone M (1974) Cross-validatory choice and assessment of statistical predictions. J R Stat Soc Ser B Methodol:111–147

Tachizawa EM, Gimenez C, Sierra V (2015) Green supply chain management approaches: drivers and performance implications. Int J Oper Prod Manag 35(11):1546–1566

Tenenhaus M, Vinzi VE (2005) PLS regression, PLS path modeling and generalized procrustean analysis: a combined approach for multiblock analysis. J Chemom 19(3):145–153

Vachon, S. (2007). Green supply chain practices and the selection of environmental technologies. International Journal of Production Research, 45(18-19), 4357-4379.

Vachon S, Klassen RD (2006) Extending green practices across the supply chain: the impact of upstream and downstream integration. Int J Oper Prod Manag 26(7):795–821

Vachon S, Klassen RD (2008) Environmental management and manufacturing performance: the role of collaboration in the supply chain. Int J Prod Econ 111(2):299–315

Vanalle RM, Ganga GMD, Godinho Filho M, Lucato WC (2017) Green supply chain management: an investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J Clean Prod 151:250–259

Woo C, Kim MG, Chung Y, Rho JJ (2016) Suppliers' communication capability and external green integration for green and financial performance in Korean construction industry. J Clean Prod 112:483–493

Yang CS (2017) An analysis of institutional pressures, green supply chain management, and green performance in the container shipping context. Transportation Research Part D: Transport and Environment

Yang MGM, Hong P, Modi SB (2011) Impact of lean manufacturing and environmental management on business performance: an empirical study of manufacturingfirms. Int J Prod Econ 129(2):251–261

Yu W, Chavez R, Feng M, Wiengarten F (2014a) Integrated green supply chain management and operational performance. Supply Chain Management: An International Journal 19(5/6):683–696

Yu W, Ramanathan R, Nath P (2014b) The impacts of marketing and operations capabilities on financial performance in the UK retail sector: a resource-based perspective. Ind Mark Manag 43(1):25–31

Zailani S, Jeyaraman K, Vengadasan G, Premkumar R (2012) Sustainable supply chain management (SSCM) in Malaysia: a survey. Int J Prod Econ 140(1):330–340

Zhang H, Yang F (2016) On the drivers and performance outcomes of green practices adoption: an empirical study in China. Ind Manag Data Syst 116(9):2011–2034

Zhu Q, Sarkis J (2004) Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J Oper Manag 22(3):265–289

Zhu, Q., Sarkis, J., & Geng, Y. (2005). Green supply chain management in China: pressures, practices and performance. International Journal of Operations & Production Management, 25(5), 449-468.

Zhu Q, Geng Y, Sarkis J (2016) Shifting Chinese organizational responses to evolving greening pressures. Ecol Econ 121:65–74

Zhu Q, Sarkis J, Lai KH (2007) Green supply chain management: pressures, practices and performance within the Chinese automobile industry. J Clean Prod 15(11–12):1041–1052

Zhu Q, Sarkis J, Lai KH (2008a) Green supply chain management implications for “closing the loop”. Transportation Research Part E: Logistics and Transportation Review 44(1):1–18

Zhu Q, Sarkis J, Lai KH (2008b) Confirmation of a measurement model for green supply chain management practices implementation. Int J Prod Econ 111(2):261–273

Zhu Q, Sarkis J, Lai KH (2012) Examining the effects of green supply chain management practices and their mediations on performance improvements. Int J Prod Res 50(5):1377–1394

Zhu Q, Sarkis J, Lai KH (2013) Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J Purch Supply Manag 19(2):106–117

Zubair M, Farid M, Danish M, Zafar MN (2017) Evaluation of air pollution sources in selected zone of textile industries in Pakistan. Environmental Engineering & Management Journal (EEMJ) 16(2)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmed, W., Ashraf, M.S., Khan, S.A. et al. Analyzing the impact of environmental collaboration among supply chain stakeholders on a firm’s sustainable performance. Oper Manag Res 13, 4–21 (2020). https://doi.org/10.1007/s12063-020-00152-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12063-020-00152-1