Abstract

This research evaluates the energy efficiency and productivity growth in the industrial sector over the period of 1999 till 2013 using data envelopment analysis (DEA). Two cases are analyzed; in the first case (GVA), the output is the gross value added, whereas two outputs are considered in the second case (GCO), CO2 emission and GVA. Five key input factors are considered in both cases. From DEA window analysis, the technical inefficiency (TIE) values are zeros in windows (2001–2005) till (2003–2007), (2007–2011), and (2008–2012), whereas the pure technical inefficiency (PTIE) values are zeros in windows (1999–2003) till (2003–2007). Finally, the scale inefficiency (SIE) values are zeros in windows (2001–2005) till (2003–2007). These results help policy planners on how to better utilize resources and management efficiency over time and guide operational managers when to increase or decrease the scale. Moreover, the averages of inefficiency values in the GVA case are smaller than their corresponding in the GCO case, which indicates the negative effect of CO2 emission on efficiency. Further, Malmquist index is estimated for three 5-year energy plans. The productivity index is found less than one for the third plan (2009–2013), which indicates a decrease productivity growth. In conclusions, research results provide valuable support when assessing the progress of energy efficiency and productivity in industrial sector.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recently, there has been a growing concern about energy consumption and its adverse impact on the environment. In Jordan, energy consumption is divided into three major sectors: industrial, residential, and transportation. The industrial sector is responsible of about 22 % of energy consumption. Because the energy sources are very limited commercially, a lot of efforts have been directed to discover natural resources required for energy production. Studies revealed that the contribution of the local production did not exceed 5 % during years 2000 and 2011. Further, it is expected that the demand for the electrical energy will increase by 43 % from 2011 until 2020. Finally, the fluctuation for the oil price and the rising prices from month to month affect significantly the energy consumption (Al-Ghandoor et al. 2008).

Efficiency measurement in energy sector

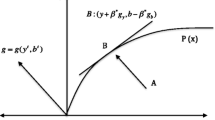

Efficiency measurement plays an important role in the formulation, application, and evaluation of energy policy (Shi et al. 2010; Martinez 2011). In practice, two output measures are used to assess the performance in energy sector, involving the gross value added and CO2 emission. These two measures are influenced by several input measures, including the number of employees, number of establishments, energy consumption, intermediate consumption, and compensation of employees. In order to assess the energy efficiency over time, it is necessary to combine these input and output measures into one single measure, which is efficiency score calculated as the sum of the weighted output measures divided by the sum of weighted input measures. A widely-known approach for efficiency measurement is using data envelopment analysis (DEA), which evaluates the performance of a number of homogeneous decision-making units (DMUs) of multiple inputs and multiple outputs (Al-Refaie et al. 2014a, b, c; Cooper et al. 2004). Figure 1 shows the basic concept of DEA. The DEA approach will be applied to the points S1, S2, S3, and S4 in Fig. 1. The DMUs are identified units S1, S2, S3, and S4 as efficient, and they provide an envelope (best practice frontier) round the entire data set; other units are within this envelope and are inefficient. An inefficient DMU can be improved by moving them to the efficient frontier.

The most well-known DEA models are the CCR model proposed by Charnes et al. (1978) and BCC model developed by Banker et al. (1984). Data envelopment analysis has been applied for assessing efficiency in a wide range of business applications (Li et al. 2014; Al-Refaie 2014; Wang et al. 2012; Al-Refaie 2009).

However, when using DEA, an important rule of thumb is that the number of DMUs is at least twice the sum of the number of inputs and outputs (Al-Refaie 2011; Al-Refaie 2010). Otherwise, the model may produce numerous relatively efficient units and decrease discriminating power. To resolve this difficulty, DEA window analysis (Charnes et al. 1985) was introduced, in which the performance of a DMU in any period can be compared with its own performance in other periods as well as to the performance of other DMUs. The window should be as small as possible to minimize the unfairness comparison over time, but still large enough to have a sufficient sample size (Asmild et al. 2004). Window analysis was used to measure the efficiency of Taiwan’s telecommunication firms over the periods of 2001–2005 (Yang and Chang 2009), investigate the relationship between size and efficiency of the Italian hospitality sector (Pulina et al. 2010), and to evaluate the performance of Iranian wood panels industry (Hemmasi et al. 2011).

Malmquist productivity index

The nonparametric Malmquist productivity index (MPI) is a formal time-series analysis technique for performing performance comparisons of DMUs over time by solving some DEA-type models (Malmquist 1953). MPI reflects the increase or decrease in efficiency with progress or regress of the frontier technology over time under multiple inputs and multiple outputs framework. The productivity of DMU from period t to t + 1 is improved when MPI is larger than one, remained unchanged when MPI equals one, and deteriorated when MPI is less than one (Fare et al. 1994). Malmquist index has been utilized in evaluating the productivity growth in several applications. For example, Odeck (2000) combined DEA and Malmquist index to analyze the efficiency and productivity growth of the Norwegian Motor Vehicle Inspection Agencies during the period of 1989–1991. Ma et al. (2002) employed the DEA approach and Malmquist index of iron and steel industry in China for the period of 1989–1997, with the aim of gaining some insights to increase the output while reducing emissions and waste. Chen et al. (2006) applied the DEA and Malmquist index to analyze the comparative performances and the growth potentials of the six high-tech industries developed at Taiwan’s Hsin Chu science park during the period of 1991–1999.

In this context, this research aims at assessing the energy efficiency for the industrial sector from 1999 till 2013. Moreover, it analyzes the efficiency and productivity growth between three 5-year energy strategic plans during 1999–2003, 2004–2008, and 2009–2013. In practice, the result of this research shall help the decision makers in the formulation, application, and evaluation of energy policy for the industrial sector in Jordan. The remaining of this paper is organized as follows: DEA models section is discussed in the next section followed by data collection and analysis, results and discussions, and research conclusions.

DEA models

CCR, BCC, and window analysis

The CCR model assumes constant return to scale (CRS) where an increase in the input results an increase in the output result. The estimated efficiency will be between 0 and 1. Figure 2 shows the production frontier of the CCR model.

Consider a set of nDMUs. For DMUk, let y rk (r = 1, …, s) denote the level of r th output and x ik (i = 1, …, m) the level of the i th input. The efficiency score of a specific DMU, DMUk, is calculated as by solving the input-oriented CCR model as follows:

Subject to:

θ unrestricted in sign

The optimal θ is denoted by θ* satisfies 0 ≤ θ* ≤ 1. If θ* equals to 1, the DMU under measurement is then technically efficient. The CCR input-oriented model seeks to minimize inputs while satisfying at least the given output levels. Thus, the resulted efficiency score represents the technical efficiency (TE), which reflects the firm’s ability to maximize output from a given set of inputs assuming that the size of operation of DMU is optimal.

On the other hand, the DMU operates under variable returns to scale if it is suspected that an increase in inputs does not result in a proportional change in the outputs. Figure 3 shows the production frontier of the BCC model, which measures the pure technical efficiency (PTE), which ignores the impact of the scale size by only comparing a DMU to a unit of similar scale.

The PTE measures how a DMU utilizes its sources under exogenous environments; a low PTE implies that the DMU inefficiently manages its resources. To calculate the PTE score, the following BCC model is developed:

Subject to:

θ unrestricted in sign

The use of the BCC model allows the decomposition of TE score into PTE and scale efficiency (SE) scores, where the relationship between them is expressed as follows:

The SE measures how the scale size affects efficiency. SE provides the ability of the management to choose the optimal size of resources, i.e., production scale, which attains the expected level of production.

Finally, to conduct DEA window analysis, consider N DMUs (n = 1,…,N) that all use r inputs to produce s outputs and are observed in T (t = 1,…,T) periods. Let DMU t n represent an observation n in period t with input vector X t n and output vector, Y t n which are given by Eq. (2b).

If the window starts at time k(1 ≤ k ≤ T) with width w(1 ≤ w ≤ T − k), then the matrices of inputs and outputs are denoted as given by Eqs. (2c) and (2d), respectively.

and

Substituting inputs and outputs of DMU t n into CCR or BCC model produces the results of DEA window analysis.

Malmquist index

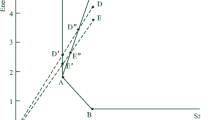

The MPI can be used to estimate the productivity growth in energy sector, which is decomposed into efficiency change and technological change. The concept of productivity usually referred to labor productivity is defined as the product of efficiency change (catch-up) and technological change (frontier-shift). If MPI index value is greater than 1, this indicates a positive MPI growth from period (t) to period (t + 1), whereas a value less than 1 indicates a decrease in MPI growth or performance relative to the previous year. The Malmquist framework is depicted in Fig. 4, where a production frontier representing the efficient level of output (y) that can be produced from a given level of input (x) is constructed. The assumption made is that the frontier can shift over time. The frontier obtained in the current (t) and future (t + 1) time periods is labeled accordingly. When inefficiency exists, the relative movement of any given DMU over time will, therefore, depends on both its position relative to the corresponding frontier (technical efficiency) and the position of the frontier itself (technical change). If the inefficiency is ignored, then the productivity growth over time will be unable to distinguish between improvements that derive from a DMU catching up to its own frontier or those that result from the frontier itself shifting up over time.

A assume θ t(x t o , y t o ) and θ t + 1(x t o , y t o ) are the input-oriented efficiency measures of DMU based on its inputs and outputs at period t for the reference technology at t and t + 1. Further assume that θ t(x t + 1 o , y t + 1 o ) and θ t + 1(x t + 1 o , y t + 1 o ) are the input-oriented efficiency measures of DMU based on its inputs and outputs at period t + 1 for the reference technology at t and t + 1. MPI is calculated using Eq. (2e).

The productivity change can be decomposed into two parts, technological change and efficiency change. The efficiency change component, the terms outside the brackets, measures the change in the relative efficiency over time. The technological change component, the terms enclosed by the square brackets, reflects the shift in the best practice frontier from t to t + 1. In order to calculate θ t + 1(x t o , y t o ) and θ t(x t + 1 o , y t + 1 o ), linear programing models must be solved. The θ t(x t + 1 o , y t + 1 o ) and θ t + 1(x t o , y t o ) are expressed as IEI t + 1 → t and IEI t → t + 1, respectively.

Subject to:

λ j ≥ 0, j = 1, …, n (8d)

Subject to:

Data collection and analysis

Data collection and descriptive analysis

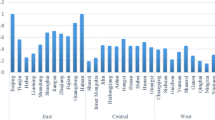

In this research, the data is collected as time series for the five input measures, including the number of employee, number of establishments, energy consumption, intermediate consumption, and compensation of employee, and the two output measures are gross value added and CO2 emission during 1999 till 2013. The collected data is then displayed in Table 1. The descriptive statistics for collected data for input and output variables are summarized in Table 2, where it is noted that the coefficient of variation (standard deviation divided by the mean) is larger than 5 % for all measures. This result indicates that significant variations in each measure over the period of 1999 to 2013. The largest coefficient of variation corresponds to intermediate consumption of 53.84 %. For output measures, the maximum (minimum) of the gross value added (1000 JD) and CO2 emission are 4,259,447.55 (1,186,882) and 4,189,903.2 (2,735,334) kg, which correspond to 2010 (1999) and 2007 (2012), respectively. Further, Table 3 displays the correlation matrix evaluated among all factors. The correlation coefficient of the value that is greater than 0.8 indicates strong correlation, whereas a value less than 0.6 implies weak correlation. It is found that the gross value added is significantly correlated with the number of employees (p value < 0.0001), number of establishments (p value = 0.004), compensation of employees (p value = 0.940), and intermediate consumption (p value = 0.931). While, the CO2 emission is significantly correlated with the number of employees (p value = 0.007), and energy consumption (p value < 0.001).

DEA window analysis

Two cases will be analyzed in DEA window analysis. The first case (GVA) considers one desirable output measure, which is the gross value added, and five input measures, including x 1 to x 5. While the second case (GCO) considers the gross value added and the CO2 emission as a desirable and undesirable output measure, respectively, and five input measures. Then, the window DEA analysis is conducted for each case as follows.

Technical efficiency

The collected input and output data over the period of 1999 to 2013 is divided into nine windows. For instance, the first row covers the period from year 1999 to 2003, that is, the window length is 5 years. The next row presents the window from year 2000 to 2004 and so on. The number of windows and the number of data points as follows:

where n denotes the number of the production lines, p is the length of window, w is the number of windows, and k is the number of periods. In this research, the number of windows was 15 − 5 + 1 = 11 and the number of “different” lines was n × p × w = 1 × 5 × 11 = 55. The technical score, TE scores, which measure inefficiencies due to input/output configuration, is calculated using the CCR model and then the results are displayed in Table 4. In window analysis, the rows can be used to examine the trends that occur in each window. The columns used to examine the stability properties. In Table 4, for the illustration in GVA, the TE CCR score = 1.00 for window (1999–2000) is calculated using the CCR model as follows:

Subject to:

The TE CCR scores for all the other window periods are estimated similarly. The TE CCR scores for GCO are calculated with weight ratio (4:1) between gross values added to CO2 emission in a similar manner.

Generally, the efficiency scores listed in each column assess the performance stability. In Table 4, the differences between the efficiency scores in most years are negligible for both cases. For example, using the CCR model, the efficiency scores in year 2001 to 2004 are zeros. This indicates the performance stability. On the other hand, the efficiency scores in each row determine whether a trend pattern occurs within each window. The coefficient of variation (CV) is used to assess dispersion. Usually, a CV value larger than 5 % indicates the existence of a trend pattern. In Table 4, dispersion is significant in windows (2004–2008) till window (2007–2011) for both cases. Moreover, observing the average TE scores of both models, it is seen that the TE score is less than 1 in eight out of eleven windows for GVA and seven out of eleven windows for GCO. These windows are concluded inefficient.

Comparing the TE scores between GVA and GCO, it is found that the TE scores for GVA are equal or larger to their corresponding for GCO. This shows the negative effect of CO2 emission on the technical efficiency.

Analysis of pure technical efficiency

The technical efficiency calculates the efficiency without scale consideration by comparing a DMU to other DMUs of the same size only. In contrast, the PTE scores are estimated under the assumption of variable returns to scale (VRS) using the BCC model. Typically, the PTE score reflects the managerial performance to organize the inputs in the production process. Table 5 displays the calculated PTE scores in all windows for both models. For illustration, the PTE score (PTE BCC = 1.000) for window (1999–2003) in year 1999 is calculated for GVA as:

Similarly, the PTE BCC scores are calculated in all the other windows. In a similar manner, the PTE BCC scores are calculated in all windows for GCO. Clearly, the PTE BCC scores indicate the stability and lack of significant dispersion in all windows for both cases. Further, the PTE scores are equal to 1, or the PTE efficiency, in seven out of eleven windows for both GVA and GCO. However, the PTE scores are less than 1 for windows (2004–2008) till (2006–2010) and (2009–2013) of both cases, and hence, they are concluded the PTE inefficient.

Similar to TE scores, it is noticed that the PTE scores for GVA are equal or larger to their corresponding scores for GCO. This reveals the negative effect of CO2 emission on gross value added.

Analysis of scale efficiency

Once the TE scores and PTE scores are estimated, the scale efficiency (SE) scores are obtained for each window as TE score divided by its corresponding PTE score. If the TE score equals PTE score, the SE score equals 1 and thereby the size of operation is concluded optimal. Otherwise, returns to scale analysis are required to determine if the operations of energy production need expansion or reduction of their sizes. When operations have a small size, then the facilities/operations’ expansion is needed. In contrast, when inefficiency is due to the large size of operations, then operations should be reduced. The SE scores are calculated and then displayed in Table 6 for both models, where it is seen that the average SE values are less than 1 in eight out of eleven windows. Consequently, these windows are considered scale inefficient. However, the SE averages are equal to 1 in windows (2001–2005) till (2003–2007) and therefore are concluded the SE efficient. Finally, the average of SE averages for model I (0.97630) is larger than that (0.96371) of the GCO.

The analysis of Malmquist index

Generally, most organization set long-term plans that cover a time span of 5 years. Consequently, the collected data can be divided into three plans for the year periods of 1999 to 2003 (plan A), 2004 to 2008 (plan B), and 2009 to 2013 (plan C). The MPI values are calculated and the results are displayed in Tables 7 and 8 for GVA and GCO, respectively. In MPI, the efficiency change measures the change in relative efficiency over time. Firstly, the TE values are computed using the CCR model. For instance, the technical efficiency value (0.83860) in year 2009 for GVA is calculated using the inputs and output of years 2004 and 2009 as follows:

Similarly, the other scores of TE are calculated. Then, the technical efficiency change (TECH = 1.138847), which calculated between years 2009 and 2010, is computed as:

Similarly, the other TECH t → t + 1 values are calculated. The TECH t → t + 1 values in Table 8 for GCO are calculated in a similar manner.

Further, the technological change reflects the shift in the best practice frontier over time. The IEI t → t + 1 and IEI t + 1 → t values are calculated for the three plans and then listed in Table 9. For example, the IEI t = 1 → 2 (0.91677) for the first period (year 1999) of the first plan is calculated using the input and outputs of the second periods (P2) of years 2000 (P1, 2), 2005 (P2, 2), and 2010 (P3, 2) as follows:

And IEI t = 2 → 1 (0.87249) for the second period (year 2000) of the first plan is calculated using the input and outputs of the first periods (P1) of years 1999 (P1, 1), 2004 (P2, 1), and 2009 (P3,1) as follows:

The other IEI t → t + 1 and IEI t + 1 → t estimates are calculated in a similar manner. The technological change (TECHCH) estimates are calculated for each window. For example, the technological change, TECHCH 21 , between years 1999 and 2000 equals 0.914148 is calculated as:

Finally, MPI during the period of 1999–2000 is finally calculated as:

The MPI estimates for the other periods are calculated in a similar manner. The MPI values are calculated for GCO similarly and then the results are displayed in Table 8.

Research results

Results of window analysis

Providing guidance on what can be achieved in the short and long terms is done by decomposing technical efficiency scores into pure technical efficiency and scale efficiency. The TIE, PTIE, and SIE for the technical, pure technical, and scale inefficiencies, respectively, are summarized in Table 6 and used for determining the main contributor of inefficiency. In GVA, it is noted that the averages of TIE (0.02602), PTIE (0.00245), and SIE (0.02370) averages are smaller than their corresponding in GCO of 0.04049, 0.00447, and 0.03629, respectively. This result reveals the influence of CO2 emission on technical efficiency. In order to improve the efficiency, energy planner should set plans to reduce CO2 emission in order to improve the technical performance by using environmental friendly energy sources. Further, the TIE values are zeros in windows (2001–2005) till (2003–2007), (2007–2011), and (2008–2012) in both cases, which indicate the operational efficiency in producing maximum gross added value from the given set of inputs. However, in the other windows, the TIE values are greater than zero, which indicates the deficiency in reducing input excess and turn it to maximize the gross value added. Moreover, the PTIE values are zeros in windows (1999–2003) till (2003–2007). Consequently, these windows reveal the management efficiency in planning and utilizing the inputs. In contrast, caused by poor input, utilization or managerial inefficiency is the cause of inefficiency in windows of which the PTIE is nonzero. Finally, the SIE values are zeros in windows (2001–2005) till (2003–2007). In this case, the scale is optimal and hence there will be no efficiency gain by changing the scale of production. Consequently, introducing new technology, technology-based energy alternatives are encouraged. Similar conclusions are obtained from the analysis of TIE, PTIE, and SIE values for GCO. Table 9 identifies the returns to scale for each window, where it is noted that 39 out of 55 data lines are CRS that is operating at optimal scale level. However, the returns to scale in 19 out of 55 are IRS. That is, the proportional of all input levels produces less than the proportional increase in the gross value added. Consequently, the size of the scale should be expanded to optimize scale and reduce excess input slacks.

On the other hand, observing the returns to scale for each year in Table 9, it is seen that the 5 out of 15 years are IRS, including years 2000, 2005–2007, and 2011, which are technically inefficient but pure technical efficient is shown in Tables 4 and 5. Consequently, the main contributor of technical inefficiency is only the scale size.

Results of Malmquist index

Observing the MPI values for GVA, which is displayed in Table 7, it is found that the efficiency change (TECH) is greater than 1 for all the three plans. This indicates positive efficiency change relative to the previous period. However, the technological change (TECHCH) values are found smaller than 1, which indicates change decrease, for the first, second, and third plan in three, two, and two out of four, respectively. To illustrate, for the first plan in GVA, the MPI (0.99849) of the third period indicates that the productivity in year 2002 decreases relative to year 2001, while a productivity decrease is observed in years 2005 and 2006 in the second plan. For the third plan, a negative productivity growth is observed in years 2011 and 2013. Knowing that the positive efficiency changes, the contributor to MPI decrease is due to TECHCH. Further, the geometric average is larger than 1 for the first (1999–2003) and second (2004–2008) plans, whereas it is less than 1 for the third plan (2009–2013). Similar results are concluded when analyzing the MPI values for the three plans for GCO. As a result, the energy sector should focus on introducing new technology to face the decrease productivity growth.

Conclusions

In this research, DEA window analysis and Malmquist index are employed to assess the energy efficiency and productivity growth of the industrial sector in Jordan over the period of 1999 till 2013. Two cases are evaluated; the first model (GVA) treats the gross value added as the output, whereas the second model (GCO) considers CO2 emission and gross value added as the undesired and desirable output, respectively. Five input factors are identified, including the energy consumption, number of employees, number of establishments, compensation of employees, and intermediate consumption. Correlation analysis is carried out to examine the factor relations. DEA window analysis and Malmquist index are then used in data analyses. The CCR and BCC models are utilized for calculating the technical and pure technical efficiency, respectively. Then the technical, pure technical, and scale inefficiency averages, TIE, PTIE, and SIE, respectively, are calculated. Understanding the sources of inefficiency and reducing excessive energy consumption and intermediate consumption are the main solution to maximize gross value added. Further, increasing returns to scale is observed in 19 out of 55 data lines, which indicate that the size of the operational scale (number of employees and establishments) should be increased to optimize scale. Finally, the results of Malmquist index showed that the geometric average is larger than 1 for the first (1999–2003) and second (2004–2008) plans, whereas it is less than 1 for the third plan (2009–2013). This result indicates the need for introducing technology rather than increasing efficiency is the way to achieve the productivity growth. In conclusions, the progress of efficiency and productivity should be regularly during the formulation, application, and evaluation of energy policy for the industrial sector in Jordan.

References

Al-Ghandoor, A., Al-Hinti, I., Jaber, J. O., & Sawalha, S. A. (2008). Electricity consumption and associated GHG emissions of the Jordanian industrial sector: empirical analysis and future projection. Energy Policy, 36, 258–267.

Al-Refaie, A. (2009). Optimizing SMT performance using comparisons of efficiency between different systems technique in DEA. IEEE Transactions, Electronic Packaging Manufacturing, 32(4), 256–264.

Al-Refaie, A., Li, M. H. M., Jarbo, M., Yeh, C. H., & Bata, N. (2014a). Imprecise data envelopment analysis model for robust design with multiple fuzzy quality responses. Advances in Production Engineering & Management, 9(2), 83–94.

Al-Refaie, A. (2014). Optimizing performance with multiple responses using cross-evaluation and aggressive formulation in data envelopment analysis. IIE Transactions, 44(4), 262–276.

Al-Refaie, A. (2010). Super-Efficiency DEA approach for optimizing multiple quality characteristics in parameter design. International Journal of Artificial Life Research, 1(2), 58–71.

Al-Refaie, A. (2011). Optimising correlated QCHs in robust design using principal components analysis and DEA techniques". Production Planning and Control, 22(7), 676–689.

Al-Refaie, A., Fouad, R., Li, M. H., & Shurrab, M. (2014b). Applying simulation and DEA to improve performance of emergency department in a Jordanian hospital. Simulation Modeling Practice and Theory, 41(2), 59–72.

Asmild, M., Paradi, J. C., Aggarwall, V., & Schaffnit, C. (2004). Combining DEA window analysis with the Malmquist index approach in a study of the Canadian banking industry. Journal of Productivity Analysis, 21(1), 67–89.

Banker, R. D., Charnes, A., & Cooper, W. W. (1984). Some models for estimating technical and scale inefficiencies in data envelopment analysis. Management Science, 30(9), 1078–1092.

Charnes, A., Cooper, W. W., & Rhodes, E. (1978). Measuring the efficiency of decision making units. European Journal of Operational Research, 2(6), 429–444.

Charnes, A., Clark, C. T., Cooper, W. W., & Golany, B. (1985). A development study of data envelopment analysis in measuring the efficiency of maintenance units in the US air forces. Annals of Operations Research, 2(1), 95–112.

Chen, C. J., Lin, B. W., & Wu, H. L. (2006). Evaluating the development of high-tech industries: Taiwan’s science park. Technological Forecasting & Social Change, 73(4), 452–465.

Cooper, W. W., Seiford, L. M., & Zhu, J. (2004). Data envelopment analysis: history, models and interpretations. In L. M. Cooper, L. M. Seiford, & J. Zhu (Eds.), Handbook on Data Envelopment Analysis (pp. 1–39). Boston: Kluwer Academic Publishers.

Fare, R., Grosskopf, S., Lindgren, B., & Roos, P. (1994). Productivity Developments in Swedish Hospitals: A Malmquist Output Index Approach. In A. Charnes, W. W. Cooper, A. Y. Lewin, & L. M. Seiford (Eds.), Data Envelopment Analysis: Theory (pp. 253–272). Boston: Methodology and Applications. Kluwer Academic Publishers.

Hemmasi, A., Talaeipour, M., Khademi-Eslam, H., Farzipoor, R., & Pourmousa, S. H. (2011). Using DEA window analysis for performance evaluation of Iranian wood panels industry. African Journal of Agricultural Research, 6(7), 1802–1806.

Li, M. H., Al-Refaie, A., Jarbo, M., & Yeh, C. H. (2014). IDEA approach for solving multi-responses fuzziness problem in robust design. Journal of Quality, 21(6), 455–479.

Ma, J., Evan, D. G., Fuller, R. J., & Stewart, D. F. (2002). Technical efficiency and productivity change of China’s iron and steel industry. Production Economics, 76(3), 293–312.

Malmquist, S. (1953). Index numbers and indifference surfaces. Trabajos de Estatistica, 4(2), 209–242.

Martinez, C. I. P. (2011). Energy efficiency development in German and Colombian non-energy-intensive sectors: a non-parametric analysis. Energy Efficiency, 4(1), 115–131.

Odeck, J. (2000). Assessing the relative efficiency and productivity growth of vehicle inspection services: an application of DEA and Malmquist indices. European Journal of Operational Research, 126(3), 501–514.

Pulina, M., Detotto, C., & Paba, A. (2010). An investigation into the relationship between size and efficiency of the Italian hospitality sector: a window DEA approach. European Journal of Operational Research, 204(3), 613–620.

Shi, G.-M., Bi, J., & Wang, J.-N. (2010). Chinese regional industrial energy efficiency evaluation based on a DEA model of fixing non-energy inputs. Energy Policy, 38(10), 6172–6179.

Wang, Z.-H., Zeng, H.-L., Wei, Y.-M., & Zhang, Y.-X. (2012). Regional total factor energy efficiency: an empirical analysis of industrial sector China. Applied Energy, 97(1), 115–123.

Yang, H.-H., & Chang, C.-Y. (2009). Using DEA window analysis to measure efficiencies of Taiwan’s integrated telecommunication firms. Telecommunications Policy, 33(1-2), 98–108.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Refaie, A., Hammad, M. & Li, MH. DEA window analysis and Malmquist index to assess energy efficiency and productivity in Jordanian industrial sector. Energy Efficiency 9, 1299–1313 (2016). https://doi.org/10.1007/s12053-016-9424-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-016-9424-0