Abstract

Ventilation systems are responsible for the thermal comfort and air quality of indoor spaces. The adjustment of ventilation systems is a time-consuming task that may need multiple iterations. Incorrect adjustments of a ventilation system can reduce the quality of working and living conditions and degrade the energy efficiency of the ventilation. In this paper, a testing, adjusting, and balancing method for a ventilation system is presented that uses only the knowledge of the fan total flow rate and pressure. The method does not need additional instrumentation for the ventilation adjustment as the fan operating point can be estimated with the variable-speed drive. The method is noniterative, thereby saving time, and the ventilation system is adjusted to its minimum energy consumption setting without compromise in system operation. The proposed method is assessed with a laboratory test setup to verify the correct operation of the method in practice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Forced air ventilation systems are responsible for thermal comfort and air quality, and they are used in residential, communal, and industrial buildings of all sorts (SMACNA 2002). Obviously, these systems are great in number, and thus, ventilation accounts for approximately 10 % of the electrical energy consumption for instance in the municipal sector alone (de Almeida et al. 2003). Ventilation systems that are not correctly adjusted can cause excessive noise and reduced air quality that may degrade the quality of working and living conditions (Öhrström and Skånberg 2004; Persson Waye et al. 1997). In addition, excessive energy consumption can be a result of an incorrectly adjusted ventilation system since more pressure is needed to provide the required ventilation air flow.

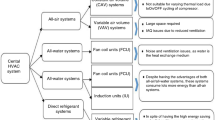

Ventilation systems, both for the supply and return air, consist of a fan and ductwork to split the flow as needed. Each split or branch in the duct requires dampers and terminals with possible diffusers to adjust the flow rate through the branch, and in each room, to achieve the design flow rates. This is illustrated by the design of a ventilation system in Fig. 1.

The testing, adjusting, and balancing (TAB) of these ventilation systems is a time-consuming and laborious task that may need iteration loops to ensure that the designed air flow is reached in every location of the building. For example, when applying the “ratio method”, multiple iterations have to be performed when the ventilation system is adjusted (SMACNA 2002). In Pedranzini et al. (2013), a noniterative method called the progressive flow method (PFM) is introduced for testing, adjusting, and balancing of a ventilation system. In the procedure, the fan is controlled to provide constant flow to the most distant terminal of a branch (RM5 in Fig. 1). The flow rate at the other terminals is adjusted in sequence from the end of the branch to the beginning (from RM4 to RM1 in Fig. 1). This ensures that no iterations are needed in the adjustment of the ventilation system. The minimum number of adjustments needed in the ratio method is 3n + 2b − 1 while with the PFM, the number of adjustments required is b + n, where n is the number of terminals and b is the number of branches. Consequently, the PFM method requires 57 % fewer adjustments than the ratio method when considering the easiest case of two terminals and one branch and 67 % fewer adjustments for the limiting case of an infinite number of terminals (Pedranzini et al. 2013). However, an additional control loop and measurement devices are needed in the PFM because of the constant flow control of the most distant terminal.

Variable-speed drives (VSDs) have become common in fan and ventilation systems because they enable the energy efficient control of the flow rate by the rotational speed control (Drbal et al. 1995). These variable-speed drives can nowadays accurately estimate the mechanical power and rotational speed of the motor as shown in Ahonen et al. (2013) and Nash (1996). These estimates make it possible to estimate the fan operating point (defined by volumetric flow rate Q V, differential pressure p F, mechanical power P, and rotational speed n) without additional instrumentation to the ventilation system as shown in Wang et al. (2005) and Tamminen et al. (2011). The methods commonly use the fan characteristic curves of mechanical power as a function of flow rate (QP curve) and the fan differential pressure as a function of flow rate (Qp F curve) as models of the fan operation.

For example, one of the ways to estimate the fan operating point is to use the well-known QP curve-based method (Tamminen et al. 2011). In this method, rotational speed and mechanical power estimates are used as inputs to the estimation method, and the fan QP curve is used as a model of the fan. The model is corrected to correspond to the rotational speed with the affinity equations

where the subscript “0” denotes the initial values. These model-based estimation methods are extensively discussed in Ahonen et al. (2010) and Tamminen et al. (2014). A graphical example of the QP curve-based estimation method is shown in Fig. 2.

In this paper, a TAB procedure is introduced that uses the capabilities of the variable-speed drive operating point estimation and the rotational speed control. The procedure applies a constant pressure control of the fan during the adjustment of the terminal diffusers. The flow rate in the terminals is adjusted step by step so that an addition in the total flow rate can be used as an indicator of the adjustment process. The benefit of this method is that only a fan pressure sensor is needed in the adjustment of the ventilation system. In addition, the number of adjustments needed with the proposed TAB is the same as with the PFM.

The remainder of the paper is organized as follows: In Chapter 2, the fan pressure-based TAB procedure is introduced and discussed, and the method is simulated. In addition, the error sources and limitation and mitigation of the errors to the method are discussed in Chapter 2. In Chapter 3, proof-of-concept experiments are conducted with both the actual flow rate and pressure sensors in the measurement setups and by the soft-sensor approach. The paper is concluded in the last chapter.

Fan pressure-based TAB method

The new TAB procedure uses the variable-speed drive in the ventilation system as a source of information of the system flow rate. The TAB procedure requires information about the total flow rate and pressure of the fan. In the procedure, the total flow rate is used to estimate the flow rate through each terminal, as the terminals are adjusted one after the other (similar to PFM method), and the additional flow rate added to the total flow rate is assumed to be the flow rate through the adjusted terminal. The fan pressure is needed for the constant pressure control of the fan. The flow rate and the pressure can be either measured or estimated. The estimation can be carried out as described in the “Introduction.” The flowchart of the proposed TAB algorithm is given in Fig. 3.

The algorithm is used as follows: First, the terminal at the very end of a ventilation branch requiring the highest pressure is selected. The diffuser and dampers of this branch and terminal are set to their minimum loss setting. This can be accomplished by fully opening the diffuser at the end of the duct. All the other terminals in the ventilation system are set so that there is no flow through them; for example, the diffusers and control valves are closed.

Second, in the algorithm, the flow rate at the terminal at the very end of the branch is adjusted by controlling the fan rotational speed. The flow rate through the fan is the same as through the terminal. After this, the pressure of the fan is saved as the reference pressure for later steps.

Third, the fan is set to produce constant pressure, and the flow rates in the other terminal are set one by one by controlling the diffuser in the terminal from the end of the duct towards the beginning. The additional flow rate through the fan can be estimated when the controlled diffuser is opened. The flow rate in the adjusted terminal is known when all of the additional flow is assumed to pass through this controlled terminal. All of the terminals are adjusted by this procedure.

Fourth, the fan is operated with a constant flow rate control so that the design flow rate is always achieved in the system even if the filter starts to accumulate dirt and produce additional losses. The variable-speed drive can be used to estimate the specific fan power that can be used to assess the energy efficiency and the design of the ventilation system.

The constant pressure control can be accomplished with the VSD using known model-based fan operating point estimation methods. For example, the QP curve-based method introduced in Wang and Liu (2005) can be easily implemented in the software of the VSD, and further, other suitable methods are presented in Tamminen et al. (2014). During the second and third step, the fan pressure is constantly estimated by the QP curve-based method. The pressure estimate can be used, for example, in a PI controller as the actual value, and thus, the rotational speed of the fan can be controlled accordingly, as can be seen in Fig. 4.

The power consumption P F of the fan in the ventilation system can be calculated by

where η sys is the fan system efficiency corresponding to the combined efficiency of the fan, motor, and variable-speed drive. In addition, if it assumed that the fan system efficiency is approximately the same regardless of the TAB procedure, the only way to influence the power consumption is to minimize the fan pressure. The minimum possible pressure that can accomplish the given ventilation task is the pressure that is needed to produce the desired flow rate at the terminal at the very end of a branch. At any higher pressure, the terminal has to be throttled to reduce the flow to the desired value. At any lower pressure, there is not enough flow through the branch. Thus, by this method, the minimum energy consumption is found.

Simulation

The method was simulated with a setup that has a similar layout as the laboratory test system (see Fig. 5). There is a single fan supplying four different branches that have only one terminal in each branch. The branches are parallel to each other. Branch 1 has the highest losses for the design flow rate.

The flow rate of terminal 1 is first set to the design value of 12 l/s between 0 and 500 s with the diffuser open and with the diffusers of all the other branches closed as shown in Fig. 6a (arrow 1). When the desired flow rate is achieved, the fan pressure reference is saved and the fan is operated in a constant pressure mode for 500–2000 s, and the other terminals are set to the designed flow rate by controlling their valves (arrows 2–4 represent the adjustment of terminals 2–4, respectively). It can be seen that after 500 s, the pressure remains constant, and the flow rate of branch 1 is not affected by the flow in the other branches. The simulations show that the algorithm for the ventilation tuning is valid and does not require additional instrumentation or any iteration to achieve the design flow rate values in each branch.

Simulation results of the soft sensor-based TAB procedure. In (a), the fan rotational speed, static pressure, and flow rate as a function of time are presented. In (b), the diffuser openings and relative flow rates in the respective terminals are given. The set point flow rates for branches 1–4 are 12, 10, 8, and 6 l/s, respectively. The numbered arrows represent the adjustment of the respective terminal

Error sources and limitations

Common duct for several terminals

There is one distinct source of error in the proposed TAB method. If there is a duct that is shared by two or more terminals in the ventilation system, the duct will have an effect on the tuning algorithm. The reason for this is that when the flow rates of the other terminal is set, the increased flow rate causes additional pressure losses in the common duct. These additional pressure losses reduce the flow rate at the first terminal. In addition, when the accumulation of the total flow through the fan is considered to pass only to the terminal under adjustment, there may be an excessive flow rate through the terminal being adjusted. This is because the desired flow rate value is a sum of set flow rate values in each terminal, and if the flow rate of one terminal decreases, then there has to be more flow rate through the other terminals to reach the desired total flow rate value. This is especially the case with air handling units that have notable internal pressure drop. In these cases, the only way to apply the presented method is to use a pressure measurement at the branching point of the ducts, control the fan pressure with that measurement, and otherwise use the TAB procedure as described above.

However, if there is no pressure measurement available, the effect of the common branch can be otherwise mitigated. If there is a flow rate measurement available for the terminal, the resulting pressure loss can be compensated by increasing the fan pressure according to the difference between the initial and current total flow rate and pressure and the measured flow rate through the respective terminal

where subscript 0 denotes the initial value, subscript 1 is the current value, and subscript B is the value in the terminal being adjusted. When no additional flow rate measurement is available, the common flow resistance has to be estimated, so the resulting fan pressure reference can be calculated by

The air filter in ventilation systems is traditionally placed in a common duct, causing the problem presented above. However, if the filter is removed for the time of the TAB procedure and inserted back afterwards, the effect of the filter can be cancelled. This can be done by controlling the fan to produce a constant flow rate that was acquired at the end of the TAB procedure. When the filter is reinstalled, the fan system automatically increases the pressure to satisfy the flow rate. This is also the case when the filter starts to build up contaminants, meaning an increase in the system pressure losses. Since the fan pressure is raised to ensure the reference flow rate, it could be used as an indicator of filter contamination.

Besides filters, ventilation systems always have leaks that affect the TAB procedure since it is based on the total flow rate through the fan. Share of the leakage flow can be around 10 % of the total flow rate produced by the fan, and it cannot be directly separated from the normal flow through an adjusted terminal (SFS 1987). However, the effect of the leakage on the TAB procedure may be mitigated with an initial test with all the terminals closed. The fan is run with multiple pressure references, and the flow due to the leakage is estimated. Then during the TAB procedure, the estimated leakage corresponding to the fan pressure is deducted from the total flow rate, ideally resulting in a leakage-free estimate of the total flow rate and thus an unaffected TAB procedure.

Moreover, if the assumption of the branch with the highest pressure loss is wrong, there will be not enough pressure to satisfy the system flow rate demand. Thus, in this case, the tuning has to be started again using the correct branch with the highest pressure loss. To avoid incorrect selection of the branch with the highest pressure requirement, a metering device may be used as with the “ratio method” to find the terminal at most disadvantage (SMACNA 2002). It also has to be noted that a meter is required if the tuning is to be validated.

In large systems consisting of multiple branches, the fan pressure-based tuning method may not be possible. The method is based on detecting the change in the total flow rate of the system. In large systems, the total flow rate tends to be large compared with the flow rate through one terminal. Thus, when adjusting a terminal, the added flow rate may not be detected as accurately as in small systems where the adjustment of one terminal causes a more significant change in the total flow rate.

Inaccuracy in the estimation of fan system operation

It also has to be noted that the estimation of the fan flow rate involves certain inaccuracies. Thus, the estimation of the flow rate can cause error also in the tuning of the ventilation system. The accuracy, error sources, and other possible ways to estimate the flow rate of a fan system are extensively discussed in Tamminen et al. (2014) and Ahonen et al. (2010). It has to be noted that the fan performance is affected by the mounting of the fan, resulting differences in the actual fan curve and the fan curve given by the manufacturer. The mounting can be taken into account for as given in (ISO 2007). However, the ductwork can cause, for example, unexpected swirl of the air to the fan changing the fan performance much like an inlet vane guide. This will reduce the accuracy of the flow rate and pressure estimates made by the variable-speed drive and thus affect the accuracy of the TAB procedure.

Laboratory measurements

The ventilation tuning algorithm was tested with a setup shown in Fig. 7 and having the same layout of the setup as in Fig. 5. The setup consists of flow rate measurement devices in each of the branches and a static pressure difference measurement between the fan inlet and outlet. Each branch has a manually controllable terminal that can be used in the adjustment of the terminal flow rate.

Proof-of-concept measurements

The idea was first tested with the flow and pressure instrumentation of the laboratory setup. The actual measurement of the total flow rate and pressure was used in the algorithm to validate the presented TAB procedure. For this measurement, each terminal had a desired flow rate of 50 m3/h. This resulted in the knowledge of how the total flow rate should behave when each terminal is tuned. The total flow rate should be 50, 100, 150, and 200 m3/h after the tuning of the first, second, third, and fourth terminal, respectively. It was known that terminal 1 had the highest pressure loss at the set flow rate. Therefore, the flow rate of terminal 1 was set first, and the fan pressure reference was found from the pressure requirement of terminal 1.

The operation of the fan can be seen in Fig. 8. The tuning is started approximately at the time of 2 min. First, the flow rate of terminal 1 is set to the desired 50 m3/h while the other valves are closed. After the pressure and flow rate had settled, the pressure reference was set to approximately 460 Pa based on the measured pressure.

From 9 to 15 min, the second branch was set to its desired flow rate value by monitoring the total flow rate of the fan while the fan was operated with a constant pressure control. Moreover, the tuning of the third and fourth branches is started at 15 and 16 min, respectively. After one diffuser was set so that the desired flow rate was acquired through the respective terminal, that diffuser was no longer controlled. Hence, the diffuser setting of terminal 1 was constant from the beginning, the second branch valve was constant from 15 min onwards, and the branch 3 valve setting was constant from 16 min onwards.

The behavior of the flow rates in each terminal can be seen in Fig. 9. The flow rate of terminal 1 remains approximately constant from 5 min onwards, when the desired flow rate is approximately reached. Moreover, the flow rate remains unchanged even when the flow rates of the other terminals are tuned. This is also the case with terminals 2 and 3: the flow rate remains unaffected by the tuning of the remaining terminals. This suggests that the total flow rate of the ventilation fan can be used as a source of information in the TAB procedure. The addition to the total flow rate is directly the flow rate in the tuned branch when the fan is constant pressure controlled.

TAB concept based on measured fan pressure and estimated flow rate

Tamminen et al. (2014) present methods for the determination of the fan flow rate that either use or do not use sensors. Since the presented TAB procedure is based on the fan pressure and flow rate, these methods can be used for the execution of the TAB procedure. Eventually, the use of the sensorless flow rate estimation methods also leads to a sensorless TAB procedure. Here, the TAB procedure is tested using the pressure-based flow rate estimation method. This applies the fan differential pressure measurement between the fan outlet and the fan inlet, the rotational speed estimate, and the fan characteristic curves to estimate the fan flow rate as presented in (1)–(3) and Fig. 2.

The fan operation during the ventilation system adjustment is presented in Fig. 10. It can be seen that there is a small difference in the estimated and measured flow rate. This was to be expected, as mentioned in Tamminen et al. (2014), since the model-based estimation methods have error sources that lead to inaccuracies in the flow rate estimation.

It can be seen from the test measurement results of the individual branch flow rates in Fig. 11 that the procedure can be carried out with the pressure-based fan flow rate estimation. Using the estimated flow rate does not affect the TAB procedure. Moreover, even though there is error in the estimated flow rate, the accuracy of the adjustment of the individual branches is adequate (within 5 % (SFS 1988)) for ventilation system purposes.

Conclusion

Ventilation systems are many in number and various in location. The tuning of a ventilation system requires specific instrumentation and is a time-consuming task. In addition, if the ventilation system is tuned incorrectly, it results in excessive energy consumption and reduced comfort in the ventilated areas. Thus, in this paper, a testing, adjusting, and balancing procedure was suggested that does not require iterations or additional sensors. The proposed method will also save energy, as the ventilation system can be operated with the lowest possible pressure reference, when it has been tuned with the TAB procedure.

The TAB procedure was simulated and tested with a laboratory ventilation system. It was found that by using only the fan total flow rate as an indicator of the system flow rate and a constant fan pressure, the ventilation system can be tuned. The TAB procedure was also tested with an estimate of the fan flow rate, and it was verified that the accuracy of the flow rate estimation is adequate for ventilation system tuning purposes.

References

Ahonen, T., Tamminen, J., Ahola, J., Viholainen, J., Aranto, N., & Kestilä, J. (2010). Estimation of pump operational state with model-based methods. Energy Conversion and Management, 51(6), 1319–1325.

Ahonen, T., Tamminen, J., Niinimäki, L., Mar, C. A. A., & Niemelä, M. (2013). Estimation accuracy of a vector-controlled frequency converter used in the determination of the pump system operating state. Proceeding of the 15th European Conference on Power Electronics and Applications (EPE). September. 2013 Lille. France.

de Almeida, A. T., Fonseca, P., Falkner, H., & Bertoldi, P. (2003). Market transformation of energy-efficient motor technologies in the EU. Energy Policy, 31(6), 563–575.

Drbal, L. F., Boston, P. G., & Westra, K. L. (1995). Power plant engineering. Kluwer Academic Pub. ISBN 0-412-06401-4.

ISO. (2007). Industrial fans—performance testing using standardized airways International Organization for Standardizaation, ISO 5801.

Nash, J. N. (1996). Direct torque control, induction motor vector control without an encoder. IEEE Transactions on Industrial Applications., 33(2), 333–341.

Öhrström, E., & Skånberg, A. (2004). Sleep disturbances from road traffic and ventilation noise—laboratory and field experiment. Journal of Sound and Vibration, 2004(271), 279–296.

Pedranzini, F., Colombo, L. P. M., & Joppolo, C. M. (2013). A non-iterative method for testing, adjusting and balancing (TAB) air ducts systems: theory, practical procedure and validation. Energy and Building, 2013(65), 322–330.

Persson Waye, K., Rylander, R., Benton, S., & Leventhall, H. G. (1997). Effects on performance and work quality due to low frequency ventilation noise. Journal of Sound and Vibration, 205(4), 467–474.

SFS. (1987).Ventilating ducts. Strength and air tightness. Finnish Standards Association SFS 3542.

SFS. (1988). Air conditioning. Air distribution and diffusion. Laboratory aerodynamics testing and rating of terminal devices. Finnish Standards Association SFS 5428.

Sheet Metal & Air Conditioning Contractors’ National Association (SMACNA). (2002). HVAC systems testing, adjusting & balancing, 3rd edn.

Tamminen, J., Ahonen, T., Ahola, J., & Kestilä, J. (2011). Sensorless flow rate estimation in frequency-converter-driven fans. In Proc. of the 14th European Conference on Power Electronics and Applications (EPE). August/September. 2011. Birmingham, United Kingdom.

Tamminen, J., Viholainen, J., Ahonen, T., Ahola, J., Hammo, S., & Vakkilainen, R. (2014). Comparison of model-based flow rate estimation methods in frequency-converter-driven pumps and fans. Energy Efficiency, 2014(7), 493–505.

Wang, G., & Liu, M. (2005). Development of power-head based fan airflow station. Proceedings of International Conference for Enhanced Building Operations, October 11–13. 2005. Pittsburgh, Pennsylvania, USA.

Acknowledgments

This work was carried out in the Efficient Energy Use (EFEU) research program coordinated by CLEEN Ltd. with funding from the Finnish Funding Agency for Technology and Innovation, Tekes, and with partial funding from Academy of Finland through its Postdoctoral Researcher Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tamminen, J., Ahonen, T., Ahola, J. et al. Fan pressure-based testing, adjusting, and balancing of a ventilation system. Energy Efficiency 9, 425–433 (2016). https://doi.org/10.1007/s12053-015-9372-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-015-9372-0