Abstract

The lack of a system for benchmarking industrial plant energy efficiency represents a major obstacle to improving efficiency. While estimates are sometimes available for specific technologies, the efficiency of one plant versus another could only be captured by benchmarking the energy efficiency of the whole plant and not by looking at its components. This paper presents an approach used by ENERGY STAR to implement manufacturing plant energy benchmarking for the cement industry. Using plant-level data and statistical analysis, we control for factors that influence energy use that are not efficiency, per se. What remains is an estimate of the distribution of energy use that is not accounted for by these factors, i.e., intra-plant energy efficiency. By comparing two separate analyses conducted at different points in time, we can see how this distribution has changed. While aggregate data can be used to estimate an average rate of improvement in terms of total industry energy use and production, such an estimate would be misleading as it may give the impression that all plants have made the same improvements. The picture that emerges from our plant-level statistical analysis is more subtle; the most energy-intensive plants have closed or been completely replaced and poor performing plants have made efficiency gains, reducing the gap between themselves and the top performers, whom have changed only slightly. Our estimate is a 13 % change in total source energy, equivalent to an annual reduction of 5.4 billion/kg of energy-related carbon dioxide emissions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cement manufacturing is an energy-intensive process that requires significant thermal energy to decarbonize limestone, the primary raw material, into clinker, the primary component of cement. Grinding limestone and clinker also uses a substantial amount of electrical energy. For more details on the industry and the process see Worrell et al. (2001). The Portland Cement Association (PCA) reports that the average energy use per ton in the USA was 4.9 Gj/t of site energyFootnote 1 in 2008 and that site energy use per tonFootnote 2 has fallen 37.6 % in the 38 years since 1972 (Fig. 1). Barcelo and Kline (2012) report that thermal requirements have dropped 50 % as a result of the replacement of wet process kilns but that there appears to be a limit on the reduction of thermal energy to decarbonize limestone. Electricity requirements have fallen 20–25 % over a similar time periodFootnote 3.

Trends in energy use per ton in the USA (PCA 2009)

Given the importance of this industry in terms of its energy intensity and its contributions to greenhouse gas (GHG) emissions, an understanding of the “efficiency” of this cement manufacturing is useful to both the industry itself as well as policy makers. However, efficiency is a measure of relative performance; but relative to what? Defining energy efficiency requires a choice of a reference point against which to compare energy use. The difference between the observed level and potential level of performance has been called the “efficiency gap.” Jaffe and Stavins (1994) discuss a range of concepts from which to define “potential,” including economic, technical, social, and hypothetical. They also explore the various market and nonmarket reasons why there is an efficiency gap, regardless of how potential is defined. The first market failure they identify that leads to an efficiency gap is lack of information. It is the lack of information regarding economic potential for lower energy use that is the focus here. In other words, we are interested in measuring economic potential based on observed practice, which is by definition economically feasible. By providing this information, we hope to lower the barrier to more widespread adoption of economic potential for lower energy use.

While an information barrier is a common problem in many industries, benchmarking in the cement industry is not new. CAC (2009) is a study similar to this paper, in that it shows the range of performance but only for small number of individual plants in Canada. That study does not control for plant characteristics in the same manner as in this paper, but does have more detail on management practices and technology. They use a “bottom up” approach to estimate best practice at the technology level, then compare that prediction to the actual while this study is best characterized as “top down.” Matthes et al. (2008) explore how benchmarks are used as a possible allocation tool for emission trading in the EU. There are also a variety of studies that use Data Envelopment Analysis (DEA) to measure efficiency while accounting for undesirable outputs, specifically carbon dioxide (CO2) emissions. Mandal (2010) and Riccardi et al. (2012) are two good examples of this approach; however, they use Indian state-level data and country-level world data as the unit of observation, while this paper uses plant-level data. We do not use DEA since we wish to develop a tool that can be used in out of sample context and are bound by nondisclosure requirement regarding individual plant results.

The remainder of this paper is organized as follows. We first provide background on the U.S. Environmental Protection Agency (EPA) ENERGY STAR program and on the role of benchmarking within that program. We then describe the general approach used and the two applications to the cement industry, focusing on the most recent application. We then compare the results between these two benchmarks to provide insight to how the industry has changed from 1997 to 2008.

ENERGY STAR industrial program

The US industrial sector was responsible for 26 % of energy-related GHG emissions in 2009Footnote 4 and 29 % of all US GHG emissions. CO2 is predominant among those emissions, mainly due to energy consumption for manufacturing processes. CO2 comprises 80 % of manufacturing GHG emissions on a CO2-equivalent basis (EPA 2011). An important strategy for reducing CO2 emissions is to improve energy efficiency. In manufacturing, energy efficiency is usually understood as using less energy to produce the same amount of product. Reducing energy requirements can result in lower combustion-generated CO2 emissions; hence, energy efficiency is the most cost-effective strategy for reducing CO2 emissions since it lowers both emissions and fuel costs.

Recognizing the potential of energy efficiency to reduce CO2 emissions, the EPA launched ENERGY STAR for Industry to educate manufacturers on steps to improve their energy efficiency. EPA examined many of the market barriers to adoption of cost-effective practices and technologies and determined that an approach focused on information and energy management strategy offered a new opportunity to overcome market barriers and transform decision making.

EPA observed that the absence of information on whole-plant energy intensity and lack of a system for benchmarking industrial plant energy efficiency represented a major obstacle to improving US industrial energy efficiency. While energy efficiency standards and measures were sometimes available for specific technologies, there was no way to determine how well these technologies operated as a system when measured at the whole-plant level. Moreover, the actual operational efficiency of one plant versus another could only be captured by benchmarking the energy efficiency of the whole plant and not by looking at its components. Because of competitiveness issues among companies, the data necessary for benchmarking industrial energy efficiency were usually considered proprietary, and thus, very few industrial plant energy efficiency benchmarking systems had been developed.

By offering a tool that would enable a corporation or industrial plant to compare energy performance to the rest of its industry, EPA hoped to help manufacturers answer key questions:

-

How do I know whether my plants are energy-efficient?

-

How much can my plants improve?

-

Which plants should I target for efficiency improvements?

-

Which plants should I examine for best practices?

By helping companies answer these questions, EPA also believed it could arrive at a “best in class” type of energy efficiency benchmark that could help strengthen overall energy management practices within an industry. For more background on the evolution and current status of this approach, see Boyd et al. (2008) and Boyd (2012). This paper focuses primarily on recent developments of the ENERGY STAR industrial energy performance benchmarking system and the change in the cement industry observed when the benchmarking system was updated.

Identifying a key barrier to energy efficiency

An inability to determine whether a manufacturing facility is energy-efficient is common to most industries. Within an industry, some companies can determine the performance of similar plants in a single portfolio. However, few companies can determine how well their plants perform compared to similar plants outside their own portfolios across the USA. This missing piece of information limits a company's ability to set competitive goals for a plant's improvement and prevents understanding how well the best plants in that industry are performing. The cement industry is unique, in as much as the PCA collects data on energy, labor, and production for the benefit of its members. With support from the PCA and its member companies, ENERGY STAR is able to expand on PCA's own use of this data to provide a detailed analysis of energy performance. EPA set out to develop a new set of tools for the industrial marketplace that would enable industry to judge plant energy performance and set goals for improving energy efficiency. These tools, known as the ENERGY STAR Energy Performance Indicators (EPI), fulfill the need that many industries have for obtaining objective, quantitative information on whether a manufacturing facility is energy-efficient within its industry.

To develop an EPI for US cement plants, EPA engaged cement manufacturers with plants in the USA in a collaborative initiative called the ENERGY STAR Focus on Energy Efficiency in Cement Manufacturing (“the Focus”). The objectives for the Focus were to produce an “energy guide” for the industry (see Worrell and Galitsky 2004), develop the cement plant EPI, and foster discussions of energy management best practices.

EPA's first step was to engage a group from the industry to guide them in implementing corporate energy management programs within their companies. EPA approached senior executives to establish the business case for energy management and secure assignment of a responsible energy director for each corporation where one was lacking, toward enabling the companies to build or improve the necessary internal energy management functions and networks. ENERGY STAR energy management tools (such as simplified program evaluation checklists, energy management guidelines, and information on forming energy management teams) guided refinement of the energy management programs at each participating company.

The Focus gave particular attention to messaging and promoting early energy achievements, as these served as motivation for expanding energy management for senior executives and production-line employees alike. EPA guided the corporate energy managers in implementing the elements of their energy management systems, from setting goals to creating action plans and communicating success. EPA learned early on that there is great benefit to the industry when energy directors network to share best practices and discuss management strategies. Through the ENERGY STAR, EPA facilitated discussions among directors that led to greater dissemination of knowledge throughout the industry. All of these activities have contributed to facilitating the improvement in energy efficiency that is now being observed in the industry.

The first EPI for the cement manufacturing industry was released in 2006 (see Boyd 2006). Since then, companies participating in the Focus have benchmarked multiple sites. Many companies have also made the EPI an integral part of their corporate energy management programs. Development of the first cement EPI began more than a decade ago. With genuine effort over time, the companies improved the energy efficiency of their plants using the EPI to gauge energy performance. Over time, it became clear that a new version of the EPI, based on more recent data, was needed to continue to motivate energy improvement. EPA agreed to develop a new EPI based on new data and released it to the industry so further improvement could be achieved.

By updating the cement manufacturing EPI and comparing the two versions, we are able to quantify the improvement in the industry and better understand how the industry has strived to improve energy efficiency. The remainder of this paper describes the data and underlying statistical analysis used to update the ENERGY STAR EPI for cement plants, and how the parameter estimates of the original and updated models have changed over time (in particular, the treatment of clinker/cement production ratios and capacity utilization). Several measures are computed to illustrate how the distribution of energy efficiency has shifted over time.

Energy performance indicator

The EPI is a statistical model of plant-level energy use that enables comparison across sites with different levels and types of production-related activities that influence energy use. EPIs are developed for a specific type of manufacturing plant (in this case, cement). An EPI is designed to enable identification of the best in class energy performance for the industry. The EPI assigns a plant a specific energy performance score on a scale of 1 to 100. EPA defines average performance as the 50th percentile, while efficient performance is in the 75th percentile or higher. This section describes the history of the model development, the underlying data, and statistical analysis and estimates of the shift in the energy intensity distribution over time.

Tracking energy performance is a fundamental component of good energy management. Base lining and benchmarking are two complementary approaches for performance tracking. Base lining involves comparing plantFootnote 5 performance over time, relative to measured performance in a specific year. Benchmarking involves comparing performance relative to average or an established best practice level of performance against an appropriate peer group. Benchmarks can be based on a variety of information, including engineering estimates or observed performance. When the observed performance is used to create a benchmark, then data on actual performance for an appropriate group of plants are needed to support the benchmarking analysis. The data tie the benchmark to the corresponding year(s) of the data; setting the benchmark year or period if multiple years of data are used. If the industry improves over time, then the benchmark is not representative of current industry performance, requiring periodic updatesFootnote 6. To reach EPA's goal of enabling an industry to continuously self-improve through the use of information on plant energy performance, regular updates to the underlying data for the EPI are necessary.

ENERGY STAR for Industry has conducted analysis to support the development of the EPI, a plant-level statistical energy benchmark for various industrial sectors. The analysis is based on statistical modeling of plant-level, industry-wide data. The analysis identifies major factors such as input choice, product mix, location (weather), capacity, and utilization that influence energy use and create differences between plants that are not attributable to energy management practices and technology. The benchmark analysis “normalizes” for these factors to create a statistical “peer group” against which to compare the performance of any specific plant. This benchmarking tool is named the ENERGY STAR Energy Performance Indicator to distinguish it from the more general practice of “benchmarking” which may involve a different scope, e.g., process units, or use different methods, e.g., engineering estimates. In other words, the EPI embodies a specific (statistical, plant-level) benchmarking approach.

In 2006, after working in close cooperation with companies in the cement manufacturing industry for nearly 2 years, the U.S. EPA released the EPI for cement plants. This benchmarking tool allows companies to compare the actual performance of an individual plant to the range of performance in the industry in the benchmark year. Development of that tool is documented in Boyd (2006). The data for this original benchmark analysis are confidential, plant-level data from the 1997 Census of Manufacturing and 1998 Manufacturing Energy Consumption Survey, combined with 1997 data from PCA on waste-derived fuel use. At the time of the study, the most recent detailed data available from the US Census Bureau was for 1997. The PCA data were felt to provide more accurate measures of waste fuels than the Census dataFootnote 7. This data period (beginning in 1997) was useful in capturing the change in the industry during the period of time when EPA was engaging companies in building energy management programs from the late 1990s and early 2000s. With the passage of time and improvement in the industry, EPA thought it was time to update the data. This paper describes the data and analysis used to update the ENERGY STAR EPI for cement manufacturing plants. The paper also compares the results of the original 1997 EPI with the updated analysis. The comparison provides insights into how the industry has changed during the last decade. The first section describes the data and the analysis used for the update. The second section compares the two models to show how the energy performance of this industry has changed over time.

Data

The PCA U.S. and Canadian Labor-Energy Survey is a proprietary annual survey of the members of PCA detailing the US and Canadian cement industry's labor and energy usage. The survey focuses on energy consumption by fuel type (including waste fuels) to compile aggregated historical labor and energy efficiency trends as well as data by type of process, size of kiln, and age of plant. Individual plant detail is not presented in the publically available report from the PCA. In cooperation with Duke University and EPA ENERGY STAR, and with the support of the PCA member companies, the confidential, plant-level version of the PCA database was made available for this study. These data are provided to Duke University under a nondisclosure agreement to support the benchmark analysis and update the cement plant EPI as a service to their member companies. All analysis presented in this paper is screened to assure that no confidential information is revealed.

PCA data preparation and summary

All variables in the data were screened visually for “reasonableness” by examining plots of ratios such as labor–energy, energy–production, production–capacity (i.e., utilization), clinker–cement, etc. The PCA survey also includes plants from Canada; these were excluded from the analysis. Table 1 presents the summary statistics for major variables in this paperFootnote 8.

All data are on an annual basis for an individual plant i in year t = 2000–2008. Energy is defined as total source energy; the sum of all combustible forms of energy at higher heating value and electricity use converted at 11,988 kJ/kWh (11,362 British thermal units (Btu)/kWh), which accounts for US average power plant conversion, transmission, and distribution losses. Production-related data are reported in million tons, with energy reported in gigajoules. Capacity is the annual capability of all kilns (in million tons) in the plant for producing clinker. Clinker is the production amount of clinker. Cement is the annual production of cement. Kiln is the number of kilns located at the plant. Wet kiln ratio is the ratio of number of wet kilns to total number of kilns in a plant. Labor is the labor usage in thousand hours. Clinker-to-cement is the ratio of clinker production to cement production. Clinker-to-capacity is the ratio of clinker production to clinker-producing capacity. Energy usage per clinker measures annual source energy usage divided by the annual production of clinker. Average capacity is the annual capability of all kilns in the plant for producing clinker divided by the number of kilns. The final data set included data for approximately 96 plants over a 9-year period, for a total of 862 plant-year observationsFootnote 9.

Benchmark statistical modeling

The EPI uses a statistical model to control for aspects of production that systematically influence the energy use. The regression error term is treated as a measure of plant-specific efficiency. This approach is commonly used to measure the dispersion of total factor or labor productivity (see Syverson 2011 for an overview). However, in this case, we focus on energy intensity—the inverse of energy productivity. Several versions of the statistical model were estimated and provided to the representatives of cement companies for commentsFootnote 10. The final version of the model reviewed is the one presented here.

The cement EPI model is an ordinary least squares (OLS) regression of the natural log of total source energy, natural log of capacity, natural log of labor, and several operating ratios. This means that the error term, ε, the difference between actual and predicted average energy use, is assumed to be log-normal, i.e., the percentage differences between actual and average are normally distributedFootnote 11. The statistical estimate of the variance error term, σ 2, is used as a measure of the plant-level dispersion of energy efficiency.

where some of the independent variables are defined as:

- energy:

-

annual total source energy

- capacity:

-

annual capacity of kilns to produce clinker

- labor:

-

total annual person hours, including production and non-production workers

- wtr:

-

wet kiln ratio = number of wet kiln/number of total kiln

- cl_ce:

-

clinker-to-cement ratio = clinker/cement

- cl_ca:

-

clinker-to-capacity ratio = clinker/capacity

- cl_ca2:

-

squared clinker-to-capacity ratio = (clinker/capacity)2

- int(lnac_kl2):

-

interaction between log of average capacity and 2 kilns dummy = ln(capacity/kiln) × dummy_kiln2

- int(lnac_kl3):

-

interaction between log of average capacity and 3 and more kilns dummy = ln(capacity/kiln) × dummy_kiln3

The error term, ε, is initially assumed to be normally distributed with 0 mean and variance σ 2. We will return to this assumption below. The dependent variable is the natural logarithm of total energy usage for plant i in year t. The independent variables include the natural logarithm of producing clinker capacity, the natural logarithm of labor usage, wet kiln ratio, clinker-to-cement ratio, clinker-to-capacity ratio, squared clinker-to-capacity ratio, interaction between the logarithm of average capacity and 2 kilns dummy, and interaction between the logarithm of average capacity and 3 and more kilns dummy. The regression has 862 plant-year observations. Table 2 gives the results from the above regression. The new model captures the joint effect of producing clinker and finish grinding cement. Normally, clinker and cement would be produced in a relatively fixed ratio, but changes in the industry allow for additional additives in the final cement product. It is also possible for plants to ship clinker for grinding elsewhere or grind cement from clinker produced at another plant. Finally, since the data are annual, differences in inventories may cause the clinker/cement ratio to deviate from the “typical mix.” The negative coefficient implies that grinding more cement (with fixed clinker production) raises energy use as expected.

During testing of the proposed EPI, it was noticed that there were differences in performance between large and small capacity plants. In addition to the fact that there were economies of scale, i.e., large plants tended to have lower energy intensity. It was also observed that the range of performance, represented by the residuals from the above regression, was wider for small plants and narrower for large ones. In statistical terms, this means that the error variance, σ 2, is not constant, but a function of some other variable. When the error variance is not constant, the error term is called heteroscedastic. Usually, the concern over heteroscedastic error is that the standard errors of the coefficients are not correct. However, in this case, we use the estimate of the error variance to compute the range of performance in the industry, the ENERGY STAR Plant Energy Performance Score (EPS) as well as the quartiles used to determine eligibility for ENERGY STAR recognition (i.e., at or above the 75th percentile). A regression of the square of the residuals against average kiln capacity (total capacity/number of kilns) is illustrated in Fig. 1. It shows the declining relationship described above. For purposes of representing the error variance for plants of different sizes, the squared residuals were regressed against the inverse of the average capacity without an intercept, i.e., \( \sigma_i^2 = \beta { \frac{1}{{{\text{average}}\;{\text{capacity}}}}_i} \). The coefficient for β was 0.00346 and was significant at the 99 % confidence level. Using this relationship and the upper and lower deciles of average capacity in Table 1, the variance of performance is estimated to range from 0.017 (smallest plants) to 0.002 (largest plants).

Given the data for any plant i in year t, we can compute the difference between the actual energy use and the predicted average energy use from Eq. (1).

Since we have estimated the variance of the error term of Eq. (1) above as a function of capacity, we can compute the probability that the difference between actual energy use and predicted average energy use is no greater than this computed difference under the assumption that the error, ε, is normally distributed with 0 mean and heteroscedastic error variance \( \sigma_i^2 \)

This probability is the EPS and is the same as a percentile ranking of the energy efficiency of the plant.

The original EPI was based on Eq. (2). It is difficult to directly compare the coefficients of the two models, but one of the most important characteristics is the estimate of the error variance. The variance represents how much difference there is between the “best” and “worst” performing plants, after accounting for differences in capacity, production, etc.

The error variance in the new modelFootnote 12 is 0.0127, compared to 0.0264 in the old model. This implies that the range of performance in the industry has narrowed substantially. Another way to quantify the difference in the variance is by the interquartile range. The interquartile range is the spread between the 25th and 75th percentiles. The interquartile range is ~20 % for the original model and ~10 % for the new model. Either the range of performance across the industry has narrowed substantially or the new model accounts for important differences in energy use that the old model did not. One way to assess which is more likely is to fit the old model (Eq. (2)) to the new data. The results are shown in Table 3. We see that the error variance is slightly higher, 0.0155 compared to 0.0127, so that the differences between the new and old modeling approach applied to the new data do not result in as high an error variance (0.0264). We conclude that only a small part of the reduced variation is from the difference in the two modeling equations (0.0155 − 0.0127 = 0.0028), and that most of the reduced variation (0.0264 − 0.0155 = 0.0109) is due to changes in industry performance.

Another difference between the original EPI and the update relates to the type of cement produced. Specialty cements can take additional energy to produce. The CM data used for the 1997 EPI included information on the type of cement produced; specifically, ASTM 4 and masonry cements were found to have higher energy use. For purposes of the updated model, we assume that this relationship still holds, so we adjust the intercept term, β 0 in Eq. (1) to reflect the 1997 estimates of the impact of specialty cement production.

These two additional terms account for the share of these specialty cements relative to total production.

The following table presents summary statistics for energy usage per ton of clinker and average capacity in each quartile. Here, we set up our quartile as the following steps: first, the differences between actual and average energy use from new model regression; second, normalize the residual by heteroscedastic error variance; and last, calculate its reversed probability under normal distribution. Very high quartile is above 75 %, high quartile is between 50 and 75 %, median quartile is between 25 and 50 %, and low quartile is below 25 %.

Figure 2 shows the kernel densityFootnote 13 of residuals from different models in 2000, 2003, 2006, and 2008. The two different residuals are respectively generated from the new model (blue line) versus the previous model (red line). The residuals are a measure of efficiency relative to the predicted average energy use. The figure shows the distribution of actual plant energy use against each model's predicted average energy use, measured as a percentage change. For example, a result of −0.5 means that the actual energy use is ~50 % lower than the predicted average. We can see from the two distributions that in the original EPI (red line), the majority of plants are shown to have energy performance well above average. This tendency increases over time as the distribution of efficient plants moves more and more to the left. The updated model (blue line), representing the current data, shows that the industry performance has changed and illustrates the shift in the benchmark (Table 4).

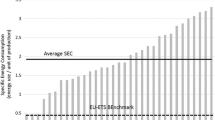

Another way to illustrate how the industry has changed is to compare the results from the original and updated EPI. The EPI shows the predicted range of performance, across the entire industry, for any given plant. Figure 3 compares the original 1997 (red) against the updated model (blue). The results show the percentile distributions per gigajoules per ton of clinker for a plant with two kilns, total capacity of 815,750 tpy clinker, at 96 % utilization, and producing 900,000 t of ASTM 1 cement per year. For example, the figure shows that the average (50th percentile) plant in the original EPI was 7.3 Gj/t, but the updated EPI is 6.0 Gj/t; 0.7 Gj/t lower. One interesting characteristic of the update is that it illustrates that the best are not getting better, but the long tail (representing the inefficient plants) is smaller and the “middle of the pack” has also improved. This figure is an example taken from just one “typical” plant (Fig. 4).

Figure 3 shows the industry distribution for a typical plant. Each plant in the database would have its own “curve” and its own “place” on each curve, represented by the EPS or ranking. If we compute the EPS using the old model for each plant, then compute the energy use per ton of clinker that it would take to maintain the same level of performance using the new model, we have a plant-specific shift. For example, suppose plant X would score a “40” under the old EPI at approximately 7.6 Gj/t. Under the new EPI a 40 would require 6.1 Gj/t, a 1.5 Gj/t reduction. If we compute the shift in the benchmark for every plant in the database and multiply this plant-specific change in energy intensity by the level of clinker production for each plant operating in the industry in 2008 and total over all plants, this is a reduction of more than 68 million Gj in energy use. This is relative to an average annual total source energy consumption of 499 million Gj per year; an almost 13 % reduction. This represents an annual reduction of 5.4 billion kg of energy-related CO2 emissions.

Worrell and Biermans (2005) pose the question for the steel industry whether the changes in aggregate energy intensity if from stock turnover or retrofit. They find that both are contributing factors. It is not possible to do a formal decomposition of the sources of the change between the two distributions discussed here, since the first estimate was based on confidential Census data and the second on confidential trade association data and so cannot be directly compared. It is possible to examine other evidence of sources of the change and compare them to our inferences. Data from PCA (2009) provide estimates of the energy use per ton for all plants in the USA broken down by those using wet versus dry process. These data show that from 1997 to 2008, the average intensity declined 11.4 % in aggregate and 8.9 % for dry process plants. The decline for wet process plants as a group is negligible (0.2 %). The difference in the aggregate trend and that for dry process plants (2.5 %) must be attributable to a decline in the share of production coming from the more energy-intensive wet process plants (7.4 versus 5.1 Gj/t site energy basis). That these wet process kilns have declined is corroborated by the fact that the share of wet process kilns in Boyd (2006) was reported as 35 %, and in the current analysis, it was 23 %, representing a reduction of 32 kilns, which is equal to the reduction in the total number of kilns operating in the USA. The total number of plants in the industry has fallen as well, from 105 to 96. The decline in the role of wet kilns is certainly consistent with the leftward shift in the long tail of the intensity distribution, yet we see evidence that dry process kilns have improved as well. This would be consistent with the shift in the “middle” of our estimated distribution. Finally, we see little improvement in the “top” of the distribution, consistent with the comments of Barcelo and Kline (2012) that there appears to be a limit on the reduction of thermal energy to decarbonize limestone.

Summary

EPA assists the US cement industry to improve its energy efficiency with energy management guidance and by providing a plant benchmarking tool that enables a corporation to compare the energy performance of its plants across its industry. This approach has demonstrated results. Through the updated cement plant EPI, we are able to estimate the improvement in the industry's performance between 1997 and 2008. While aggregate data can be used to estimate an average rate of improvement in terms of total industry energy use and production, such an estimate would be misleading as it may give the impression that all plants have made the same steady improvements. The picture that emerges from our plant-level statistical analysis is somewhat different and more subtle; the most energy-intensive plants have closed or been completely replaced and poorer performing plants from the late 1990s have made efficiency gains, reducing the gap between themselves and the top performers, whom have changed only slightly. The results from this study also focus on energy efficiency and controls for other structural changes in the industry, e.g., increases in average plant size, which tend to lower energy use. Our estimate of the overall energy efficiency improvement in the 96 plants in our database represents a 13 % change in total source energy, equivalent to an annual reduction of 5.4 billion kg of energy-related carbon dioxide emissions.

Updating the ENERGY STAR cement plant, EPI will enable US cement plants to continue to strive for better energy performance in coming years. The whole-plant benchmarking approach employed by ENERGY STAR, as is demonstrated by the experience of the cement industry, is useful for aiding an industry to shift its energy performance through informed goal setting. EPI tools exist or are under development for more than 20 industries. EPA will continue to work with industries to help them improve energy performance through this unique approach to environmental protection.

Notes

Throughout this paper, we differentiate between energy accounting on a site or source basis. Site energy use converts electricity 3,600 kJ/kWh, while source energy accounts for conversion and transmission losses and are region specific. Many published sources provide site energy only. For our analysis, we will focus on source energy estimates.

PCA uses an equivalent energy ton defined as 92 % clinker + 8 % finished cement production.

The underlying data presented in PCA (2009) were provided to the author directly by the Economic Research Department of the Portland Cement Association.

The latest data available at the time of this paper.

Throughout this paper, we consider the relevant entity to be the entire plant. Performance tracking can be more or less aggregate, i.e., at the firm or at the process unit level.

In addition to the updates, EPIs are being developed each year for additional industries.

Comparison of Census and PCA data for other energy, e.g., electric, natural gas, etc., found close agreement between the two sources.

Note that energy and production units are converted to SI units for presentation purposes, but the analysis presented below was done on a Btu and short ton basis. The coefficients for the statistical analysis do not reflect this conversion.

A small number of data points were dropped because of missing values and an erroneous plant result.

Their comments led to revisions in the way capacity and utilization were represented, corrections in the labor measure, and identification of outliers.

The ENERGY STAR EPI approach also uses Stochastic Frontier Analysis (SFA) (e.g., in Boyd 2010). Statistical testing found that the error term in the cement industry is distributed approximately log-normal. We do not report the SFA results here, but focus on the OLS.

For purposes of comparison between the new and old model, we focus on the average estimated error variance, rather than the more complex heteroscedastic form.

A kernel density is a statistical estimate that is best thought of as a smoothed histogram.

References

Barcelo, L., & Kline, J. (2012). The cement industry roadmap to reduce carbon emission. Carbon Management Technology Conference. Orlando FL, CMTC.org.

Boyd, G. A. (2006). Development of a performance-based industrial energy efficiency indicator for cement manufacturing plants. Argonne: Argonne National Laboratory.

Boyd, G. A. (2010). Assessing improvement in the energy efficiency of U.S. auto assembly plants. Nicholas Institute Environmental Economics Working Paper Series: EE 10-01.

Boyd, G. (2012). A statistical approach to plant-level energy benchmarks and baselines: The Energy Star Manufacturing-Plant Energy Performance Indicator. Carbon Management Technology Conference. Orlando, FL, USA.

Boyd, G., Dutrow, E., et al. (2008). The evolution of the ENERGY STAR® energy performance indicator for benchmarking industrial plant manufacturing energy use. Journal of Cleaner Production, 16(6), 709–715.

CAC. (2009). Canadian cement industry energy benchmarking (p. 48). Ottawa: Cement Association of Canada.

Jaffe, A. B., & Stavins, R. N. (1994). The energy-efficiency gap. What does it mean? Energy Policy, 22(10), 804–810.

Mandal, S. K. (2010). Do undesirable output and environmental regulation matter in energy efficiency analysis? Evidence from Indian cement industry. Energy Policy, 38(10), 6076–6083.

Matthes, F. C., Repenning, J., et al. (2008). Pilot on benchmarking in the EU ETS. Berlin: Öko-Institut/Ecofys.

PCA. (2009). Report on sustainable manufacturing. Skokie: Portand Cement Association.

Riccardi, R., Oggioni, G., et al. (2012). Efficiency analysis of world cement industry in presence of undesirable output: application of data envelopment analysis and directional distance function. Energy Policy, 44, 140–152.

Syverson, C. (2011). What determines productivity? Journal of Economic Literature, 49(2), 326–365.

U. S. EPA (2011). Inventory of U.S. greenhouse gas emissions and sinks: 1990–2009.

Worrell, E., & Biermans, G. (2005). Move over! Stock turnover, retrofit and industrial energy efficiency. Energy Policy, 33(7), 949–962.

Worrell, E., & Galitsky, C. (2004). Energy efficiency improvement opportunities for cement making: an ENERGY STAR guide for energy and plant managers. Environmental Energy Technologies Division. Berkeley Ernest Orlando Lawrence Berkeley National Laboratory.

Worrell, E., Price, L., et al. (2001). Carbon dioxide emissions from the global cement industry. Annual Review of Energy and the Environment, 26, 303–329.

Acknowledgments

This paper was prepared for the U.S. Environmental Protection Agency, Office of Air and Radiation, Office of Atmospheric Programs, Climate Protection Partnership Division. We would like to thank the Portland Cement Association and particularly David Czechowski, which provided the plant-level data from their annual Labor and Energy Survey, under a nondisclosure agreement with Duke University. The research results have been screened to insure that no confidential data are revealed. We would like to thank all the energy managers from companies participating in the ENERGY STAR Cement Industry Focus for their willingness to test and provide comments on earlier versions of the analysis. This process was invaluable to producing a useful tool. The paper has benefited from helpful comments from Josh Smith (ICF International), Walt Tunnessen (U.S. EPA), Elizabeth Dutrow (U.S. EPA), and one anonymous referee. Any errors or omissions remain the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boyd, G., Zhang, G. Measuring improvement in energy efficiency of the US cement industry with the ENERGY STAR Energy Performance Indicator. Energy Efficiency 6, 105–116 (2013). https://doi.org/10.1007/s12053-012-9160-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-012-9160-z