Abstract

TiO2-supported bimetallic nanocatalysts were prepared and reduced at two different temperatures, 375°C and 575°C for selective hydrogenation of citral to corresponding unsaturated alcohols (geraniol (GOL) and nerol (NOL)). The nanocatalysts were characterized by difference techniques of Fourier transform infrared spectroscopy (FT-IR), Brunauer, Emmett and Teller (BET) surface area measurement, scanning electron microscopy (SEM), Energy Dispersive X-ray Analysis (EDAX), transmission electron microscopy (TEM), X-ray diffraction (XRD) and X-ray photoelectron spectroscopy (XPS). The prepared nanocatalysts are uniformly dispersed with an average particle size of 50–100 nm and zero valence metallic state. Catalysts reduced at higher temperature lead to an increase in selectivity toward unsaturated alcohols (GOL and NOL). The Pt–Ru/TiO2 shows higher activity compared to Pt–Pd/TiO2 and Pt–Au/TiO2 nanocatalysts. In addition, a second metal (Ru) also leads to an increase in GOL and NOL selectivity during citral hydrogenation. Partially generated oxidized second metal species due to the difference in electronegativity, strongly binds the C=O group and also paves the way for selective activation of C=O bond.

The Pt-Ru/TiO2 nanocatalyst reduced at higher temperature leads to an increase in selectivity toward unsaturated alcohols (GOL and NOL). The addition of second metal (Ru) generates partial positive charge on Ru centre due to the difference in electronegativity, which strongly binds C=O group and paves way for the selective activation of the C=O bond.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Citral (3,7-dimethyl-2,6-octadienal) is an important monoterpenoid aldehyde with pairs of conjugated C=O and C=C bonds in addition to an isolated C=C bond. Compared with other α,β-unsaturated aldehydes, citral has an exclusive structure that renders hydrogenation reactions complex (as shown in scheme 1). Liquid phase selective hydrogenation of α, β-unsaturated aldehydes to their corresponding alcohols is a process of major importance for the chemical industries, especially in the fine chemical industries,[1–3] such as for the production of pharmaceuticals, detergents, cosmetics, flavours and fragrances.[4, 5] The reaction can lead to a variety of products, the C=C double bond is hydrogenated to give a saturated aldehyde or the C=O double bond is involved, yielding an unsaturated alcohol and hydrogenation of both can occur resulting in a saturated alcohol and also formation of cyclic products. Due to the fact that the C=C bond presents a lower binding energy than the C=O bond, the formation of saturated aldehydes is thermodynamically favoured, decreasing the selectivity to the unsaturated alcohol.[6–12] In the present study, selective hydrogenation of citral was studied, as this molecule and its unsaturated alcohols are of considerable interest in the perfumery industry.[13, 14]

Hydrogenation reactions are generally catalysed by transition metals of group VIII of the periodic table. However, the selectivity of these metals with relation to hydrogenation of C=O bond is specific for each metal in the order Ir > Pt > Ru > Rh.[4] Extensive literature survey is available on the selective hydrogenation of α, β-unsaturated aldehydes catalysed by different noble metals supported catalysts.[15–17] In addition, catalytic hydrogenation of α, β-unsaturated aldehydes is mostly based on supported-metal platinum-based bimetallic catalysts.[18–30] Selectivity towards unsaturated alcohols (geraniol (GOL) and nerol (NOL)) could also be increased by metal deposition on supports such as SiO2, TiO2, etc. Hydrogenation of the C=O bond can be promoted by the presence of second metals. Noble metal supported by metal oxides during catalytic activity and selectivity of hydrogenation reaction with reduction at high temperature has attracted much attention compared to reduction at lower temperature.

In this study, we report the preparation of TiO2-supported bimetallic nanocatalyst, by impregnation method, being reduced at two different temperatures, 375°C and 575°C and characterized by Fourier transform infrared spectroscopy (FT-IR), Brunauer, Emmett and Teller (BET) surface area, X-ray diffraction (XRD), scanning electron microscopy (SEM) with Energy Dispersive X-ray Analysis (EDAX), transmission electron microscopy (TEM) and X-ray photoelectron spectroscopy (XPS) techniques and their catalytic activity for selective hydrogenation of citral towards unsaturated alcohols (GOL and NOL).

2 Experimental

2.1 Catalyst preparation

Solutions of metal precursors H2PtCl6.6H2O (0.1992 g in 10 mL water) and PdCl2 (0.1250 g in 10 mL water) were mixed together by stirring. Dispersion of TiO2 (9.85 g) in 50 mL water was added to this solution with vigorous stirring and the resulting suspension was aged at 80°C for 24 h with stirring. An aqueous solution of NaBH4 (0.4116 g in 10 mL water) was added dropwise into this suspension with vigorous stirring. The NaBH4 aqueous solution was prepared in an ice bath, and molar ratio of NaBH4: (Pt and Pd) was 10. The prepared nanocatalysts denoted were as Pt–Pd/TiO2375 and Pt–Pd/TiO2575. The same produce is used for Pt–Ru and Pt–Au nanocatalysts.

2.2 BET surface area and X-ray diffraction

The BET surface area measurements were made on a Micromeritics Gemini 2360 instrument by N2 adsorption at liquid nitrogen temperature. Prior to measurements, samples were oven dried at 393 K for 12 h and flushed with argon gas for 2 h. XRD patterns were recorded on a Siemens D-5000 diffractometer, using Ni-filtered Cu K α (0.15418 nm) radiation source range of 20–90° was employed to determine the phase of the modified TiO2 powders. Crystalline phases were identified with the help of ASTM Powder Data Files.

2.3 Scanning electron microscopy and transmission electron microscopy

The SEM analyses were carried out with a Jeol JSM 5410 microscope, operating with an accelerating voltage of 15 kV. Micrographs were taken after coating by gold sputtering. Elemental analysis was carried out on a Kevex, Sigma KS3 Energy Dispersive X-ray Analysis (EDAX) instrument operating at a detector resolution of 136 eV. TEM studies were carried out on a JEOL-JEM 100 electron microscope. Samples for direct examination were prepared by suspending the powder in ethanol, and a drop of the suspension was allowed to dry on a copper grid coated with a carbon film. Extractive replica was performed by ultrasonically dispersing the catalyst powder and depositing a drop of the suspension on freshly cleaved mica. After drying, the dispersed powder was covered with a carbon film. The mica was then plunged into a solution containing a mixture of water, acetone and hydrofluoric acid. The acid concentration was chosen in order to dissolve the support without dissolving the metal particles. They remained stuck to the carbon film, which was collected on a copper grid. Area distribution of particles was determined by counting a large number of particles on the TEM micrographs and by plotting \(n_i d_i^2 \) as a function of d i (n i is the number of particles within different intervals with a given average diameter d i ). Mean surface diameter of the particles is then given by \(d={\sum {n_i d_i^3 } }/{\sum {n_i d_i^2 } }\). High-resolution TEM (HRTEM) images were obtained by employing a JEOL-3010 device with 300 kV accelerating voltage.

2.4 X-ray photoelectron spectroscopy

XPS was used to analyse the atomic surface concentration on each catalyst. The spectra were recorded on a Perkin-Elmer model 5300 X-ray photoelectron spectrometer using Mg Kα-1253.6 eV as a radiation source at 300 W.

All binding energies were referenced to the C 1s peak at 284.6 eV, which is invariably present on the film surface. The spectra were fitted by XPSPEAK with a linear background and to 80% Gaussian/20% Lorentzian peak shape. The structure of anatase TiO2 provided in the article was constructed by the Ca.R.Ine version 3.1 crystallography program package.

2.5 Activity test

Citral (mixture of E and Z forms, Merck, 99%) and isopropanol (Fluka, 99.5%) were used as received. Liquid phase citral hydrogenation experiments were performed in a stirred semi-batch reactor (model 4574, Parr Instrument Co.). Before the reaction, the catalysts were reduced in situ under hydrogen (gas purity, 99.995%) flow (80–100 mL/min) for 2 h under 10 MPa at 250°C. Then, the reactor was cooled to reaction temperature. Reactant mixture (200 mL of 0.1 M citral in isopropanaol) was injected into the bubbling unit to remove the dissolved oxygen before it entered the reactor and reach the catalysts. Citral hydrogenation reaction was performed at 90°C, 10 MPa and at a stirring speed of 750 rpm. Preliminary runs carried out at different stirring rates, loading and catalyst grain size demonstrated the absence of internal and external transfer limitations under the selected conditions. Liquid samples were periodically withdrawn through sample tube extending inside the reactor and analysed in a HP 4890 gas chromatography (GC) furnished with an HP 5 semi-capillary column of 15 M and 0.53 mm ID. The GC analysis was performed using a flame ionization detector, using helium gas as carrier and the column was kept at a constant temperature, i.e., at 393 K. Under these analytical conditions, the product peaks are identified by the use of mass spectroscopy-gas chromatography (GCMS QP2010 Plus). From the results obtained in these analyses, information such as catalytic activity, selectivity of the reaction and conversion could be derived.

3 Results and discussion

3.1 Physicochemical characterization

3.1a Surface area measurement: Figure 1 shows N2 adsorption–desorption isotherm of Pt–Pd/TiO2, Pt–Ru/TiO2 and Pt–Au/TiO2 nanocatalysts. According to IUPAC nomenclature, all the isotherms are type IV isotherms.[31] Sharp adsorption and desorption steps followed by a plateau at high P/P o, which is characteristic of capillary condensation and evaporation in the pores, are clearly observed.[32] A hysteresis loop similar to H1-type is observed for the TiO2 support. The hysteresis loop changes with incorporation of noble metals. Then, evolution from H1 to H2-type is observed (figure 1). Absence of any sharp rise in nitrogen uptake as P/P o nears 1 also tends to conclude on a homogeneous pore size repartition, without large pores in the support.[33, 34]

In addition, pore size (D p) and pore volume (V p) (table 1) decrease with increase in reduction temperature of the prepared nanocatalysts. Further, the nanocatalyst exhibits decrease in surface area at higher temperature reduction than at lower temperature. The decrease in pore volume is more marked as shown in table 1.

3.1b FTIR spectroscopy: Infrared spectral study of the prepared bimetallic Pt–Pd/TiO2, Pt–Ru/TiO2 and Pt–Au/TiO2 nanocatalysts reduced at 375 and 575°C are given in figures 2 and 3 respectively, and the data are shown in table 2. Absorption band at 480 cm−1 is due to Ti–O–Ti bending vibration.[35] The band observed at 750 cm−1 is attributed to the Ti–O–Ti symmetric stretching vibration, and the band at 985 cm−1 corresponds to Ti–OH bending vibration.[36–38] The band at 1114 cm−1 is due to Ti–O stretching vibration.[39, 40] The presence of band at 1633 cm−1 corresponding to OH shows that a large number of OH groups (H2O) exists on the surface of TiO2, which plays a key role in bonding metal ions from the impregnating solution.[41] It is observed that narrow and more intense peaks at 1074, 964, and 816 cm−1 in Pt–Pd/TiO2 are due to stretching vibrations of Ti–O–Ti bond respectively. Similar features were observed for the other two bimetallic catalysts. Catalysts reduced at higher temperature show less intense OH bands compared to catalysts reduced at lower temperature.

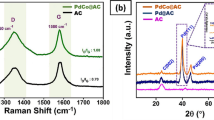

3.1c XRD analysis: Powder XRD patterns of Pt–Pd/TiO2375 and Pt–Pd/TiO2575 nanocatalysts are given in figure 4a, which exhibit diffraction peaks at 25.5°, 37.7° and 48.2° that are consistent with corresponding planes of (101), (004) and (200) characteristic of anatase TiO2 (JCPDS 84–1286).[42] They also exhibit other peaks at 39.9°, 46.3° and 67.45° with corresponding planes of (111), (200) and (220) characteristic of Pt (JCPDS 04-802); and peaks at 40.1°, 46.7° and 68.1° with corresponding planes of (111), (200) and (220) of Pd (JCPDS 05-0681) face-centred phase.

Powder XRD patterns of Pt–Ru/TiO2375 and Pt–Ru/TiO2575 nanocatalysts are given in figure 4b. In figure 4c, the diffraction peaks at 38.3°, 42.2°,44.0°, 58.3°, 69.5°, and 78.4° corresponding to (100), (002), (101), (102), (110) planes is due to (JCPDS 06-0663) hexagonal Ru. Furthermore, the diffraction peaks correspond to Pt and TiO2.

Figure 4c shows powder XRD patterns of Pt–Au/TiO2375 and Pt–Au/TiO2575 nanocatalysts. Diffraction peaks 38.1°, 44.4°, 64.3°, and 77.5° corresponding to (111), (200), (220), (311) and (112) planes are due to fcc phase (JCPDS 06-0663) of Au. Further, diffraction peaks corresponding Pt and TiO2 are also seen in figure 4c.

3.1d Scanning electron microscopy: Morphology of the synthesized nanocatalysts was investigated using SEM analysis. SEM images and the corresponding EDAX spectra of Pt–Ru/TiO2 reduced at 575°C is shown in figure 5. Micrographs show that the particles were spherical irregular particles with average diameter in nm range. For the nanocatalysts, reduced at higher temperature, relatively larger particles are observed due to agglomeration during sintering process. The EDAX spectrum shows the presence of Pt, and Ru along with Ti and O.

3.1e Transmission electron microscopy: The prepared nanocatalysts were subjected to TEM analysis to study their morphology. The TEM images and SAED pattern of the Pt–Ru/TiO2, nanocatalysts, thermally reduced at 375° and 575°C are given in figures 6 and 7, respectively. Particles in the samples were spherical and well-dispersed and the size of the particles was in the range of 50–100 nm. It is observed that catalysts reduced at 375°C have smaller particle size than catalysts reduced at 575°C. The SAED patterns show that nanocatalysts are crystalline in nature. Reduction at higher temperatures leads to significant increase in size and agglomeration of nanoparticles at the exterior surface compared to the catalysts reduced at lower temperature. High magnification HRTEM images reveal the presence of orderly crystallites in the particles.

3.1f XPS of bimetallic supported on TiO 2 nanocatalysts: XPS analysis was conducted to determine oxidation state of the elements. Figure 8 show the survey spectra of Pt–Ru/TiO2575 which exhibit peaks of Pt, Ru and along with Ti and O. Figure 9 shows the core level spectra of Pt 4f and Ru 3d of Pt–Ru/TiO2375 nanocatalyst. Core level spectrum of Pt 4f shows (figure 9a) two sets of peaks with binding energies of Pt 4f7/2 at 70.24 eV and 4f5/2 at 73.58 eV, which suggest that Pt is present in zerovalent state; and same peaks are observed in higher temperature reduction (Pt 4f7/2 at 70.27 eV and 4f5/2 at 73.65 eV), which suggest the existence of Pt0 species on the surface. Core level spectrum of Ru 3d spectrum has been obscured (figure 9b) by the C 1s (286.6 eV) spectrum, but the deconvoluted spectrum shows a doublet with peak binding energies of 282.29 eV (3d5/2) and 286.286.1 eV (3d3/2). It is difficult to resolve the small Ru peak from the large peak of C 1s. The Ru3d spectra revealed the presence of only Ru0 at 3d5/2 at 282.32 eV48.[43–45] Regarding the Ti species, curve fitting indicated the presence of the dominant Ti4 + peak.

3.2 Nanocatalyst testing

3.2a Effect of second metal addition for higher selectivity of unsaturated alcohols: Figure 10 shows unsaturated alcohol conversion and selectivity as a function of Pt–Pd/TiO2, Pt–Ru/TiO2 and Pt–Au/TiO2 catalysts, thermally reduced at 375°C and 575°C. Catalysts reduced at low temperature (375°C) show overall conversion and selectivity of GOL and NOL 48%, 72% and 45%, and 45%, 70%, and 40% for bimetallic catalysts Pt–Pd/TiO2, Pt–Ru/TiO2 and Pt–Au/TiO2, respectively (shown in figure 10a). Catalysts thermally reduced at high temperature (575°C) exhibit overall conversion and selectivity of GOL and NOL 55%, 78% and 53% and 52%, 75% and 48% for bimetallic Pt–Pd/TiO2, Pt–Ru/TiO2 and Pt–Au/TiO2 catalysts, respectively (shown in figure 10b). Catalysts reduced at 575°C show higher activities than their counterparts reduced at 375°C. Bimetallic catalysts relatively show higher activity than monometallic catalysts, which may be due to the cooperative activity of the two metals.[46–51]

3.2b Effects of ruthenium promoter on Pt catalysts: Among the prepared TiO2-supported bimetallic (Pt–Pd/TiO2 and Pt–Ru/TiO2 and Pt–Au/TiO2) nanocatalysts, Pt–Ru/TiO2 shows highest overall conversion and selectivity towards GOL and NOL. The XPS analysis shows presence of Pt0 and Ru0. In the Pt–Ru/TiO2 nanocatalyst, the contact between Pt and Ru atoms favours partial electronic transfer from Ru0 towards Pt0 due to difference in electronegativity. In this way, there is + δ charge density in the Ru atoms and a − δ charge density in Pt atoms (scheme 2). Although, Ru, Pd and Au have the same electronegativity; Ru is a hard acid, whereas Pd and Au are soft acids. Considering a molecule of α, β-unsaturated aldehyde, it is accepted that the C=O group could be adsorbed on to the Ru metal surface[49] due to partial negative charge (− δ) on the O atom, which favours hydrogenation of the C=O group resulting in the formation of unsaturated alcohols. Mode of adsorption of citral over Pt–Ru/TiO2 catalyst is shown in the scheme 2.

4 Conclusion

Characterization techniques showed that TiO2-supported platinum-based bimetallic nanocatalysts have porous nature with high surface area and pore volume. Catalyst reduction at higher temperature leads to an increase in selectivity towards unsaturated alcohols (GOL and NOL) for Pt–Ru/TiO2 compared to Pt–Pd/TiO2 and Pt–Au/TiO2 nanocatalysts. In addition, a second metal (Ru) also leads to an increase in GOL and NOL selectivity during citral hydrogenation. The generated partially oxidized second metal species due to difference in electronegativity, strongly binds the C=O group and also paves the way for selective activation of the C=O bond.

References

Claus P 1998 Top. Catal. 5 51

Gallezot P and Richard D 1998 Catal. Rev. Sci. Eng. 40 81

Smith G V and Nothei F 1999 Heterogenous catalysis in organic chemistry (San Diego: Academic Press)

Ponec V 1997 Appl. Catal. A 149 27

Coq B, Figueras F, Geneste P, Moreau C, Moreau P and Warawdekar M 1993 J. Mol. Catal. 78 211

Reyes P, Rojas H, Pecchi G and Fierro J L G 2002 J. Mol. Catal. A179 293

Mukherjee S and Albert Vannice M 2006 J. Catal. 243 108

Alvarez-Rodrıguez J, Guerrero-Ruiz A, Rodrıguez-Ramos I and Arcoya-Martın A 2006 Micropor. Mesopor. Mater. 97 122

Vilella I M, Borbath I, Margitfalv J L, Lazar K, Miguel de O A and Scelza S R 2007 Appl. Catal. A 326 37

Neri G, Milone C, Donato A, Mercadante L and Visco A M 1994 J. Chem. Tech. Biotechnol. 60 83

Serrano-Ruiz J C, Sepulveda-Escribano A, Rodrıguez-Reinoso F and Duprez D 2007 J. Mol. Catal. A268 227

Chiang S, Yang C, Chen Y and Liaw B 2007 Appl. Catal. A326 180

Manikandan D, Divakar D and Sivakumar T 2008 Catal. Lett. 123 107

Galvagno S, Milone C, Neri G, Donato A and Pietropaolo R 1993 Stud. Surf. Sci. Catal. 78 163

Centomo P, Zecca M, Lora S, Vitulli G, Caporusso A M, Tropeano M L, Milone C, Galvagno S and Corain B 2005 J. Catal. 229 283

Neri G, Mercadante L, Donato A, Visco A M and Galvagno S 1994 Catal. Lett. 29 379

Burgener M, Furrer R, Mallat T and Baiker A 2004 Appl. Catal. A268 1

Arvela P M, Tiainen L P, Neyestanaki A K, Sjöholm R, Rantakylä T K, Laine E, Salmi T and Murzin D Y 2002 Appl. Catal. A237 181

Consonni M, Jokic D, Murzin D Y and Touroude R 1999 J. Catal. 188 165

Singh U K and Vannice M A 2001 J. Catal. 199 73

Malathi R and Viswanath R P 2001 Appl. Catal. A208 323

Ammari F, Lamotte J and Touroude R 2004 J. Catal. 221 32

Abid M, Ehret G and Touroude R 2001 Appl. Catal. A217 219

Baeza B B, Rodríguez I and Ruiz A G 2001 Appl. Catal. A205 227

Aumo J, Lilja J, Arvela P M, Salmi T, Sundell M, Vainio H and Murzin D Y 2202 Catal. Lett. 84 219

Silva A M, Santos O A A, Mendes M J, Jordao E and Fraga M A 2003 Appl. Catal. A241 155

Li Y, Li Z-G and Zhou R-X 2008 J. Mol. Catal. A279 140

Reyes P, Aguirre M C, Fierro J L G, Santori G and Ferretti O 2002 J. Mol. Catal. A184 431

Vilella I M J, de Miguel S R and Scelza O A 2008 J. Mol. Catal. A284 161

Sordelli L, Psaro R, Vlaic G, Cepparo A, Recchia S, Dossi C, Fusi A and Zanoni R 1999 J. Catal. 182 186

Gregg S J and Sing K S 1982 Adsorption surface area and porosity, 2nd ed. (New York: Academic Press)

Margolese D, Melero J A, Christiansen S C, Chmelka B F and Stucky G D 2000 Chem. Mater. 12 2448

Sen T, Tiddy G J T, Casci J L and Anderson M W 2003 Chem. Commun. 9 2182

Zhu H, Jones D J, Zajac J, Dutartre R, Rhomari M and Roziere J 2002 Chem. Mater. 14 4886

Sabataityté J, Oja I, Lenzmann F, Volobujeva O and Krunks M 2006 C.R. Chimie 9 708

Kim H W, Lee M C, Yoo J C and Hahurst D T 2000 Micropor. Mesopor. Mater. 41 76

Mihailova B, Valtchev V, Mintova S and Konstantinov L 1996 Zeolites 16 22

Yu M, Wang Z, Fu J, Wang S, Zhang H J and Han Y C 2002 Chem. Mater. 14 2224

Yu M, Lin J and Fang J 2005 Chem. Mater. 17 1783

Kook Mah S and Chung I J 1995 Non-Cryst. Solids 183 252

Lihitkar N B, Abyaneh M K, Samuel V, Pasricha R, Gosavi S W and Kulkarni S K 2007 J. Coll. Inter. Sci. 314 310

Lihitkar N B, Abyaneh M K, Samuel V, Pasricha R, Gosavi S W and Kulkarni S K 2007 J. Coll. Inter. Sci. 314 310

Rochefort D, Dabo P and Guay D 2003 Electrochim. Acta 48 4245

Aaltonen T, Alen P and Ritala M 2003 Chem. Vapor Deposit. 9 45

Oh Y J, Moon S H and Chung C H 2001 J. Electrochem. Soc. 148 F56

Silva A M, Santos O A A, Mendes M J, Jordão E and Fraga M A 2003 Appl. Catal. A241 155

Ismagilov Z R, Matus E V, Yakutova A M, Protasova L N, Ismagilov I Z, Kerzhentsev M A, Rebrov E V and Schouten J C 2009 Catal. Today 147S S81

Rojas H, Borda G, Reyes P, Martínez J J, Valencia J, Fierro J L G 2008 Catal. Today 699 133

Ekou T, Vicente A, Lafaye G, Especel C, Marecot P 2006 Appl. Catal. A314 73

Singh U K, Vannice M A 2000 J. Mol. Catal. A163 233

Protasova L N, Rebrov E V, Glazneva T S, Berenguer A-Murcia, Ismagilov Z R and Schouten J C 2010 J. Catal. 271 161

Acknowledgements

Authors gratefully acknowledge TEM and XPS facilities provided by National Centre for Nanoscience and Nanotechnology, University of Madras, and thank SAIF IIT Madras.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

ANANTHAN, S.A., SURESH, R., GIRIBABU, K. et al. Synthesis and characterization of bimetallic nanocatalysts and their application in selective hydrogenation of citral to unsaturated alcohols. J Chem Sci 125, 1365–1374 (2013). https://doi.org/10.1007/s12039-013-0515-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-013-0515-6