Abstract

Measurements of open circuit potential and electrochemical impedance spectroscopy (EIS) at open circuit condition have been employed to characterize the behaviour of the mechanically polished bismuth surface in hydrochloric acid solution of various concentrations (0.01–1.0 M). The air-formed (pre-immersion) bismuth oxide grows on the surface in all the test solutions, but its thickness decreases as the HCl concentration increases. The impedance results showed that bismuth surface reactivity towards oxide thickening decreases as chloride ions concentration increases as a result of their aggressiveness nature. The equivalent circuit model for fitting the spectra of the EIS data of bismuth in HCl solution indicated that the mechanism of Bi corrosion is controlled by the charge-transfer and diffusion processes. The mechanically polished bismuth surface was examined by scanning electron microscopy before and after immersion in 0.023 M HCl solution. The scanning electron micrographs have shown that the flawed regions formed on the mechanically polished Bi surface were repaired after immersion in the acid solution due to thickening of the oxide film.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Investigation of the electrochemical behaviour of bismuth by the impedance technique showed that oxide formation was observed in NaOH and at a higher rate in \(\hbox {Na}_{2}\hbox {SO}_{4}\), in contrast to \(\hbox {H}_{2}\hbox {SO}_{4}\), where the oxide dissolution was observed to increase with the increase in acid concentration [1]. The potential and impedance results of bismuth in NaOH under open circuit conditions indicated that the thickness of the film on Bi increases with the increase in NaOH concentration up to 0.5 M [2]. The electrochemical behaviour of bismuth in phosphate solutions of different pH values under open circuit conditions was also examined [3]. The results showed that the pre-immersion oxide layer on bismuth grows as inferred from the raising of the potential \(E_{\mathrm {h}}\), oxide thickness \(1/C_{\mathrm {m}}\) and the oxide resistance \(R_{\mathrm {m}}\) with time.

In weakly acidic electrolytes (glycol borate), bismuth passivates by a dissolution–precipitation mechanism [4]. The dissolution of the bismuth is followed by the deposition of a crystalline precipitate, which blocks off the surface partially, leading to an increase in current density and a corresponding increase in electrode potential. Bismuth can be used in military industries, alloy materials, chemical pipes, flame retardants and electrocatalysis processes. Since, corrosion study of bismuth in chloride solutions is rare, consequently the aim of the existing study is to have a look at the effect of HCl solution of various concentrations (0.01–1.0 M) at the bismuth surface. This study is more interesting in different applications in industries, such as corrosion of bismuth and choosing the dissolving solutions in the hydrometallurgical processes.

2 Experimental

Bismuth electrode was made from 99.9% bismuth rod (Koch-Light Laboratories Ltd., UK). The electrode was fixed in a glass tube with epoxy resin, leaving a surface area of 0.126 \(\hbox {cm}^{2}\) exposed to the electrolyte. Before each experiment, Bi surface was abraded using successively finer grade of metallurgical paper down to 4/0 until a mirror-bright surface was obtained, then rubbed with a soft cloth until acquired a mirror-bright surface and washed with triply distilled water. HCl solutions were prepared from analytical grade HCl and triply distilled water. The solutions were used as naturally aerated and stagnant at 25°C. The bismuth potential was measured vs. a saturated calomel electrode (SCE) by means of a valve voltmeter (Electronic Instruments Ltd., UK) and then referred to normal hydrogen electrode (NHE). The electrochemical impedance spectroscope (EIS) measurements were carried out using the electrochemical Germany workstation 1M6e Zahner-electrik GmbH [5]. The input signal was usually 10 mV peak to peak in the frequency domain of 0.1–10\(^{5}\) Hz.

3 Results and discussion

3.1 Open circuit potential

The potential of the mechanically polished bismuth electrode at open circuit was followed with time for 180 min in HCl solutions of various concentrations ranging from 0.01 to 1.0 M. The variation of the potential with immersion time is shown in figure 1. It is clear from this figure that the pre-immersion (air formed) oxide film is not sufficient to impart complete passivity to the metal, as the potential changes rapidly with the time towards more noble values. The ennobling of the bismuth potential with time indicates film repair and healing. Previously, we reported that for bismuth in buffer solutions of phosphate [3] and for titanium and its Ti–6Al–4V alloy in azide solutions [5], the potential shifted to more positive values with time, indicating that the air-formed film became thicker. The final steady state potentials are attained after a time, which increases with the decrease in HCl concentration. Also, the steady state potentials values are shifted to less noble values as the acid concentration increases, similar results were observed for titanium [6] and niobium [7] in HCl solutions.

The potential at the steady state (corrosion potential) is considered a mixed one, i.e. at this potential the anodic and cathodic processes must be at the same rate on the bismuth surface. From figure 2, it can be seen that the corrosion potential of bismuth changes linearly with the chloride ions concentration according to the equation:

where a is the potential value at chloride ions concentration equals unity. The slope b (d\(E_{\mathrm {corr}}/\hbox {d log}\)[\(\hbox {Cl}^{-}\)]) of the linear relationship equal to −67 mV per decade. When bismuth comes in contact with the test solution, the driving force required for the corrosion process is the free energy change of the reaction between the bismuth and the solution to form the oxide film [8]. Oxide formation occurs by migration of positive bismuth ion and/or oxygen ion vacancies from bismuth surface towards the electrolyte or, possible migration of negative oxygen ions in the opposite direction. It is assumed that this charge migration tends to charge bismuth negatively and at charge compensation, a potential equal to the electromotive force of the reaction arises across the oxide.

In solution containing \(\hbox {Cl}^{-}\) ions, it is assumed that these ions penetrate the formed oxide film through pores and defects, and increases its permeability. Further, \(\hbox {Cl}^{-}\) ions adsorb on the bismuth surface in competition with the dissolved \(\hbox {O}_{2}\) or \(\hbox {OH}^{-}\) and this decreases the oxide formation rate on bismuth surface [9]. This behaviour causes the slowness of the electrode potential in attaining the steady state values. The aggressiveness of \(\hbox {Cl}^{-}\) ions appears very clear from the progressive shift of the steady state potential towards less positive values with increase in chloride ions concentration (cf. figure 2). The nature film formed on the abraded Bi surface by tarnishing reaction in air is the thin adherent barrier layer of \(\hbox {Bi}_{2}\hbox {O}_{3}\) [10], which is a stable oxide and has a high resistance to dissolution [11]. However, when this film interacts with a solution, it may be thickened by a rate depending on the conditions.

3.2 EIS

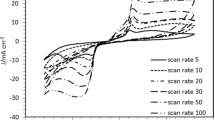

The EIS measurements for the bismuth surface at different immersion times in 0.023 M HCl solution are shown in figures 3 and 4 as Bode and Nyquist plots. Bode plots are recommended as standard impedance plots, since all impedance data are equally represented and the phase angle \(\theta \) is a sensitive parameter for any surface changes [12, 13]. This format enables the best data fitting to equivalent circuit model. The process of data fitting was carried out using a complex non-linear least squares procedure with minimum error and the used program enables data fitting in the required frequency. Bode plots in figure 3 reveal that Bi surface exhibits capacitive behaviour from medium to low frequencies and both the absolute impedance (\(\left| Z \right| )\) and the maximum phase angle \(\theta _{\mathrm {max}}\) increase with increasing the immersion time of bismuth surface in the test solution. Also, the Nyquist plots in figure 4 show that the diameter of the capacitive semicircle increases with immersion time. These results indicate thickening of the pre-immersion oxide film on bismuth surface in 0.023 M HCl solution and are in good agreement with those of potential in figure 1.

Figure 5 presents the equivalent electrical circuit for fitting the spectra of the EIS of bismuth surface immersed in HCl solutions. In the circuit, the components are as follows: \(R_{\mathrm {s}}\), solution resistance; \(C_{\mathrm {f}}\), capacitance due to the dielectric nature of the surface film; \(R_{\mathrm {f}}\), film resistance due to the surface film; \(C_{\mathrm {dl}}\), double layer capacitance; \(R_{\mathrm {ct}}\), charge transfer resistance that related to the corrosion process; W is Warburg impedance due to ion diffusion through the passive film indicating that the corrosion mechanism is controlled not only by a charge-transfer process, but also by a diffusion process. Similar electrical equivalent circuit was used for analysing the electrical behaviour of aluminium alloy 2024-T3 in 0.05 M NaCl solution saturated with cerium cinnamate [14]. Our present results indicate that the Warburg impedance value increases from 0.2 to 4.1 \(\Omega \hbox { s}^{-0.5}\) with increasing immersion time from 10 to 120 min of bismuth electrode in HCl solution. Also the charge-transfer resistance increases from 0.25 to 4.8 \(\hbox {k}\Omega \,\hbox {cm}^{2}\) with immersion time. Simulation of the impedance spectra can be performed by replacing the capacitance with a constant phase element (CPE). The usage of CPE is due to frequency dispersion as a result of distribution of relaxation times and inhomogeneity as well as static disorders, such as porosity [15]. The impedance of CPE is described by the following expression [16]:

where Q is the frequency independent real constant of the CPE, which is identical to the idealized capacitance at \(\alpha =1, \omega \) being the angular frequency (\(\omega =2\pi f\) rad \(\hbox {s}^{-1}), j= \sqrt{-1}\) and \(\alpha \) is an adjustable empirical exponent varies between 1.0 for a purely capacitive behaviour associated with a perfectly smooth surface and 0.5 for semi-infinite diffusion [17]. In the present work, \(\alpha \) value increases with immersion time up to 0.89, which indicate that the oxide film formed on bismuth does not behave as perfect capacitor. Two time constants are included in the equivalent electrical circuit due to the surface film and electrode surface. The time constant in high frequency range can be related to the formation of a surface oxide film on the bismuth [18], whilst the other in the low and middle frequency ranges can be attributed to the charge-transfer resistance and the double layer capacitance at the electrode/electrolyte interface [19].

Figure 6 shows that the reciprocal of passive film capacitance \((1/C_{\mathrm {f}})\), which is proportional to the oxide thickness [20] increases rapidly with time initially and then slowly. This indicates that the thickness of air-formed oxide film on bismuth increases. The results obtained here are in reasonable agreement with those reported before on titanium [6] and niobium [7] in HCl solutions and on bismuth in phosphate solutions [3].

Figure 7 shows the variation of the initial (after one min of electrode immersion) and final (after 180 min from immersion) reciprocal film capacitance, \(1/C_{\mathrm {f}}\), with HCl concentration. In this figure, the final \(1/C_{\mathrm {f}}\) values are greater than the initial ones indicating the thickening of the native film on bismuth surface. Also from this figure, it is clear that the initial and final \(1/C_{\mathrm {f}}\) values decrease with increase in HCl concentration. This means that the thickness of the oxide film formed on Bi decreases with an increase in \(\hbox {Cl}^{-}\) ions concentration, indicating the aggressive behaviour of such ions, in retarding formation of oxide. Therefore, the capacitance results flourish with the interpretation of potential measurements in figure 1.

The results of the passive film resistance \(R_{\mathrm {f}}\), on bismuth electrode in HCl solutions are represented in figure 8. The resistance increases as time increases, which gives more evidence on thickening of the naturally formed film on bismuth. The same phenomenon was observed earlier for thickening of the native oxide film on tantalum in chloride solutions [21] and on bismuth in 0.05 M NaOH [1] and in phosphate buffer solutions [3]. Therefore, the resistance results further confirm those of the potential and the capacitance in figures 1 and 6, respectively. Figure 9 represents the change of the initial (after 1 min of immersion) and final (after 180 min of immersion) oxide film resistance \(R_{\mathrm {f}}\) values with HCl concentration. This figure reveals that the final resistance values are greater than the initial ones indicating the formation of passive layer on bismuth surface. The initial and final resistances decrease with the increase in the HCl concentration. This means that the passivation of bismuth surface decreases as HCl concentration increases.

3.3 SEM

Scanning electron microscopy (SEM) is an important technique to examine the surface morphology of material [22]. Figure 10a and b shows the scanning electron micrographs of the mechanically polished Bi surface before and after immersion in 0.023 M HCl for 180 min. It is clear that the defects and notches which appear in figure 10a were decreased due to the growth of the pre-immersion oxide film on Bi surface in the acid solution as shown in figure 10b.

4 Conclusions

Increase in the HCl concentration led to a decrease in both the steady state potential of bismuth surface and the thickness of the spontaneously grown oxide film. The results of EIS showed that the absolute impedance and the maximum phase angle (from Bode plots) as well as the capacitive semicircle diameter (from Nyquist plots) increase with increase in the immersion time of Bi in HCl solution These characteristics denote that the passive layer on Bi grows as time passes. SEM technique reveals repairing of the flawed regions on bismuth surface due to the growth of passive film on its surface in HCl solution.

References

Heakal F E, Mazhar A A and Ameer M A 1988 Br. Corros. J. 23 41

Mazhar A A, Heakal F E and Ameer M A 1988 J. Appl. Electrochem. 18 555

Ghoneim A A, Mogoda A S, Ameer M A and Heakal F E 1996 Bull. Electrochem. 12 578

Ikonopisov S and Nikolov T S 1972 J. Electrochem. Soc. 119 1544

Heakal F E, Ghoneim A A, Mogoda A S and Awad Kh 2011 Corros. Sci. 53 2728

El-Basiouny M S and Gadallah A G 1981 Ann. Chim. 71 391

El-Basiouny M S, Bekheet A M and Gadallah A G 1984 Corrosion 40 116

Latimer W M 1952 The oxidation states of the elements and their potentails in aqueous solutions (New York: Prentice-Hall Inc.) p 262

Hoar T P, Mears D and Rothwell G 1965 Corros. Sci. 5 279

Bard A J, Parsons R and Jordan J 1985 Standard potential in aqueous solutions (New York: Marcel Dekker) p 180

Smith J D 1973 Comprehesive inorganic chemistry (Oxford: Pergamon Press) p 553

Macdonald J R 1987 Impedance spectroscopy (New York: Wiley) chap 4

El-Gamel N E A and Fekry A M 2015 Bioelectrochem. 104 35

Sh W, Han E H and Liu F C 2011 Corros. Sci. 53 2374

Davenport A, Oblonsk L and Ryan M 2000 J. Electrochem. Soc. 147 2162

Juttner K 1990 Electrochim. Acta 35 1501

Rammelt U and Reinhard G 1990 Electrochim. Acta 35 1045

Tsai C H and Mansfeld F 1993 Corrosion 49 726

Cabrera-Sierra R, Sosa E and Oropeza M T 2002 Electrochim. Acta 47 2149

Breiter M W 1970 Electrochem. Acta 15 1145

Bekheet A M, Hefny M M, Mazhar A A and El-Basiouny M S 1983 Ann. Chim. 73 63

May A 2017 Bull. Mater. Sci. 40 395

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mogoda, A.S. Electrochemical behaviour of bismuth in HCl solutions. Bull Mater Sci 43, 100 (2020). https://doi.org/10.1007/s12034-020-2062-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-2062-3