Abstract

This paper deals with the surface modification of Grewia optiva fibre through benzoylation and graft copolymerization process. Benzoylation of Grewia optiva fibre has been carried out on mercerized fibre with varying concentrations of benzoyl chloride solution. Graft copolymerization of acrylonitrile (AN) onto Grewia optiva fibre was carried out with ceric ammonium nitrate as the redox initiator in aqueous medium under the influence of microwave radiation. Raw, graft copolymerized and benzoylated fibres were subjected to evaluation of some of their properties like swelling behaviour, moisture absorbance and chemical resistance behaviour. It has been observed that 5% benzoyl chloride treated and graft copolymerized Grewia optiva show more resistance towards moisture, water and chemicals when compared with that of raw fibre. Further morphological, structural changes, thermal stability and crystallinity of raw, graft copolymerized, pretreated and benzoylated fibres have also been studied by SEM, FTIR, TGA and XRD techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

During the last few years polymers have replaced many of conventional materials in various applications. This is because of their various advantages over conventional materials such as ease of processing, productivity and cost reduction. In most of applications, polymers are modified using fillers and fibres to suit the high strength/high modulus requirements. Fibre reinforced polymers are finding extensive applications in various fields ranging from appliances to spacecrafts etc. Recently, natural fibre reinforced composites have attracted the attention of scientists and technologists because of their potential of serving as alternative for artificial fibre composites (Cantero et al 2003; Arbelaiz et al 2005; Akil et al 2009; Sreekumar et al 2009). These natural fibres are biodegradable, readily available, low cost fibres with low density and have high specific properties comparable to those of other fibres used for reinforcements (Donnell et al 2004; Singha et al 2008; Avella et al 2009). However, certain drawbacks such as poor resistance to moisture, low chemical resistance, incompatibility between hydrophilic fibre with non-polar matrix and tendency to form aggregates during processing reduce the potential of natural fibre as reinforcement. In order to overcome above mentioned drawbacks surface treatments are necessary for modifying the fibre morphology. A variety of physical (Corona, cold plasma) and chemical treatments for surface modification have been reported in literature (Mohanty et al 2000a; Sreekala and Thomas 2003; Bessadok et al 2007). Different chemical treatments include dewaxing, mercerization, acetylation, benzoylation, silanation, cyanoethylation and graft copolymerization. Graft copolymerization is one of the finest methods to impart a variety of functional groups on the polymer backbone (Tripathy et al 1999; Mohanty et al 2000b; Singha et al 2004; Arifuzzaman et al 2009). Several oxidant systems such as photo active quinnes, ozone hydroxyl radicals, ceric ammonium nitrate, potassium bromate etc have been used to initiate graft copolymerization onto cellulosic backbone. Polymerization of vinyl monomers may be initiated by free radicals or certain ions. Depending upon the monomer, one or other type of initiator may be preferred. The grafting process depends upon the reactivity of monomer used, the type on initiation and cellulose accessibility (Habish and Mehta 1967, 1968). Graft copolymerization of vinyl monomers onto lignocellulosic fibres is generally considered to take place in three steps. First step is the generation of active sites on surface of polymeric backbone. Second step is addition of monomer to backbone to propagate the chain and last step is termination of the growing polymeric chain. In comparison to conventional techniques of grafting, the microwave radiation induced grafting is one of the efficient methods for graft copolymerization of vinyl monomers as it not only consumes less time but also causes minor change in the texture of the fibre (Tsukada et al 2005). Different researchers have studied benzoylation and grafting of vinyl monomers reactions onto natural fibres and reported increase in thermal, moisture, chemical resistance behaviour and better interlocking between the fibres and matrices (Manikandan et al 2001; Singha et al 2004; Sreekumar et al 2009).

Literature survey has revealed that not much efforts have been made on surface modification of Grewia optiva fibre and its subsequent use as reinforcement in the synthesis of fibre reinforced polymer composites (Singha and Thakur 2008, 2009). Grewia optiva is a multipurpose tree of the Himalayan region and is found on the boundaries of field up to 2000 m. Grewia optiva, locally known as Bhimaal or Bihul, is a small to medium-sized deciduous tree with 9–12 m in height. It is an important fodder tree during the winters for villagers. It provides fodder, fibre, fuel and edible fruits, and is also used medicinally, as a dye and as a detergent. Traditionally this fibrous material has been used by people of this state for making low cost articles like ropes, bags, socks, boots, mats, etc. The specific objective of the present investigation is to study the effect of benzoylation and graft copolymerization onto Grewia optiva fibre on physicochemical and thermal properties of fibres so that these fibres could be used for various industrial applications including synthesis of biocomposites.

2 Experimental

2.1 Materials

Acrylonitrile (AN) was purified by initially washing with 5% sodium hydroxide and then drying over anhydrous Na2SO4. Finally it was subjected to distillation and middle fraction of distillate was used for further studies. Ceric ammonium nitrate (CAN) obtained from Merck Chemicals was used as an initiator. Weighing of the samples was done on Libror AEG-220 (Shimadzu) electronic balance. Humidity chamber of Swastika make was used to study the moisture absorbance behaviour of the graft copolymers.

2.2 Sample preparation

Grewia optiva tree branches were collected from Palampur region in Himachal Pradesh, India. These branches were first retted into water for 3–4 weeks, and then fibre was separated from stick by dissolving cementing and gummy materials. The fibres thus obtained were at first washed thoroughly with 2% detergent solution and then followed by drying them in a hot air oven at 70°C for 24 h. The dried fibres were designated as untreated fibres. Then these fibres were further subjected to soxhlet extraction with acetone for 72 h followed by washing with double distilled water and air drying to remove waxes and other water soluble impurities prior to various chemical treatments.

2.3 Surface modification of fibres

The surface modification of Grewia optiva fibres was carried through the following chemical treatments:

2.3.1 Benzoylation

Fibres were pretreated with 10% (w/v) NaOH solution for 240 min in order to activate the OH groups of cellulose and lignin in the fibre. The fibres were then washed several times with distilled water to remove any traces of NaOH sticking to the fibre surface, neutralized with 2% (w/v) dilute acetic acid solution and finally washed again with distilled water. The fibres were then dried at room temperature for 48 h followed by hot air oven drying at 70°C to a constant weight. One gram of pretreated fibre was then suspended in 100 ml of 10% NaOH solution and agitated well with different benzoyl chloride concentrations (1, 2, 3, 5, 7 and 9%) for 10–15 min, followed by filtration, washing thoroughly with water and finally drying between folds of filter papers. The isolated fibres were then soaked in ethanol for 1 h to remove any unreacted benzoyl chloride and finally washed with distilled water and then dried.

2.3.2 Graft copolymerization

Grewia optiva fibre was subjected to preswelling in 100 ml of distilled water at room temperature for 24 h prior to carrying out graft copolymerization. Preswelling of fibre activates the active sites on the polymeric backbone. Grafting was then carried out under the influence of microwave radiations in a microwave oven at 110 W microwave power. A known amount of the CAN and nitric acid was added to the reaction mixture followed by addition of the monomer in small fractions with continuous stirring of the reaction mixture. The reaction flask was then put in the microwave oven for a definite period of time. Optimum conditions of time, CAN concentration, nitric acid and monomer concentration were worked out so as to get maximum graft yield (7·04%). Homo-polymer formed during the graft copolymerization was removed by extraction with dimethylformamide (DMF). The grafted samples were dried in a hot air oven at 60°C to a constant weight. The amount of graft added onto the fibre was determined gravimetrically. The percent grafting (P g) and percent efficiency (P e) were then calculated as per the following equations:

where W is the weight of raw fibre, W g the weight of grafted fibre, W m the weight of monomer.

3 Evaluation of physical and chemical properties

3.1 Chemical resistance

The chemical resistance of raw and grafted fibre was studied as a function of percent weight loss of fibre when treated with different chemicals. A known amount (W i) of raw and grafted fibre was treated with a definite volume of hydrochloric acid and sodium hydroxide of different strengths for a time interval of 24 h. The fibres were then washed 2–3 times with distilled water and finally dried in an oven at 70°C to a constant weight to get the final weight (W f). The percent weight loss was determined by using the following formula:

3.2 Swelling behaviour

The swelling behaviour of the raw and surface modified samples of Grewia optiva fibre was studied in different solvents such as water, butanol, dimethyl formamide and carbon tetra chloride. Dry samples of grafted as well as raw fibres (1 g) were suspended in 100 ml of the solvents kept at 35°C for 24 h. The solvent that adhered on the surface of the samples was removed by softly pressing between folds of the filter paper. The samples were then weighed to get the final weight. The percent swelling was calculated by using the following relationship:

where W i is the initial weight of the dried fibre and W f the final weight after swelling.

3.3 Moisture absorption

The moisture absorption study of grafted as well as raw fibre was performed at different humidity levels ranging from 20–80% for a fixed time period of 2 h. The percent moisture absorption was studied as a function of weight gain and was calculated using the following formula:

where W f and W i are the final and initial weights of the fibre.

3.4 Crystallinity index (CI)

Crystallinity index (CI) was determined by using the wide angle X-ray diffraction counts at 2\(\theta\) angle close to 22° and 15°. The counter reading of peak intensity close to 22° and 15° is said to represent the crystalline and amorphous contents in cellulose, respectively. Percent crystallinity and crystallinity index (CI) were calculated using the following equation (Mwaikambo and Ansell 2002):

where I C and I A are the crystalline and amorphous intensities at 2\(\theta\) scale close to 22° and 15° angles.

4 Results and discussion

4.1 Benzoylation of Grewia optiva fibre

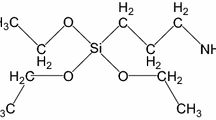

Benzoylation is an important transformation in organic synthesis and it introduces aryl radical (C6H5CO.) into a molecule. Benzoyl chloride is most often used for this purpose. Grewia optiva fibres were pretreated first with NaOH in order to activate hydroxyl groups of cellulose and lignin (Liu and Hu 2008). Pretreated (mercerized) fibres were then soaked in NaOH solutions and agitated well with benzoyl chloride. This treatment helps in replacing hydroxyl groups of the cellulosic fibres with benzoyl groups and makes them hydrophobic in nature. The reaction between the hydroxyl group of the fibre and benzoyl chloride is shown in scheme 1 (Joseph and Thomas 1993).

A possible mechanism for grafting of benzoyl chloride onto Grewia optiva fibre (Joseph and Thomas 1993).

4.2 Graft copolymerization of acrylonitrile onto Grewia optiva fibre

C2, C3 and C6 hydroxyls and C–H groups are active sites for the incorporation of polymeric chains through grafting onto Grewia optiva fibre. Grafting reaction proceeds through redox mechanism in which Ce(IV) ions are reduced to Ce(III) ions by the transfer of electron from the cellulose molecules. This creates active sites on the polymeric backbone which are then attacked by monomer radicals (scheme 2). Ceric ions form complexes with carbon chain of polymer backbone as well as monomer chains and generate free radicals ((3) and (4)). Free radicals then result in the formation of graft copolymer [GOC-g-poly (AN)] as per the reaction sequence given ((5) and (6)). Monomer free radicals also combine with more monomer molecules to form homopolymer [poly (AN)] free radicals (7), which further react with the cellulose chain to form homopolymer and GO free radicals (8). On the other hand, ceric ion combines with the free radical to form GOC-g-poly(AN) (9) as well as stable poly (AN) chain (10) and terminates the polymerization process.

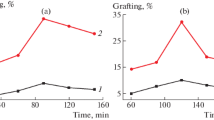

4.3 Optimization of different reaction parameters for graft copolymerization of AN

The extent of grafting on the natural fibre mainly depended upon availability of the active sites on the polymeric backbone. However, reaction variables such as time, microwave radiation power (MWR), concentration of initiator, nitric acid and monomer had a pronounced effect on graft yield.

4.3.1 Effect of treatment time on grafting

Time plays a very important role in graft copolymerization. The graft copolymerization has been recorded at different timings ranging from 5–30 min at 110 W (table 1). Initially P g increased with the increase in time up to 15 min and thereafter, P g decreased. Increase in P g up to 15 min is due to high copolymerization reaction between reactive sites of Grewia optiva fibre and the activated monomer radicals. But after 15 min, P g decreases due to the availability of lesser number of the reactive sites and also due to the mutual destruction of growing polymeric chains leading to homo polymerization at the exposure of grafting (Bhattacharya and Misra 2004). Grafting in the presence of MWR took lesser time because of passage of electromagnetic wave in solution, which oscillates speed of molecules.

4.3.2 Effect of initiator concentration on grafting

The initiator concentration also plays a very important role on graft copolymerization onto polymeric backbone as shown in table 1. Initially P g has been found to increase with the increase in CAN concentration up to 2·73 × 10 − 2 mol L − 1 due to increase in the free radical active sites on the polymeric backbone. However, at higher CAN concentration the percentage of grafting decreases as high concentration of initiator accelerates the dissociation rate of Ce(IV) (Bhattacharya and Misra 2004), which reduces the concentration of Ce(IV) participating in the graft copolymerization ((9) and (10)).

4.3.3 Effect of nitric acid concentration on grafting

In aqueous medium, CAN exists as Ce4 + , [Ce(OH)]3 + and [Ce–O–Ce]6 + ions ((11) and (12)). Due to the large size, these ions are not able to form complexes with polymer backbone. However, in the presence of HNO3, equilibrium shifts more and more towards Ce4 + ions, therefore, graft copolymerization increases with increase in nitric acid concentration.

Table 1 shows effect of nitric acid concentration on grafting parameters. It can be seen that P g increased significantly with the increase in nitric acid concentration, and P e also follows similar trend. However, P g decreased with further increase in nitric acid concentration beyond optimum value (3·60 × 10 − 2 mol L − 1) probably due to termination of growing grafted chains, which has been accelerated because of formation of considerable amount of [Ce4 + ] and [CeOH]3 + (Bhattacharya and Misra 2004). Also increased concentration of nitric acid may result in hydrolysis of the fibre (scheme 3).

4.3.4 Effect of monomer concentration on grafting

The effect of monomer concentration on graft copolymerization onto polymeric backbone at constant concentration of CAN and nitric acid at 110 watt power has been shown in table 1. It is observed from the table that P g increased with increase in AN concentration up to 3·05 × 10 − 1 mol L − 1 and after that P g showed a decreasing trend. The above behaviour of the monomer concentration may be explained on the basis that initially more and more free radicals reach onto the polymeric backbone, resulting in increased P g. The decrease in P g beyond optimum value of AN was probably due to preferential homopolymerization over graft copolymerization as well as due to agglomeration of fibre.

4.4 Physical and chemical properties

4.4.1 Swelling behaviour

Figures 1 and 2 show percent swelling of the raw, benzoylated and graft copolymerized fibres in different solvents at a temperature of 35°C. The raw fibre possesses hydrophilic groups at C2, C3 and C6 of glucose unit, which have strong affinity with water. Therefore, raw Grewia optiva fibre shows maximum swelling (74·28%) in water and least swelling (10·24%) with the non-polar solvent like CCl4. Due to presence of polar –OH groups in ethanol the raw fibres are more solvolysed and hence show more swelling than in DMF. The following order of different solvents toward the swelling of raw Grewia optiva fibre was observed.

The percent swelling of Grewia optiva-g-poly(AN) in different solvents varies as a function of maximum grafting and follows the trend: DMF > H2O > CCl4 > C2H5OH (figure 11). The grafted fibres have hydrophobic poly-(AN) chains incorporated in them, because of which reverse swelling trend has been found in various solvents when compared with that of raw fibre. This happens due to increase in hydrophobicity of fibre on account of the blockage of hydroxyl groups (active sites) by poly acrylonitrile chains. Higher percent swelling in the case of DMF occurs by solvolysis of grafted fibre in DMF due to its dipolar aprotic nature as compared to water and ethanol. Percent swelling of Grewia optiva-g-poly (AN) in carbon tetrachloride increases as a function of P g because of development of the hydrophobic character due to grafting on the polymeric backbone. The grafted fibre exhibits least swelling in ethanol due to presence of bulkier alkyl group in ethanol, which leads to less solvolyzation of polymeric chains on grafted fibres.

However, in case of benzoylated fibre (figure 2), decrease in swelling with polar solvent and increase with the non-polar solvents has been observed. Further 5% benzoyl chloride treated Grewia optiva fibre showed maximum hydrophobic character which could be due to maximum penetration of the benzoyl molecules into fibre pores resulting in mechanical interlocked coating on the fibre surface. With further increase in benzoyl chloride concentration beyond 5% a decrease in the hydrophobic character has been observed. This could be due to increase in the viscosity of reaction medium which may cause hindrance in the penetration of benzoyl molecules and lesser availability of active sites for penetration onto cellulosic backbone.

4.4.2 Chemical resistance

The effect of acid (HCl) and base (NaOH) has been studied in terms of weight loss of the fibre by keeping the raw, benzoylated and AN graft copolymerized fibres in acid or base for a period of 24 h. It is clear from figure 3 that with increase in P g the weight loss of the fibre decreases and the minimum weight loss was found at higher P g (7·04%). This probably occurred due to blockage of active sites vulnerable to chemical attack on polymeric backbone by grafted polyacrylonitrile chains.

From figure 4 it is also observed that chemical resistance behaviour of benzoylated fibre with base decreases initially with increase in benzoyl chloride concentration in the reaction mixture. Further, maximum weight loss was found at 5% benzoyl chloride concentration. This probably could be due to the formation of corresponding sodium salt (hydrolysis of ester). But increase in concentration beyond 5% led to decrease in % weight loss. This could be explained on the same basis as discussed in §4.4.1. It has also been observed that the benzoylated fibre shows maximum resistance towards action of acid as compared to that of base (figure 5).

4.4.3 Moisture absorption

Raw Grewia optiva fibres absorb maximum moisture due to affinity of –OH groups on cellulosic backbone with water. However, moisture absorbance has been found to decrease upon acrylonitrile graft copolymerization and benzoylation of Grewia optiva fibre (figures 6 and 7). It has also been found that moisture absorbance decreases with increase in P g. Further among 1, 2, 3, 5, 7 and 9% treated fibre, 5% benzoylated fibre showed the best result. These results can also be explained on the same basis as discussed above in §4.4.2.

4.5 FTIR analysis

IR spectra of raw, pretreated, benzoylated and AN graft copolymerized lignocellulosic fibres were recorded with KBr pellets on PERKIN ELMER RXI Spectrophotometer and the results are shown in figure 8(a–d). FT–IR spectrum of raw Grewia optiva fibre showed a broad peak at 615·71 cm − 1 (due to out of plane –OH bending), 896·31 cm − 1 (due to \(\beta\)-glycosidic linkage), 1247·68 cm − 1 (due to –C–O–C– and –C=O stretching in xylan side substituent and lignin aromatic C=O stretching), milder peaks at 1377·2–1431·31 cm − 1 (due to –CH, –CH2 and –CH3 bending), 1638·82 cm − 1 (due to H–O–H bending of absorbed water and for lignin C–H deformation), 1729·9 cm − 1 (to carbonyl group of pectins), 2131·29 cm − 1 (due to O–H stretching of absorbed moisture), 2335·5 cm − 1 (due to C–H stretching in polysaccharide chains), 2923·49 cm − 1 (for C–H stretching vibration of aliphatic methylene group) and an intense broad peak ranging from 3024–3691 cm − 1 (due to the hydrogen bonded –OH vibration of the cellulose structure fibre). It has been found that upon pretreatment strong bands around 1735 and 1247 cm − 1 disappears (figure 8b). This behaviour has been associated with mercerization of lignocellulosic fibres which removes the waxy epidermal tissues, substitutional portion of uranic acid, lignins, adhesive pectins and hemicelluloses that bind fibre bundles to each other and to the pectins and hemicelluloses rich sheet core.

In case of FTIR study on benzoylated fibre (figure 8c), it is observed that hydroxyl vibration adsorption at 3395·9 decreased due to the esterification of hydroxyl group. The ester group is identified by presence of peaks at 1729·29 cm − 1 and 1275·9 cm − 1, while absorption bands obtained at 1600 cm − 1 and 711·76 cm − 1 were assigned to aromatic rings. In order to confirm the higher level of benzoylation among 3, 5 and 7% benzoyl chloride treated lignocellulosic fibres, the extent of benzoylation for all samples was quantitatively determined by calculating the ratio R between the intensity of the acetyl C=O stretching of ester at 1725–1735 cm − 1 and the intensity of C–O stretching vibration of cellulose backbone at about 1020–1040 cm − 1 (figure 9). The value of R varies with benzoyl chloride concentration and it was found maximum (0·828) at 5% benzoyl chloride treated fibres followed by 7% (0·813) and 3%(0·8001) benzoyl chloride treated fibres. Also there is maximum increase in intensity of carbonyl group of ester for 5% benzoyl chloride treated fibre as compared to 3 and 7% treated fibre which further confirms the maximum blockage of –OH active sites and also higher degree of esterification. However, in the FTIR spectra of Grewia optiva-g-poly (AN), one notable absorption band at 2244·05 cm − 1 has been obtained due to the presence of nitrile group in the grafted structure (figure 8d). There has also been a decrease in the peak intensity at 3395·9 cm − 1 due to blockage of –OH groups on cellulosic backbone by AN chains. Further decrease in intensity of band at 1640 cm − 1, assigned to adsorbed water molecules, after esterification of pretreated fibre with benzoyl chloride and graft copolymerization with AN supports better swelling and moisture resistance behaviour of resulted fibre.

4.6 Morphological studies

Scanning electron microscopic (SEM) studies of raw, pretreated, benzoylated and grafted Grewia optiva fibres were carried out on a LEO 435 VP electron microscope and results are shown in figures 10(a–d). Prior to conducting SEM studies, all the samples were sputtered in order to make them conducting. Scanning was synchronized with microscopic beam for the maintenance of small size over large distance relative to the specimen. All the images were taken at a resolution of 1000×. The untreated fibre surface (figure 10a) clearly showed the presence of oil and waxy substances. In comparison to untreated fibres, a clear surface morphology was typical for pretreated fibres (figure 10b), because of the removal of lignin, waxes and hemicelluloses and other structural defects. However, after benzoylation surface morphology is not clear because of penetration of benzoyl molecules onto polymer backbone (figure 10c). Further it was observed that upon graft copolymerization the surface of fibre became rough as compared to raw fibres (figure 10d). This may be probably due to deposition of poly-(AN) chains on the surface of raw fibres upon grafting.

4.7 Thermal analysis

Thermogravimetric analysis (TGA) of the raw, pretreated, benzoylated and AN graft copolymerized Grewia optiva fibre was conducted on a Mettler Toledo TGA analyser. Samples were heated at a constant rate of 15°C/min from 0–800°C, under a nitrogen flow of 20 mL/min. Thermal behaviour of raw, pretreated, benzoylated and AN graft copolymerized Grewia optiva fibre samples were studied as a function of % weight residue with increase in temperature and results are shown in figure 11. In case of raw fibre, first weight loss between 60 and 120°C occurs due to volatilization of water molecules chemically adsorbed onto fibre surface. The second weight loss at about 330°C is due to depolymerization of hemicelluloses and cleavages of glucosidic linkages of cellulose (Naugen et al 1981). The third weight loss at about 460°C may be due to further decomposition of the product of stage II leading to formation of tar through levoglucosan (Tang and Bacon 1964).

For raw fibres, the initial decomposition temperature (IDT) has been found to be 262·5°C (3·26 % weight loss) and final decomposition temperature (FDT) to be 394·32°C (66·93 % weight loss). For pretreated fibres, the value of IDT and FDT were 262·9°C and 395·3°C, respectively. In case of benzoylated fibre, IDT and FDT were found to be 250·22°C and 395·4°C, respectively. However, in case of graft copolymerized fibre, IDT and FDT values have been found to be 265°C (4·25 % weight loss) and 404°C (50·19 % weight loss), respectively.

From the above data it is clear that benzoylation process causes decrease in thermal stability in comparison to pretreated and raw fibre. This behaviour could be attributed to the disruption of crystalline lattice of cellulosic bio-fibres after esterification reaction. However, Grewia optiva-g- poly(AN) fibre shows considerable increase in thermal stability as compared to raw fibre which in turn have more thermal stability than pretreated and benzoylated fibre. These results also find support if we consider % weight loss at different decomposition temperatures (DT) as a standard of comparison for all samples (table 2).

4.8 Crystallinity study

X-ray diffraction studies were performed on X-ray diffractometer (Bruker D8 Advance), using Cu K\(\alpha\) (1·5418 Å) radiation, a Ni-filter and a scintillation counter as a detector at 40 kV and 40 mA on rotation from 10° to 50° at 2\(\theta \) scale. X-ray diffraction studies of the raw, pretreated, benzoylated and AN graft copolymerized Grewia optiva fibre have been shown in table 3. Since cellulosic fibres generally contain both crystalline and amorphous regions so it is evident that X-ray diffraction patterns of such materials will show both regions in the form of sharp peak and diffused pattern (figure 12).

From the table it has been observed that % crystallinity as well as crystallinity index of pretreated fibre is higher than raw fibre. Crystallinity index (CI) gives quantitative measure of orientation of cellulose crystals in the fibres with respect to the fibre axis. This could be due to the removal of waxy materials, lignin, pectins, cementing materials and hemicelluloses, which lead to the interfibrillar regions to be less dense and less rigid and better packing of the cellulose chains (Gassan and Bledzki 1999). However, upon benzoylation of pretreated fibre a slight decrease in percent crystallinity of the fibre has been observed. This could be due to disturbance in structure of polymer backbone by penetration of bulky benzoyl groups into the polymer backbone. In case of Grewia optiva-g-poly(AN) decrease in CI has also been observed which could be due to the disorientation of cellulose crystals when poly-(AN) chains are incorporated in the fibre.

5 Conclusions

Surface modification of Grewia optiva fibre through benzoylation and graft copolymerization has been confirmed by FTIR, SEM, TGA and XRD. Thermal stability of AN graft copolymerized fibres has been found higher than that of raw and benzoylated fibre. XRD study showed that there is an increase in CI and crystallinity of pretreated fibre, however, after benzoylation and graft copolymerization a slight decrease in CI has been observed. Enhancement in hydrophobic character and chemical resistance behaviour of surface modified Grewia optiva fibre has also been observed. All these properties of surface modified fibres could help in their applications especially in the synthesis of natural fibre reinforced composites for their better end use.

References

Akil H M, Cheng L W, Ishak Z A M, Bakar A A and Rahman M A A 2009 Compos. Sci. & Technol. 69 1942

Arbelaiz A, Fernandez B, Ramos J A, Retegi A, Llano-Ponte R and Mondragon I 2005 Compos. Sci. & Technol. 65 1582

Arifuzzaman Khan G M, Shaheruzzaman M, Rahman M H, Abdur Razzaque S M, Sakinul Islam M and Shamsul Alam M 2009 Fibres Polym. 10 65

Avella M, Buzarovska A, Errico M E, Gentile G and Grozdanov A 2009 Materials 2 911

Bessadok A, Marais S, Gouanve F, Colasse L, Zimmerlin I, Roudesli S and Matayer M 2007 Compos. Sci. & Technol. 67 685

Bhattacharya A and Misra B N 2004 Prog. Polym. Sci. 29 767

Cantero G, Arbelaiz A, Llano-Ponte R and Mondragon I 2003 Compos. Sci. & Technol. 63 1247

Donnell A O, Dweib M A and Wool R P 2004 Compos. Sci. & Technol. 64 1135

Gassan J and Bledzki A K 1999 Compos. Sci. & Technol. 59 1303

Habish J A and Mehta P C 1967 Text. Res. J. 37 911

Habish J A and Mehta P C 1968 Appl. Polym. Sci. 12 1625

Joseph K and Thomas S 1993 J. Reinf. Plast. & Compos. 12 134

Liu Y and Hu H 2008 Fibres Polym. 9 735

Manikandan Nair K C, Thomas S and Groeninckx G 2001 Compos. Sci. Technol. 61 2519

Mohanty A K, Khan M A and Hinrichsen G 2000a Compos. Sci. & Technol. 60 1115

Mohanty A K, Tripathy P C, Misra M, Parija S and Sahoo S 2000b J. Appl. Polym. Sci. 77 3035

Mwaikambo L Y and Ansell M P 2002 J. Appl. Polym. Sci. 84 2222

Naugen T, Zavarian E and Barall E M 1981 J. Macromol. Sci. Rev. Macromol. Chem. C20 1

Singha A S and Thakur V K 2008 Int. J. Polym. Mat. 57 1059

Singha A S and Thakur V K 2009 Int. J. Polym. Anal. Charact. 14 301

Singha A S, Kaith B S and Kumar S 2004 Int. J. Chem. Sci. 2 472

Singha A S, Shama A and Thakur V K 2008 Int. J. Polym. Anal. Charact. 1 447

Sreekala M S and Thomas S 2003 Compos. Sci. & Technol. 6 861

Sreekumar P A, Thomas S P, Saiter J M, Joseph K, Unnikrishnan G and Thomas S 2009 Composites: Part A 40 1777

Tang M M and Bacon R 1964 Carbon 2 211

Tripathy P C, Misra M, Parija S, Misra M and Mohanty A K 1999 Polym. Int. 48 868

Tsukada M, Islam S, Arai T, Boschi A and Freddi G 2005 Autex Res. J. 5 40

Acknowledgements

Authors are highly thankful to the Director, National Institute of Technology, Hamirpur, for providing laboratory facilities and the Ministry of Human Resources and Development, for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singha, A.S., Rana, A.K. Effect of surface modification of Grewia optiva fibres on their physicochemical and thermal properties. Bull Mater Sci 35, 1099–1110 (2012). https://doi.org/10.1007/s12034-012-0400-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-012-0400-9