Abstract

Fabrication method is one of the essential factors which directly affect on the properties of scaffold. Several techniques have been well established to fabricate nanofibrous scaffolds such as electrospinning. However, preparing a three-dimensional (3-D) interconnected macro-pore scaffold essential for transporting the cell metabolites and nutrients is difficult using the electrospinning method. The main aim of this study was developing a highly porous scaffold by poly (L-lactic acid) (PLLA)/chitosan blend using liquid–liquid phase separation (LLPS) technique, a fast and cost–benefit method, in order to use in nerve tissue engineering. In addition, the effect of different polymeric concentrations on morphology, mechanical properties, hydrophilicity, in vitro degradation rate and pH alteration of the scaffolds were evaluated. Moreover, cell attachment, cell viability and cell proliferation of scaffolds as candidates for nerve tissue engineering was investigated. PLLA/chitosan blend not only had desirable structural properties, porosity, hydrophilicity, mechanical properties, degradation rate and pH alteration but also provided a favorable environment for attachment, viability, and proliferation of human neuroblastoma cells, exhibiting significant potential for nerve tissue engineering applications. However, the polymeric concentration in blend fabrication had influence on both characteristics and cell responses. It concluded that PLLA/chitosan nanofibrous 3-D scaffold fabricated by LLPS method as a suitable candidate for nerve tissue engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Trauma, cancer, or congenital defects can lead to peripheral nerve injuries (PNIs), one of the challenging clinical issues [13]. Treatment of gaps more than 10 mm is more difficult compared to shorter defects which can be reconnected surgically with micro sutures [37] or various nerve guidance channels [10]. The autologous nerve graft has been still the gold standard treatment to bridge the long defects of the peripheral nerve even though it is followed by some disadvantages including donor site morbidity, donor source limitation, multiple surgical sites, and possible size inconsistency [17]. Using either allografts or xenografts is the other treatment options that may be followed by the risk of disease transmission and immune rejection. However, tissue engineering can introduce alternative treatment options without the above mentioned shortcomings [2, 23, 35]; for instance, using platelet concentrates such as platelet-rich plasma demonstrated favorable effect on PNIs [3, 4]. In addition, the outstanding efforts have been dedicated to develop conduits which not only improve the nerve regeneration but also recover the function of peripheral nerve defects [16].

Biocompatible and biodegradable materials have been used for scaffold fabrication and serving as a provisional environment for proliferation, attachment, migration, and differentiation of host cells [1, 23, 31]. Using hybrid natural/synthetic materials can lead to have advantages of both natural and synthetic polymers in one composition as a scaffold in tissue engineering. Chitosan a natural polymer derived from chitin demonstrated great biocompatibility and had interactions with biological systems; in fact, its cationic nature makes electrostatic reactions with proteoglycans and glycosaminoglycans (GAGs), anionic components in the body. Furthermore, although insignificant mechanical properties of chitosan limited its applications in tissue engineering [11], the application of CS for regeneration of PNIs was demonstrated in a recent study [27]. PLLA, FDA approved polymer, has demonstrated proper mechanical properties, although its biocompatibility can be decreased because of its hydrophobic nature [32, 39]. Many studies have shown that the PLLA/CS combination can enhance both polymers' properties [9, 30]. For instance, carbonyl groups of PLLA could form hydrogen bonds with hydroxyl and amino groups on the molecular chains of CS [6]. Also, PLLA crystallization reduced by the hydrogen bonding between PLLA and CS [36].

The fabrication method is one of the essential factors which has direct influence on the properties of the scaffold. Several techniques have been well established to fabricate nanofibrous scaffolds such as electrospinning. However, preparing a three-dimensional (3-D) interconnected macro-pore scaffold essential for transporting the cell metabolites and nutrients is difficult using the electrospinning method [15, 34]. Thermally induced phase separation (TIPS) which has attracted much attention due to its plain, quick and relatively inexpensive technique [22, 36]. TIPS is based on the thermodynamic dissociation of a homogeneous polymer–solvent system to the polymeric and solvent-rich phases by quenching the solution into its binodal region [25]. The quenching can be accomplished using either solid–liquid (SLPS) or liquid–liquid phase separation (LLPS). In practice, if the quenching temperature stays higher or reaches underneath the freezing point of the solvent, LLPS or SLPS happens, respectively. SLPS induced by the solidification of the solvent and contains anisotropic ladder-like structure with relatively small pores forms while LLPS in the unstable region, an open porous and well-interconnected structure can be obtained [21, 38].

Using the TIPS method, variety of 3-D nanofibrous polymer scaffolds have been successfully fabricated for tissue engineering applications [8, 19, 26]. The parameters which have effect on the morphology of the scaffolds in this method are type of polymer, solvent and quenching temperature [36, 40]. Therefore, the aim of this study was to utilize LLPS method to fabricate PLLA/CS blend 3-D highly macroporous and nanofibrous scaffold for nerve tissue engineering. In addition, we evaluated the effect of different polymeric concentrations on morphology, mechanical properties, hydrophilicity, in vitro degradation rate, and pH alteration of the scaffolds. We, also, evaluated attachment, viability, and proliferation of human neuroblastoma cells on the scaffolds as candidates for nerve tissue engineering.

Materials and Methods

Materials

Chitosan (Mw = 220,000, 90% deacetylation) was purchased from Easter holding group, China. Dulbecco’s modified Eagle’s medium (DMEM) and fetal bovine serum (FBS) were purchased from Gibco, Grand Island, NY. Poly (L-lactic acid) (PLLA, intrinsic viscosity of ~ 2.0 dl/g), acetic acid, chloroform, DPPH (1, 1-diphenyl-2-picrylhydrazyl), DAPI (4',6-diamidino-2-phenylindole), and all other reagents and solvents were bought from Sigma-Aldrich, USA. All the materials were of analytical grade. Lactate Dehydrogenase Activity Assay Kit was purchased from Sigma-Aldrich, USA.

Scaffold Fabrication

PLLA and chitosan were dissolved in chloroform and acetic acid/water (50:50) at 60 °C for 4 h, respectively. We chose PLLA and CS with the ratio of 1:5 (v:v) because of appropriate mechanical properties and good biocompatibility according to the literature [43]. To prepare PLLA/CS blends, CS solutions 3, 4, 6, and 8w/v% was added to PLLA 3, 4, 6 and 8w/v% solutions, respectively, with the rate of one droplet per minutes using a syringe pump (SP1000, Fanavaran Nano-Meghyas, Iran), and stirred at 60 °C for 2 h. To start LLPS, the solutions were rapidly pre-quenched from 60 °C to 20 °C and maintained at this temperature for 10 min. 20 °C was chosen to maintain the solutions over the freezing point of used solvents (-63.5 °C and 16 °C for chloroform and acetic acid, respectively). The cloud-point was determined by visual turbidimetry according to the method recently explained by Hua et al. [21]. After placing the scaffolds into a liquid nitrogen at − 196 °C for 3 h, they were instantly transferred into a freeze dryer at − 77 °C (121550PMMA, Christ, Spain) for 48 h. Crosslinking of CS was performed by placing it into glutaraldehyde solution [0.25% (w/w)] overnight at 25 °C. Afterward, the scaffolds were washed several times and kept in the refrigerator at 4 °C for further assessments.

Scaffold Characterization

Scanning Electron Microscopy

The specimens were coated by gold using a sputter coater (SCD 004, Balzers, Germany), and observed with a Scanning Electron Microscope (SEM, DSM 960A, Zeiss, Germany) at 15–20 kV.

Porosity Measurement

Liquid displacement method was considered for porosity measurement with regard to this equation [18]:

V1 is initial volume, V2 is volume after the scaffold was soaked into 96% ethanol, and V3 is the volume of ethanol after the scaffold was removed.

Mechanical Properties Measurement

Both tensile and compressive strengths of the scaffolds were measured. For tensile strength measurement, rectangular samples (60 × 10 mm) were stretched using Instron 5566 (Instron, USA) at a strain rate of 1 mm/min. For compressive strength measurement, cylindrical samples (height of 35 mm and diameter 20 mm) were squeezed using a dynamic testing machine (HCT400/25, Zwick/Roell, Germany) at a crosshead speed of 1.3 mm/min.

Contact Angle Measurement

The hydrophilicity of the specimens was evaluated by utilizing static water contact angle measurements with a sessile drop method (contact angle measuring system G10, KRUSS, Germany). The water contact angles of scaffolds were evaluated by the Zisman method [35].

In Vitro Degradation and pH Alteration

In order to measure scaffold weight loss, the specimens were immersed in 10 ml of three different media; distilled water, DMEM, and DMEM supplemented with FBS (10% v/v) for 30 and 60 days. The medium was replaced with the fresh one every week. After each interval, the samples were filtrated, washed with distilled water, and dried under vacuum. The weight loss was measured using this equation [5, 24]:

where W0 is the initial weight of samples and W1 is the dry weight after being removed from the media.

Scaffolds were kept in normal saline (pH 6.70) at 37 °C for a total period of 6 weeks. The pH was evaluated every week using Inolab pH 720 (WTW, Germany).

In Vitro Study

Cell Culture and Seeding

Human neuroblastoma cell line (BE (2)-C) (Pasteur Institute national cell bank, Tehran, Iran) was used. The cells were cultured in DMEM supplemented with 10% (v/v) FBS in a humidified incubator at 37 °C with 5% CO2. For scaffold sterilization, the samples were immersed into 75% ethanol for 1 h and dried under vacuum for 12 h, then exposed to ultra-violet (UV) radiation for 30 min. The scaffolds were put into a 96-well plate and 1 × 104 third passage cells were seeded on each scaffold and incubated for 3 h. Then, 0.5 ml cell culture medium was added into each well. The medium was replaced every day. The samples were triplicate for each further analysis.

Cell Attachment on the Scaffold

Morphology of human neuroblastoma cells attached to the scaffolds was evaluated 72 h after cell seeding using SEM. The attached cells were fixed with glutaraldehyde 2.5% for 2 h, dried with ethanol 30, 70, 80, 90, and 100% each for 10 min, respectively, and freeze-dried in -55ºC for 24 h.

The number of attached cells was measured using MTT (3-(4,5-Dimethylthiazol-2-yl)-2,5-Diphenyltetrazolium Bromide) assay. The cells were seeded on the scaffolds and immediately incubated for 6 h; then, the scaffolds were washed twice with PBS for 30 s. MTT assay was performed on the scaffolds placed in new wells, and the percentage of attached cells was computed according to the bellow equation: [7]

where ODt is the mean absorbance value of the specimens and ODc is the mean absorbance value of the positive control.

Cell Proliferation and Viability on the Scaffold

Cell proliferation was assessed by MTT analysis after 24 and 72 h of cell seeding. After removing the medium, 0.2 ml of 0.5 mg/ml MTT was added to each well and incubated at 37 °C for 4 h. Then, after adding 0.1 ml dimethyl sulfoxide (DMSO) to dissolve formed purple formazan crystals, absorption was determined at 570 nm using a microplate spectrophotometer (Stat fax-2100, Awareness technology Inc, USA). The positive control was the medium without the scaffold.

In order to assess the effects of free radical released from the scaffolds on cell viability, a DPPH assay was performed after 72 h of cell seeding. The violet DPPH solution was prepared by adding 4.3 mg DPPH powder to 3.3 ml methanol on a magnetic stirrer for 20 min. The scaffolds were soaked in distilled water for 20 min and after being transferred to a 96-well plate, 0.05 ml methanol was added to each well. After 45 min, 0.1 ml of DPPH solution was added and the plate was placed in a dark room for 15 min. The absorption rate was observed by a microplate spectrophotometer at 490 nm.

The rate of cell death on the scaffold was analyzed using a lactate dehydrogenase (LDH) activity assay after 72 h of cell seeding using Lactate Dehydrogenase Activity Assay Kit. Changing the color was quantified after 15 min using a microplate spectrophotometer at 450 nm.

Statistical Analysis

SPSS version 21 (Microsoft, IL, USA) was used for data analysis. The data were expressed as the mean and standard deviation. An independent sample t-test was performed for comparing the differences in terms of absorbance obtained from MTT, DPPH and, LDH analyses. P < 0.05 was considered statistically significant.

Results and Discussion

Morphology of the Scaffolds

In this study, we used the LLPS method to fabricate a desirable highly porous PLLA/CS blend scaffold which can be utilized in nerve tissue engineering. The morphology of the fabricated scaffolds is shown in Fig. 1. The SEM images showed that the diameter of pores decreased by increasing total concentration of polymeric solutions. With changing the PLLA solvent of 1,4 dioxane/water (87:13) used in a previous study [36] with chloroform in the current study, the formation of nanofibrous structure could be observed in PLLA/CS blend scaffolds.

The porosity of the scaffolds was evaluated using the liquid displacement method [Table1]. Data indicated that the porosity of the prepared scaffolds was decreased by increasing the polymeric concentration. In fact, the increase of the polymeric concentration which leads to the reduction of the volume of solvent can be the reason of decreasing the porosity and pore size since it causes the rise of viscosity which leads to the reduction of phase separation process kinetics and slow growth of the polymer-rich and solvent-rich [20].

Mechanical Properties of the Scaffolds

Proper flexibility is an essential factor for the engineered conduit to resist rearing and stretching forces [28, 42]. However, it should be noticed that the high rigidity of the conduit may exert chronic compression to the regenerated nerve. Panseri et al., also, demonstrated that electrospun nerve conduits without enough mechanical support could not bear forces and collapse in vivo [29]. Mechanical properties of the current scaffolds are shown in Table 2. Both compressive and tensile strength of the PLLA/CS blend scaffolds was in the favorable range for not only nerve tissue engineering but also for cartilage tissue engineering [33, 45]. The tensile strength of PLLA/CS blend scaffolds was greater than CS scaffold but lower than PLLA scaffold. Although the incorporation of CS reduced the tensile strength of the PLLA, it increased compressive strength and the more desirable behaviors of human neuroblastoma cells on the scaffolds (according to the part of 3.5). Also, it can be observed that increasing the polymeric concentration can lead to a decrease of tensile strength in PLLA/CS blend scaffolds; therefore, PLLA/CS (3w/v%) showed the best tensile strength compared to other blend scaffolds. Furthermore, the compressive strength was enhanced by blending PLLA with CS. In addition, it was increased by increasing the polymeric concentration in PLLA/CS blend scaffolds; in fact, increasing polymeric concentration led to a decrease in the percentage of porosity and pore size, which can be the reason of the mechanical strength increasing.

Hydrophilicity of the Scaffolds

The hydrophilicity of the scaffolds was measured using water contact angle measurement. The water contact angle of the scaffolds is shown in Table 3. It can be observed that the contact angle of PLLA/CS blends was greater than chitosan and less than pure PLLA. To illustrate, the hydrophobicity of pure PLLA which is due to the methyl groups decreased by blending with CS due to its hydroxyl (OH) and NH2 groups [36]. It was reported that optimal water contact angle values should be in the range of 45–70° or in the region of 30–60° in order to obtain maximal cell adhesion [12]. Increasing the polymeric concentration in PLLA/CS blend scaffolds led to decrease of the water contact angle value and more hydrophilicity. Indeed, in a very low contact angle value, protein adsorption which is necessary for cell recognition and attachment is reduced because of increasing the water uptake of scaffolds. Also, at very high contact angle values, cell-conductive behaviors are excessively low, and protein denaturing response can be observed [12].

In Vitro Degradation and pH Alterations of the Scaffolds

The proper degradation rate is an important factor to retain the stability of engineered conduit shape during the nerve regeneration process [14, 42]. In vitro degradation of the scaffolds was measured after 30 and 60 days post immersing scaffolds in 3 different media [Table 4]. The results indicated that weight loss in DMEM/FBS medium was greater than others, which can be attributed to the presence of some enzymes in FBS [5, 24]. La Carrubba et al. reported weight loss of PLLA scaffolds fabricated by TIPS method after 30 and 60 days about 1.1 and 1.3% in DMEM and 22.1 and 24.6% in DMEM/FBS, respectively [5, 24]. Increasing the polymeric concentration in PLLA/CS blend scaffolds led to slow degradation rate in the three different media. However, scaffolds consisting of CS revealed more weight loss compared to other scaffolds. In fact, the high hydrophilicity of CS made this polymer highly degradable in the medium.

The pH changes are shown in Fig. 2. After 3 weeks, the PLLA scaffold revealed a significant decreasing in the pH value from 6.7 to 5.21, but pH value of the CS and PLLA/CS scaffolds reduced slowly from 6.7 to 6.49 and a minimum of 6.34, respectively. Hydrolytic degradation of steric bonds in PLLA results in non-toxic byproducts of lactic acid which decreases the pH range [47].While the decline of the pH value can increase the degradation rate of the polymer [41], the degradation of the PLLA scaffold followed by the further release of lactic acid into the medium can cause a significant decrease in the pH value. Nevertheless, CS can increase the pH value because of the amino (NH2) groups on its chains, so slow down of the pH value reduction can be seen in PLLA/CS blend scaffolds.

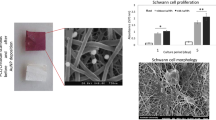

Attachment, Viability, and Proliferation of Human Neuroblastoma Cells on the Scaffolds

The human neuroblastoma cells attachment on the scaffolds is shown in Fig. 3. The cells attached on the PLLA scaffolds showed almost spherical morphology with a poor spreading tendency (Fig. 3E). Better cell adhesion and spreading were observed in both CS and PLLA/CS scaffolds. It can be due to the suitable hydrophilicity of the fabricated blend provided by functional groups of CS.

The percentage of attached cells on the scaffolds was evaluated by MTT assay is shown in Fig. 4A. All of the scaffolds provided a favorable environment for cell adhesion. The control human neuroblastoma undoubtedly showed the highest cell attachment percentage to the plate and considered as a reference. Cell attachment enhanced from 78.2% in PLLA to 94.3% in PLLA/CS 3w/v%. Cell attachment decreased by increasing the polymeric concentration in PLLA/CS blend scaffolds.

MTT assay, also showed cell viability and proliferation on all scaffolds after 24 and 72 h of cell seeding (Fig. 4B). The PLLA/CS blend scaffolds showed more cell viability compared to both PLLA and CS scaffolds; however, there were no statistically significant differences between all of the scaffolds (P > 0.05). Also, PLLA/CS (3w/v%) had more optical density compared to others. PLLA/CS blend scaffolds demonstrated increasing cell viability compared to PLLA scaffold; in fact, not only high hydrophobicity of pure PLLA be the main cause of this result, but also the cationic nature of CS improve cell proliferation and attachment due to the negative charge of the cell surface[46]. CS scaffolds despite the fact that had higher hydrophilicity compared to PLLA/CS, they were unable to increase the cell attachment compared to PLLA/CS blend scaffolds, as PLLA/CS blend scaffolds showed favorable cell viability in the literature [43].

The results of DPPH assay of cells seeded scaffolds after 72 h displayed significantly decreasing of cell viability on PLLA scaffolds compared to the other scaffolds Fig. 4C. It could be noticed that the effect of free radical release could be more exhibited by increasing the polymeric concentration in PLLA/CS blend scaffolds. DPPH assay prepares facilitate way to measure the free radical release of scaffolds which can be cytotoxic for the cells. In the presence of free radicals, the color of DPPH solution changes from deep violet to light yellow. Implement this method on the scaffolds showed that the pure PLLA was more potent to release free radicals and decline cell viability, but the blend form of PLLA with CS could decrease the free radical release.

The results of the LDH assay showed no significant differences between scaffolds 72 h after cell seeding (P > 0.05) (Fig. 4D). Nonetheless, LDH activity was higher in PLLA group than others. Cell death processes finally cause an increasing in cell membrane permeability leading to the release of cytoplasmic enzymes like LDH into the culture medium [44]; in other words, LDH release into the culture medium indicates compromised membrane integrity, so the greater LDH activity the greater cell damage. Pure PLLA showed more cell death compared to others even though the differences were not statistically significant. It can be because of more free radical release from pure PLLA consistent with the results of DPPH assay. However, blending with CS diminished the cytotoxicity of pure PLLA.

Conclusions

In the present study, we successfully introduced the PLLA/CS nanofibrous 3-D scaffold fabricated by the LLPS method as a suitable candidate for nerve tissue engineering. We demonstrated improvement of physical characteristics by blending PLLA with CS. Also, the PLLA/CS blend scaffolds demonstrated not only favorable cell compatibility, but also desirable proliferation and attachment of human neuroblastoma cells. Moreover, increasing the polymeric concentration in PLLA/CS blend scaffolds can influence their characteristics and cell behaviors.

References

Bastami, F., & Khojasteh, A. (2016). Use of leukocyte-and platelet-rich fibrin for bone regeneration: a systematic review regeneratio. Regeneration Reconstruction & Restoration, 1, 47–68.

Bastami, F., Paknejad, Z., Jafari, M., Salehi, M., Rad, M. R., & Khojasteh, A. (2016). Fabrication of a three-dimensional β-tricalcium-phosphate/gelatin containing chitosan-based nanoparticles for sustained release of bone morphogenetic protein-2: Implication for bone tissue engineering. Materials Science and Engineering C, 72, 481–491.

Bastami, F., Vares, P., & Khojasteh, A. (2016). Healing Effects of Platelet-Rich Plasma on Peripheral Nerve Injuries. Journal of Craniofacial Surgery, 28(1), 49–57.

Bastami, F., Vares, P., & Khojasteh, A. (2017). Healing effects of platelet-rich plasma on peripheral nerve injuries. Journal of Craniofacial Surgery, 28, e49–e57.

Carrubba, V., Pavia, F. C., Brucato, V., & Piccarolo, S. (2008). PLLA/PLA scaffolds prepared via thermally induced phase separation (TIPS): Tuning of properties and biodegradability. International Journal of Material Forming, 1, 619–622. https://doi.org/10.1007/s12289-008-0332-5

Chen, C., Dong, L., & Cheung, M. K. (2005). Preparation and characterization of biodegradable poly(l-lactide)/chitosan blends. European Polymer Journal, 41, 958–966. https://doi.org/10.1016/j.eurpolymj.2004.12.002

Chen, L., et al. (2013). Electrospun poly (L-lactide)/poly (ε-caprolactone) blend nanofibrous scaffold: characterization and biocompatibility with human adipose-derived stem cells. PLoS ONE, 8(8), e71265.

Chen, S., He, Z., Xu, G., & Xiao, X. (2016). Fabrication and characterization of modified nanofibrous poly (L-lactic acid) scaffolds by thermally induced phase separation technique and aminolysis for promoting cyctocompatibility. Journal of Biomaterials Science Polymer Edition, 27, 1058–1068.

Chen, S., Zhao, X., & Du, C. (2018). Macroporous poly (l-lactic acid)/chitosan nanofibrous scaffolds through cloud point thermally induced phase separation for enhanced bone regeneration. European Polymer Journal, 109, 303–316.

Dahlin, L., Johansson, F., Lindwall, C., & Kanje, M. (2009). Future perspective in peripheral nerve reconstruction. International Review of Neurobiology, 87, 507–530.

Duarte, A. R. C., Mano, J. F., & Reis, R. L. (2010). Novel 3D scaffolds of chitosan–PLLA blends for tissue engineering applications: Preparation and characterization. The Journal of Supercritical Fluids, 54, 282–289. https://doi.org/10.1016/j.supflu.2010.05.017

Edlund, U., Sauter, T., & Albertsson, A. C. (2011). Covalent VEGF protein immobilization on resorbable polymeric surfaces. Polymers for Advanced Technologies, 22, 166–171.

Evans, G. R. (2001). Peripheral nerve injury: A review and approach to tissue engineered constructs. The Anatomical Record, 263, 396–404.

Farokhi, M., Mottaghitalab, F., Shokrgozar, M. A., Kaplan, D. L., Kim, H.-W., & Kundu, S. C. (2017). Prospects of peripheral nerve tissue engineering using nerve guide conduits based on silk fibroin protein and other biopolymers. International Materials Reviews, 62, 367–391.

Ghasemi-Mobarakeh, L., Prabhakaran, M. P., Morshed, M., Nasr-Esfahani, M.-H., & Ramakrishna, S. (2008). Electrospun poly (ɛ-caprolactone)/gelatin nanofibrous scaffolds for nerve tissue engineering. Biomaterials, 29, 4532–4539.

Ghasemi-Mobarakeh, L., Prabhakaran, M. P., Morshed, M., Nasr-Esfahani, M.-H., & Ramakrishna, S. (2008). Electrospun poly(ɛ-caprolactone)/gelatin nanofibrous scaffolds for nerve tissue engineering. Biomaterials, 29, 4532–4539. https://doi.org/10.1016/j.biomaterials.2008.08.007

Habre, S. B., Bond, G., Jing, X. L., Kostopoulos, E., Wallace, R. D., & Konofaos, P. (2018). The surgical management of nerve gaps: Present and future. Annals of Plastic Surgery, 80, 252–261.

Ho, S. T., & Hutmacher, D. W. (2006). A comparison of micro CT with other techniques used in the characterization of scaffolds. Biomaterials, 27, 1362–1376. https://doi.org/10.1016/j.biomaterials.2005.08.035

Holzwarth, J. M., & Ma, P. X. (2011). Biomimetic nanofibrous scaffolds for bone tissue engineering. Biomaterials, 32, 9622–9629.

Hua, F. J., Kim, G. E., Lee, J. D., Son, Y. K., & Lee, D. S. (2002). Macroporous poly (L-lactide) scaffold 1. Preparation of a macroporous scaffold by liquid–liquid phase separation of a PLLA–dioxane–water system. Journal of Biomedical Materials Research, 63, 161–167.

Hua, F. J., Kim, G. E., Lee, J. D., Son, Y. K., & Lee, D. S. (2002). Macroporous poly(L-lactide) scaffold 1. Preparation of a macroporous scaffold by liquid–liquid phase separation of a PLLA–dioxane–water system. Journal of Biomedical Materials Research, 63, 161–167.

Jeon, S., Karkhanechi, H., Fang, L.-F., Cheng, L., Ono, T., Nakamura, R., & Matsuyama, H. (2018). Novel preparation and fundamental characterization of polyamide 6 self-supporting hollow fiber membranes via thermally induced phase separation (TIPS). Journal of Membrane Science, 546, 1–14.

Khojasteh, A., et al. (2016). Development of PLGA-coated β-TCP scaffolds containing VEGF for bone tissue engineering. Materials Science and Engineering C, 69, 780–788.

La Carrubba, V., Pavia, F. C., Brucato, V., & Piccarolo, S. (2008). PLLA/PLA scaffolds prepared via Thermally Induced Phase Separation (TIPS): tuning of properties and biodegradability International. Journal of Material Forming, 1, 619–622.

Li, X.-T., Zhang, Y., & Chen, G.-Q. (2008). Nanofibrous polyhydroxyalkanoate matrices as cell growth supporting materials. Biomaterials, 29, 3720–3728.

Lim, J. I., Im, H., & Lee, W.-K. (2015). Fabrication of porous chitosan-polyvinyl pyrrolidone scaffolds from a quaternary system via phase separation Journal of Biomaterials Science. Polymer Edition, 26, 32–41.

Meyer, C., et al. (2016). Chitosan-film enhanced chitosan nerve guides for long-distance regeneration of peripheral nerves. Biomaterials, 76, 33–51.

Mohamadi, F., et al. (2017). Electrospun nerve guide scaffold of poly (ε-caprolactone)/collagen/nanobioglass: An in vitro study in peripheral nerve tissue engineering. Journal of Biomedical Materials Research Part A, 105, 1960–1972.

Panseri, S., et al. (2008). Electrospun micro-and nanofiber tubes for functional nervous regeneration in sciatic nerve transections. Bmc Biotechnology, 8, 1.

Prabaharan, M., Rodriguez-Perez, M. A., de Saja, J. A., & Mano, J. F. (2007). Preparation and characterization of poly(L-lactic acid)-chitosan hybrid scaffolds with drug release capability. Journal of Biomedical Materials Research Part B Applied Biomaterials, 81B, 427–434. https://doi.org/10.1002/jbm.b.30680

Ranjbar-Mohammadi, M., Prabhakaran, M. P., Bahrami, S. H., & Ramakrishna, S. (2016). Gum tragacanth/poly (l-lactic acid) nanofibrous scaffolds for application in regeneration of peripheral nerve damage. Carbohydrate Polymers, 140, 104–112.

Rasal, R. M., Janorkar, A. V., & Hirt, D. E. (2010). Poly(lactic acid) modifications. Progress in Polymer Science, 35, 338–356. https://doi.org/10.1016/j.progpolymsci.2009.12.003

Rotter, N., Bücheler, M., Haisch, A., Wollenberg, B., & Lang, S. (2007). Cartilage tissue engineering using resorbable scaffolds. Journal of Tissue Engineering and Regenerative Medicine, 1, 411–416.

Salehi, M., & Bastami, F. (2016). Characterization of wet-electrospun poly (ε-caprolactone)/poly (L-lactic) acid with calcium phosphates coated with chitosan for bone engineering regeneration. Reconstruction & Restoration, 1, 69–74.

Salehi, M., Farzamfar, S., Bastami, F., & Tajerian, R. (2016). Fabrication and characterization of electrospun PLLA/collagen nanofibrous scaffold coated with chitosan to sustain release of aloe vera gel for skin tissue engineering. Biomedical Engineering Applications Basis and Communications, 28, 1650035.

Salehi, M., Naseri Nosar, M., Amani, A., Azami, M., Tavakol, S., & Ghanbari, H. (2015). Preparation of pure PLLA, pure chitosan, and PLLA/Chitosan blend porous tissue engineering scaffolds by thermally induced phase separation method and evaluation of the corresponding mechanical and biological properties. International Journal of Polymeric Materials and Polymeric Biomaterials, 64, 675–682.

Scherman, P., Kanje, M., & Dahlin, L. B. (2003). Bridging short nerve defects by direct repair under tension, nerve grafts or longitudinal sutures. Restorative Neurology and Neuroscience, 22, 65–72.

Schugens, C., Maquet, V., Grandfils, C., Jerome, R., & Teyssie, P. (1996). Polylactide macroporous biodegradable implants for cell transplantation. II Preparation of polylactide foams by liquid-liquid phase separation. Journal of Biomedical Materials Research, 30, 449–461.

Shao, J., Chen, C., Wang, Y., Chen, X., & Du, C. (2012). Early stage structural evolution of PLLA porous scaffolds in thermally induced phase separation process and the corresponding biodegradability and biological property. Polymer Degradation and Stability, 97, 955–963. https://doi.org/10.1016/j.polymdegradstab.2012.03.014

Vasita, R., & Katti, D. S. (2006). Nanofibers and their applications in tissue engineering. International Journal of Nanomedicine, 1, 15.

Vieira, A. C., Vieira, J. C., Ferra, J. M., Magalhães, F. D., Guedes, R. M., & Marques, A. T. (2011). Mechanical study of PLA–PCL fibers during in vitro degradation. Journal of the Mechanical Behavior of Biomedical Materials, 4, 451–460. https://doi.org/10.1016/j.jmbbm.2010.12.006

Wang, W., Itoh, S., Matsuda, A., Ichinose, S., Shinomiya, K., Hata, Y., & Tanaka, J. (2008). Influences of mechanical properties and permeability on chitosan nano/microfiber mesh tubes as a scaffold for nerve regeneration. Journal of Biomedical Materials Research Part A, 84, 557–566.

Xie, F., Li, Q. F., Gu, B., Liu, K., & Shen, G. X. (2008). In vitro and in vivo evaluation of a biodegradable chitosan–PLA composite peripheral nerve guide conduit material. Microsurgery, 28, 471–479.

Ying, H. S., Gottron, F. J., & Choi, D. W. (2001). Assessment of cell viability in primary neuronal cultures. Current Protocols in Neuroscience, 7(18), 11–17.

Yu, W., et al. (2011). Sciatic nerve regeneration in rats by a promising electrospun collagen/poly (ε-caprolactone) nerve conduit with tailored degradation rate. BMC Neuroscience, 12, 1.

Yue, Z.-G., Wei, W., Lv, P.-P., Yue, H., Wang, L.-Y., Su, Z.-G., & Ma, G.-H. (2011). Surface charge affects cellular uptake and intracellular trafficking of chitosan-based nanoparticles. Biomacromolecules, 12, 2440–2446.

Zhang, X., Hua, H., Shen, X., & Yang, Q. (2007). In vitro degradation and biocompatibility of poly(l-lactic acid)/chitosan fiber composites. Polymer, 48, 1005–1011. https://doi.org/10.1016/j.polymer.2006.12.028

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ehterami, A., Masoomikarimi, M., Bastami, F. et al. Fabrication and Characterization of Nanofibrous Poly (L-Lactic Acid)/Chitosan-Based Scaffold by Liquid–Liquid Phase Separation Technique for Nerve Tissue Engineering. Mol Biotechnol 63, 818–827 (2021). https://doi.org/10.1007/s12033-021-00346-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12033-021-00346-3