Abstract

The goal of quality by design (QbD) in cell culture manufacturing is to develop manufacturing processes which deliver products with consistent critical quality attributes (CQAs). QbD approaches can lead to better process understanding through the use of process parameter risk ranking and statistical design of experiments (DOE). The QbD process starts with an analysis of process parameter risk with respect to CQAs and key performance indicators (KPIs). Initial DOE study designs and their factor test ranges are based on the outcomes of the process parameter risk ranking exercises. Initial DOE studies screen factors for significant influences on CQAs as well as characterize responses for process KPIs. In the case study provided here, multifactor process characterization studies using a scale-down model resulted in significant variation in charge heterogeneity of a monoclonal antibody (MAb) as measured by ion-exchange chromatography (IEC). Iterative DOE studies, using both screening and response surface designs, were used to narrow the operating parameter ranges so that charge heterogeneity could be controlled to an acceptable level. The data from the DOE studies were used to predict worst-case conditions, which were then verified by testing at those conditions. Using the approach described here, multivariate process parameter ranges were identified that yield acceptable CQA levels and that still provide operational flexibility for manufacturing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of quality by design (QbD) concepts in process characterization and validation of cell culture processes that produce therapeutic recombinant proteins is evolving within the biopharmaceutical industry. QbD involves conducting science-based risk analyses which in turn define the statistically designed studies used to gain understanding of how variation in process parameters affects product quality [1]. Design of experiments (DOE)-based strategies to validate cell culture processes producing monoclonal antibodies (MAbs) have been used previously [2], and QbD approaches have been published for various aspects of integrated bioprocesses [3]. Advances in analytical methods and the increased scrutiny on product quality attributes and process-related impurities have made the use of DOE increasingly important during process validation because of the need to build quality into processes rather than rely on quality control testing [1, 4]. DOE-based approaches can provide a deeper understanding of how product quality attributes and process-related impurities change when several process operating parameters vary simultaneously for a given unit operation, and thus lead to increased process knowledge with respect to the robustness of a culture step or combination of culture steps.

In this work, a QbD approach was used to characterize the inoculum and production culture steps of a Chinese Hamster Ovary (CHO) MAb process. After operating parameters were assessed for risks to critical quality attributes (CQAs) and key performance indicators (KPIs), initial multivariate studies were designed and executed. Statistical modeling of factor effects on CQAs was performed, and follow-up studies were designed to further understand and control the parameter impact to the CQA with the widest variation, (acidic MAb species, i.e. acidic variants). Acidic variant levels of the product, as quantified by ion-exchange chromatography (IEC), are a surrogate for multiple CQAs (such as deamidation and glycation). Finally, the model-predicted worst-case conditions were tested for each step separately, and in combination, to define the multivariate operating ranges (MARs) of each tested operating parameter. The results showed that the acidic variants could be controlled to acceptable levels even when the process parameters were operated at the edges of their proposed MARs. The combination of MARs and proven acceptable ranges or PARs, as defined in industry guidance documents [1, 5] and which are derived from univariate studies, eventually lead to the design space description for the process.

Methods

A 2-l scale-down bioreactor system which has previously been qualified for various Genentech commercial products [6] was used to generate data for the QbD characterization approach for this MAb production process. In the process, CHO cells expressing the MAb of interest are first cultured in selective media (seed train) followed by three non-selective media passages (inoculum train) prior to the fed-batch production culture. CHO cultures, grown in proprietary media, are maintained in the seed train up to a pre-defined length of time prior to initiating all inoculum trains. All production cultures were maintained for at least the target harvest duration. Samples are analyzed daily for packed cell volume % (PCV %), culture viability, pH, glucose concentration and MAb titer. Clarified harvested cell culture fluid was processed through a qualified scale-down Protein A chromatography step prior to performing any product quality or process-related impurity assays. While this report focuses on the response in charge variants, specifically the acidic species of the MAb resulting from the cases within each multivariate study, other product quality attributes and process-related impurities were also measured (data not shown). Acidic variants were quantified by high performance IEC following carboxypeptidase B treatment (to remove C-terminal lysine residues) of Protein A product pools of each production culture.

For characterization of the last non-selective culture (N-1) prior to production (N), five operating parameters were studied. N-1 cultures from each DOE case (for all N-1 characterization studies) are used to inoculate a production culture performed at target conditions, where the CQAs are then assessed. Four parameters: culture pH, culture temperature, culture medium concentration and seeding density were evaluated in fractional factorial designs. An additional parameter, culture duration, was extended for all study cases in the initial wide range study. In the follow up, narrowed range study, N-1 cultures were grown to the target duration based on cell growth as assessed by PCV %. In the narrowed range study, three of the four factors had their operating ranges narrowed (all but culture pH) based on least squares regression (ANOVA) modeling of acidic variant levels in the initial study data. Data from these two studies were used to derive the worst-case operating levels of all four parameters. Those worst-case conditions were tested in combination along with extended culture duration for a true worst-case evaluation.

For characterization of the production culture (N), nine operating parameters were initially studied at wide ranges. Eight parameters were evaluated in a fractional factorial design and included culture pH, culture temperature, culture medium concentration, seeding density, pH and temperature shift times, batch feed level (combining feed concentration and volume) and batch feed time. Similar to the initial N-1 study, all N culture cases in the initial wide range study were carried out for an extended duration. The three most significant factors, as determined from statistical modeling of acidic variant results from the initial study, were the focus of a follow up study in which their operating ranges were narrowed. The factors of interest in the narrowed range study were pH, temperature, and temperature shift time. The narrowed range study (second study) was a 3-factor central composite design (factorial and axial points) which included the other five operating parameters set at their targets and the cultures being carried out to their target duration. Data from these two studies were used to predict the worst-case levels of all eight operating parameters and those conditions were tested in combination with extended N culture duration for a true worst-case evaluation of the MAb production process. Table 1 summarizes the study designs described here for the N-1 and N culture steps. The overall strategy for N-1 inoculum train and production process characterization can be thought of as testing the key operating parameters for multivariate acceptable ranges (MARs) and then verifying those ranges by testing the predicted worst case process with respect to a governing CQA.

Results

As the operating parameter ranges were narrowed, and extended N-1 culture duration was removed from the study design, the acidic variant response was improved (i.e. lowered; Fig. 1). Individual acidic variant responses are shown along with process parameter values for each case in Fig. 1 panels A and B. Controls cases performed at target process conditions resulted in acidic variant levels of 28–31% (Fig. 1, panels A and B arrows). Acidic variant levels were as high as 41% in the initial study (Fig. 1, panel A). Cases at low seed density led to high acidic variants compared to the target process. When medium concentration, lower seed density and culture temperature levels were narrowed, as well as the elimination of extended culture duration, the acidic variant levels in the low seed cases dropped dramatically relative to the initial study (Fig. 1, panel B). The highest level of acidic variants in the narrowed range study was 32%, which is a value very close to the control process range.

The data are acidic variant levels from production cultures derived from inoculum cultures grown under the stated conditions. Arrows mark the control process, where medium concentration = 100%, temperature = 37 °C, pH = 7.15 and seed density = 0.10 PCV %. Panel A shows data from the initial, wider range, N-1 study. Panel B shows data from the narrowed range N-1 study. In both the panels, data to the left of the control are all low seed density cases and data to the right of the control are all high seed density cases. In the narrowed range study, the lower level of seed density was increased to 0.06 PCV%, the temperature range was narrowed to ±0.6 °C and medium concentration was narrowed to ±15% of target. This led to decreased acidic variants in the low seed cases

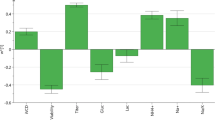

The initial wide range N study main effects model is described in Table 2, including parameter estimates and p-values from ANOVA, for each operating parameter that was tested. In the initial N study, acidic variant responses rose as high as 44%. Control production cultures harvested at the same run duration had acidic variant levels of 29–32%, which is normal for the process when culture duration is extended. The parameter estimates in Table 2 show the predicted effect of the operating parameter on acidic variant levels as the parameter level changes from its midpoint to its high or low setting. For example, as initial culture temperature is changed from 37 to 38 °C, acidic variants are predicted to increase 1.9%. The standard error of the main effect model from this study is 0.73%. In the initial N study, three operating parameters had estimates with p < 0.10. These parameters were culture pH, temperature and temperature shift time (Table 2). These three factors were further studied in a 3-factor central composite design; this type of experimental design includes full factorial cases and axial (or univariate) cases for all three factors. The test ranges in the factorial portion of the design for temperature and temperature shift time were narrowed in this study while initial pH, due to manufacturing capability considerations, was tested under the same range as in the initial production study. Figure 2 shows the predicted response in acidic variants, as derived from the 3-factor central composite study, as pH and temperature vary within the factorial (multivariate) and axial (univariate) ranges tested. Temperature shift time in this study had a much smaller effect on acidic variants compared to pH and temperature.

Culture temperature and pH had the largest effects on acidic variants in the narrowed range production study. The contour plot shows the predicted response in acidic variants as these two operating parameters change within their prospective multivariate and proven acceptable ranges (MAR and PAR, respectively). The highest level of acidic variants was 35% in this study. Temperature and pH had the largest impact on acidic variants for this cell culture production process

Worst-case settings with respect to acidic variant levels for each operating parameter, for both the N-1 and N culture steps, were predicted from the data described in Figs. 1 and 2 and Table 2. Three worst-cases were studied: [1] the worst-case N-1 settings, including extended N-1 culture duration, followed by target N; [2] worst-case N with extended N culture duration, derived from target N-1 culture; and [3] the combination of worst-case N-1 and worst-case N, both with extended culture duration. Based on statistical models of the previous studies, acidic variant levels were expected to be higher than in the narrowed range study, but lower than those observed in the initial wide range study. Table 3 shows that this expectation was met.

Discussion

This work illustrates that a QbD approach can be successfully used to characterize a CHO cell culture MAb production process. The approach that was used is conceptually similar to the current guidance on QbD [1, 5, 7]. In general, the strategy is to identify CPPs and to define the operating ranges of process parameters through the use of iterative multivariate (DOE) and targeted univariate experiments. Statistical modeling is then applied and predicted worst-case conditions are tested to confirm the representativeness of the model. The experiments for a QbD-based validation of an overall manufacturing process should include linkage of upstream and downstream unit operations. The results of experiments which link unit operations serve to rigorously establish an overall process design space which delivers acceptable CQA levels. The way in which QbD and linkage studies are performed is evolving.

At target processing conditions, the cell culture process used for this work typically generates acidic variant levels of 27–31%. Multivariate studies where culture parameters were operated at initially wide ranges showed that acidic variant levels could become as high as 44%. The use of iterative DOE enabled focusing on key parameters driving the acidic variant response. Narrowing process parameter ranges reduced acidic variant to acceptable levels. Although this work focused only on acidic variants, due to the large change in their levels in response to the operating conditions tested, several other CQAs such as glycoforms affecting compliment-dependent cytotoxicity (CDC) and antibody-dependent cellular cytotoxicity (ADCC) potencies, MAb aggregate, as well as process-related impurities were evaluated from the same body of work and found to meet acceptable levels across the proposed design space.

References

FDA (2006) Guidance for industry. Q8 pharmaceutical development. http://www.fda.gov/cder/guidance/6746fnl.pdf.

Moran, E. B., McGowan, S. T., McGuire, J. M., Frankland, J. E., Oyebade, I. A., Waller, W., et al. (2000). A systematic approach to the validation of process control parameters for monoclonal antibody production in fed-batch culture of a murine myeloma. Biotechnology and Bioengineering, 69(3), 242–255.

Xie, L., Wu, H., Shen, M., Augsberger, L. L., Lyon, R. C., Khan, M. A., et al. (2008). Quality-by-design (QbD): Effects of testing parameters and formulation variables on the segregation tendency of pharmaceutical powder measured by the ASTM D 6940-04 segregation tester. Journal of Pharmaceutical Sciences, 97(10), 4485–4497.

McKenzie, P., Kiang, S., Tom, J., Rubin, A. E., & Futran, M. (2006). Can pharmaceutical process development become high tech? AIChE Journal, 52(12), 3990–3994.

Parenteral Drug Association (2005). Process validation of protein manufacturing. Journal of Pharmaceutical Science and Technology, 59, 1–28 (PDA technical report No. 42).

Chaderjian, W. B., Chin, E. T., Harris, R. J., & Etcheverry, T. M. (2005). Effect of copper sulfate on performance of a serum-free CHO cell culture process and the level of free thiol in the recombinant antibody expressed. Biotechnology Progress, 21, 550–553.

van Hoek, P., Harms, J., Wang, X., & Rathore, A. S. (2009) Case study in definition of process design space for a microbial fermentation step. In A. S. Rathore & R. Mhatre (Eds.), Quality by design for biopharmaceuticals (pp. 85–109) New York: Wiley.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horvath, B., Mun, M. & Laird, M.W. Characterization of a Monoclonal Antibody Cell Culture Production Process Using a Quality by Design Approach. Mol Biotechnol 45, 203–206 (2010). https://doi.org/10.1007/s12033-010-9267-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12033-010-9267-4