Abstract

To valorize starchy waste from rice noodle factory, bioconversion of gelatinized starchy waste (GSW) to value-added product as L(+)-lactic acid, the monomer for polylactate synthesis, was investigated using amylolytic lactic acid bacterium, Enterococcus faecium K-1. Screening for appropriate nitrogen source to replace expensive organic nitrogen sources revealed that corn steep liquor (CSL) was the most suitable regarding high efficacy for L(+)-LA achievement and low-cost property. The successful applying statistic experimental design, Plackett-Burman design incorporated with central composite design (CCD), predicted the maximum L(+)-LA of 93.07 g/L from the optimized medium (OM) containing 125.7 g/L GSW and 207.3 g/L CSL supplemented with CH3COONa, MgSO4, MnSO4, K2HPO4, CaCl2, (NH4)2HC6H5O7, and Tween80. Minimizing the medium cost by removal of all inorganic salts and Tween80 from OM was not an effect on L(+)-LA yield. Fermentation using the optimized medium without minerals (OM-Mi) containing only GSW (125.7 g/L) and CSL (207.3 g/L) in a 10-L fermenter was also successful. Thinning GSW with α-amylase from Lactobacillus plantarum S21 increased L(+)-LA productivity in the early stage of 24-h fermentation. Not only showing the feasible bioconversion process for GSW utilizing as a substrate for L(+)-LA production, this research also demonstrated the efficient model for industrial starchy waste valorization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thailand was recognized as one of the large global rice producer, and approximately 55% of the rice production has been distributed for domestic consumption [1, 2]. Apart from the rice consumption as a daily meal, the raw rice is also significantly used as a main substrate for a noodle production in Thailand. In rice noodle-processing factories, large amount of carbohydrate-rich waste/wastewater daily generated during production processes. Those include raw starchy waste suspended in wastewater effluent generated during rice washing, soaking, and milling steps and the gelatinized starchy waste generated during noodle-forming process. Gelatinized starchy waste (GSW), a high concentration of gelatinized rice flour, consists of approximately 9–10% (w/w) total carbohydrate [3, 4]. Regarding the waste management, the bioconversion of carbohydrate-rich waste/wastewater into an alternative fuel and high value-added product, e.g., ethanol and organic acids, has been given attention and developed as one of the efficient and sustainable technologies [5, 6]. In recent years, the lactic acid (LA) production from various carbohydrate-rich or starchy wastes has been interested as its high market potential and various applications in food, textile, leather, and electronic industries as well as the demand of optically pure L(+) or D(−)-LA for serving the bioplastic industry [7, 8].

Direct conversion of starch to LA has been alternatively done by amylolytic lactic acid bacteria (ALAB) which enable to enzymatically hydrolyze starch to refined sugars and LA in single step without saccharification and liquefaction processes. The use of ALAB for LA production from starch waste, i.e., GSW, is cost effective and promising a waste biorefinery technology. Previously, Unban et al. [9] studied the L(+)-LA production from cassava starch using Enterococcus faecium K-1, which a homofermentative ALAB isolated from starchy waste discharged from factory in northern Thailand, cultivated in de Man, Rogosa, and Sharpe (MRS) medium under anaerobic conditions [9]. The authors obtained 99.2% of optically pure L(+)-LA production under the controlled pH conditions of 6.5 even though high starch concentrations up to 150 g/L were applied. This is one of the advantages for industrial LA production from starch-related substrates. The MRS medium used for LA production has conventionally used beef extract, peptone, and yeast extract, as the main nutrient source. Yeast extract is reported for high content of nitrogenous compounds as well as abundant purine, pyrimidine bases, and B vitamins [10, 11]. However, using yeast extract, beef extract, and peptone is uneconomic for LA production which takes almost 40% of the total production cost [12]. Thus, it is necessary to find a cheap nitrogen sources for replacing of the high cost nitrogen source in the medium while the high yield of LA production is still achieved. Some inexpensive nutrients such as corn steep liquor (CSL), hydrolyzed cotton seed flour, hydrolyzed soy flour, and ethanol stillage are capable of yeast extract replacement [13,14,15].

In this paper, we aim to improve the efficiency of L(+)-LA production from a carbohydrate-rich waste, i.e., GSW, by using an effective strain, E. faecium K-1, and find the most cost-effective nitrogen source to substitute for conventional nitrogen sources in MRS medium. The statistical approaches were used to evaluate the optimal nutrient composition for L(+)-LA production from GSW using E. faecium K-1. The optimized low-cost medium obtained in this study has also investigated the feasibility for practical application.

Materials and Methods

Raw Materials

GSW was collected from a rice noodle factory in Chiang Mai, Thailand, and was used as the sole carbon source for L(+)-LA production. The composition of GSW was analyzed particularly the carbohydrate content using the method described by Kanpiengjai et al. [3] which is consisted of starch 97.4% (g/g dry weight) and reducing sugar 4.6% (g/g dry weight). CSL was purchased from Friendship Corn Co., Ltd. (Samutprakarn, Thailand).

Microorganisms

E. faecium K-1 isolated from starchy waste from factory in Chiang Mai area, Thailand, was maintained in the MRS broth with 25% (v/v) glycerol at − 80 °C. It was activated by cultivation in MRS broth at 37 °C for 12 h under static conditions and streaked to single colony prior to utilizing [9].

Modified MRS Medium and Cultivation Conditions

In this study, the modified MRS (mMRS) medium was previously described by Unban et al. [9], but GSW was used as a sole carbon source. The mMRS medium that contained (per liter) 10.0 g of GSW (dry weight basis), 5.0 g of yeast extract, 10.0 g of beef extract, 10.0 g of peptone, 5.0 g of CH3COONa, 1.0 g of Tween80, 2.0 g of K2HPO4, 2.0 of g (NH4)2HC6H5O7, 0.2 g of MgSO4, 0.2 g of MnSO4, and 0.01 g of CaCl2 E. faecium K-1 was enriched by transferring a single colony of the culture to the mMRS medium and incubated at 37 °C for 18 h prior to applying in the test. The obtained culture was used as an inoculum in this study.

Preliminary experiments were conducted in batch cultivations to investigate (i) the activity of E. faecium K-1 in the mMRS medium containing GSW as a sole carbon source and (ii) the optimal nitrogen source for LA production. To evaluate the performance of E. faecium K-1 cultivated in the mMRS medium containing GSW, 1.0% (v/v) inoculum was transferred to a 250-mL laboratory glass bottles (DURAN, Wertheim, Germany) containing 200-mL mMRS medium. The pH was maintained at 6.5 with 10 N NaOH during the incubation. The tested flask was done in triplicate and incubated at 37 °C under static condition for 48-h test. Culture broth was sampling at 6-h intervals to determine viable cell count, the maximum LA production, and amylase activity.

To evaluate the optimal nitrogen source for LA production, beef extract, yeast extract, and peptone in the mMRS medium were omitted and replaced with various organic and inorganic nitrogen sources, i.e., CSL, skim milk, casein, soybean meal, urea, (NH4)2SO4, NH4NO3, and (NH4)2HPO4. The nitrogen source providing the highest yield of LA production was selected for further studies. In this study, the cultivations were carried out in 250-mL laboratory glass bottles containing 200-mL mMRS medium with different nitrogen sources in each flask inoculated with 1.0% (v/v) inoculum (109 CFU/mL). The flasks were incubated at 37 °C for 48 h under pH-controlled conditions at 6.5. To determine LA production from the mMRS with each different nitrogen sources, the culture broth was aseptically sampling production at 12-h interval for 48 h.

Experimental Design

In this study, a 15-run Plackett-Burman design was used to screen and identify the nutritional factors that had significant influence on L(+)-LA production among nine nutritional factors including GSW, CSL, Tween80, K2HPO4, CH3COONa, (NH4)2HC6H5O7, MgSO4, MnSO4, and CaCl2. Each factor was examined at two levels, low level (− 1) and high level (+ 1). The factors and their corresponding levels used in the experimental design are listed in supplementary Table S1. The statistical software package Design-Expert 8.0 (Stat-Ease Inc., Minneapolis, MN, USA) was used to generate a set of 11 experimental designs. The most significant nutritional factors (i.e., GSW, CSL) obtained from Plackett-Burman design determined their optimal concentrations for high effective LA production by using central composite design (CCD) and described their interactive effects of GSW and CSL on LA production by using response surface methodology. These factors were tested at five levels, combining factorial points (− 1, + 1), axial points (−α, +α), and central point (0), as presented in supplementary Table S2. The combination of different optimized factors, which yielded the maximum response, was determined in an attempt to verify the validity of the model. The results of the experimental design were analyzed and interpreted using Design Expert Version 8.0 (Stat-Ease Inc., Minneapolis, MN, USA) statistical software. To evaluate the reliability of the quadratic model and the best fit, time course of LA production was performed using the optimum quantities of the two variables suggested by quadratic equation.

Validation Experiment and Effect of Minerals Deletion on the L(+)-Lactic Acid Production

The optimal concentrations of GSW and CSL obtained from the experimental design were experimentally validated for L(+)-LA production. The validation experiments were carried out in 250-mL laboratory glass bottles containing 200-mL optimized medium (OM) comprising 125.7 g/L of GSW (dry weight basis), 207.3 g/L of CSL, 5.0 g/L of CH3COONa, 1.0 g/L of Tween80, 2.0 g/L of K2HPO4, 2.0 g/L of (NH4)2HC6H5O7, 0.2 g/L of MgSO4·7H2O, 0.2 g/L of MnSO4·H2O, and 0.01 g/L of CaCl2. In order to minimize the production cost of medium, LA fermentation of E. faecium K-1 on optimized medium without minerals (OM-Mi) (125.7 g/L of GSW (dry weight basis) and 207.3 g/L of CSL) was also investigated. To evaluate L(+)-LA production from both cultivations in OM and OM-Mi broths, 1.0% (v/v) inoculum was transferred in 250-mL laboratory glass bottles containing 200-mL medium at 37 °C for 48 h. The pH was controlled at 6.5 during the cultivation. The culture broths were aseptically sampling at 6 h interval for 48 h to measure LA production, viable cell count, and amylase activity.

L(+)-Lactic Acid Production in 10-L Fermenters

In order to compare the efficiency of common commercial nutrient with the low-cost optimized medium obtained from this experiment, the large-scale trial experiment in 10-L jar fermenter (BEMT Expert of Bioengineering model, Marubishi Ltd., Japan) was operated with the working volume of 8 L under anaerobic conditions and mixed mechanically at 100 rpm to provide a homogenous condition. The temperature and pH were maintained at 37 °C and 6.5, respectively, with on-line monitoring equipment. In addition, the effect of GSW thinned with amylolytic enzyme using as substrate on bacterial growth and L(+)-LA production was also investigated. Three experimental sets were carried out to evaluate the performance of L(+)-LA production in three different cultivation media: (i) modified MRS medium (mMRS), (ii) optimized medium without mineral (OM-Mi) containing 125.7 g/L of GSW (dry weight basis) and 207.3 g/L of CSL, and (iii) optimized medium without mineral using thinned GSW (OM-Mi + Amy). GSW thinning process was performed using 375 U of maltose forming α-amylase from L. plantarum S21 expressed in E. coli [16] for 10 min at 37 °C before being used as substrate.

Amylase Activity Assay

The activity of amylase was assayed by measuring the amount of reducing sugars released during starch hydrolysis using the dinitrosalicylic (DNS) method [17]. The reaction mixture containing 0.125 mL of appropriately diluted enzyme and 0.125 mL of 10 g/L of soluble starch in 0.1 M phosphate buffer (pH 6.5) was incubated at 37 °C for 30 min. The reaction was stopped by adding 0.25 mL of DNS (Sigma-Aldrich, St. Louis, MO, USA), boiled for 10 min and 2 mL of distilled water was added, and the absorbance was measured at 540 nm. One unit of amylase activity was defined as the amount of enzyme that released 1 μmole of reducing sugar per min under the assay condition. Glucose was used as the standard.

Analytical Methods

LA content in culture broth was analyzed by HPLC equipped with Aminex HPX-87H column (Bio-Rad Laboratories, Richmond, CA, USA). HPLC was operated using 0.005 M H2SO4 pH 2.2 as a mobile phase with 0.8 mL/min flow rate, at 65 °C column temperature, and detected with a refractive index detector. Optically, pure D(−) and L(+)-LA were analyzed by D-/L-lactic acid assay kit (Megazyme, Bray, Co. Wicklow, Ireland).

Results and Discussion

Microbial Growth and Time Course of Amylase and L(+)-Lactic Acid Production

The cultivation of E. faecium K-1 on mMRS broth using GSW as a sole carbon source at 37 °C for 48 h under pH at 6.5 was conducted. The values of maximum viable cell, amylase activity, and L(+)-LA were 9.1 logCFU/mL, 2.0 U/mL, and 7.9 g/L, respectively, after 48 h of fermentation (Fig. 1). An amylase activity gradually increased and reached to the maximum value of 2.1 U/mL at 18 h, then stable until 48 h, while the viable cell number was stable approximately 9.0 logCFU/mL since only 6 h until the end of cultivation. This result confirmed the ability of L(+)-LA production from GSW as carbon source by E. faecium K-1 under pH control as 6.5 which corresponded with the results clearly described by Unban et al. [9]. Therefore, GSW had been considered as carbon source for the L(+)-LA production during this study.

Screening for Appropriate Nitrogen Sources for L(+)-Lactic Acid Production

An inexpensive organic and inorganic nitrogen sources were investigated with the purpose of finding the inexpensive nitrogen source for replacing the high-cost nitrogenous components, i.e., yeast extract, beef extract, and peptone, in mMRS formulation. The highest L(+)-LA value of 7.8 g/L was obtained from the mMRS medium using CSL as nitrogen source (yeast extract, beef extract, and peptone replaced by CSL) at 48-h cultivation which was almost nearly close to L(+)-LA yield obtained from the cultivation in mMRS medium (Fig. 2). The results agreed with the previously reported work which CSL was the most appropriate nitrogen source used for L(+)-LA production instead of yeast extract, beef extract, and peptone in MRS medium [11, 14, 18, 19]. The most important, up to 85% of CSL, is nitrogenous components. However, the components of CSL are varying depend on manufacturer that may bring the undesirable component for microbial fermentation processes. Based on the results obtained from our study, CSL obtained from Friendship Corn Starch Company, Thailand, was a good option for an alternative nitrogen source for the growth and metabolism of E. faecium K-1 and the negative effect of the formation of targeted fermentative product was not observed. Regarding the previous study by Hull et al. [20], the chemical composition of four different corn steep waters was analyzed and found that iron was the most prevalent heavy metal present in corn steep water; meanwhile, chromium and cadmium were not detected in all samples. Copper and nickel were detected at approximately 1.6 mg/L or less, while lead was detected in only one sample at concentration of 36 μg/L. Those heavy metals found in CSL are able to cause the inhibitory effect on the bacterial growth; however, based on our results in this experiment, CSL obtained from the local factory was proven to be a good option for alternative nitrogen source for the growth and metabolism of E. faecium K-1 and did not show any negative effect of the formation of targeted fermentative product.

Screening of Nutritional Factors Influence on L(+)-Lactic Acid Production Using Plackett-Burman Design

Nine nutritional factors were analyzed for their effects on L(+)-LA production using Plackett-Burman design. Statistical analyses of the responses were conducted via t test for ANOVA (see supplementary Table S3 for details). Factors evidenced the p values of less than 0.05 were considered to have significant effects on the response and selected for further optimization studies. Among the variables screened, GSW and CSL were indicated as the most significant factors enhancing L(+)-LA production at p value less than 0.05 while the other nutritional factors had no significant effect. According to the most efficient process for the L(+)-LA production obtained in this study, GSW was successfully used as sole carbon source, while CSL could serve as a main nitrogen source and essential mineral for the bacteria growth. These results were in good agreement with Jin et al. [21] who investigated the effect of nitrogen sources on LA production from potato starchy waste effluents by Rhizopus arrhizus DAR 36017. The authors reported that supplementation of nitrogen source might be unnecessary if starchy waste effluents was used. However, Zhang et al. [22] who studied on the effect of different ratios of carbon to nitrogen sources (C/N) on LA production using the same fungal strain, R. arrhizus DAR 36017, found that low C/N ratio enhanced the production of LA, while a high C/N ratio favored the production of by-products.

Optimal Medium Composition

Based on the Plackett-Burman design, two factors (GSW and CSL) significantly influenced the L(+)-LA production were used to determine the optimum levels of these factors. The results are presented in supplementary Table S4. The second-order polynomial equation based on the actual values was as follows:

where X1 and X2 are the concentrations of GSW and CSL, respectively.

The 3D response surface plots are the graphical representations of the regression equation and are plotted to understand the interaction of the variables to locate the optimum level of each variable for maximum response. Each response surface plots for L(+)-LA production are shown in Fig. 3. The optimum concentrations of GSW and CSL based on the model equation were 125.7 g/L and 207.3 g/L, respectively. Using these optimized parameters, the predicted maximum L(+)-LA production was 93.07 g/L at 48 h, while the C/N ratio was 3.06. In general, LA fermentation is associated cell growth, the product does not synthesize if the medium contains insufficient nitrogen concentration for promoting bacteria growth. On the other hand, high concentrations of nitrogen may lead to cell death and inhibition of the product [23].

Validation of Statistical Optimized Medium and Effect of Mineral Deletion on L(+)-Lactic Acid Production

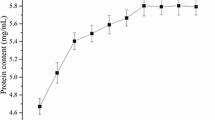

The growth kinetics in the L(+)-LA production using the predicted OM are shown in Fig. 4. The cell grew rapidly and reached stationary phase after 12 h. The maximum L(+)-LA production of 90.2 g/L was obtained at 48 h which was calculated to be 96.9% validation. The obtained maximum production indicates that CSL can provide a sufficient source of nutrients to support microbial growth and L(+)-LA production which could be indicated by the trend of microbial growth and L(+)-LA concentration. In view of the complex nutritional requirements of the L(+)-LA fermentation, it was observed that the nutrient in CSL was adequate to promote microbial growth and L(+)-LA production.

Since only two factors (GSW and CSL) were considered to be the most significant factors affecting L(+)-LA production, however, other mineral salts composed in the mMRS medium were also included in the OM composition. The effect of mineral salts on the LA production by E. faecium K-1 has been revealed in Fig. 4. The maximum LA production, amylase activity, and bacterial growth from OM without other inorganic mineral salts and Tween80 (OM-Mi) have been obtained as 90.1 g/L, 1.62 U/mL, and 9.2 logCFU/mL, respectively, after 48 h with 37 °C under static condition. It had been observed from our data that E. faecium K-1 shows the well growing and performs LA production efficiently in OM-Mi as the same as OM for the whole fermentation period. This result confirmed that CSL is an excellent low-cost nitrogen source used for L(+)-LA production by E. faecium K-1. This may be due to the fact that CSL contains abundance of sufficient vitamins and minerals for supporting the bacterial cell growth [24]. This evidentially supported the conclusion that the OM-Mi is also able to be used for efficient production of L(+)-LA by E. faecium K-1.

L(+)-Lactic Acid Production in 10-L Jar Fermenter

The kinetic parameters of L(+)-LA concentration, productivity, and viable cell of E. faecium K-1 during fermentation for comparison between the cultivation in mMRS, OM-Mi, and OM-Mi using GSW thinned with recombinant α-amylase (OM-Mi + Amy) were carried out and the results are presented in Table 1. In comparison between OM-Mi, a new low-cost medium discovered from this research, and mMRS, the capability of E. faecium K-1 in bioconversion of GSW to L(+)-LA was non-significantly different particularly at the fermentation time given the highest productivity at 24 h. The result confirms the efficacy of the new low-cost medium for replacing the high cost medium as mMRS. However, comparison of three media tested in this experiment revealed that the highest quantity of L(+)-LA at 89.6 g/L was found from OM-Mi + Amy after 48-h fermentation. Moreover, even the highest productivity of all media were found at the same cultivation time at 24 h, but OM-Mi + Amy gave the highest productivity (3.15 g/L/h) significantly different from 2.93 to 2.89 from mMRS and OM-Mi, respectively. This may be due to the fact that thinned GSW had lower viscosity than normal GSW which directly affected on mass transfer of microbial fermentation and influenced on L(+)-LA production. Meanwhile, viable cell number from all conditions was almost similar since 12 h of fermentation and stable until 48 h which means that the medium composition from all conditions was not affected on the microbial growth, but directly influenced on the bacterial cellular metabolism in conversion of starch to L(+)-LA.

The data of LA production from starch-based substrates by some lactic acid bacterial strains using various nitrogen sources is presented in Table 2. Though it is improper to compare all producing parameters from the different experiments, it is able to distinguish roughly on the nitrogen sources used in this study and others in which the high cost nitrogen sources (yeast extract, peptone, and beef extract) are used in the LA production by ALAB [3, 25,26,27]. In case of non-amylolytic LAB, most of the starch-based substrates have to be used in the form of hydrolysate [28,29,30,31,32,33,34]. That means the pre-treatment process by either chemical hydrolysis or enzymatic digestion is required and becoming the cost-effective factor for the production in the larger scale. Overall results from this study indicate the success of the application of experimental design in medium optimization for L(+)-LA production by the ALAB E. faecium K-1 in 10-L scale batch fermentation and a low-cost medium is achieved as it is composed of only two agricultural wastes, GSW and CSL. This research is not only confirmed the successful in L(+)-LA production by the single-step fermentation using ALAB, the feasible model of attractive starchy waste treatment process is also demonstrated. However, more further experiments are required for the production of L(+)-LA from GSW and CSL in the larger scale such as the trial experiment in various fermentation types in order to reduce the time of fermentation and obtain the higher productivity. Moreover, the economic evaluation of L(+)-LA directly from GSW by low-cost medium should be more studied to evaluate the techno-economic feasibility of its commercial production. Since many researchers developed the model to provide the competitive economic benefits of lactic acid production from starch and lignocellulosic materials [35,36,37].

Conclusions

E. faecium K-1 had potentiality in production of L(+)-LA directly from GSW. The low-cost medium was achieved by using an alternative inexpensive nitrogen source. CSL completely replaced the traditional costly sources (yeast extract, beef extract, and peptone). The optimization of medium composition was successfully performed by using the statistic experimental design and a low-cost medium containing only GSW and CSL as carbon and nitrogen sources was achieved. LA fermentation in a 10-L fermenter using a low-cost medium was also successful; however, more further experiments are required for the L(+)-LA production from GSW and CSL in the larger scale.

References

Muthayya, S., Sugimoto, J. D., Montgomery, S., & Maberly, G. F. (2014). An overview of global rice production, supply, trade, and consumption. Annals of the New York Academy of Sciences, 1324(1), 7–14.

Titapiwatanakun, B. (2012). The rice situation in Thailand. Manila.

Kanpiengjai, A., Lumyong, S., Pathom-aree, W., & Khanongnuch, C. (2014). Starchy effluent from rice noodle manufacturing process as feasible substrate for direct lactic acid production by Lactobacillus plantarum S21. Journal of the Korean Society for Applied Biological Chemistry, 57(2), 217–220.

Muangrat, R., & Nuankham, C. (2018). Moisture sorption isotherm and changes in physico-mechanical properties of films produced from waste flour and their application on preservation quality of fresh strawberry. Food Science & Nutrition, 6(3), 585–593.

Pandey, A., Soccol, C. R., Nigam, P., & Soccol, V. T. (2000). Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresource Technology, 74(1), 69–80.

Ohkouchi, Y., & Inoue, Y. (2007). Impact of chemical components of organic wastes on L (+)-lactic acid production. Bioresource Technology, 98(3), 546–553.

Tang, J., Wang, X., Hu, Y., Zhang, Y., & Li, Y. (2016). Lactic acid fermentation from food waste with indigenous microbiota: effects of pH, temperature and high OLR. Waste Management, 52, 278–285.

Liang, S., Gliniewicz, K., Gerritsen, A. T., & McDonald, A. G. (2016). Analysis of microbial community variation during the mixed culture fermentation of agricultural peel wastes to produce lactic acid. Bioresource Technology, 208, 7–12.

Unban, K., Kanpiengjai, A., Takata, G., Uechi, K., Lee, W. C., & Khanongnuch, C. (2017). Amylolytic enzymes acquired from L-lactic acid producing Enterococcus faecium K-1 and improvement of direct lactic acid production from cassava starch. Applied Biochemistry and Biotechnology, 183(1), 155–170.

Yu, L., Lei, T., Ren, X., Pei, X., & Feng, Y. (2008). Response surface optimization of L-(+)-lactic acid production using corn steep liquor as an alternative nitrogen source by Lactobacillus rhamnosus CGMCC 1466. Biochemical Engineering Journal, 39(3), 496–502.

Liu, B., Yang, M., Qi, B., Chen, X., Su, Z., & Wan, Y. (2010). Optimizing l-(+)-lactic acid production by thermophile Lactobacillus plantarum As.1.3 using alternative nitrogen sources with response surface method. Biochemical Engineering Journal, 52(2–3), 212–219.

Kwon, S., Lee, P. C., Lee, E. G., Keun Chang, Y., & Chang, N. (2000). Production of lactic acid by Lactobacillus rhamnosus with vitamin-supplemented soybean hydrolysate. Enzyme and Microbial Technology, 26(2–4), 209–215.

Maddipati, P., Atiyeh, H. K., Bellmer, D. D., & Huhnke, R. L. (2011). Ethanol production from syngas by Clostridium strain P11 using corn steep liquor as a nutrient replacement to yeast extract. Bioresource Technology, 102(11), 6494–6501.

Thakur, A., Panesar, P. S., & Saini, M. S. (2019). L (+)-lactic acid production by immobilized Lactobacillus casei using low cost agro-industrial waste as carbon and nitrogen sources. Waste and Biomass Valorization, 1–11.

Unban, K., Kanpiengjai, A., Khatthongngam, N., Saenjum, C., & Khanongnuch, C. (2019). Simultaneous bioconversion of gelatinized starchy waste from the rice noodle manufacturing process to lactic acid and maltose-forming α-amylase by Lactobacillus plantarum S21, using a low-cost medium. Fermentation, 5(2), 32.

Kanpiengjai, A., Lumyong, S., Nguyen, T. H., Haltrich, D., & Khanongnuch, C. (2015). Characterization of a maltose-forming α-amylase from an amylolytic lactic acid bacterium Lactobacillus plantarum S21. Journal of Molecular Catalysis B: Enzymatic, 120, 1–8.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Yu, N. Y., Wagner, J. R., Laird, M. R., Melli, G., Rey, S., Lo, R., Dao, P., Sahinalp, S. C., Ester, M., & Foster, L. J. (2010). PSORTb 3.0: improved protein subcellular localization prediction with refined localization subcategories and predictive capabilities for all prokaryotes. Bioinformatics, 26.

Chiani, M., Akbarzadeh, A., Farhangi, A., & Mehrabi, M. (2010). Production of desferrioxamine B (Desferal) using corn steep liquor in Streptomyces pilosus. Pakistan Journal of Biological Sciences, 13(23), 1151–1155.

Hull, S. R., Yang, B. Y., Venzke, D., Kulhavy, K., & Montgomery, R. (1996). Composition of corn steep water during steeping. Journal of Agricultural and Food Chemistry, 44(7), 1857–1863.

Jin, B., Huang, L. P., & Lant, P. (2003). Rhizopus arrhizus–a producer for simultaneous saccharification and fermentation of starch waste materials to L (+)-lactic acid. Biotechnology Letters, 25(23), 1983–1987.

Zhang, Z., Jin, B., & Kelly, J. (2007). Production of lactic acid and byproducts from waste potato starch by Rhizopus arrhizus: role of nitrogen sources. World Journal of Microbiology and Biotechnology, 23(2), 229–236.

de Lima, C. B., Coelho, L. F., Blanco, K. C., & Contiero, J. (2009). Response surface optimization of D (−)-lactic acid production by Lactobacillus SMI8 using corn steep liquor and yeast autolysate as an alternative nitrogen source. African Journal of Biotechnology, 8(21), 5842–5846.

Xiao, X., Hou, Y., Du, J., Sun, D., Bai, G., & Luo, G. (2012). Determination of vitamins B2, B3, B6 and B7 in corn steep liquor by NIR and PLSR. Transactions of Tianjin University, 18(5), 372–377.

Shibata, K., Flores, D. M., Kobayashi, G., & Sonomoto, K. (2007). Direct L-lactic acid fermentation with sago starch by a novel amylolytic lactic acid bacterium, Enterococcus faecium. Enzyme and Microbial Technology, 41(1–2), 149–155.

Altaf, M., Naveena, B. J., & Reddy, G. (2007). Use of inexpensive nitrogen sources and starch for L(+) lactic acid production in anaerobic submerged fermentation. Bioresource Technology, 98(3), 498–503.

Ohkouchi, Y., & Inoue, Y. (2006). Direct production of L(+)-lactic acid from starch and food wastes using Lactobacillus manihotivorans LMG18011. Bioresource Technology, 97(13), 1554–1562.

John, R. P., Nampoothiri, K. M., & Pandey, A. (2006). Simultaneous saccharification and fermentation of cassava bagasse for L-(+)-lactic acid production using Lactobacilli. Applied Biochemistry and Biotechnology, 134(3), 263–272.

Lu, Z., He, F., Shi, Y., Lu, M., & Yu, L. (2010). Fermentative production of L (+)-lactic acid using hydrolyzed acorn starch, persimmon juice and wheat bran hydrolysate as nutrients. Bioresource Technology, 101(10), 3642–3648.

Yun, J. S., Wee, Y. J., Kim, J. N., & Ryu, H. W. (2004). Fermentative production of dl-lactic acid from amylase-treated rice and wheat brans hydrolyzate by a novel lactic acid bacterium, Lactobacillus sp. Biotechnology Letters, 26(20), 1613–1616.

Oh, H., Wee, Y. J., Yun, J. S., Han, S. H., Jung, S., & Ryu, H. W. (2005). Lactic acid production from agricultural resources as cheap raw materials. Bioresource Technology, 96(13), 1492–1498.

Bhanwar, S., Singh, A., & Ganguli, A. (2014). Effective conversion of industrial starch waste to L-lactic acid by Lactococcus lactis in a dialysis sac bioreactor. Annals of Microbiology, 64(3), 1447–1452.

Pagana, I., Morawicki, R., & Hager, T. J. (2014). Lactic acid production using waste generated from sweet potato processing. International Journal of Food Science & Technology, 49(2), 641–649.

Moon, S. K., Lee, J., Song, H., Cho, J. H., Choi, G. W., & Seung, D. (2013). Characterization of ethanol fermentation waste and its application to lactic acid production by Lactobacillus paracasei. Bioprocess and Biosystems Engineering, 36(5), 547–554.

Liu, G., Sun, J., Zhang, J., Tu, Y., & Bao, J. (2015). High titer L-lactic acid production from corn stover with minimum wastewater generation and techno-economic evaluation based on Aspen plus modeling. Bioresource Technology, 198, 803–810.

Manandhar, A., & Shah, A. (2020). Techno-economic analysis of bio-based lactic acid production utilizing corn grain as feedstock. Processes, 8(2), 199.

Åkerberg, C., & Zacchi, G. (2000). An economic evaluation of the fermentative production of lactic acid from wheat flour. Bioresource Technology, 75(2), 119–126.

Acknowledgments

We acknowledge the Material Science Research Center, Chiang Mai University for supports and encouragement on this research.

Funding

Chiang Mai University provided financial support via the postdoctoral fellowship and adjunct professorship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 25 kb)

Rights and permissions

About this article

Cite this article

Unban, K., Khanongnuch, R., Kanpiengjai, A. et al. Utilizing Gelatinized Starchy Waste from Rice Noodle Factory as Substrate for L(+)-Lactic Acid Production by Amylolytic Lactic Acid Bacterium Enterococcus faecium K-1. Appl Biochem Biotechnol 192, 353–366 (2020). https://doi.org/10.1007/s12010-020-03314-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-020-03314-w