Abstract

In this presented work, magnetic poly(HEMA-GMA) nanoparticles were synthesized, characterized, and used for immobilization of an anti-leukemic enzyme L-asparaginase. The average particle size of the synthesized magnetic nanoparticles was found to be as 117.5 nm. L-asparaginase was successfully immobilized onto the synthesized magnetic nanoparticles, and attached amount of L-asparaginase was found to be as 66.43 mg/g nanoparticle. The effects of the medium pH, temperature, and substrate concentration on the L-asparaginase activity were also tested. Optimum pH of the free and immobilized L-asparaginase was found to be as 7.5 and 6.5, respectively. Optimum temperature of the free L-asparaginase was 45 °C, while optimum temperature was shifted to 55 °C after immobilization onto the magnetic nanoparticles. Also, kcat value of free L-asparaginase (47,356 min−1) was calculated to be higher than that of immobilized L-asparaginase (497 min−1). Thermal stability of both asparaginase preparation was followed for 10 h, and at the end of the incubation time, free asparaginase almost lost its activity, while immobilized asparaginase protected 50% of its initial activity. Storage stabilities of free and immobilized asparaginase were also tested, and at the end of the 40 days storage, free asparaginase lost all of its activity, while immobilized asparaginase still showed 30% activity. Operational stability of immobilized asparaginase was tested for 8 successive usage, and immobilized asparaginase lost only 15% of its initial activity. In present study, activities of free and immobilized L-asparaginase were tested in artificial human serum medium, to foresee the in vivo efficiency, and it was demonstrated here that immobilized L-asparaginase protected its 74.74% of its initial activity in artificial serum medium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tumor cells, especially lymphatic tumor cells, require a large amount of asparagine to maintain rapid malignant proliferation [1]. Healthy cells get asparagine from the diet (blood serum) or can synthesize asparagine with their own enzyme asparagine synthetase. Leukemic lymphoblast and some other tumor cells lack of asparagine synthetase enzyme (or enzymatic level is too low), and therefore cannot synthesize asparagine de novo and thus inevitably need serum asparagine to survive. Asparaginase reduces the blood asparagine level and so kills tumor cells by removing the essential factor (asparagine) of protein synthesis. Healthy cells, which have enough amount of asparagine synthetase enzyme, are not affected by asparaginase, and remain intact [2]. L-asparaginase is an enzyme, which catalyze the specific hydrolysis of L-asparagine to L-aspartic acid and ammonia, and used as a chemotherapy agent for the treatment of acute lymphoblastic leukemia (Fig. 1A) [3]. Despite its high therapeutic effect, L-asparaginase has some disadvantageous such as causing allergic reactions and having a short half-life, which necessitates frequent dosing [4]. In order to overcome these disadvantageous, L-asparaginase has been immobilized onto various carriers such as organic, inorganic, or hybrid materials for more than 30 years.

In order to improve the stability and the sensitivity, the L-asparaginase has been immobilized onto various support systems, such as homologous albumin [5]; porous hollow fiber plasma filters [6]; biocompatible poly(ethylene glycol)-albumin hydrogel [7]; fructose polymer levan [8]; glutaraldehyde activated agarose [9]; silk sericin protein microparticles [10]; hydrogel-magnetic nanoparticles [11]; poly(glycidyl methacrylate-co-ethylene glycol dimethacrylate) monolithic column [12]; nanofibers of polyaniline [13]; glutaraldehyde activated silica gel, agarose, activated carbon, celite, carboxymethyl cellulose, egg shell, and tricalcium phosphate supports [14]; magnetic nanoparticles functionalized with poly(2-vinyl-4,4-dimethylazlactone) [15]; chitosan-tripolyphosphate nanoparticles [16]; composites of poly(methyl methacrylate-co-methacrylic acid)-starch [17]; poly(2-hydroxyethyl methacrylate) and poly(2-hydroxyethyl methacrylate)-starch composites [18]; calcium-alginate beads [19]; Au/Ni/Au/PEDOT-PPy-COOH segment carrying ultrasound propelled nanowires [20]; graphene oxide nanosheet modified with aspartic acid [21]; glutaraldehyde modified aluminum oxide pellets [22]; and chloro-modified magnetic Fe3O4@MCM-41 core-shell nanoparticles [23].

Upon immobilization onto solid support, stability and resistance of the enzyme develops and increases for the different environmental changes such as medium pH and temperature. Unlike free counterparts, enzymes show more stability and easy to handle properties when immobilized onto solid supports. Additionally, because of its easy to remove capability from reaction medium, reaction products are not contaminated with the enzyme molecules. This phenomenon is very useful when applying enzymes for the food and pharmaceutical industries that are very sensitive for the contaminations. Moreover, when using protease enzymes for any application, the autolysis process is dramatically reduced upon immobilization onto solid supports. Besides, some significant properties of enzymes are improved upon immobilization, such as stability for organic solvents, pH tolerance, selectivity, heat stability, and functional durability [24].

One of the intensively preferred solid materials for the immobilization studies is nanostructured materials, which provide high surface area for the immobilization of an enzyme. Among nanostructured materials, magnetic nanoparticles have been attracted great attention due to their unique physical and chemical properties, such as superparamagnetism, high surface area, and large surface to volume ratio. Also, magnetic nanoparticles demonstrate easy separation properties under the external magnetic field [25]. Moreover, because of the ability to synthesize the magnetic nanoparticles by covering with a polymer, carrying various functional groups on the surface of the nanoparticle and using for various application areas, magnetic nanoparticles have been frequently preferred nowadays [26].

This work describes the immobilization of L-asparaginase onto magnetic nanoparticles. For this purposes, magnetic nanoparticles were synthesized and then characterized by ESR, SEM, and AFM analysis. Synthesized nanoparticles were used for the immobilization of L-asparaginase. Optimum parameters for the free and the immobilized form of the L-asparaginase were tested against different medium pHs, temperature, and substrate concentration. Thermal, operational and storage stability of the immobilized L-asparaginase were also investigated. Additionally, activities of free and immobilized L-asparaginase were tested in artificial human serum, and the efficiencies were compared.

Materials

Materials

L-asparaginase (from E. coli), L-asparagine, trichloroacetic acid (TCA), Nessler reagent, 2-hydroxyethyl methacrylate (HEMA), glycidyl methacrylate (GMA), and magnetic powder (Fe3O4; average diameter, 20–50 nm) were obtained from Sigma (St. Louis, MO, USA). All other reagents were of analytical grade and used without further purification. All solutions were prepared with deionized Millipore Simplicity® (18.2 mΩ cm) water.

Synthesis and Characterization of L-Asparaginase Immobilized Magnetic Nanoparticles

Magnetic poly(HEMA-GMA) nanoparticles were prepared according to the previous work [27]. Basically, in the presence of Fe3O4, HEMA, and GMA, which were the monomers, were polymerized with emulsion polymerization technique. For covalent immobilization of L-asparaginase, magnetic poly(HEMA-GMA) nanoparticles were equilibrated with pH 8.0 phosphate buffer (100 mM). Then appropriate amount of asparaginase (in pH 8.0, 100 mM of phosphate buffer) was added to magnetic nanoparticles. And the mixture was continuously stirred for 24 h. Covalent attachment between magnetic nanoparticles and asparaginase molecules was carried out by the help of epoxy groups of GMA monomer of magnetic nanoparticles. Enzyme attachment was showed with FTIR (Fourier-Transform Infrared Spectroscopy) and EDX (Energy Dispersive X-Ray Spectroscopy) analysis. The FTIR spectrum of magnetic poly(HEMA-GMA) nanoparticles was examined by using a FTIR spectrophotometry (BX, Perkin Elmer, USA). Asparaginase loading on the magnetic nanoparticles was demonstrated by using EDX instrument (Bruker-125 eV, Germany).

Incorporation of Fe3O4 particles onto nanoparticles was showed by ESR (Electron Spin Resonance) spectrophotometer (JEOL, JES-FA300, USA). The size and the shape of the magnetic nanoparticles were examined by SEM (Scanning Electron Microscope) device (Philips XL-305 FEG, the Netherlands), and surface morphology of the magnetic nanoparticles was investigated by AFM (Atomic Force Microscope) device (Digital Instruments, MMSPM, Nanoscale IV, USA).

Activity of Free and Immobilized L-Asparaginase

Asparaginase activity was measured by using the method defined by Mashburn and Wriston [28]. Briefly, 10 μl of the enzyme was mixed with 990 μl of L-asparagine solution (in 0.05 M pH 8.6 Tris-HCl buffer) and incubated at 37 °C for 30 min. Then the reaction was stopped by addition of 0.1 ml of 1.5 M TCA, and this solution was centrifuged for 5 min at 10000 g. 0.5 ml of supernatant was diluted with 1.75 ml of distilled water and mixed with 0.25 ml of Nessler reagent. After 10 min incubation, the absorbance of the final solution was read spectrophotometrically at 480 nm. A calibration curve with ammonium sulfate was prepared to determine the released amount of ammonia. One unit of L-asparaginase activity is defined as the amount of enzyme that liberates 1 μmol of ammonia from L-asparagine per min at 37 °C.

The effects of pH and temperature on free and immobilized asparaginase were determined in a batch system. The optimum pH of free and immobilized asparaginase was defined by using 10 mM L-asparagine substrate in acetate buffer (for 4.5–5.5), in phosphate buffer (for 6.5), in Tris-HCl buffer (for 7.5–8.5), and carbonate buffer (pH 9.5) at 37 °C. To observe the effect of temperature, the activity of free and immobilized asparaginase was examined with increasing temperatures in the range of 15–65 °C. The Lineweaver-Burk plots were used for the determination of the kinetic parameters. For this, different L-asparagine concentrations (1.0–25.6 mM) were used for both free an immobilized asparaginase.

Thermal, Storage and Operational Stability of Immobilized L-Asparaginase

Thermal stability of free and immobilized asparaginase was determined by incubating at 55 °C for 10 h. After incubation, specific activities of the enzymes were determined at different time intervals by the activity method. To compare the storage stability of the free and immobilized asparaginase, enzyme preparations were stored in 50 mM Tris-HCl buffer (pH 7.5) at 4 °C for 15 days. Activities of the samples were measured periodically at 37 °C in terms of the L-asparagine hydrolysis. To determine of operational stability of immobilized L-asparaginase, immobilized enzyme was used 8 times, and enzyme activities were measured after each use by using same immobilized L-asparaginase preparations to determine the efficiency of the enzyme in human serum samples.

Usage of Immobilized L-Asparaginase for L-Asparagine Hydrolysis

The most important point of the presented work is the usability of the asparaginase immobilized nanoparticles for in vivo cancer treatment. For this purposes, in order to mimic the complex mixture of the human serum, commercial human serum was chosen. It is important that the immobilized asparaginase maintains its activity in the serum medium. Therefore, activity tests of the immobilized L-asparaginase were repeated in the artificial human serum medium. Because of the fact that commercial serum sample contains no L-asparagine, a certain amount of L-asparagine was added into the human serum and hydrolysis of the immobilized and free enzyme was compared.

Results and Discussion

Synthesis and Characterization of L-Asparaginase Immobilized Magnetic Nanoparticles

In this work, magnetic poly(HEMA-GMA) nanoparticles were synthesized by surfactant-free emulsion polymerization method. Chemical structure and schematic presentation for the synthesis of magnetic nanoparticles is demonstrated in Fig. 1B. ESR spectrum was recorded as an evidence for magnetic properties of magnetic nanoparticles (Fig. 1C). By using the data from this graph and g = hV/βHr equation, g factor was calculated as 2.14. The g factor for Fe3+ was reported as 1.4–3 (for low spin complex) and 2.0–9.7 (for high spin complex). In this present work, g value of magnetic nanoparticles was 2.14, and this demonstrated that nanoparticles have magnetic properties. Surface morphology and size of the synthesized magnetic nanoparticles were determined by SEM and AFM analysis and presented in Fig. 1D and Fig. 1E, respectively. As clearly seen in the Fig. 1D, the synthesized magnetic polymers were spherical and showed mono size distribution. The average size of the nanoparticles was calculated as 117.5 nm. As also seen in AFM picture, prepared nanoparticles were nanosized, and partially aggregated.

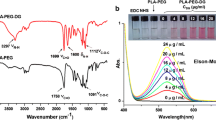

Covalent attachment of asparaginase enzyme onto the nano polymeric structure is demonstrated by FTIR and EDX analysis. Figure 2A shows FTIR spectra of plain nanopolymers and enzyme attached nanopolymers. As seen here, -OH stretching bands are located around 3500 cm−1, while -CH stretching band is located around 3300 cm−1. Additionally -C=O and -C-O stretchings are seen at 1750 cm−1 and 1260 cm−1, respectively. Especially amide II band, which placed 1570 cm−1, was resulted due to the protein structure of asparaginase. EDX analysis is demonstrated in Fig. 2B and incorporation of asparaginase onto nano polymeric structure was proved with the presence of N and S atoms. S atoms only come from cysteine and methionine amino acids of asparaginase, and by this way, attached amount of asparaginase was calculated as 66.43 mg asparaginase/g particle.

The Activity of Free and Immobilized L-Asparaginase

Although L-Asparaginase is intensively preferred chemotherapy agent, which used for the treatment of the some malignancies, it demonstrates toxicities for some cases, and causes some side effects such as allergy and hypersensitivity. In order to overcome these side effects, L-asparaginase can be immobilized onto solid support materials. However, it is vital to protect the enzymatic activity of the immobilized enzyme, and to investigate the activity response of the immobilized enzyme against the ambient conditions. For this purpose, effect of pH on the activity free and immobilized asparaginase was investigated by using different buffers between pH 4.5 and pH 9.5, and results are shown in Fig. 3. As clearly seen here optimum pH of free and immobilized asparaginase was found to be as pH 7.5 and 6.5, respectively. Optimum pH of E.coli L-asparaginase enzyme was reported as pH 7.0, 8.0, and 8.5 in literature [10, 18, 29]. When comparing with literature, optimum pH of free asparaginase was close to previous works, and it is demonstrated that the optimum pH of immobilized asparaginase shifted acidic region.

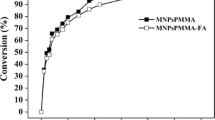

Effect of temperature on the activity of free and immobilized asparaginase was studied between 15 and 65 °C, and results are demonstrated in Fig. 4. As seen here, the optimum temperature of free asparaginase was 45 °C and optimum temperature of immobilized asparaginase was 55 °C. Zhang et al. [10] were reported that the optimum temperature of free asparaginase was 50 °C, while the optimum temperature of immobilized asparaginase was 60 °C. Improvement of temperature stability by immobilization is generally expected. Kinetic constants of free and immobilized asparaginase were determined by using L-asparagine substrate via Lineweaver-Burk plots (Fig. 5), and findings were summarized in Table 1. Vmax is the maximum reaction rate at the saturated substrate concentration and highly effected by diffusional limitations. In this work, the maximum velocity of immobilized asparaginase was found to be lower than of free asparaginase (approximately 10 times). Km shows the affinity of an enzyme to its substrate and generally increases with immobilization due to steric hindrances. However, in this work, Km decrease by immobilization, in other words, the affinity of the enzyme toward its substrate increased. Same findings also demonstrated by Ulu et al. [18]. kcat is known as the turnover number and it is very important to comment enzyme behavior by immobilization. In this work, kcat value of immobilized asparaginase was found as 497 min−1, while kcat value of free asparaginase was 47,356 min−1. The decreased activity of the immobilized asparaginase may be explained by the change in the three-dimensional structure of enzyme as result of the immobilization on the solid polymeric support, reduced diffusion of the substrate molecules toward to enzyme, which attached the surface of the polymeric matrix, and steric hindering of the support [21].

Thermal, Storage and Operational Stability of Immobilized L-Asparaginase

Stability of enzyme at high temperatures generally increases with immobilization and this provides some advantages and economic benefits in the industrial applications. In this work activity of free and immobilized asparaginase was investigated at 55 °C for 600 min, and at the end of this time, free enzyme almost lost its activity while immobilized asparaginase protected 50% of its activity. Youssef et al. [30] immobilized L-asparaginase onto calcium-alginate-gelatin composites and evaluated its thermal stability at 60 °C for 30 min. Researchers reported that immobilized asparaginase protected 66% of its initial activity. In our study immobilized asparaginase showed 66.9% of activity at 55 °C and the end of 30 min. Another important factor for the immobilization process is the storage stability of the immobilized enzyme. In this work storage stability of free and immobilized asparaginase was followed by 40 days and at the end of this time free enzyme showed approximately 1% of its initial activity, while immobilized enzyme showed 30% of its activity (Fig. 6). Ulu et al. [18] immobilized asparaginase onto pHEMA-starch composites, and the storage stability of immobilized asparaginase was followed for 15 days. At the end of this time, they reported that immobilized asparaginase protected 60% of its initial activity. Another important advantage of immobilized enzyme is their reusability, and the activity of immobilized enzyme should be protected during each use. In this work, immobilized asparaginase was used for eight successive activity tests, and it was showed that 60% of activity was protected at the end of 8th reuse (Fig. 7). Zhang et al. [10] used sericin microparticles for asparaginase immobilization, and the operational stability of immobilized enzyme was studied for 5 successive reuse. At the end of the 5th reuse, the immobilized enzyme showed almost 80% of its initial activity. However, in our present study after the five reuse immobilized asparaginase demonstrated 85.14% of its initial activity.

Usage of Immobilized L-Asparaginase for L-Asparagine Hydrolysis at Serum

For the usability of immobilized asparaginase in a biological medium such as serum, 25 mM asparagine spiked artificial human serum was used for the activity test of immobilized enzyme and compared with the free enzyme in this same medium. The activity of immobilized asparaginase in artificial serum was found to be as 74.74% as against free asparaginase activity and this is a very important value to use the immobilized enzyme in various biological applications.

Conclusions

In order to develop and increase the enzyme activity and stability in aqueous and non-aqueous media, enzymes have been immobilized onto various types of support materials. From this point of view, it is very important to select and design the support material for enzyme immobilization studies. Recently, magnetic nanoparticles have been attracted great attention for the immobilization studies due to their small size, extremely high surface area and easy separation behaviors. In this presented study, L-asparaginase enzyme, which is an anti-cancer agent, was successfully immobilized onto magnetic nanoparticles, and the thermal, storage, and operational stabilities of the enzyme increased significantly. Additionally, immobilized L-asparaginase protects 74.74% of its initial activity in artificial serum samples. These findings of this present study demonstrated that the immobilization of L-asparaginase onto magnetic nanoparticles gives promising results. Finally, it can be concluded here that these in vitro studies will be the driving force of future in vivo investigations for the unique applications of immobilized form of L-asparaginase.

References

Narta, U. K., Kanwar, S. S., & Azmi, W. (2007). Pharmacological and clinical evaluation of L-asparaginase in the treatment of leukemia. Critical Reviews in Oncology/Hematology, 61(3), 208–221.

Verma, N., Kumar, K., Kaur, G., & Anand, S. (2007). L-asparaginase: a promising chemotherapeutic agent. Critical Reviews in Biotechnology, 27(1), 45–62.

Earl, M. (2009). Incidence and management of asparaginase-associated adverse events in patients with acute lymphoblastic leukemia. Clinical Advances in Hematology & Oncology: H&O, 7(9), 600–606.

Agrawal, N. R., Bukowski, R. M., Rybicki, L. A., Kurtzberg, J., Cohen, L. J., & Hussein, M. A. (2003). A phase I–II trial of polyethylene glycol-conjugated L-asparaginase in patients with multiple myeloma. Cancer, 98(1), 94–99.

Poznansky, M. J., Shandling, M., Salkie, M. A., Elliott, J., & Lau, E. (1982). Advantages in the use of L-asparaginase-albumin polymer as an antitumor agent. Cancer Research, 42(3), 1020–1025.

Gombotz, W. R., Hoffman, A. S., Schmer, G., & Uenoyama, S. (1985). The immobilization of L-asparaginase on porous hollow fiber plasma filters. Journal of Controlled Release, 2, 375–383.

Jean-Francois, J., & Fortier, G. (1996). Immobilization of L-asparaginase into a biocompatible poly (ethylene glycol)-albumin hydrogel: I: preparation and in vitro characterization. Biotechnology and Applied Biochemistry, 23(3), 221–226.

Vına, I., Karsakevich, A., & Bekers, M. (2001). Stabilization of anti-leukemic enzyme L-asparaginase by immobilization on polysaccharide levan. Journal of Molecular Catalysis B: Enzymatic, 11(4–6), 551–558.

Balcao, V. M., Mateo, C., Fernández-Lafuente, R., Malcata, F. X., & Guisán, J. M. (2001). Structural and functional stabilization of L-asparaginase via multisubunit immobilization onto highly activated supports. Biotechnology Progress, 17(3), 537–542.

Zhang, Y. Q., Tao, M. L., Shen, W. D., Zhou, Y. Z., Ding, Y., Ma, Y., & Zhou, W. L. (2004). Immobilization of L-asparaginase on the microparticles of the natural silk sericin protein and its characters. Biomaterials, 25(17), 3751–3759.

Teodor, E., Litescu, S. C., Lazar, V., & Somoghi, R. (2009). Hydrogel-magnetic nanoparticles with immobilized L-asparaginase for biomedical applications. Journal of Materials Science: Materials in Medicine, 20(6), 1307–1314.

Qiao, J., Qi, L., Mu, X., & Chen, Y. (2011). Monolith and coating enzymatic microreactors of L-asparaginase: kinetics study by MCE–LIF for potential application in acute lymphoblastic leukemia (ALL) treatment. Analyst, 136(10), 2077–2083.

Ghosh, S., Chaganti, S. R., & Prakasham, R. S. (2012). Polyaniline nanofiber as a novel immobilization matrix for the anti-leukemia enzyme L-asparaginase. Journal of Molecular Catalysis B: Enzymatic, 74(1–2), 132–137.

Sundaramoorthi, C., Rajakumari, R., Dharamsi, A. B. H. A. Y., & Vengadeshprabhu, K. (2012). Production and immobilization of L-asparaginase from marine source. International Journal of Pharmacy and Pharmaceutical Sciences, 4, 229–232.

Mu, X., Qiao, J., Qi, L., Dong, P., & Ma, H. (2014). Poly (2-vinyl-4, 4-dimethylazlactone)-functionalized magnetic nanoparticles as carriers for enzyme immobilization and its application. ACS Applied Materials & Interfaces, 6(23), 21346–21354.

Bahreini, E., Aghaiypour, K., Abbasalipourkabir, R., Mokarram, A. R., Goodarzi, M. T., & Saidijam, M. (2014). Preparation and nanoencapsulation of L-asparaginase II in chitosan-tripolyphosphate nanoparticles and in vitro release study. Nanoscale Research Letters, 9(1), 340.

Ulu, A., Koytepe, S., & Ates, B. (2016). Design of starch functionalized biodegradable P (MAA-co-MMA) as carrier matrix for l-asparaginase immobilization. Carbohydrate Polymers, 153, 559–572.

Ulu, A., Koytepe, S., & Ates, B. (2016). Synthesis and characterization of biodegradable pHEMA-starch composites for immobilization of L-asparaginase. Polymer Bulletin, 73(7), 1891–1907.

Bahraman, F., & Alemzadeh, I. (2017). Optimization of l-asparaginase immobilization onto calcium alginate beads. Chemical Engineering Communications, 204(2), 216–220.

Uygun, M., Jurado-Sánchez, B., Uygun, D. A., Singh, V. V., Zhang, L., & Wang, J. (2017). Ultrasound-propelled nanowire motors enhance asparaginase enzymatic activity against cancer cells. Nanoscale, 9(46), 18423–18429.

Monajati, M., Borandeh, S., Hesami, A., Mansouri, D., & Tamaddon, A. M. (2018). Immobilization of L-asparaginase on aspartic acid functionalized graphene oxide nanosheet: enzyme kinetics and stability studies. Chemical Engineering Journal, 354, 1153–1163.

Agrawal, S., Sharma, I., Prajapati, B. P., Suryawanshi, R. K., & Kango, N. (2018). Catalytic characteristics and application of l-asparaginase immobilized on aluminum oxide pellets. International Journal of Biological Macromolecules, 114, 504–511.

Ulu, A., Noma, S. A. A., Koytepe, S., & Ates, B. (2019). Chloro-modified magnetic Fe 3 O 4@ MCM-41 core–shell nanoparticles for L-asparaginase immobilization with improved catalytic activity, reusability, and storage stability. Applied Biochemistry and Biotechnology, 187(3), 938–956.

Ahmad, R., & Sardar, M. (2015). Enzyme immobilization: an overview on nanoparticles as immobilization matrix. Biochemistry and Analytical Biochemistry, 4(2), 1.

Vaghari, H., Jafarizadeh-Malmiri, H., Mohammadlou, M., Berenjian, A., Anarjan, N., Jafari, N., & Nasiri, S. (2016). Application of magnetic nanoparticles in smart enzyme immobilization. Biotechnology Letters, 38(2), 223–233.

Orhan, H., Evli, S., Dabanca, M. B., Başbülbül, G., Uygun, M., & Uygun, D. A. (2019). Bacteria killer enzyme attached magnetic nanoparticles. Materials Science and Engineering: C, 94, 558–564.

Alpay, P., & Uygun, D. A. (2015). Usage of immobilized papain for enzymatic hydrolysis of proteins. Journal of Molecular Catalysis B: Enzymatic, 111, 56–63.

Mashburn, L. T., & Wriston Jr., J. C. (1963). Tumor inhibitory effect of L-asparaginase. Biochemical and Biophysical Research Communications, 12(1), 50–55.

Zhang, Y. Q., Zhou, W. L., Shen, W. D., Chen, Y. H., Zha, X. M., Shirai, K., & Kiguchi, K. (2005). Synthesis, characterization and immunogenicity of silk fibroin-L-asparaginase bioconjugates. Journal of Biotechnology, 120(3), 315–326.

Youssef, M. M., & Al-Omair, M. A. (2008). Cloning, purification, characterization and immobilization of L-asparaginase II from E. coli W3110. Asian J. Biochem, 3(6), 337–350.

Funding

This study was funded by Adnan Menderes University Research Fund (grant number FEF-17001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Orhan, H., Aktaş Uygun, D. Immobilization of L-Asparaginase on Magnetic Nanoparticles for Cancer Treatment. Appl Biochem Biotechnol 191, 1432–1443 (2020). https://doi.org/10.1007/s12010-020-03276-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-020-03276-z