Abstract

The genera Dysgonomonas, Coprococcus, Sporomusa, Bacteroides, Sedimentibacter, Pseudomonas, Ruminococcus, and Clostridium predominate in compost residue, and vadimCA02, Anaerobaculum, Tatlockia, Caloramator, and Syntrophus prevail in soil used as inoculum in batch rectors. This mixed consortium was used as inoculum for biogas production using different concentrations of sugarcane bagasse (SCB) (from 1.58 to 4.42 g/L) and yeast extract (YE) (from 0.58 to 3.42 g/L) according to a composite central design. The maximum ethanol production (20.11 mg L−1) was observed using 2.0 and 3.0 g L−1 of YE and SCB, respectively (C6). Likewise, the highest hydrogen production (0.60 mmol L−1) was observed using 3.0 and 4.0 g L−1 of YE and SCB, respectively (C1). Methane was also observed, reaching the maximum production (1.44 mmol L−1) using 1.0 and 4.0 g L−1 of YE and SCB, respectively (C2). The archaeal similarity between these conditions was above 90%; however, the richness and diversity were higher in the C2 (12 and 2.42, respectively) than in C1 (5 and 1.43, respectively) and C6 (11 and 2.29, respectively). Equally, the bacterial similarity between C1 and C6 was 60% while richness of 24 and 17 and diversity of 3.13 and 2.81 were observed in C1 and C6, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sugarcane bagasse (SCB) waste is among the most produced residues in the Brazilian sugar and alcohol industry. The inappropriate disposal of this waste can lead to environmental problems, especially as burning is currently the main form of SCB disposal to generate electricity [1].

SCB is composed of approximately 50% cellulose [2], which is formed of high tensile strength crystalline cellulose with intervening amorphous regions grouped into bundles of microfibrils inserted in an amorphous matrix of hemicellulose and tightly bound to the lignin. Small amounts of pectin, extractives, and ashes are also included in the SCB composition [3]. The interaction between these components makes this biomass highly resistant and recalcitrant; therefore, the hydrolysis often becomes the rate-limiting step for its bioconversion [4]. Due to its recalcitrance, the SCB used as substrate in fermentative process requires a microbial consortium composed of cellulolytic, acidogenic, acetogenic bacteria and methanogenic archaea for its efficient bioconversion into high-quality biofuel.

The hydrolysis of lignocellulosic biomass has been related to different bacteria, such as Clostridium, Cellulomonas, Bacillus, Thermomonospora, Ruminococcus, Baceriodes, Acetovibrio, and Microbispora genera. While the acidogenesis is commonly performed by bacteria from the genera Lactobacillus, Streptococcus, Bacillus, and Escherichia, and the acetogenesis is associated to the genera Acetobacterium, Syntrophomonas, Clostridium, Sporomusa, Syntrophospora, Thermosyntropha, and Eubacterium. Lastly, the genera Methanococcus, Methanosarcina, and Methanolobus are responsible for the final step of the anaerobic digestion [5]. Therefore, soil and compost residue are potential sources to find a microbial community able to perform the complete anaerobic digestion of lignocellulosic biomass.

In many studies, compost residue and soil are used as an inoculum for biogas production [6,7,8,9]. Due to the biochemical diversity of microorganisms on soil and composting residue, they have application on biotechnology industry such as food and fermentation and cellulose industry [10]. Compostable domestic waste comprises, together with vegetable compounds, varying amounts of other residues such as papers and boards [11]. Therefore, this is a high cellulolytic-active system consisting of cellulose-producing bacteria such as Bacillus and Pseudomonas, which have great potential for bioconversion of lignocellulosic materials [10] and consequently hold exceptional interest in large-scale biotechnological process [12], justifying its application in anaerobic digestion process for sugarcane bagasse bioconversion.

However, the rigid structure of the SCB makes it very difficult to be converted into bioenergy, once most biofuel-producing microorganisms can utilize only simple sugars, such as glucose to grow and produce metabolites. Thus, SCB and related lignocellulosic biomass utilization is not a trivial process and requires pretreatments and/or enzymatic hydrolysis to release sugar monomers for fermentation.

The hydrothermal pretreatment can disrupt the recalcitrant structures, allowing an increase of the contact surface area and improving the accessibility for enzyme attack in the hydrolysis step [13]. Additionally, many parameters can affect the enzymatic hydrolysis of SCB and its bioconversion into biofuels. Thus, the application of SCB in a biological process requires optimized conditions to favor the activity of the ethanol-producing and hydrogen-producing bacteria.

Central composite design (CCD) is an experimental design widely used for response surface methodology (RSM) to estimate the effect of independent variable in a response [14] such as hydrogen [15], ethanol [16], and organic acids [17]. The polynomial model, obtained from the experimental design, can be used to describe the effect of independent variables on the response and to optimize the generation of biotechnological products [14]

The availability of nitrogen to microbial metabolisms is an important factor related to growth and consequently degradation of recalcitrant compounds [18]. Thus, the supplementation of culture medium with nitrogen source, such as yeast extract, is fundamental to stimulate the microbial growth during fermentation. Many studies used yeast extract as nutritional supplementation to microbial growth [15, 19,20,21]. According to Kalil and co-workers [22], the availability and concentration of nitrogen in the culture medium are important factors related to bacterial growth and consequently biofuel production. So, nitrogen supplementation is required by different bacteria, mainly during the fermentation of complex substrate as sugarcane bagasse. Soares and co-workers [15] evaluated the same yeast extract concentration range used in this study (from 0.58 to 3.42 g L−1) and sugarcane bagasse as substrate in thermophilic condition using an anaerobic consortium obtained from an upflow anaerobic sludge blanket (UASB) reactor treating vinasse and reported significant effect of this factor on hydrogen production, justifying its application in biological process for the conversion of SCB into value-added chemicals.

The substrate concentration is another important parameter that affects microbial growth and consequently the metabolite production from lignocellulosic biomass [23]. Rabelo and co-workers [17] evaluated the SCB concentration on hydrogen and organic acid production using a CCD, and reported 7.0 g SCB L−1 as optimum substrate concentration for hydrogen production. These authors, as they also reported that the increase in substrate concentration from 0.8 to 5.0 g SCB L−1 increased the succinic and butyric acid production [17], reinforce the importance to exploit different range of substrate concentration for bioconversion of lignocellulosic biomass into hydrogen through microbial routes.

Therefore, the aim of this study was to find optimum conditions of yeast extract and substrate concentration to maximize ethanol and hydrogen productions using a microbial consortium from soil and compost residue.

Material and Methods

Microorganisms and Culture Conditions

The consortium employed in this study was obtained from a mixed culture from soil and composting residue. Composting waste and soil were collected at the University of São Paulo in São Carlos, Brazil. For this, 100 g of each residue was sieved (2-mm mesh) and then added in Erlenmeyer containing 900 mL of dissociation solution (0.1% sodium pyrophosphate and 0.1% Tween 80), 50 g of glass beads (5 mm), and maintained under stirring for 20 min at room temperature. The liquid fraction corresponded to the inoculum. Each inoculum (composting waste and soil) was acclimated separately for 48 h in 300 mL of cellulose anaerobe medium [24] plus 1 g L−1 yeast extract and 1 g L−1 carboxymethyl cellulose Sigma-Aldrich® (St. Louis, USA). Finally, both inoculums were mixed in a single reactor, which became the MIX inoculum (2.55 g L−1 of volatile solids).

SCB Pretreatment

The SCB was obtained from São Martinho sugar mill (Pradópolis, SP, Brazil). The SCB was air-dried until constant weight and subsequently pretreated using a hydrothermal system of 100-mL capacity at 200 °C for 10 min at 16 bar [15] and severity of 3.94. The solid phase was separated from the liquid phase by vacuum filtration; the SCB fiber was air-dried until constant weight and stored at room temperature. The solid fraction was used as substrate in batch reactors.

Central Composite Design

Two independent variables, namely yeast extract concentration (X1) and SCB concentration (X2), were studied at five levels (+ 1; − 1; 0; + 1.42; − 1.42) with three repetitions at the central point (CP) and two replicates at axial and factorial points. Based on literature values [15], the variable ranges (central point) of yeast extract concentration and SCB concentration were determined to be 2.0 g L−1 and 3.0 g L−1, respectively (Table 1), resulting in a total of 11 conditions.

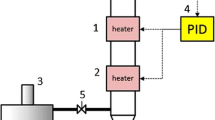

Batch Reactors

The experiments were performed in triplicate in a 1-L batch reactor with 500-mL working volume consisting of culture medium [24] with pH adjusted to 6.0 [17], inoculum (10% v/v−1) and the substrate. The reactors were supplemented with yeast extract according to the factorial experimental design (Table 1), submitted to N2 (100%) for 10 min, sealed with a butyl rubber stopper and plastic seal, and then incubated at mesophilic condition (37 °C) for 400 h.

Analytical Methods

The ethanol and organic acids were analyzed by high-performance liquid chromatography (HPLC) equipped with a UV diode array detector (SPD-M10 AVP), a refraction index detector (RID-10A), a CTO-20A oven, an LC-10 ADVP Pump, an SCL 10 AVP control, and an Aminex HPX-87H column (300 mm × 7.8 mm) (BioRad). The mobile phase consisted of H2SO4 (0.01 N) at 0.5 mL min−1 flow rate [25]. The hydrogen and methane contents in the biogas were determined by gas chromatography using a GC 2010 Shimadzu system equipped with a thermal conductivity detector (TCD) and a Carboxen 1010 PLOT column (30 m × 0.53 mm) according to Ratti and co-workers [26].

Kinetic Analysis

The hydrogen experimental data was adjusted to the average values obtained from triplicates using the software package Statistica® 8.0. The data of the accumulated hydrogen production was adjusted using the Gompertz equation, modified by Zwietering and co-workers [27] (Eq. 1).

where P—potential production of H2 (mmol L−1), Rm—production rate of H2 (mmol L h−1), t—time of incubation (h), e—Euler number (2.71828), and λ—start time of H2 production (h).

PCR-DGGE Analysis

For DNA extraction, cell lysis was carried out using acid-washed glass beads (Sigma®), followed by washing consecutively with phenol and chloroform according to Griffiths and co-workers [28]. The polymerase chain reaction (PCR) of 16S rRNA gene of Archaea and Bacteria was performed using the primers 1100 FGC and 1400R [29] and 968 FGC and 1401 R [30], respectively. The DGGE was performed according to Muyzer and co-workers [31], using the 45 and 65% denaturing gradients (100% denaturing gradient = 7 M urea and 4% v/v deionized formamide). Pearson’s similarity coefficient was calculated using Bionumerics® software version 3.5. The Shannon-Winer diversity and Chao-1 richness index have been computed based on the height of the densitometric curve peaks using the Past Software.

Sequencing

The sequencing of 16S rRNA gene fragments of V3 and V4 regions of microbial communities from the soil and composting was performed in platform MiSeq-Illumina, 2 × 250 cycles, with the set primer 341F (5′-CCT ACG GGNGGC WGC AG-3) and 785 R (5′-GAC TAC HVGGG TAT CTA ATC C-3′) [32]. The bioinformatic analyses were performed with the SeqyClean software (http://bitbucket.org/izhba nnikov/seqyclean) using cutoff platforms lower than 24 QScore. The database used was Univec (http://www.ncbi.nlm.nih.gov/VecSc reen/UniVe c.html). Database RDP was employed for the metagenomic analysis [33]. The pipeline used was the QIIME platform v1.9 [34] in three steps: (1) concatenation of paired-end reads; (2) filtering, search, and identification of OTUs; (3) rarefaction analysis, alpha diversity. The diversity (Shannon index) was performed using the Past Software program. The raw reads were uploaded in Sequence Read Archive (SRA) database (http://www.ncbi.nlm.nih.gov/sra) under the BioProject PRJNA338740 with the accession number from SRS1629920.

Results and Discussion

Composting Microbial Consortium

The composting microbial consortium was composed mainly of the Porphyromonadaceae (35.6%), Ruminococcaceae (10.55%), Lachnospiraceae (7.3%), Veillonellaceae (6.49%), Clostridiaceae (2.41%), Bacteroidaceae (1.53%), Tissierellaceae (1.38%), and Pseudomonadaceae (1.20%) families (Fig. 1).

Anaerobic indigenous bacteria from the human and animal gastrointestinal tracts are included in the Porphyromonadaceae family. The major end products are acetic acid, butyric acid, isobutyric acid, isovaleric acid, lactic acid, propionic acid, phenylacetic acid, and succinic acid [35]. In the Ruminococcaceae family, all species are obligate anaerobes which use carbohydrates like fructose, glucose, and starch as carbon and energy sources. The bacteria belonging to the family Clostridiaceae are generally obligate anaerobic, endospore-forming, hydrogen, and organic acids. This family includes homoacetogenic genera which produce acetic acids through Wood–Ljungdahl pathway [36].

All species from the Lachnospiraceae family are anaerobes which include acetogenic and fermentative metabolisms [36]. Members of the Veillonellaceae family are gram-stain-negative and obligate anaerobes, whose main end products are acetic and propionic acids, H2, and CO2. Anaerobic and saccharolytic bacteria are included in the Bacteroidaceae family, which produces succinic, acetic, isobutyric, isovalérico, and lactic acids and ethanol, H2, and CO2 from glucose. The Pseudomonadaceae family is composed of aerobic bacteria with oxygen as the terminal electron acceptor; however, in some cases, nitrate can be used as an alternative electron acceptor, allowing the anaerobic growth [36]. The Tissierellaceae family is related to biogas production and participates in the anaerobic bioconversion of complex carbohydrate, protein, and peptides into volatile fatty acids [37]. Due to the origin of this consortium (composting residue) and the presence of many organic acids as end fermentation products, these anaerobic bacteria probably played a key role in the bioconversion of sugarcane bagasse. Only few genera were identified in relative abundance of more than 1% (Dysgonomonas, Coprococcus, Sporousa, Bacteroides, Sedimentibacter, Pseudomonas, Ruminococcus, and Clostridium) (Fig. 2).

The genera Sporomusa (4.06%) and Sedimentibacter (1.37%) can be favored in the culture condition once both require yeast extract as a nutrient and amino acid source [38, 39]. The genus Clostridium (1.0%) is widely reported to be related to hydrogen production from lignocellulosic biomass in anaerobic system [20, 21, 40] and able to develop many metabolic pathways, such as fermentative, acidogenic, homoacetogenic, and solventogenic [41].

Dysgonomonas spp., the more prevalent genus in the composting residue consortium, is a facultative anaerobe bacteria with saccharolytic activity and able to produce acids but no gas [42]. The elevated occurrence of this genus justifies the organic acid production in this study.

The Pseudomonas genus comprehend a strictly aerobic bacterial group found in the soil samples; however, some species are able to use nitrogen oxides as electron acceptor allowing its growth under anaerobic condition [43]. The genera Coprococcus and Ruminococcus are obligate chemoorganotrophic anaerobes able to ferment cellobiose to produce mainly butyric, acetic formic, and propionic acids [44]. In the same way, the genus Bacteroides includes strictly anaerobic and cellulolytic species able to grow on a variety of carbohydrates to produce acetic, propionic, and succinic acids [45], which were produced in this study.

Soil Microbial Consortium

The soil microbial consortium was composed mainly of the BS11 (52.11%), F16 (10.48%), Synergistaceae (7.07%), Ruminococcaceae (4.61%), Syntrophaceae (2.35%), and Clostridiaceae (1.06%) (Fig. 3). The BS11 represents uncultivated gut groups from the Bacteroidetes family which has potential and express key genes for the carbon transformations in the rumen [46].

The F16 family belongs to the TM17 phyla and is constituted by symbiotic ruminal bacterial populations [47,48,49]. The family Synergistaceae has been related to the potential involvement in amino acid fermentation in the termite gut [50, 51]. Strictly anaerobic bacteria belonging to the family Syntrophaceae have either the respiratory or fermentative-type metabolism and are H2/formate-utilizing partners in syntrophic associations [52].

Despite the elevated number of family identified in the soil consortium, only the vadimCA02 genus was observed in relative abundance of more than 1% (7.07%). This genus includes uncultured bacteria widely found in mesophilic reactors [53]. However, the genera Anaerobaculum, Tatlockia, Caloramator, and Syntrophus were found in low relative abundance (0.91, 0.85, 0.71, and 0.70%, respectively) (Fig. 4).

Syntrophic relation can be established between hydrogen/formate-using microorganisms and bacteria belonging to the genus Syntrophus, which is able to syntrophically oxidize aromatic compounds [54]. The genus Tatlockia was proposed as a division of the family Legionellaceae [55] but other investigators have not reinforced the proposal and recommended that a single genus called Legionella be maintained [56]. The genus Anaerobaculum can ferment organic acids, few carbohydrates, and amino acids to produce hydrogen, and it is commonly found in biogas reactors in association with methanogenic archaea [57]. In the same way, Caloramator was reported in anaerobic batch reactors fed with glucose and xylose and was able to convert C6 sugars into H2, CO2, ethanol, and acetic and formic acids, highlighting the potential hydrogen production [58]. The main substrate consumed and metabolites produced are shown in Fig. 5.

Effect of Significant Factors on the Ethanol and Hydrogen Productions

The yeast extract concentration had linear and quadratic effects on the hydrogen and ethanol productions, respectively. It is worth mentioning that the presence of the genera Sporomusa and Sedimentibacter in the microbial consortium requires yeast extract for growth [38, 39]. So, these genera probably were favored by the increase of this nitrogen source.

In the same way, the SCB concentration had linear and quadratic effects on the hydrogen production and quadratic effect on the ethanol production. There are interactions between both independent variables for hydrogen as well for ethanol production. Table 1 shows the matrix for CCD along with the experimental and predicted values for hydrogen and ethanol productions. It is important to note that the significance of quadratic effects would have been lost if the experiments were carried out using the conventional methods, based on the “one-variable-at-a-time” approach which carries out individual factors but not mutual factors.

The maximum ethanol production (20.11 mg/L) was obtained in the central point (2.0 and 3.0 g/L of yeast extract and sugarcane bagasse, respectively). Higher ethanol concentration (about 500 mg/L) was reported by Silva et al. [58] using 2 g/L of yeast extract and 1 g/L of xylose as substrate. This was probably due to the substrate type and incubation temperature, once these authors used commercial xylose as carbon source at thermophilic condition (55 °C). In this study, the genera Ruminococcus, Clostridium, and Caloramator, which are ethanol producers, were identified in the microbial inoculum and can be related to the ethanol-type fermentation.

The polynomial equation was obtained by applying multiple regression analysis on the experimental results to describe the ethanol and hydrogen productions using the coded independent variables (Eqs. 2 and 3, respectively). The adequacy of the model was determined by analysis of variance (ANOVA) as shown in Table 2.

where Y is the response ethanol (mg L−1); Z is the response hydrogen production (mmol L−1); X1 is the yeast extract concentration; and X2 is the substrate concentration.

The values of X1, X12, and X22 were less than zero, indicating a negative effect of linear and quadratic increase of yeast extract and quadratic increase of sugarcane bagasse on the ethanol production. In the same way, the X12 and X22 were less than zero, also indicating the negative effect of the quadratic increase of both independent variables on the hydrogen production.

However, the linear effect of substrate concentration on ethanol production and the linear effect of yeast extract and substrate concentration on the hydrogen production was positive, as the values of X1 and X2 were greater than zero, indicating the improvement of the metabolite production as results of the linear increase of both independent variables.

95% significant level

The optimum level of the independent variables and their interaction on the ethanol and hydrogen productions were evaluated by response surface plot (Fig. 6).

In the present study, the hydrogen production increased from 0.34 mmol L−1 using 1.58 g L−1 of SCB to 0.60 mmol L−1 using 4.00 g L−1 of SCB and decreased to 0.41 mmol L−1 which increased the SCB concentration to 4.42 g L−1. In the same way, Pattra and co-workers [59] obtained the highest hydrogen production (8.03 mmol L−1) with 20 g COD L−1 of substrate which decreased to 6.70 mmol L−1 with 40 g COD L−1 of SCB hydrolyzed, in a batch reactor inoculated with Clostridium butyricum TISTR 1032 in mesophilic condition (37 °C) [59]. Therefore, the increase on the substrate concentration led to the increase in hydrogen production to some extent and then had a negative effect on the generation of end metabolites. In this study, the genera Clostridium, Anaerobaculum, and Caloramator were identified in the microbial inoculum and can be related to the hydrogen production.

The highest hydrogen production (0.60 mmol L−1) was obtained using 3.00 g L−1 of yeast extract and 4.00 g L−1 of SCB, but half of the hydrogen production (0.31 mmol L−1) was obtained when the yeast extract concentration was reduced to 1.00 g L−1 and the SCB concentration was maintained (4.00 g L−1). In the same way, the lowest hydrogen production (0.28 mmol L−1) was obtained when the lower yeast extract concentration was applied (0.58 g L−1) using 3.00 g L−1 of SCB; therefore, the yeast extract was fundamental for the building blocks of the cell and provided trace minerals which contributed to the hydrogen production.

The increase in the hydrogen production with the increase in the yeast extract concentration was also reported by Xu and co-workers [60]. These authors showed that the hydrogen production increased rapidly from 67.2 to 104.6 mmol L−1 when 0.05 and 0.3 g L−1 of yeast powder were added in the culture medium, using glucose as substrate. In the present study, the hydrogen production was lower than that reported by these authors; however, the solid fraction of the hydrothermally pretreated SCB, which is a complex feedstock, was used in the present study, while glucose was used as substrate by Xu and co-workers [60].

The highest ethanol production (20.11 mg L−1) was obtained using 2.0 and 3.0 g L−1 of yeast extract and substrate concentrations, respectively. Maintinguer and co-workers [61] reported maximum ethanol production of 41.5 mg L−1, using 1.8 g xylose L−1 by a microbial consortium from sludge of the UASB reactor treating slaughterhouse wastewater in a batch reactor at 37 °C.

In contrast, the lowest ethanol production obtained in this study was of 8.32 mg L−1 using 1.0 and 4.0 g L−1 of yeast extract and substrate concentrations, respectively. At higher SCB concentrations (4.00 and 4.42 g L−1), a clear reduction in ethanol production was observed (12.25; 8.32 and 13.87 mmol L−1 with 3.00, 1.00, and 2.00 g L−1 of yeast extract, respectively). Further increase of SCB did not result in increased end products, probably due to the fact that fermenting bacteria can have limited tolerance in relation to increased substrate concentration resulting in a reduction of metabolite production at high substrate concentrations.

Higher ethanol production, than that observed in the present study, was reported by Sigurbjornsdottir and Orlygsson (2012) using glucose (939.62 mg L−1), acid-treated cellulose (1,363.37 mg L−1), acid-treated hemp stem (1,142.28 mg L−1), base-treated hemp leaf (700.11 mg L−1), acid-treated grass (1,344.95 mg L−1), acid-treated newspaper (663.26 mg L−1), and base-treated barley straw (1,096.23 mg L−1).

The higher ethanol production reported in the literature, in relation to that obtained in the present study, was probably due to the fact these authors used the liquid fraction (hydrolyzed) from the acid or base pretreatments of lignocellulosic biomass, in which high concentration of fermentable sugars is released. In contrast, in the present study, the solid fraction of hydrothermal pretreatment, which is constituted by cellulose, hemicellulose, and lignin, was used as substrate. So, the bioconversion of the fiber fraction of SCB requires a cellulolytic enzymatic complex to hydrolyze the biomass and provide fermentable sugars to the next step of bioconversion, while the hydrolyzed biomass and fermentable sugars (such as glucose, cellulose, and xylose) used by these authors are readily available to the microorganisms, resulting in the generation of higher end products.

Fermentative Pathways and Metabolites

The main organic acids produced were acetic, butyric, and propionic. In all conditions, the main end product associated with the hydrogen production generated was acetic acid (Table 3), in agreement with Maintinguer and co-workers [61] that obtained the maximum acetic acid concentration (1207.6 mg L−1) using high xylose concentration (3.59 g L−1). Many genera identified in the microbial inoculum, such as Dysgonomonas, Bacteroides, Coprococcus, Ruminococcus, Clostridium, Caloramator, and Anaerobaculum, are able to produce acetic acid from carbohydrates and probably have a key role in the selected metabolic pathway to sugarcane bagasse conversion.

In the present study, the maximum acetic acid production (433.76 mg L−1) was reached using the highest SCB concentration (4.42 g L−1) and 2.00 g L−1 of yeast extract. The acetic acid production can led to the formation of 4 mol H2.mol glucose−1 (Eq. 4) [62].

High hydrogen productions are associated with a mixture of acetic and butyric acid generation (Eq. 5).

The ratio of acetic/butyric acid is a crucial factor for biological hydrogen production, once the higher the acetic/butyric ratio, the better the theoretical hydrogen yields are reached [63]. In all conditions, this ratio was higher than 1, indicating that the acetic pathway was favored over the butyric pathway.

The acetic acid production can also be performed by autotrophic acetogenic bacteria, which consume about 11% of the H2 yield in batch fermentations via homoacetogenesis pathway (Eq. 6) [64].

Once the homoacetogenesis pathway is performed by acetogenic bacteria which modify their metabolism under stress condition or depletion of organic substrate, to autotrophic growth on H2 + CO2 [64] in this study, the reverse route could be triggered due to the recalcitrance of the sugarcane bagasse, which causes a stress situation related to the low availability of fermentable sugars.

Homoacetogenic bacteria such as Clostridium and Sporomusa, identified in the microbial inoculum, were widely reported [64]. The genus Sporomusa, identified in the microbial inoculum, is able to produce acetic acid from H2 + CO2 via Wood–Lyngdahl route [65]. In the same way, the genus Syntrophus, also identified in the microbial inoculum, is a H2-consumer bacteria, which grow slowly in a syntrophic relationship with methanogens to maintain a low hydrogen partial pressure and produce acetic acid [66].

The low hydrogen productions are related to acetogenesis pathways but are also associated with the formation of propionic acid as end products [67]. In the condition C9, under which the lower hydrogen production was obtained (0.28 mmol L−1), higher propionic acid was observed (433.76 mg L−1). The propionic production is harmful to hydrogen production because its formation requires the consumption of 2 moles of hydrogen [68] (Eq. 7).

Methane production was obtained in all conditions. The maximum methane production was obtained in C2 (1.44 mmol L−1), while the minimum methane production (0.24 mmol L−1) was observed in C4, demonstrating the effect of SCB concentration (2.0 and 4.0 g L−1, respectively), once the yeast extract concentration in both conditions was 1.0 g L−1. The longer starting time for methane (221.01 h) occurred in condition C4, under which the lowest methane production was obtained. Methane can be produced mainly via hydrogenotrophic (Eq. 8) or acetoclastic methanogenesis (Eq. 9) [69].

In this study, only 0.31 and 0.03% of the sequences were identified as methanogenic archaea in the composting and soil, respectively, such as the genera Methanosaeta, Methanobacterium, Methanocella, Methanoculeus, Methanolobus, and Methanomassiliicoccus. However, these microorganisms probably had a key role in the methanogenesis pathway once methane was produced in all experimental conditions.

PCR/DGGE Analysis

Fewer modifications were observed for the archaeal communities under the conditions applied in this study (Fig. 7). The lower archaeal population similarity (87%) was observed between C8 and C9, conditions with the same substrate concentration (3.0 g L−1 of SCB), but with lower (0.58 g L−1) and higher (3.42 g L−1) yeast extract concentrations. Probably, the archaeal populations were affected more by the nitrogen availability than by substrate concentration once similarity of 90% was observed between C10 and C11, conditions with lower (1.52 g L−1) and higher (4.48 g L−1) SCB and the same yeast extract concentration (2 g L−1).

DGGE band patterns of archaeal (a) and bacterial (b) 16S rRNA gene PCR fragments. C1—3.00 g L−1 of yeast extract and 4.00 g L−1 of SCB; C2—1.00 g L−1 of yeast extract and 4.00 g L−1 of SCB. C3—3.00 g L−1 of yeast extract and 2.00 g L−1 of SCB. C4—1.00 g L−1 of yeast extract and 2.00 g L−1 of SCB. CP—central point—2.00 g L−1 of yeast extract and 3.00 g L−1 of SCB; C8—3.42 g L−1 of yeast extract and 3.00 g L−1 of SCB. C9—0.58 g L−1 of yeast extract and 3.00 g L−1 of SCB; C10—2.00 g L−1 of yeast extract and 4.42 g L−1 of SCB; C11—2.00 g L−1 of yeast extract and 1.58 g L−1 of SCB. Arrows indicate a dominant archaeal group

The archaeal population similarity between C2 and C8, conditions with the highest (1.44 mmol L−1) and lowest (0.38 mmol L−1) methane production, was of 88%. The highest methane production in C2, in relation to C8, was favored by the low hydrogen accumulation (0.31 mmol L−1) which probably caused low hydrogen pressure, and by the low acids production (420 mg L−1) which, perhaps, maintained stability and thus favored the methanogenic metabolism. While in C8, the high hydrogen and acid productions (0.58 mmol L−1, 726.58 mg L−1, respectively) affected negatively the methanogenic archaeal, resulting in lower methane production in this condition. It is important to note that in C8, there were also high ethanol and propionic acid productions (328.28 and 13.07 mg L−1, respectively) in relation to C2 (275.40 and 8.32 mg L−1, respectively), which demonstrates a metabolic pathway deviation to its productions.

It is important to highlight that the Methanosaeta, Methanobacterium, Methanocella, Methanoculeus, Methanolobus methanogenic genera were identified in the microbial inoculum from composting and soil, and were probably selected and enriched in the anaerobic batch reactors leading to methane production in all experimental conditions.

The higher bacterial similarity (92%) was obtained between C3 and C4, whose yeast extract concentration varied from 1.0 to 3.0 g L−1 and the same SCB was used (2.0 g L−1). Probably, the high similarity between these conditions was due to the selection and favoring of microorganisms such as Anaerobaculum, Sporomusa, and Sedimentibacter, in which growth was enhanced by the increase in the yeast extract concentration.

In contrast, lower similarity (50%) was observed between C10 and C11, conditions with 2.0 g L−1 of yeast extract and with the highest (4.42 g L−1) and lowest (1.58 g L−1) substrate concentration, showing that the substrate concentration affected the bacterial populations. In these conditions, similar acetic and butyric acids (488.8 and 457.6 mg acetic acid/L, 60.7 and 61.8 mg butyric acid/L, in C10 and C11, respectively) and ethanol productions (13.8 and 13.5 mg/L in C10 and C11, respectively) were observed. Considering the potential phylogenetic and biochemical aspects of the microbial inoculum, the Clostridium and Caloramator were favored in this condition once both are capable of fermenting complex carbohydrates and their main fermentation products include butyric and acetic acid and ethanol.

Concerning the conditions with the highest and lowest ethanol production (20.11 and 8.32 mg L−1 in C6 and C2, respectively), the bacterial population similarity was of 70%. In C2, low hydrogen and acetic acid productions were observed, while high concentrations of propionic acid and methane were obtained (275.4 mg L−1 and 1.44 mmol L−1). Probably, in this condition, the propionic-forming bacteria and methanogenic archaea were favored. Propionic pathways is associated with the genera Bacteroides and Ruminococcus [44], whereas the dominant genera among archaea that produces methane include Methanosaeta, Methanobacterium, Methanocella, Methanoculeus, and Methanolobus.

On the other hand, in C6 besides the high ethanol production, high hydrogen and acetic acid productions were obtained (0.50 mmol L−1and 329.82 mg L−1), which may have caused an increase on the hydrogen partial pressure and a decrease on pH (5.6), leading to low methane production (0.75 mmol L−1). So in this condition, the acidogenic and acetogenic-producing bacteria were favored, such those belonging to the Syntrophus and Sporomusa genera.

In the same way, in relation to the highest (0.60 mmol L−1 in C1) and lowest (0.28 mmol L−1 in C9) hydrogen production, the bacterial population similarity was only 50% (Fig. 2). The ethanol production in both conditions was similar (12.25 and 11.11 mg L−1, in C1 and C9, respectively), indicating that the independent variables probably modified the hydrogen-producing metabolism, performed by the genera Clostridium and Caloramator, to ethanol-producing metabolism. In contrast, the low hydrogen production observed in C9 was concomitant with the production of high acetic and propionic acids (401.57 and 433.76 mg L−1, respectively) indicating it probably favored homoacetogenic and propionic bacteria such as Sporomusa, once hydrogen is consumed in both pathways to produce acetic and propionic acids, respectively.

Similar methane production (0.94 and 0.93 mmol L−1) was observed in conditions C1 and C9, in which both the highest and the lowest diversity and archaeal richness were obtained, indicating dominance of a specific archaeal group in both conditions. It was clearly verified in Fig. 7a, in which a marked band (Fig. 7a—see arrow) in the inoculum sample was selected and favored in all conditions.

In the same way, the lower richness (15 Chao-1 index) and bacterial diversity (2.68 Shannon index) were obtained in C9 (Table 4); the condition which presented the lowest hydrogen (0.28 mmol L−1) and the highest propionic acid production, indicating that it probably favored bacteria able to produce propionic acids such as Dysgonomonas [70] and Coprococcus [44] selected from microbial inoculum.

In contrast, the higher richness (28 Chao-1 index) and bacterial diversity (3.26 Shannon index) were obtained in C10 (Table 4); the condition which has the highest acetic acid production (488.8 mg L−1), probably due to favoring the acidogenic, acetogenic and homoacetogenic bacteria.

Conclusion

The main goal of this study was to highlight a mixed consortium from soil and compost residue composed of H2, acids, and ethanol-producing bacteria and methanogenic archaea as a potential inoculum for producing biofuels and building-block chemicals simultaneously from sugarcane bagasse. In addition, the optimization of the key factors and prediction of models for enhancement of hydrogen and ethanol production were also reached. The highest ethanol production (20.11 mg L−1) was obtained using 2.0 and 3.0 g L−1 of yeast extract and SCB, respectively, while the maximum hydrogen production (0.60 mmol L−1) was obtained using 3.0 and 4.0 g L−1 of yeast extract and SCB, respectively. Therefore, the response surface methodology was useful to optimize the production of high-quality metabolites from sugarcane bagasse using microbial populations from soil and compost residue as inoculum.

References

Rabelo, S. C., Carrere, H., Maciel Filho, R., & Costa, A. C. (2011). Production of bioethanol, methane and heat from sugarcane bagasse in a biorefinery concept. Bioresource Technology, 102, 7887–7895. https://doi.org/10.1016/j.biortech.2011.05.081.

Pandey, A., Soccol, C. R., Nigam, P., & Soccol, V. T. (2000). Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresource Technology, 74, 69–80.

Khattab, S. M. R., & Watanabe, T. (2019). Bioethanol from sugarcane bagasse: status and perspectives. Amsterdam: Elsevier Inc..

Sawatdeenarunat, C., Surendra, K. C., Takara, D., Oechsner, H., & Khanal, S. K. (2015). Anaerobic digestion of lignocellulosic biomass: challenges and opportunities. Amsterdam: Elsevier Ltd.

Parsaee, M. (2019). Kiani Deh Kiani, M., Karimi, K.: A review of biogas production from sugarcane vinasse. Biomass and Bioenergy, 122, 117–125. https://doi.org/10.1016/j.biombioe.2019.01.034.

Logan, B. E., Oh, S. E., Kim, I. S., & Van Ginkel, S. (2002). Biological hydrogen production measured in batch anaerobic respirometers. Environmental Science & Technology, 36(11), 2530–2535. https://doi.org/10.1021/es015783i.

Ueno, Y., Haruta, S., Ishii, M., & Iqarashi, Y. (2002). Microbial community in anaerobic hydrogen-producing microflora enriched from sludge compost. Applied Microbiology and Biotechnology, 57, 555–562. https://doi.org/10.1007/s002530100806.

Kawagoshi, Y., Hino, N., Fujimoto, A., Nakao, M., Fujita, Y., Sugimura, S., & Furukawa, K. (2005). Effect of inoculum conditioning on hydrogen fermentation and pH effect on bacterial community relevant to hydrogen production. Journal of Bioscience and Bioengineering, 100(5), 524–530. https://doi.org/10.1263/jbb.100.524.

Van Ginkel, S., Sung, S., & Lay, J. J. (2001). Biohydrogen production as a function of pH and substrate concentration. Environmental Science & Technology, 35(24), 4726–4730. https://doi.org/10.1021/es001979r.

Alariya, S. S., Sethi, S., Gupta, S., Lal, B., & Lal, G. B. (2013). Amylase activity of a starch degrading bacteria isolated from soil. Sch. Res. Libr. Arch. Appl. Sci. Res., 5, 15–24.

Tuomela, M., Vikman, M., Hatakka, A., & Itavaara, M. (2009). Biodegradation of lignin in a compost environment: a review. Bioresource Technology, 72, 169–183.

Sahni, T. K., & Goel, A. (2015). Microbial enzymes with special reference to a -amylase. Bioevolution, 2, 19–25.

Batista, G., Souza, R. B. A., Pratto, B., dos Santos-Rocha, M. S. R., & Cruz, A. J. G. (2019). Effect of severity factor on the hydrothermal pretreatment of sugarcane straw. Bioresource Technology, 275, 321–327. https://doi.org/10.1016/j.biortech.2018.12.073.

Wang, J., & Wan, W. (2009). Factors influencing fermentative hydrogen production: a review. International Journal of Hydrogen Energy, 34(2), 799–811. https://doi.org/10.1016/j.ijhydene.2008.11.015.

Soares, L. A., Braga, J. K., Motteran, F., Sakamoto, I. K., Silva, E. L., & Varesche, M. B. A. (2017). Design and optimization of hydrogen production from hydrothermally pretreated sugarcane bagasse using response surface methodology. Water Science and Technology, 75, 95–105.

Dasgupta, D., Suman, S. K., Pandey, D., Ghosh, D., Khan, R., Agrawal, D., Jain, R. K., Vadde, V. T., & Adhikari, D. K. (2013). Design and optimization of ethanol production from bagasse pith hydrolysate by a thermotolerant yeast Kluyveromyces sp. IIPE453 using response surface methodology. Springerplus, 2, 1–10.

Rabelo, C. A. B. S., Soares, L. A., Sakamoto, I. K., Silva, E. L., & Varesche, M. B. A. (2018). Optimization of hydrogen and organic acids productions with autochthonous and allochthonous bacteria from sugarcane bagasse in batch reactors. Journal of Environmental Management, 223, 952–963. https://doi.org/10.1016/j.jenvman.2018.07.015.

Bibi, R., Arshad, M., & Asghar, H. N. (2012). Optimization of factors for accelerated biodegradation of reactive black-5 azo dye. International Journal of Agriculture and Biology, 14, 353–359.

Bielen, A., Verhaart, M., van der Oost, J., & Kengen, S. (2013). Biohydrogen production by the thermophilic bacterium Caldicellulosiruptor saccharolyticus: current status and perspectives. Life., 3(1), 52–85. https://doi.org/10.3390/life3010052.

Ratti, R. P., Delforno, T. P., Sakamoto, I. K., & Varesche, M. B. A. (2015). Thermophilic hydrogen production from sugarcane bagasse pretreated by steam explosion and alkaline delignification. International Journal of Hydrogen Energy, 40(19), 6296–6306. https://doi.org/10.1016/j.ijhydene.2015.03.067.

Soares, L. A., Braga, J. K., Motteran, F., Sakamoto, I. K., Monteiro, P. A. S., Seleghim, P., & Varesche, M. B. A. (2018). Bioconversion of sugarcane bagasse into value-added products by bioaugmentation of endogenous cellulolytic and fermentative communities. Waste and Biomass Valorization. https://doi.org/10.1007/s12649-018-0201-5.

Kalil, M. S., Alshiyab, H. S., Mohtar, W., Yusoff, W., & Selangor, B. (2008). Effect of nitrogen source and carbon to nitrogen ratio on hydrogen production using C. acetobutylicum. Department of Chemical and Process Engineering , Faculty of Engineering , School of Bioscience and Biotechnology , Faculty of Science and Technology. American Journal of Biochemistry and Biotechnology, 4, 393–401.

Jo, J. H., Lee, D. S., Park, D., Choe, W. S., & Park, J. M. (2008). Optimization of key process variables for enhanced hydrogen production by Enterobacter aerogenes using statistical methods. Bioresource Technology, 99(6), 2061–2066. https://doi.org/10.1016/j.biortech.2007.04.027.

Atlas, R. M. (2005). Handbook of media for environmental microbiology, vol. 2 Cellulose Anaerobic Medium (Taylor & Francis Group, ed), CRC press, Boca Raton, pp. 90–91.

Penteado, E. D., Lazaro, C. Z., Sakamoto, I. K., & Zaiat, M. (2013). Influence of seed sludge and pretreatment method on hydrogen production in packed-bed anaerobic reactors. International Journal of Hydrogen Energy, 38(14), 6137–6145. https://doi.org/10.1016/j.ijhydene.2013.01.067.

Ratti, R. P., Botta, L. S., Sakamoto, I. K., & Varesche, M. B. A. (2013). Microbial diversity of hydrogen-producing bacteria in batch reactors fed with cellulose using leachate as inoculum. International Journal of Hydrogen Energy, 38(23), 9707–9717. https://doi.org/10.1016/j.ijhydene.2013.05.089.

Zwietering, M. H., Jongenburger, L., Rombouts, F. M., & Van’t, R. K. (1990). Modeling of the bacterial growth curve. Applied and Environmental Microbiology, 56(6), 1875–1881.

Griffiths, R. I., Whiteley, A. S., Anthony, G., Donnell, O., & Bailey, M. J. (2000). Rapid method for coextraction of DNA and RNA from natural environments for analysis of ribosomal DNA- and rRNA-based microbial community composition. Applied and Environmental Microbiology, 66, 1–5. https://doi.org/10.1128/AEM.66.12.5488-5491.2000.Updated.

Kudo, Y., Nakajima, T., Miyaki, T., & Oyaizu, H. (1997). Methanogen flora of paddy soils in Japan, Microbiology Ecology, 22, 9–48.

Nubel, U., Engelen, B., Felsre, A., Snaidr, J., Wieshuber, A., Amann, R. I., Ludwig, W., & Backhaus, H. (1996). Sequence heterogeneities of genes encoding 16S rRNAs in Paenibacillus polymyxa detected by temperature gradient gel electrophoresis. Journal of Bacteriology, 178, 5636–5643.

Muyzer, G., De Waal, E. C., & Uitterlinden, A. G. (1993). Profiling of complex microbial populations by denaturing gradient gel electrophoresis analysis of polymerase chain reaction-amplified genes coding for 16S rRNA. Applied and Environmental Microbiology, 59, 695–700.

Klindworth, A., Pruesse, E., Schweer, T., Peplies, J., Quast, C., Horn, M., & Gluckner, F. O. (2013). Evaluation of general 16S ribosomal RNA gene PCR primers for classical and next-generation sequencing-based diversity studies. Nucleic Acids Research, 41. https://doi.org/10.1093/nar/gks808.

Cole, J. R., Wang, Q., Fish, J. A., Chai, B., McGarrell, D. M., Sun, Y., Brown, C. T., Porras-Alfaro, A., Kuske, C. R., & Tiedje, J. M. (2014). Ribosomal database project: data and tools for high throughput rRNA analysis. Nucleic Acids Research, 42(D1), D633–D642. https://doi.org/10.1093/nar/gkt1244.

Caporaso, J. G., Kuczynski, J., Stombaugh, J., Bittinger, K., Bushman, F. D., Costello, E. K., Fierer, N., Peña, A. G., Goodrich, J. K., Gordon, J. I., Huttley, G. A., Kelley, S. T., Knights, D., Koenig, J. E., Ley, R. E., Lozupone, C. A., McDonald, D., Muegge, B. D., Pirrung, M., Reeder, J., Sevinsky, J. R., Turnbaugh, P. J., Walters, W. A., Widmann, J., Yatsunenko, T., Zaneveld, J., & Knight, R. (2010). QIIME allows analysis of high-throughput community sequencing data. Nature Methods, 7, 335–336. https://doi.org/10.1038/nmeth.f.303.

Sakamoto, M. (2014). The family porphyromonadaceae. In: Rosenberg E., DeLong E.F., Lory S., Stackebrandt E., Thompson F. (eds) The prokaryotes. Berlin, Heidelberg: Springer.

HJ, B., & G, A. (2005). The Proteobacteria part C, the alpha, beta, delta and epsilonproteobacteria. In Bergey’s manual of systematic bacteriology, vol. 2. (Springer ed.), Michigan State University, EL, pp. 323–439.

Granada, C. E., Hasan, C., Marder, M., Konrad, O., Vargas, L. K., Passaglia, L. M. P., Giongo, A., De Oliveira, R. R., Pereira, L. D. M., De Jesus, F., & Sperotto, R. A. (2018). Biogas from slaughterhouse wastewater anaerobic digestion is driven by the archaeal family Methanobacteriaceae and bacterial families Porphyromonadaceae and Tissierellaceae. Renewable Energy, 118, 840–846. https://doi.org/10.1016/j.renene.2017.11.077.

Aryal, N., Tremblay, P., Lizak, D. M., & Zhang, T. (2017). Bioresource technology performance of different Sporomusa species for the microbial electrosynthesis of acetate from carbon dioxide. Bioresource Technology, 233, 184–190. https://doi.org/10.1016/j.biortech.2017.02.128.

Breitenstein, A., Wiegel, J., Haertig, C., Weiss, N. (2019). Reclassification of Clostridium hydroxybenzoicum as Sedimentibacter hydroxybenzoicus gen. nov., comb. nov., and description of Sedimentibacter saalensis sp. nov. 801–807. https://doi.org/10.1099/ijs.0.01998-0.Abbreviations

Botta, L. S., Ratti, R. P., Sakamoto, I. K., Ramos, L. R., Silva, E. L., & Varesche, M. B. A. (2016). Bioconversion of waste office paper to hydrogen using pretreated rumen fluid inoculum. Bioprocess and Biosystems Engineering, 39(12), 1887–1897. https://doi.org/10.1007/s00449-016-1663-0.

Akinosho, H., Yee, K., Close, D., Ragauskas, A., Fong, S. (2014). The emergence of Clostridium thermocellum as a high utility candidate for consolidated bioprocessing applications. 2, 1–18. https://doi.org/10.3389/fchem.2014.00066.

Cardena, R., Valdez-VasquezIdania, & Buitron, G. (2017). Effect of volatile fatty acids mixtures on the simultaneous photofermentative production of hydrogen and polyhydroxybutyrate. Bioprocess and Biosystems Engineering, 40, 231–239. https://doi.org/10.1007/s00449-016-1691-9.

Kuever, J., Rainey, F.A., & Widdel, F. (2005). The Archaea and the deeply branching and phototrophic bacteria. In Bergey’s Manual of systematic bacteriology, vol. 1. (Springer ed.), New York, NY, pp. 1007–1010.

Moraes, B. D. S., Mary, G., Delforno, T. P., Fuess, L. T., & José, A. (2018). Enriched microbial consortia for dark fermentation of sugarcane vinasse towards value-added short-chain organic acids and alcohol production. Journal of Bioscience and Bioengineering, 127(5), 594–601. https://doi.org/10.1016/j.jbiosc.2018.10.008.

Robert, C., Chassard, C., Lawson, P. A., & Bernalier-Donadille, A. (2007). Bacteroides cellulosilyticus sp. nov., a cellulolytic bacterium from the human gut microbial community. International Journal of Systematic and Evolutionary Microbiology, 57, 1516–1520. https://doi.org/10.1099/ijs.0.64998-0.

Solden, L. M., Hoyt, D. W., Collins, W. B., Plank, J. E., Daly, R. A., Hildebrand, E., Beavers, T. J., Wolfe, R., Nicora, C. D., Purvine, S. O., Carstensen, M., Lipton, M. S., Spalinger, D. E., Firkins, J. L., Wolfe, B. A., & Wrighton, K. C. (2016). New roles in hemicellulosic sugar fermentation for the uncultivated Bacteroidetes family BS11. The ISME Journal, 11, 691–703. https://doi.org/10.1038/ismej.2016.150.

Pitta, D. W., Indugu, N., Vecchiarelli, B., Rico, D. E., & Harvatine, K. J. (2018). Alterations in ruminal bacterial populations at induction and recovery from diet-induced milk fat depression in dairy cows. Journal of Dairy Science, 101(1), 295–309. https://doi.org/10.3168/jds.2016-12514.

Jewell, K. A., Mccormick, C. A., Odt, C. L., Weimer, P. J., & Suen, G. (2015). Ruminal bacterial community composition in dairy cows is dynamic over the course of two lactations and correlates with feed efficiency. Applied and Environmental Microbiology, 81, 4697–4710. https://doi.org/10.1128/AEM.00720-15.

Jiao, J., Wu, J., Zhou, C., Tang, S., & Wang, M. (2016). Composition of ileal bacterial community in grazing goats varies across non-rumination, transition and rumination stages of life. Frontiers in Microbiology, 7, 1–9. https://doi.org/10.3389/fmicb.2016.01364.

Reid, N. M., Addison, S. L., West, M. A., Lloyd-jones, G. (2014). The bacterial microbiota of Stolotermes ruficeps (Stolotermitidae), a phylogenetically basal termite endemic to New Zealand. https://doi.org/10.1111/1574-6941.12424.

Hongoh, Y., Sato, T., Dolan, M. F., Noda, S., Ui, S., Kudo, T., & Ohkuma, M. (2007). The motility symbiont of the termite gut flagellate Caduceia versatilis is a member of the “Synergistes” group. Applied and Environmental Microbiology, 73, 6270–6276. https://doi.org/10.1128/AEM.00750-07.

Kuever, J. (2014). The family Syntrophaceae. In E. Rosenberg, E. F. DeLong, S. Lory, E. Stackebrandt, & F. Thompson (Eds.), The prokaryotes. Berlin, Heidelberg: Springer.

Gaby, J. C., Zamanzadeh, M., & Horn, S. J. (2017). The effect of temperature and retention time on methane production and microbial community composition in staged anaerobic digesters fed with food waste. Biotechnology for Biofuels, 10(1), 302. https://doi.org/10.1186/s13068-017-0989-4.

Jackson, B. E., Bhupathiraju, V. K., Tanner, R. S., Woese, C. R., & Mcinerney, M. J. (1999). A new anaerobic bacterium that degrades fatty acids and benzoate in syntrophic association with hydrogen-using microorganisms. Archives of Microbiology, 171, 107–114.

Garrity, G. M., Brown, A., & Vickers, R. M. (1980). Tatlockia and Fluoribacter: two new genera of organisms resembling Legionella pneumophila. International Journal of Systematic Bacteriology, 609–614.

Brenner, D. O. N. J., Steigerwalt, A. G., Gorman, G. W., Wilkinson, H. W., Bibb, W. F., Hackel, M., Tyndall, R. L., Campbell, J., James, C., Thacker, W. L., Skaliy, P., Martin, W. T., Brake, B. J., Barry, S., Mceachern, H. V., & Corcoran, L. K. (1985). Ten new species of Legionella. International Journal of Systematic Bacteriology, 35(1), 50–59.

Treu, L., Tsapekos, P., Peprah, M., Campanaro, S., Giacomini, A., Corich, V., Kougias, P. G., & Angelidaki, I. (2019). Bioresource technology microbial profiling during anaerobic digestion of cheese whey in reactors operated at different conditions. Bioresource Technology, 275, 375–385. https://doi.org/10.1016/j.biortech.2018.12.084.

Silva, V., Ratti, R. P., Sakamoto, I. K., Andrade, M. V. F., & Varesche, M. B. A. (2018). Biotechnological products in batch reactors obtained from cellulose, glucose and xylose using thermophilic anaerobic consortium. Renewable Energy, 125, 537–545. https://doi.org/10.1016/j.renene.2018.02.124.

Pattra, S., Sangyoka, S., Boonmee, M., & Reungsang, A. (2008). Bio-hydrogen production from the fermentation of sugarcane bagasse hydrolysate by Clostridium butyricum. International Journal of Hydrogen Energy, 33(19), 5256–5265. https://doi.org/10.1016/j.ijhydene.2008.05.008.

Xu, L., Ren, N., Wang, X., & Jia, Y. (2008). Biohydrogen production by Ethanoligenens harbinense B49: nutrient optimization. International Journal of Hydrogen Energy, 33(23), 6962–6967. https://doi.org/10.1016/j.ijhydene.2008.09.005.

Maintinguer, S. I., Fernandes, B. S., Duarte, I. C. S., Saavedra, N. K., Adorno, M. A. T., & Varesche, M. B. (2011). Fermentative hydrogen production with xylose by Clostridium and Klebsiella species in anaerobic batch reactors. International Journal of Hydrogen Energy, 36, 13508–13517. https://doi.org/10.1016/j.ijhydene.2011.07.095.

Das, D., & Veziroglu, T. N. (2008). Advances in biological hydrogen production processes. International Journal of Hydrogen Energy, 33(21), 6046–6057. https://doi.org/10.1016/j.ijhydene.2008.07.098.

Cavalcante de Amorim, E. L., Barros, A. R., Rissato Zamariolli Damianovic, M. H., & Silva, E. L. (2009). Anaerobic fluidized bed reactor with expanded clay as support for hydrogen production through dark fermentation of glucose. International Journal of Hydrogen Energy, 34, 783–790. https://doi.org/10.1016/j.ijhydene.2008.11.007.

Saady, N. M. C. (2013). Homoacetogenesis during hydrogen production by mixed cultures dark fermentation: unresolved challenge. International Journal of Hydrogen Energy, 38(30), 13172–13191. https://doi.org/10.1016/j.ijhydene.2013.07.122.

Tremblay, P. L., Höglund, D., Koza, A., Bonde, I., & Zhang, T. (2015). Adaptation of the autotrophic acetogen Sporomusa ovata to methanol accelerates the conversion of CO2 to organic products. Scientific Reports, 5(1), 1–11. https://doi.org/10.1038/srep16168.

Tsavkelova, E. A., & Netrusov, A. I. (2012). Biogas production from cellulose-containing substrates: a review. Applied Biochemistry and Microbiology, 48(5), 421–433. https://doi.org/10.1134/s0003683812050134.

Levin, D. B., Pitt, L., & Love, M. (2004). Biohydrogen production: prospects and limitations to practical application. International Journal of Hydrogen Energy, 29(2), 173–185. https://doi.org/10.1016/S0360-3199(03)00094-6.

Li, C., & Fang, H. H. P. (2007). Fermentative hydrogen production from wastewater and solid wastes by mixed cultures. Critical Reviews in Environmental Science and Technology, 37, 1–39.

Serrano-Silva, N., Sarria-Guzmán, Y., Dendooven, L., & Luna-Guido, M. (2014). Methanogenesis and methanotrophy in soil: a review. Pedosphere., 24(3), 291–307. https://doi.org/10.1016/S1002-0160(14)60016-3.

Xiong, Z., Hussain, A., Lee, J., & Lee, H. S. (2019). Food waste fermentation in a leach bed reactor: reactor performance, and microbial ecology and dynamics. Bioresource Technology, 274, 153–161. https://doi.org/10.1016/j.biortech.2018.11.066.

Funding

The authors thank the financial support of the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP—process numbers 2013/22346-6, 2009/15984-0, and 2015/06246-7) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brazil (CAPES)-Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

We declare that the authorship and content of the manuscript “Screening and bioprospecting of anaerobic consortia for biofuel production enhancement from sugarcane bagasse” has been approved by all authors, and prevailing that all local, national and international conventions and regulations, and the normal scientific ethical practices have been respected. The authors of this study attribute rights to Applied Biochemistry and Biotechnology where this is published. We ask that academics have the rights to post and use this paper.

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soares, L.A., Silva Rabelo, C.A.B., Sakamoto, I.K. et al. Screening and Bioprospecting of Anaerobic Consortia for Biofuel Production Enhancement from Sugarcane Bagasse. Appl Biochem Biotechnol 190, 232–251 (2020). https://doi.org/10.1007/s12010-019-03074-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03074-2