Abstract

This study aimed to evaluate the properties of xanthan gum produced by Xanthomonas campestris pv. campestris 1866 and 1867 from lignocellulosic agroindustrial wastes. XG was produced using an orbital shaker in a culture medium containing coconut shell (CS), cocoa husks (CH), or sucrose (S) minimally supplemented with urea and potassium. The XG production results varied between the CS, CH, and S means, and it was higher with the CH in strains 1866 (4.48 g L−1) and 1867 (3.89 g L−1). However, there was more apparent viscosity in the S gum (181.88 mPas) and the CS gum (112.06 mPas) for both 1866 and 1867, respectively. The ability of XGCS and XGCH to emulsify different vegetable oils was similar to the ability of XGS. All gums exhibited good thermal stability and marked groups in the elucidation of compounds and particles with rough surfaces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polysaccharides have attracted industry attention because of their significant properties, such as biocompatibility, biodegradability, non-toxicity, and renewability [1]. Xanthan gum (XG) is a natural polysaccharide that has a primary structure composed of repeated pentasaccharide units and a central chain consisting of [1, 2] β-D-glucose units. The trisaccharide side chains contain one unit of D-glucuronic acid between two D-mannose units. The D-mannose moiety has an acetyl group and a pyruvate group [2,3,4].

XG is produced by Gram-negative bacteria from the genus Xanthomonas, and the most commonly used species is Xanthomonas campestris [5]. The microorganism is strictly aerobic; therefore, oxygen is essential for its growth and xanthan gum production [6, 7]. Varying the bacterial strains and the fermentation conditions used in the production process significantly affects the degree of pyruvation, acetylation, and physicochemical properties of the XG [8, 9].

XG has several applications in industry (food, cosmetics, pharmaceutical, and petroleum), mainly due to its various physicochemical properties, including stable viscosity at varying pH levels and temperatures, and its associated pseudoplastic behavior at low concentrations [1, 10, 11].

Considering the total volume XG produced worldwide, 65% is used in the food industry, 15% is used in the oil industry, and approximately 20% is used in other applications. The use of XG is increasing for many applications, and its estimated annual growth is approximately 5–10% [2, 7]. The primary manufacturers of this biopolymer are located in China (Fufeng Group, Shandong Province and Deosen Biochemical, Zibo City) and Austria (Jungbunzlauer, Pernhofen). Brazil consumes approximately 30,000 t of XG per year, which is supplied by international industries [12].

Because the preferred substrates are glucose and sucrose, the XG production process is often limited by cost [13, 14]. However, to minimize these costs, several alternative carbon sources have been used [1, 15], such as crude glycerin from biodiesel [16, 17], liquid residue from sisal [18], crustaceans and bivalves, cocoa bark residue [19], cassava whey [20], date extract [21], cane juice [22], and sugar beet molasses [23]. These alternatives can reduce the total cost of XG production, as well as add value to the environmentally sustainable waste generated from agroindustrial processes since most of this waste does not receive adequate disposal and causes environmental problems [15, 23].

The novelty of this work is to high yield of xanthan gum produced by Xanthomonas campestris pv. campestris IBSBF 1866 and 1867 from coconut shells (CS) and cocoa husks (CH), enabling the reuse of industrial waste, providing subsidies for its industrial applications, such as thermal stability, the ability to form emulsions, and strong presence of functional chemical groups. The importance of the present work is part of the effort to reduce the cost of the materials, excessive consumption of petroleum resources, and the environmental impact resulting from industrial products.

Material and Methods

Materials

Xanthomonas campestris pv. campestris 1866 and 1867 (Collection of the Section of Bacteriology Plant Pathology, SP-Brazil), Ágar YM (Acumedia, Brazil), refrigerated incubator with shaking (Tecnal, Brazil), sucrose (Sigma, Brazil), Centrífuge 5702-R (Eppendorf, Brazil), and Oven (DeLeo, Brazil).

Agroindustrial Waste Composition and Proximate

The coconut shells (CS) and cocoa husks (CH) used as alternative fermentable substrates were dried in an oven with forced ventilation (New Ethics, model 400/ND) at an average temperature of 50 °C to a constant weight, ground in a mini-processor (Walita Master), conditioned at ambient temperature, and evaluated for moisture, ash, protein content [24], and total lipids [25]. Carbohydrate content was calculated by subtracting the sum of the percentages of the moisture, protein, total fat, and ash from 100. Analyses were performed in triplicate. The medium containing 2% (w/v) CH and CS were self-hydrolyzed under sterilization conditions (121 °C for 15 min), and the resulting medium were subjected to total and reducing sugar analysis following Eynon-Lane [26] method and non-reducing sugars were calculated by difference between the content of reducing sugars and the total of sugars.

Xanthan Gum Production (XG): Microorganism, Medium Composition, and Fermentation Description

Xanthomonas campestris pv. campestris 1866 and 1867 was provided by the Culture Collection of the Section of Bacteriology Plant Pathology, Biological Institute of Campinas, SP-Brazil. The cultures were maintained on petri plates containing YM agar (2.0% w/v), kept at a cool temperature and subcultured periodically [18]. The inoculum was prepared in a YM medium standard (0.3% w/v malt extract, 0.3% w/v yeast extract, 0.5% w/v bacterial peptone and 1.0% w/v glucose), with a scoop of the Xanthomonas campestris 1866 or 1867 culture and incubated on a rotary shaker (shaker Tecnal, TE-424) (28 °C/180 rpm/24 h) [13, 19]. For XG production, samples were transferred to 16-mL conical flasks of inoculum (250 mL) containing 80 mL of fermentation medium composed of 2.0% substrate, CS, CH, or sucrose (control) supplemented with urea (0.01% w/v) and KH2PO4 (0.1% w/v). The aerobic fermentation occurred in a rotary shaker (28 °C/250 rpm/96 h) [14, 20]. All media were autoclaved (vertical autoclaves, alpha, 121 °C/15 min). XG production was performed in triplicate. The XG was separated by isolating the X. campestris cells by centrifugation (Eppendorf 5702R) (×16,128g/4 °C/30 min) and adding ethanol to the supernatant (three parts alcohol to one part fermentative medium). The gum was then dried in an oven (30 °C/48 h) and ground for gravimetric determination of the yield (g L−1) and characterization [22].

XG Characterization

Apparent Viscosity

The apparent viscosity was measured as a function of the shear rate using a rheometer with concentric cylinders (Haake CV-20) and 25 mL of aqueous XG solution (0.5% w/v) [13]. The apparent viscosity of the XG aqueous solution was determined at 25 °C and a shear rate of 25 to 1000 s−1. The effect of the shear rate on the viscosity of the XG solution is described by the Ostwald-de Waele kinetic model [27], compared to standard xanthan gum sigma according to Eq. (1). The results were compared with standard xanthan gum sigma.

where K is the consistency index, n is the flow behavior index, μ is the apparent viscosity, and γ is the shear rate.

Fourier Transform Infrared Spectroscopy (FTIR)

To identify the main functional groups, spectroscopic analysis of the XG was performed by the ATR technique Shimadzu (IR prestige 21), operating in a spectral window with 600–4000 waves cm−1 with a 32-scan/sample resolution of 4 waves cm−1 and a detector scanning speed equal to 10 kHz [28]. The results were compared with standard xanthan gum sigma.

Emulsification Index (IE24)

XGs and four different vegetable oils (cotton, olive oil, corn, and soybean) were used to determine the emulsification index (IE24). The suspension gum (0.1% w/v) and each oil sample were added to tubes at a ratio of 2:3 (v/v) and vortexed for 2 min. After 24 h of rest, the height of the emulsified layer and the total height of the liquid layer were measured [29]. The IE24 was calculated according to the equation below:

Thermal Gravimetric Analysis (TGA/dTGA)

Thermal analyses of the XGs were made by thermogravimetry (TGA-Perkin Elmer Mod. Pyris 1 TGA). Approximately 5.0 mg of the initial weight of each sample was subjected to a temperature change between 25 and 700 °C at a heating rate of 10 °C min−1 29 and an N2 atmosphere at a flow rate of 20 mL min−1. The results were compared with standard xanthan gum sigma.

Differential Scanning Calorimetry (DSC)

The DSC (Shimadzu, Mod. TA-60) curves were obtained in the temperature range of 25 to 400 °C, with a heating rate of 10 °C min−1 and a dynamic atmosphere of synthetic air with a flow rate of 50 mL min−1. An aluminum crucible was used as the sample holder, and the mass of the analyzed samples ranged from 4.0 to 10.0 mg [30]. The results were compared with standard xanthan gum sigma.

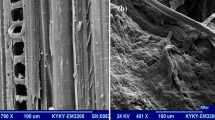

Scanning Electron Microscopy (SEM)

Morphological analyses of the CS, CH, and S XGs produced by strains 1866 and 1867 were performed using an SEM (Tescan, Mod. Vega-3 LMU). The samples were fixed in a metal support with double-sided carbon tape and covered with a thin layer of gold (Quorum Technologies, Mod. Q150R). Samples were viewed at a 1000-fold increase, with a 3-kV excitation voltage [31].

Results and Discussion

Agroindustrial Waste Composition and Proximate

Table 1 shows that the chemical composition of the coconut shells (CS) and cocoa husks (CH) had very marked differences, especially in moisture, ash, and crude protein, resulting in differences in the composition of the fermentable substrates used to produce xanthan gum (XG). Because nutrients and micronutrients influence the cell growth of Xanthomonas bacteria and the production of XG during the fermentation process, analysis of the centesimal composition of the fermentable substrates is crucial [20, 32].

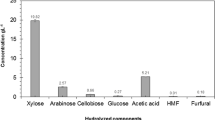

CH and CS are composed of a high concentration of directly fermentable carbohydrates (cellulose, fibers, hemicellulose, lignin etc.), which can be bioconverted into free sugars. Basically this conversion occurs by way of a self-hydrolysis during the sterilization of the medium (121 °C for 15 min), followed by the enzymatic action of the bacteria themselves during fermentation [33]. After sterilization, the CH medium showed a contraction of 2.55% total sugar, of which 1.42% is reducing sugars and 1.13% non-reducing sugars, whereas the medium containing CS showed 2.50% of total sugar, of which 1.45% reducing sugars and 1.05% of non-reducing sugars. Although these sugars are preferentially consumed by microorganisms, studies of the genomic analysis of Xanthomonas campestris pv campestris reveal that these phytopathogens are capable of producing and secreting various enzymes involved in the degradation of plant cell wall components, such as structural polysaccharides, cellulose, and hemicellulose. Among these enzymes are the pectinases, lyases, xylanases, and cellulases, especially endoglucanases. [34, 35].

Production of XG is influenced by a high C:N ratio, which differed between the CS and CH (Table 1). According to Nitschke et al. [36], the accumulation of polymers is favored in media where the carbon content is high and nitrogen is low, which may explain the higher production of XG from the CH cultivation. When the nitrogen concentration in the medium is higher, there is rapid cell growth and the XG that is produced has a low apparent viscosity. Industrial processes prefer conditions that favor both growth and gum accumulation.

Diniz et al. [14] reported XG yields of 0.65 to 5.42 g L−1 using cocoa shells with different strains of Xanthomonas, after 120 h of fermentation. Nery et al. [32] evaluated the XG production from X. campestris strain 1866 using milk whey as the substrate, and it yielded 12.36 g L−1. Biopolymer production depends on the composition of the medium, the lineage, and the fermentation conditions used, such as temperature, stirring speed, and initial nitrogen concentration, and can therefore lead to variations in yield and polymer quality [37, 38].

XG Characterization

Apparent Viscosity

The rheological properties of the XG aqueous solutions were assessed by apparent viscosity analysis and are shown in Fig. 1. The curve shows that the shear rate increases the viscosity decreases, demonstrating the pseudoplastic behavior characteristic of XG [12, 13]. The viscosity of the biopolymers from the CS (134.20 mPa s, 112.06 mPa s) and CH (120.51 mPa s, 72.46 mPa s), strains 1866 and 1867, respectively, showed values close to those obtained with S (181.88 mPa s, 93.59 mPa s), demonstrating that alternative fermentable substrates have biotechnological potential. Xanthan gum sigma showed a viscosity value of 295.85 mPa s.

Higher viscosity values were obtained from strain 1867, indicating that the strain had a greater effect on the variation in maximum apparent viscosity than the substrate. Similarities in the production and rheological behavior of the gum produced by strains 1866 and 1867 were also observed. In addition, the acetate and pyruvate contents influenced the viscosity of the xanthan solution, so that high pyruvate content and low acetate content contribute to increase the viscosity of the solutions [39, 40]. Thus, CS and CH have significant chemical compositions, and they can be used as alternative substrates in XG production, providing a method for reducing production costs that is environmentally sustainable.

The pseudoplastic behavior of the manufactured polysaccharides was confirmed by fitting the Ostwald-de Waele model (Eq. 1) to the experimental data, based on the power regression (Table 2).

Samples from the XG solutions had correlation coefficients (R2) equal to 0.99, indicating that the model is valid and the flow behavior index (n < 1) is less than one unit, confirming the pseudoplastic behavior of the solutions prepared with the polysaccharides. The value of the consistency index (K) indicates the level of fluid resistance in the flow. A higher K value indicates that the fluid is more viscous [28], which is preferable in the food industry since it will further reduce the number of additives required [41].

Fourier Transform Infrared Spectroscopy (FTIR)

The FTIR spectra of the XGs, CS, and CH were compared with the xanthan gum S and xanthan gum sigma to identify functional groups (Fig. 2). All samples showed hydroxyl (3285 cm−1), carbonyl (2950, 1639, and 694 cm−1), carboxyl (1450 cm−1), and acetyl groups (1049 cm−1) in the XG structure.

The gums produced from the three media and the two strains showed a higher proportion of carbonyl groups; however, the gum produced by the 1867 strain also had a higher proportion of acetyl groups. This results in higher solubility and, consequently, increases the possibilities of industrial applications of xanthan gum [42]. In addition, the FTIR spectra showed that the vibration frequencies of these groups were more intense in the XGs from strain 1867, indicating that the strain that is used influences the vibration intensities of the chemical groups.

Gilani et al. [43], demonstrated that commercial XG contains the following chemical groups: hydroxyl (3386 cm−1), carbonyl (1627 cm−1), carboxyl (1529 cm−1), and acetyl (1160 cm−1). Thus, it can be inferred that the XGs from different substrates and different strains have similar spectral behavior.

Emulsification Index (IE24)

Polysaccharides are used to control the rheological properties of the emulsions, contributing to the stability of the emulsion. Xanthan gum is one of the main stabilizers in food emulsions because it is a good thickening agent for aqueous solutions. Its ability to increase both the viscosity and the stability of the emulsion depends on the concentration and structure of the polymer [44]. The results of the emulsification capacity of the XG after 24 h of preparation with different oils are shown in Table 3.

Strain 1866 with olive oil had the best IE24 of the XG solutions produced in the three media, reaching values of 71, 72, and 75% by S, CS, and CH, respectively. The gums from strain 1867 behaved differently in the IE24 analysis, with the XG solutions from S (64%) and CH (67%) both having better results with cottonseed oil, and the XG solution from the CS (70%) obtaining the best result with the soybean oil.

Iyer et al. [29] rated the IE24 of a commercial xanthan gum solution (1 g L−1 w/v) with different vegetable oils and found a greater IE24 with peanut oil (61%). Thus, the gum produced with the CS and CH showed good emulsification ability with different vegetable oils.

Thermogravimetric Analysis (TGA/dTGA)

The TGA/dTGA XG curves produced from CS, CH, and S as carbon sources and xanthan gum sigma are shown in Fig. 3.

As shown in Fig. 3, the CS and CH gums produced by strain 1867 had similar behavior to that of the S gum and xanthan gum sigma, where two thermal events were observed. The CS and CH gums produced by strain 1866 presented three thermal events.

The first thermal event corresponds to the dehydration of the polysaccharides. The presence of water in the samples may be related to the rapid absorption of water during gum weighing. According to Faria et al. [45], XG absorbs water due to the presence of polar groups in its chemical structure. The second thermal event is associated with the degradation of the xanthan polymer chain [46], which begins by disrupting groups belonging to the side chain, and subsequently causes the main chain to unfold. The third thermal event may indicate that part of the substrate was not bioconverted. The initial degradation temperature (Tonset), maximum decomposition temperature (Tmax) and mass losses are shown in Table 4.

As shown in Fig. 3 and Table 4, only the CS and CH gums from strain 1866 showed a third thermal event, suggesting that part of the substrate was not bioconverted into a polymer and remained adhered to the gum during the separation process. This may also explain the higher yield values from the fermentation by X. campestris 1866.

According to Zohuriaan and Shokrolahi [46], the degradation temperature range for commercial XG is between 251.15 and 330.30 °C, with weight loss ranging from 8.7 to 41.6%. For the gums obtained from production with CS and CH, strains 1866 and 1867 have similar thermal stability to the control (S) and sigma XG, indicating their potential for use in processes that require high temperatures. Faria et al. [45] evaluated the thermal conditions of XG from cane juice and showed that thermal degradation occurred at temperatures between 220 and 320 °C with a mass loss of 40% and the maximum loss occurring at 283 °C.

Differential Scanning Calorimetry (DSC)

The DSC curves shown in Fig. 4 show that the XGs from S, CS, and CH by X. campestris strains 1866 and 1867 and xanthan gum sigma behaved similarly when subjected to the same temperature conditions.

Two events can be identified, one endothermic peak, and one exothermic peak. The first event varied between 25 and 150 °C, showing an endothermic peak at approximately 86 °C, attributed to a loss of moisture in the sample. The second event started at approximately 250 °C, showing an exothermic peak related to polysaccharide degradation [45].

Maia et al [30] demonstrated that the commercial xanthan gum sample had a broad endothermic peak below 100 °C and an exothermic peak at 275 °C. According to Zohuriaan and Shokrolahi [46], the degradation phase is probably exothermic, since the formed products (CO, CO2, CH4) are more stable than the polysaccharide chain.

Scanning Electron Microscopy (SEM)

Figure 5 shows the scanning electron microscopy analysis of the XGs from the different substrates with strains 1866 and 1867 at a magnification of ×1000.

The structural changes in the gums from the different strains, regardless of the substrate, are shown. The gums from strain 1866 (Fig. 5a–c) presented a rough surface, presence of fibers, and irregular particles and reticles. The gums obtained from strain 1867 (Fig. 5d–f) were more heterogeneous and well-defined. The difference in the micrographs of the CS gums (Fig. 4b) and the CH gums (Fig. 4c) from strain 1866 relative to the other gums, suggests that part of the substrate remained in the gum during the separation process, which corroborates the TGA data that presented three events, as well as the highest production values. According to Ahuja et al. [31], samples that have rough surfaces cause blockage and result in less flow of irregularly shaped particles.

Conclusions

These results show the possibility of using coconut shells and cocoa husks to produce xanthan gum by X. campestris 1866 and 1867, representing a method of reusing these agroindustrial wastes in addition to reducing the production costs of biopolymers. Both strains produced approximately three times more xanthan gum with the alternative substrates compared to sucrose, and cocoa husk showed a greater capacity for bioconversion. The viscosities of the culture medium influenced the transfer of nutrients and micro cells and consequently affected the extracellular production of the biopolymer. Gums obtained from the alternative substrates showed thermal stability, the ability to form emulsions with different vegetable oils, a strong presence of functional chemical groups and a structural change in the gum shape when altering the strain during the fermentation process.

References

Niknezhad, S. V., Mohammad, A. A., Zamani, A., & Biria, D. (2016). Production of xanthan gum by free and immobilized cells of Xanthomonas campestris and Xanthomonas pelargonii. International Journal of Biological Macromolecules, 82, 751–756.

Rosalam, S., & England, R. (2006). Review of xanthan gum production from unmodified starches by Xanthomonas campestris sp. Enzyme and Microbial Technology, 39(2), 197–207.

Barua, R., Alam, M. J., Salim, M., & Ashrafee, T. S. (2016). Smalls acle production and characterization of xanthan gum synthesized by local isolates of Xanthomonas campestris. Journal of Experimental Biology, 54, 151–155.

Jin, C. Q., & Park, S. M. (2001). The fractal behavior of polyaniline-dodecylbenzenesulfonate salt and polyaniline-chlorophyll studied by small-angle X-ray scattering. Synthetic Metals, 124(2-3), 443–447.

Badwaik, H. R., Sakure, K., Alexander, A., Ajazuddin, Dhongade, H., & Tripathi, D. K. (2016). Synthesis and caracterisation of poly(acryalamide) grafted carboxymethyl xanthan gum copolymer. International Journal of Biological Macromolecules, 85, 361–369.

García-Ochoa, F., Gómez, E. C., & Santos, V. E. (2000). Oxygen transfer and uptake rates during xanthan gum production. Enzyme and Microbiology Technology, 27(9), 680–690.

Lopes, B. M., Lessa, V. L., Silva, B. M., Carvalho Filho, M. A. S., Schnitzler, E., & Lacerda, L. G. (2015). Xanthan gum: properties, production conditions, quality and economic perspective. Journal of Food Nutrition Research, 54, 185–194.

Desplanques, S., Renou, F., Grisel, M., & Malhiac, C. (2012). Impact of chemical composition of xanthan and acacia gums on the emulsification and stability of oil-in-water emulsions. Food Hydrocolloids, 27(2), 401–410.

Ross-Murphy, S. B., Shatwell, K. P., Sutherland, I. W., & Dea, I. C. M. (1996). Influence of acyl substituents on the interaction of xanthans with plant polysaccharides. Food Hydrocolloids, 10(1), 117–122.

Hayati, I. N., Ching, C. W., & Rozaini, M. Z. H. (2016). Flow properties of o/w emulsions as affected by xanthan gum, guar gum and carboxymethyl cellulose interactions studied by a mixture regression modelling. Food Hydrocolloids, 53, 199–208.

Wang, Z., Wu, J., Zhu, L., & Zhan, X. (2017). Characterization of xanthan gum produced from glycerol by a mutant strain Xanthomonas campestris CCTCC M2015714. Carbohydrate Polymers, 157, 521–526.

Luvielmo, M., & Scamparini, A. (2009). Xanthan gum: production, recovery, properties and application. Estudos Tecnológicos, 5(1), 50–67.

Assis, D. J., Brandão, L. V., Costa, L. A. S., Figueiredo, T. V. B., Sousa, L. S., Padilha, F. F., & Druzian, J. I. (2014). A study of the effects of aeration and agitation on the properties and production of xanthan gum from crude glycerin derived from biodiesel using the response surface methodology. Applied Biochemistry and Biotechnology, 172(13), 2769–2785.

Diniz, D. M., Druzian, J. I., & Audibert, S. (2012). Production of xanthan gum by Xanthomonas campestris strains native from bark cocoa or whey. Polímeros: Ciência e Tecnologia, 22(3), 278–281.

Assis, D. J., Gomes, G. V. P., Pascoal, D. R. C., Pinho, L. S., Chaves, L. B. O., & Druzian, J. I. (2016). Simultaneous biosynthesis of polyhydroxyalkanoates and extracellular polymeric substance (eps) from crude glycerol from biodiesel production by different bacterial strains. Applied Biochemistry and Biotechnology, 180(6), 1110–1127.

Wang, Z., Wu, J., Zhu, L., & Zhan, X. (2016). Activation of glycerol metabolism in Xanthomonas campestris by adaptive evolution to produce a high-transparency and low-viscosity xanthan gum from glycerol. Bioresource Technology, 211, 390–397.

Wang, Z., Wu, J., Gao, M., Zhu, L., & Zhan, X. (2017). High production of xanthan gum by a glycerol-tolerant strain Xanthomonas campestris WXLB-006. Biochemistry & Biotechnology., 47, 468–472.

Assis, D. J., Costa, L. A. S., Campos, M. I., de Souza, C. O., Druzian, J. I., Nunes, I. L., & Padilha, F. F. (2014). Influence of the nature agro-industrial waste fermented by Xanthomonas axonopodis pv. manihotis the porperties of xanthan gums resulting. Polímeros: Ciência e Tecnologia, 24(2), 176–183.

Costa, L. A. S., Campos, M. I., Druzian, J. I., de Oliveira, A. M., & de Oliveira Jr., E. N. (2014). Biosynthesis of xanthan gum from fermenting shrimp shell: yield and apparent viscosity. International Journal of Polymer Science, 2014, 8.

Brandão, L. V., Esperidião, M. C. A., & Druzian, J. I. (2010). Use of the cassava serum as fermentative substrate in xanthan gum biosynthesis: apparent viscosity and production. Food Science and Technology, 20, 1–6.

Moosavi-nasab, M., Shekaripour, F., & Alipoor, M. (2009). Use of date syrup as agricultural waste for xanthan production by Xanthomonas campestris. Agricultural Research, 27, 89–98.

Brandão, L. V., Nery, T. B. R., Machado, B. A. S., Esperidião, M. C. A., & Druzian, J. I. (2008). Production of xanthan gum obtained from sugarcane. Food Science and Technology, 28, 217–222.

Kalogiannis, S., Lakovidou, G., Liakopoulou-Kyriakides, M., Kyriakidis, D. A., & Skaracis, G. N. (2003). Optimization of xanthan gum production by Xanthomonas campestris grown in molasses. Process Biochemistry, 39(2), 249–256.

Horwitz, W. (2000). Official methods of analysis of AOAC international (17 th ed.). Gaithersburg, Maryland: Association of official analytical chemists international.

Bligh, E. G., & Dyer, W. J. J. (1959). A rapid method of total lipid extraction and purification. Journal of Biochemistry and Physiology, 37, 911–917.

Lane, J. H., & Eynon, L. (1934). Determination of reducing sugars by Fehling’s solution with methylene blue indicator. London: Normam Rodge.

Chhabra, R. P., & Richardson, J. F. (1999). Non-Newtonian flow in the process industries fundamentals and engineering applications. Oxford: Butterworth-Heinemann.

Gomes, G. V. P., Assis, D. J., da Silva, J. B. A., Santos-Ebinuma, V. C., Costa, L. A. S., & Druzian, J. I. (2015). Obtaining xanthan gum impregnated with cellulose microfibrils derived from sugarcane bagasse. Materials Today: Proceedings, 2(1), 389–398.

Iyer, A., Mody, K., & Jha, B. (2006). Emulsifying properties of a marine bacterial, exopolysaccharide. Enzyme and Microbial Technology, 38(1-2), 220–222.

Maia, A. M. S., Silva, H. V. M., Curti, P. S., & Balaban, R. C. (2012). Study of the reaction of grafting acrylamide onto xanthan gum. Carbohydrate Polymers, 90(2), 778–783.

Ahuja, M., Kumar, A., & Drug, K. S. (2012). Synthesis, characterization and in vitro release behavior of carboxymethyl xanthan. International Journal of Biological Macromolecules, 51(5), 1086–1090.

Nery, T. B. R., Brandão, L. V., Esperidião, M. C. A., & Druzian, J. I. (2008). Biosynthesis of xanthan gum from the fermentation of milk whey: productivity and viscosity. Química Nova, 39, 1937–1941.

Nery, T. B. R., Cruz, A. J. D., & Druzian, J. I. (2013). Use of green coconut shells as an alternative substrate for the production of xanthan gum on different scales of fermentation. Polímeros, 23(5), 602–607.

Van Sluys, M. A., Monteiro-Vitorello, C. B., Camargo, L. E. A., Menck, C. F. M., da Silva, A. C. R., Ferro, J. Á., Oliveira, M. C., Setubal, J. C., Kitajima, J. P., & Simpson, A. J. (2002). Comparative genomic analysis of plant-associated bacteria. Annual Review of Phytopathology, 40, 169–189.

Rosseto, F. R., Manzine, L. R., Neto, N. O., & Polikarpov, I. (2016). Biophysical and biochemical studies of a major endoglucanase secreted by Xanthomonas campestris pv. campestris. Enzyme and Microbial Technology, 91, 1–7.

Nitschke, M., Rodrigues, V., & Schinatto, L. F. (2001). Formulation of whey-based media for xanthan gum production by X. campestris C7L isolate. Food Science and Technology, 21(1), 82–85.

Casas, J. A., Santos, V. E., & García-Ochoa, F. (2000). Xanthan gum production under several operational conditions: molecular structure and rheological properties. Enzyme and Microbial Technology, 26(2-4), 282–291.

Garcia-Ochoa, F., Santos, V. E., Casas, J. A., & Gomez, E. (2000). Xanthan gum: production, recovery, and properties. Biotechnology Advanced, 18(7), 549–579.

Flores-Candia, J. L., & Decker, W. D. (1999). Effect of the nitrogen source on pyruvate content and rheological properties of xanthan. Biotechnology Progress, 15, 531–538.

Hassler, R. A., & Doherty, D. H. (1990). Genetic engineering of polysaccharide structure: production of variants of xanthan gum in Xanthomonas campestris. Biotechnology Progress, 6(3), 182–187.

Druzian, J. I., & pagliarini, A. P. (2007). Xanthan gum production by fermentation from residue of apple juice. Food Science and Technology, 27(1), 26–31.

Niknezhad, S. V., Mohammad, A. A., Zamani, A., Biria, D., & Doostmohammadi, M. (2015). Optimization of xanthan gum production using cheese whey and response surface methodology. International Journal of Biological Macromolecules, 2, 453–460.

Gilani, S. L., Najafpour, G. D., Heydarzadeh, H. D., & Zare, H. (2011). Kinetic models for xanthan gum production using Xanthomonas campestris from molasses. Chemical Industry & Chemical Engineering Quarterly, 17(2), 179–187.

McClements, D. J. (1999). Food emulsions: principles, practice and techniques. Boca Raton: CRC Press.

Faria, S., Petkowicz, C. L. O., Moraes, S. L., Terrone, M. G. H., Resende, M. M., França, F. P., & Cardoso, V. L. (2011). Characterization of xanthan gum produced from sugar cane broth. Carbohydrate Polymers, 86(2), 469–476.

Zohuriaan, M. J., & Shokrolahi, F. (2004). Thermal studies on natural and modified gums. Polymer Testing, 23(5), 575–579.

Funding

We would like to thank the funding agencies CAPES, FAPESP, and the CNPq project PVE 400710/2014-5 for financial support and the Graduate Programs in Chemical Engineering and Food Sciences of the Federal University of Bahia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

da Silva, J.A., Cardoso, L.G., de Jesus Assis, D. et al. Xanthan Gum Production by Xanthomonas campestris pv. campestris IBSBF 1866 and 1867 from Lignocellulosic Agroindustrial Wastes. Appl Biochem Biotechnol 186, 750–763 (2018). https://doi.org/10.1007/s12010-018-2765-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2765-8