Abstract

Gaucher disease, which is caused by deficiency of glucocerebrosidase (GCD), is currently treated by enzyme replacement therapy. Plant-based systems produce glycoproteins and can be combined with targeting strategies to generate proteins with terminal mannose structures for macrophage uptake. However, the gliding step for the purification is essential since the produced protein still exists inside cells. In the case of rice-amylase 1A (RAmy1A) secretion signal peptide, GCD protein is secreted outside of cells and simplifies the purification step. Here, an established cell line was confirmed as having fundamental characteristics of growth and production. GCD from transgenic calli was examined by Western blot analysis and compared with that from Chinese hamster ovary (CHO) cells. Calli expressing high levels of GCD were used to establish suspension cell lines. Growth and production characteristics were investigated in suspension cell cultures. Production of GCD in suspension cultures was confirmed upon induction for 12–24 h. The amount of GCD in medium increased until 60–84 h and decreased thereafter. Purification of GCD was performed in three steps (ion exchange, hydrophobic interaction, and size exclusion chromatography) and verified. Purified GCD was able to hydrolyze the synthetic substrate. Thus, a rice expression system could be a suitable alternative to GCD expression in mammalian cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gaucher disease is a hereditary deficiency of the enzyme β-glucocerebrosidase (GCD), which hydrolyzes the glucose moiety from glucosylceramide, and is the most common lysosomal storage disease [1]. Recombinant human enzyme (Cerezyme®, Genzyme-Sanofi, USA), as an enzyme replacement therapy for Gaucher disease, has been produced in genetically engineered Chinese hamster ovary (CHO) cells [2, 3]. To be an effective enzyme replacement therapy (ERT), terminal mannose residues of glycan chains must be exposed for GCD binding to macrophage mannose receptors [4]. Production of CHO-derived protein has been achieved by serial treatment with α-neuraminidase, β-galactosidase, and β-N-acetylglucosaminidase to expose core mannose residues for macrophage targeting [5].

In 2009, a manufacturing plant belonging to the biotechnology company Genzyme was shut down due to Vesivirus 2117 contamination detected during cell culture in a bioreactor producing Cerezyme and Fabrazyme. As an alternative, two recombinant ERTs were approved: velaglucerase alfa (Vpriv®, Shire, USA) from genetically engineered human fibroblast cells and taliglucerase alfa (Elelyso®, Protalix, Israel) from transgenic carrot cell cultures [6]. Production of taliglucerase alfa requires no additional steps or reagents to produce a mature enzyme with exposed terminal mannose structures [7]. Taliglucerase alfa was the first plant-made pharmaceutical (PMP) approved by the US Food and Drug Administration (FDA) in May 2012. Due to its success, Pfizer entered into an agreement with Protalix in 2009 for exclusive worldwide licensing rights to taliglucerase alfa, except in Israel [8, 9]. Taliglucerase alfa costs 15 % less than imiglucerase [10, 11].

Taliglucerase alfa was previously produced and targeted to storage vacuoles in a carrot cell suspension culture to expose mannose residues on the glycan [7]. However, the gliding step for the purification purpose was inevitable in which was essential due to protein that was produced still existed inside of the cell. In this case of using rice-amylase 1A (RAmy1A) secretion signal peptide, the GCD protein would secrete outside from the cell in which would be a lot simple to perform the purification step.

Transgenic plant cells are used as host systems for production of therapeutic proteins to produce PMPs [12]. Transgenic plant cell cultures are expected to be safer since they do not propagate mammalian viruses and pathogens, and they have advantages such as post-translational modifications (PTM), genetic stability, and public perception as an environment-friendly system [13].

In this report, we used the rice α-amylase expression system rice α-amylase 3D promoter (RAmy3D) to produce GCD in transgenic rice cell cultures as a high-producing system. GCD was expressed in transgenic rice cell suspension cultures, and its characteristics were investigated. The established cell line was confirmed to have fundamental characteristics of growth and production. To further characterize GCD, the protein was purified in a three-step procedure based on ion exchange chromatography, hydrophobic interaction chromatography, and size exclusion chromatography.

Materials and Methods

Construction of Plant Expression Vector

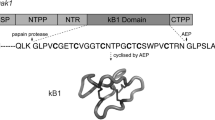

Human glucocerebrosidase cDNA was synthesized by RT-PCR using mRNA from blood from a healthy volunteer with no medical history of Gaucher disease. A pair of PCR primers (N-terminal primer 5′-cctgaggggatggagttttc-3′ and C-terminal primer 5′-catatgcatcactggcgacgccacag-3′) was designed to generate the human GCD structural gene fragment (Fig. S1). Signal peptides of RAmy1A were fused to the GCD sequence in two steps by overlapping PCR (Fig. S2), after which the product was subcloned into the multiple cloning site (MCS) of pGEM-T easy vector (Promega, USA) to generate pMYN75 vector containing the RAmy3D promoter (GenBank accession No. M59351.1), 3′-untranslated region (UTR), and hygromycin phosphotransferase gene. The XbaI/SacI-cleaved cDNA fragment containing the signal peptide-fused GCD gene was ligated into pMYN75 at the same sites. The resulting plasmid, pMYN75-GCD (Fig. 1), was used to transform rice calli (Oryza sativa L. cv. Dongjin).

Construction of pMYN75-GCD expression vector for GCD expression in rice cell system. GCD gene was cloned into pMYN75 expression vector between XbaI/SacI sites of the multiple cloning site. RB, T-DNA right border; RAmy3D, rice α-amylase 3D promoter; 3′-UTR, 3′-untranslated region of rice α-amylase gene; 35S-pro, CaMV 35S promoter; HPT, hygromycin phosphotransferase gene; 35S-ter, CaMV 35S transcription terminator; LB, T-DNA left border; Kan, Kanamycin resistance gene; ori, pBR322-derived origin

Transformation and Screening of Transgenic Rice Calli

Embryogenic calli were derived from mature seeds of rice. Sterilized mature seeds were cultured on N6CI medium at 28 °C in the dark for about 2 weeks, after which calli derived from scutellum were obtained. Small and vigorously dividing calli were selected, transferred to fresh 2N6 medium, and cultured continuously for about 1 week. Rice calli were then immersed in a transformed bacterial suspension (OD600 = 2.46) for 10 min, after which excess bacteria were removed by blotting calli on dry sterile paper towels. Following co-cultivation of calli and Agrobacterium tumefaciens LBA4404 for infection, calli were rinsed to remove A. tumefaciens. Calli were placed on N6 selection medium supplemented with 2,4-dichlorophenoxyacetic acid (2 mg/L), sucrose (30 g/L), casamino acid (250 mg/L), and hygromycin B (50 mg/L) and then cultured in the dark for 3–4 weeks at 28 °C. Transgenic calli resistant to hygromycin B were grown in N6 media minus sucrose for 8 days and then analyzed for GCD in transgenic calli by Western blot analysis. The initial selection was done by checking the protein expression of the callus that was cultivated in solid medium. The selected high expressed calli were suspended in the liquid culture medium, and the secreted GCD was observed.

Rice Cell Cultures

Transgenic rice suspension cells were maintained in amino acid (AA) medium supplemented with sucrose (30 g/L), 2,4-dichlorophenoxyacetic acid (2 mg/L), and kinetin (0.2 mg/L). A 500-mL Erlenmeyer flask containing 126 mL of AA medium was autoclaved, after which 14 mL of a 10-fold concentrated amino acid mixture was sterilized using 0.22-μm syringe filters along with 0.1 mg/L of gibberellic acid and 50 mg/L of hygromycin. Composition of the 10-fold concentrated amino acid mixture was 1.3 mM l-arginine, 2.0 mM l-aspartic acid, 1.0 mM glycine, and 6.0 mM l-glutamine. Cell suspensions were cultured in medium at 120 rpm and 28 °C in a gyratory shaking incubator and transferred to fresh medium every 9 days. To investigate growth characteristics, 1 g of vacuum-filtered cells was inoculated into 30 mL of AA media with sucrose in 100-mL flasks and periodically sampled. Suspension samples were measured for cell mass, pH, and F/D ratio. To induce GCD expression, 3 g of vacuum-filtered cells was inoculated into 30 mL of sucrose-free AA media in 100-mL flasks and periodically sampled. Suspension samples were measured for cell mass, pH, relative cell viability, and protease activity. All experiments were performed in duplicate.

Genomic DNA PCR

Genomic DNA was isolated from transgenic calli using a DNeasy plant mini kit (Qiagen). Reaction mixture (20 μL) containing EX Taq polymerase (Takara, Japan), which is the same primer set for cloning GCD, and the fused signal peptide using RT-PCR was prepared according to the manufacturer’s protocol. A thermal cycle consisting of 45 s at 94 °C, 45 s at 55 °C, and 1.5 min at 72 °C was repeated 30 times. PCR products were then analyzed by 1 % agarose gel electrophoresis and visualized by ethidium bromide staining.

Cell Mass Measurement

After sampling every 2 days, media from suspension cells were filtered through Whatman no. 1 filter paper under vacuum conditions. Fresh cell weight (FCW) was measured after transferring from filter paper to a pre-weighed dish. To estimate dry cell weight (DCW), fresh cells were dried at 60 °C for 2 days and weighed.

Measurement of Cell Viability

A solution of triphenyltetrazolium chloride (TTC) (pH 9) was used to measure cell viability. For reaction mixtures, 0.1 g of fresh cells was added to 1.6 mL of TTC solution in a microtube and incubated at 20 °C for 24 h. Free cells were collected by centrifugation at 12,000 rpm for 15 min. Formazan from viable cells was extracted by adding 1 mL of 95 % ethanol at 60 °C for 30 min. The supernatants containing formazan were separated by centrifugation at 15,000 rpm for 30 min. To analyze cell viability, the absorbance of extract was measured at 485 nm using an Agilent 8453 spectrophotometer (Agilent Technologies, USA).

Protease Activity Assay

A modification of Anson’s method was used to measure extracellular protease activity. Sample (0.5 mL) and substrate solution (0.5 mL) (1 % (w/v) Na-caseinate in 67 mM phosphate buffer, pH 7.0) were mixed and incubated at 50 °C for 10 min. The reaction was terminated by adding 0.3 mL of 30 % trichloroacetic acid. Then, reaction mixtures were centrifuged to obtain supernatants at 12,000 rpm for 10 min. Using an Agilent 8453 spectrophotometer (Agilent Technologies, USA), absorbance levels of the supernatants at 280 mm were converted into tyrosine concentration based on the concentration curve of the standard solution. One unit of protease is defined as the amount of enzyme liberating 1 mg of tyrosine per minute under the reaction conditions.

Western Blot Analyses

SDS-PAGE was carried out using XCell II™ (Invitrogen, USA) on a 10 % polyacrylamide gel. Protein bands of gel were stained with a SilverXpress Silver Staining kit (Invitrogen, USA) according to the manufacturer’s protocols. For Western blotting, proteins were electrotransferred onto a PVDF membrane (Invitrogen, USA), which was blocked for 1 h with blocking buffer (5 % skim milk in TBST buffer; 10 mM Tris–HCl, 150 mM NaCl, 0.02 % sodium azide, and 0.1 % Tween 20) at room temperature. As primary antibody, mouse anti-human GCD antibody (Abcam, USA) was diluted (1:500) in SignalBoost solution no. 1 (Calbiochem-Novabiochem Ltd., UK) and incubated with the PVDF membrane for 1 h. After each step, the membrane was washed three times using TBST for 10 min each. As secondary antibody, peroxidase-labeled goat anti-mouse IgG (KPL Inc., USA) was diluted (1:2000) in SignalBoost solution no. 2 (Calbiochem-Novabiochem Ltd., UK). The membrane was then incubated in secondary antibody solution for 1 h. After washing, the membrane was incubated with TMB membrane peroxidase substrate (KPL Inc., USA).

Purification of GCD

Protein purification was performed on an AKTA-FPLC system using a three-step procedure based on ion exchange chromatography, hydrophobic interaction chromatography, and size exclusion chromatography. GCD production medium was harvested, centrifuged (11,000 rpm, 30 min), filtered through a 0.22-μm glass microfiber filter, and adjusted to pH 5.5 by acetic acid. The adjusted sample was then filtered through a PVDF filter, mixed with binding buffer, and loaded onto AKTA-FPLC. The first purification step was performed on a Hitrap sepharose FF column (Bio-Rad Laboratories Inc., USA). Sodium citrate (pH 5.5, 25 mM) was used as equilibrium and binding buffer, whereas 1 M sodium chloride was used as elution buffer. The second loading sample was prepared by mixing the elution fraction from the first purification step and binding buffer at a ratio of 1:5. The second purification step was performed on a Hitrap phenyl sepharose HP column (GE Healthcare, Amersham Biosciences, UK). Ammonium sulfate (2 M) was used as equilibrium and binding buffer, whereas 25 mM sodium citrate (pH 5.5) was used as elution buffer. The third purification step was performed on a Superdex-200 column (GE Healthcare, Amersham Biosciences, UK). Albumin (67 kDa) and Cerezyme (68 KDa) were used as a standard substance for predicting retention volume.

Enzyme Assay

GCD activity was assayed using p-nitrophenyl-β-d-glucopyranoside (pNPG) as the substrate. The elution sample (50 μL from size exclusion chromatography) was added to 150 μL of assay buffer (60 mM phosphate-citrate buffer, 4 mM beta-mercaptoethanol, 1.3 mM EDTA, 0.15 % Triton X-100, 0.125 % sodium taurocholate) containing 4 mM pNPG, after which the solution was incubated for 60 min at 37 °C. After incubation, 6 μL of 5 N NaOH was added to stop the reaction and develop color. The absorbance was read at 405 nm.

Results and Discussion

Genomic DNA PCR Analysis of GCD Gene in Transgenic Rice Calli

Structure of the GCD expression vector pMYN75-GCD containing the hygromycin phosphotransferase (HPT) gene as a selection marker is shown in Fig. 1. After transformation with pMYN75-GCD plasmid by A. tumefaciens LBA4404, the GCD gene was detected in transformed calli showing hygromycin resistance by genomic DNA PCR using specific primers containing rice α-amylase signal peptide. Genomic DNA PCR obtained from transformed calli confirmed presence of the GCD gene (1.6 kp), partial GCD (800 bp), and HPT (550 bp) derived from pMYN75-GCD (Fig. 2).

Expression of GCD in Transgenic Rice Calli

Transformation step was carried out with a total of 260 calli, and eight transformants were obtained. Among them, four high growth calli were selected through phenotypic selection. Expression of GCD protein in transgenic rice calli was assessed by immunoblot analysis using anti-GCD antibody. As GCD gene expression in this vector is controlled by the RAmy3D promoter, expression was induced by removing sucrose from N6 agar media. Transgenic rice calli cultured in N6 agar media for 8 days were inoculated at the same inoculum density. After sampling every 2 days, extracts of calli obtained by grinding were analyzed by Western blot analysis.

Figure 3 shows the time course of GCD expression. The S-N01 cell line showed consistently increased GCD expression during the production phase. In contrast, GCD expression in S-N02 and S-N03 cell lines decreased during the later culture stage. Further, GCD expression was low in the S-N04 cell line. The two high-producing cell lines (S-N01 and S-N02) were selected to establish suspension cell cultures. Differences in expression of GCD can be attributed to the cell line or random expression vector insertion in genomic DNA.

Growth and Production Characteristics in Rice Suspension Cell Cultures

Calli showing high levels of GCD expression were used to establish suspension rice cell cultures. Patterns of DCW and GCD production according to time were evaluated (Figs. 4, 5, and 6). Cell growth was observed in established suspension cell cultures (Fig. 4). Maximum cell masses of S-N01 and S-N02 cell lines increased up to 10.1 and 9.7 g DCW/L, respectively, after 10 days (Fig. 4a). Specific growth rates of S-N01 and S-N02 cells were 0.24 and 0.35 day−1, respectively. During growth phase, maximum cell mass (DCW) and overall specific growth rates were similar between S-N01 and S-N02 cell lines. In addition, both cell lines showed similar pH levels and FCW/DCW ratios as an indicator of water content and cell size.

GCD protein was produced in sugar-depleted AA medium (production medium) in transgenic rice cells harboring RAmy3D promoter. Changes in DCW, pH, cell viability, and protease activity were evaluated at 12-h intervals (Fig. 5). In both cultures, cell mass decreased and remained generally constant during production (Fig. 5a). Cells began to rupture, and complex mixtures of chemicals were released into the medium during production. As a result, pH level of the medium increased up to pH 7 at 24 h after induction. Similar pH levels were observed in both cultures (Fig. 5b). As shown in Fig. 5c, relative cell viability of S-N01 cells was higher than that of S-N02 cells during production. However, cell viability decreased sharply in S-N01 cells after 48 h. To confirm production of GCD, Western blot analysis was performed (Fig. 6). Maximum GCD production in S-N01 cells was observed after 48 h, whereas GCD level rapidly decreased after 60 h. Protease activity of S-N01 cells increased after 48 h and was higher than that of S-N02 cells (Fig. 5d). GCD production declined due to increased activity of protease, which was secreted and released upon cell rupture. Based on the above results, S-N02 cell line was selected for production of GCD.

Optimization of GCD Purification Process

To further characterize GCD, the protein was purified using a three-step procedure based on ion exchange chromatography, hydrophobic interaction chromatography, and size exclusion chromatography. To optimize GCD purification, S-N02 cell culture medium was used. Culture medium containing GCD protein was loaded onto a cation exchange column (Hitrap sepharose FF column), which was packed with 10 mL of resin equilibrated with equilibrium buffer (25 mM sodium citrate, pH 5.5) and then eluted under three elution conditions (0.1, 0.2, and 0.5 M NaCl). Fractions were collected and analyzed by SDS-PAGE and Western blotting to confirm optimal elution conditions. Figure 7b shows the SDS-PAGE and Western blotting results for the loading sample, flow-through, and elution fractions. Whereas peaks 2 and 3 showed similar GCD bands as the positive control, GCD protein was not detected in peak 1 (data not shown) or the flow-through. The 0.5 M NaCl elution fraction was used as the loading sample for hydrophobic interaction chromatography since the elution volume of its main GCD peak was higher than that of 0.2 M NaCl (Fig. 7).

GCD purification using cation exchange column chromatography. a Chromatogram of step 1 (blue line, UV; brown line, conductivity). b SDS-PAGE and Western blot analysis of each peak derived from purification step 1; Marker, Seeblue Plus2™ Western standard (Invitrogen); P.C, GCD-positive control (Cerezyme®). Ten micrograms of TSP is loaded in each lane

GCD protein was further separated from contaminating proteins using hydrophobic interaction chromatography (Fig. 8). Elution sample from the first step was mixed with equilibrium buffer (2 M ammonium sulfate) at a ratio of 1:5, followed by loading onto a Hitrap phenyl Sepharose HP column. Elution buffer (25 mM sodium citrate, pH 5.4) was loaded using a step gradient (20, 40, 60, 80, and 100 %) with equilibrium buffer. Figure 8b shows the SDS-PAGE and Western blotting results for the loading sample and five elution fractions. GCD protein was mainly observed in peak 5. However, SDS-PAGE showed not only the presence of GCD but also various impurities.

Hydrophobic interaction column chromatography. a Chromatogram of step 2 (blue line, UV; green line, % of B buffer). b SDS-PAGE and Western blot analysis of each peak derived from purification step 2; Marker, Seeblue Plus2™ Western standard (Invitrogen); P.C, GCD-positive control (Cerezyme®). 10 μg of TSP is loaded in each lane.

To separate impurities from GCD, gel filtration chromatography was carried out. Cerezyme (68 kDa) and albumin (67 kDa) were used as standards for gel filtration chromatography to predict elution volumes of GCD in purified samples (Fig. 9a). A large peak was observed at an elution volume from 10 to 20 mL for the purified sample using hydrophobic interaction chromatography. This peak likely represents impurities such as proteins and amino acids. High purity albumin produced a sharp peak at an elution volume of 13–15 mL in gel filtration chromatography, which corresponds to the elution volume of GCD. All predicted fractions were analyzed by SDS-PAGE and Western blotting (Fig. 9b). The major fraction, fraction no. 4 (14–15 mL), included GCD protein. SDS-PAGE and Western blot analysis of the GCD elution after gel filtration chromatography showed higher purity compared to the previous hydrophobic interaction chromatography step.

Final purification of GCD using size exclusion column chromatography: (a) Chromatogram of step 3 (blue line, UV); (b) SDS-PAGE and Western blot analysis of each peak derived from purification step 3; Marker, Seeblue Plus2™ Western standard (Invitrogen); P. C, GCD-positive control (Cerezyme®). Ten micrograms of TSP is loaded in each lane

Enzyme Activity Assay of Different Types of GCD

The activity of purified GCD was analyzed by pNPG assay (Fig. 10). The assay was performed using 1 μg of total protein from either the 80 or 100 % elution fraction purified by hydrophobic interaction chromatography. Enzyme activities of the 80 and 100 % elution fractions were about 66 and 28 % lower than that of Cerezyme, respectively. Comparing the wild type and the peak 5, the peak 5 result appears to be caused by the purified GCD. Also, the peak 4, in which the band was not confirmed in the Western blot (Fig. 8), can be assumed to include the plant β-glucosidase in which was originated in the plant cell and the activity of plant β-glucosidase is thought to affect the analysis result.

Enzyme activity of purified GCD. Purified plant-derived GCD and Cerezyme® were assayed using p-nitrophenyl-β-d-glucopyranoside. The assay was performed using 1 μg of total protein from either the 80 or 100 % elution fraction purified by hydrophobic interaction chromatography. Wild-type sample was acquired by purification of wild-type rice cell culture medium and was used as the 100 % elution fraction in hydrophobic interaction chromatography

There are several endogenous plant β-glucosidases in rice cells, and their activities interfere with detection of target GCD [14]. Real-time quantitative PCR was performed for identification and relative quantification of plant β-glucosidase expression (i.e., Os3bglu7 and Os3bglu8) in transgenic rice cells (data not shown). Expression of plant β-glucosidase was observed in various rice cell lines producing recombinant GCD as well as wild-type rice cells. The results indicate that endogenous expression of plant β-glucosidases is an obstacle to GCD assay. Therefore, separation of target GCD among mixtures of plant β-glucosidases is needed for correct GCD assay in transgenic rice cells.

Conclusions

In this study, GCD was expressed in transgenic rice cells and its characteristics investigated. We report the application of rice α-amylase RAmy3D expression vector for production of GCD, which was fused to signal peptide for secretion. Rice calli were stably transformed with A. tumefaciens LBA4404 harboring expression vector. Changes in DCW and production were confirmed, and two cell lines were selected to establish suspension cell cultures. Growth parameters such as DCW, pH, F/D ratio, and specific growth rate were similar between the two cell lines, and there was no significant difference in growth between transformed and wild-type cells. Further, differences in DCW, pH, cell viability, and protease activity were evaluated to select a high throughput cell line. Lastly, the GCD purification process was optimized. Target protein was purified using a three-step procedure based on ion exchange chromatography, hydrophobic interaction chromatography, and size exclusion chromatography. Variable conditions such as column volume, composition of buffer, and concentration of elution buffer were tested for optimization of the purification procedure. To compare enzyme activity between purified GCD and Cerezyme, enzymatic hydrolysis of the synthetic substrate pNPG was measured. Plant-derived GCD was able to hydrolyze the synthetic substrate.

To be an effective ERT, terminal mannose residues of glycan chains must be exposed. A previous study in 2010 reported the glycosylation patterns of glycoproteins secreted from rice cell suspension cultures under sugar starvation conditions. The most abundant N-glycan structures in rice extracellular glycoproteins are terminal mannose and N-acetylglucosamine residues. On the other hand, small amounts of terminal galactose residues are present [15]. Further, macrophage mannose receptor recognizes terminal mannose and N-acetylglucosamine residues on glycans attached to proteins [16]. Therefore, if terminal galactose residues of secreted glycoproteins can be removed by purification, plant suspension cell cultures can become useful for producing recombinant GCD.

In conclusion, a rice α-amylase RAmy3D expression system could be a suitable alternative to expression in mammalian cells. However, analysis of the glycosylation pattern of secreted GCD as well as the effects of variable glycosylation on in vivo protein activity should be studied. For commercial use of GCD, slight differences in glycosylation should be eliminated.

References

Guggenbuhl, P., Grosbois, B., & Chales, G. (2008). Gaucher disease. Joint, Bone, Spine, 75, 116–124.

Beck, M. (2007). New therapeutic options for lysosomal storage disorders: enzyme replacement, small molecules and gene therapy. Human Genetics, 121, 1–22.

Deegan, P. B., & Cox, T. M. (2012). Imiglucerase in the treatment of Gaucher disease: a history and perspective. Drug Design Development Therapy, 6, 81–106.

Bijsterbosch, M. K., Donker, W., van de Bilt, H., van Weely, S., van Berkel, T. J., & Aerts, J. M. (1996). Quantitative analysis of the targeting of mannose-terminal glucocerebrosidase. European Journal of Biochemistry, 237, 344–349.

Doebber, T. W., Wu, M. S., Bugianesi, R. L., Ponpipom, M. M., Furbish, F. S., Barranger, J. A., Brady, R. O., & Shen, T. Y. (1982). Enhanced macrophage uptake of synthetically glycosylated human placental beta-glucocerebrosidase. Journal of Biological Chemistry, 257, 2193–2199.

Allison, M. (2010). As Genzyme flounders, competitors and activist investors swoop in. Nature Biotechnology, 28, 3–4.

Shaaltiel, Y., Bartfeld, D., Hashmueli, S., Baum, G., Brill-Almon, E., Galili, G., Dym, O., Boldin-Adamsky, S. A., Silman, I., Sussman, J. L., Futerman, A. H., & Aviezer, D. (2007). Production of glucocerebrosidase with terminal mannose glycans for enzyme replacement therapy of Gaucher’s disease using a plant cell system. Plant Biotechnology Journal, 5, 579–590.

Fox, J. L. (2012). First plant-made biologic approved. Nature Biotechnology, 30, 472.

Grabowski, G. A., Golembo, M., & Shaaltiel, Y. (2014). Taliglucerase alfa: an enzyme replacement therapy using plant cell expression technology. Molecular Genetics and Metabolism, 112, 1–8.

Burrow, T. A., & Grabowski, G. A. (2011). Velaglucerase alfa in the treatment of Gaucher disease type 1. Clinical Investigator, 1, 285–293.

Opar, A. (2011). ‘Pharmers’ hope for first plant drug harvest. Nature Reviews Drug Discovery, 10, 81–82.

Gomord, V., Chamberlain, P., Jefferis, R., & Faye, L. (2005). Biopharmaceutical production in plants: problems, solutions and opportunities. Trends in Biotechnology, 23, 559–565.

Twyman, R. M., Stoger, E., Schillberg, S., Christou, P., & Fischer, R. (2003). Molecular farming in plants: host systems and expression technology. Trends in Biotechnology, 12, 70–578.

Babajani, G., Tropak, M. B., Mahuran, D. J., & Kermode, A. R. (2012). Pharmacological chaperones facilitate the post-ER transport of recombinant N370S mutant β-glucocerebrosidase in plant cells: evidence that N370S is a folding mutant. Molecular Genetics and Metabolism, 106, 323–329.

Shin, Y. J., Chong, Y. J., Han, K. B., Yang, M. S., & Kwon, T. H. (2010). N-linked glycan analysis of glycoproteins secreted from rice cell suspension cultures under sugar starvation. Enzyme and Microbial Technology, 47, 189–193.

Taylor, M. E., & Drickamer, K. (1993). Structural requirements for high affinity binding of complex ligands by the macrophage mannose receptor. Journal of Biological Chemistry, 268, 399–404.

Acknowledgments

This work was supported by a grant (No. NRF-2013M3A9B6075887) from the National Research Foundation of Korea, by a grant (No. 10051111) from the Ministry of Trade, Industry & Energy, and by Inha University.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

ESM 1

(DOCX 24 kb)

Rights and permissions

About this article

Cite this article

Nam, HJ., Kwon, JY., Choi, HY. et al. Production and Purification of Recombinant Glucocerebrosidase in Transgenic Rice Cell Suspension Cultures. Appl Biochem Biotechnol 181, 1401–1415 (2017). https://doi.org/10.1007/s12010-016-2292-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2292-4