Abstract

The degradation kinetics of swine and buffalo manure for methane production was investigated. Six kinetic models were employed to describe the corresponding experimental data. These models were evaluated by two statistical measurements, which were root mean square prediction error (RMSPE) and Akaike’s information criterion (AIC). The results showed that the logistic and Fitzhugh models could predict the experimental data very well for the digestion of swine and buffalo manure, respectively. The predicted methane yield potential for swine and buffalo manure was 487.9 and 340.4 mL CH4/g volatile solid (VS), respectively, which was close to experimental values, when the digestion temperature was 36 ± 1 °C in the biochemical methane potential assays. Besides, the rate constant revealed that swine manure had a much faster methane production rate than buffalo manure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Methane is a clean, flammable, high-calorific value fuel, which is used in many areas and considered as one of the substitute fuels currently [1–3]. It can be obtained from different organic wastes, such as livestock droppings, industrial waste water, agricultural residues, and municipal solid wastes, through anaerobic digestion. Anaerobic digestion was considered as a commercially viable process for conversing organic waste to methane. Biogas technology was widely used to deal with the animal wastes and generate heat and power for local uses. There were many researches on biogas production from livestock manure through anaerobic digestion especially from swine and ruminal animal manure [4–6]. Generally, relatively low yield of biogas was produced from swine manure and ruminal manure due to their feeding and treatment patterns. Tuesorn et al. [5] assessed the biomethane potential from fiber-rich swine manure under mesophilic and thermophilic conditions. Biogas and methane yields of 355 and 180 mL/g volatile solid (VS)added were obtained at 37 °C, respectively, with a lignocellulolytic microbial consortium to swine manure ratio of 1.5:1 on a weight to weight basis (mg volatile suspended solid (VSS)/g VS). Comparisons of methane production potential between buffalo and other animals’ manure have been done in a previous study [4, 7, 8]. However, few results reported the digestion differences between swine and buffalo manure, specifically from the perspective of kinetic study.

What were the reasons for the different substrates giving out different biogas yields and digestion rates? The methane and energy contents of the generated gas usually vary and are dependent on the physical and chemical properties of the substrate [9]. Some animal excreta such as poultry droppings containing enough easily degradable organic materials might be easily digested by microorganisms. While agricultural waste products such as crop straw or ruminant manure were known to have high content of lignin and lignocellulose (40–50 % of the total solid (TS)), which were hard to be digested both naturally and artificially. This would at least lead to a prolonged digestion period [10]. In order to better understand the digestion process, predict the biogas yield, and even improve the biogas production, some parameter factors like rate of digestion and lag time were vital to accommodate a digestion process. This makes it necessary to do kinetic research on the biogas production from different sorts of substrate. Study on kinetic parameters in anaerobic digestion process is always beneficial to the analysis of digester performance and the ideal reactor design [11]. Besides, it is also helpful for understanding inhibitory mechanisms of biodegradation.

In literatures, there were several statistical and dynamic mechanistic models for predicting methane yield from animal manure (i.e., cattle and sheep) [12–14]. Statistical models predicting methane production mainly refer to nutrient intake directly, while dynamic mechanistic models evaluate methane production by employing mathematical descriptions of the biochemistry methane potentials [12, 13, 15]. These models such as logistic [16], exponential [17], Fitzhugh [18], cone [18], monomolecular [19], and Gompertz [16] were quite useful to predict methane emission from animal manure, but there was not a model adequate for all substrates.

The aim of this work was to investigate the adequate models for the digestion of swine and buffalo manure for methane production. The best-fit non-linear models would be selected for predicting the biogas production from swine and buffalo manure by comparing the model parameters and statistical analysis.

Materials and Methods

Inoculum and Raw Materials

Fresh swine and buffalo manure generated within 1 day were collected from Jiangxi province of China. Cellulose was bought from the Sinopharm Chemical Reagent Co., Ltd. After collection, the manures preserved at 4 °C no more than 3 days before use. Grab samples were taken to analyze the substrate properties simultaneously. Sewage sludge was taken from Bailonggang Sewage Treatment Plant (mesophilic) in Shanghai, China, and acted as an inoculum. After arrival, the sludge was sieved through a screen (around 18 meshes, 880 μm) to remove certain bulky grain which otherwise would lower the homogeneity of the inoculum. Then, the inoculum was activated in an incubator at 36 ± 1 °C for 3 days before use.

Biogas Production

The mesophilic static biochemical methane potential (BMP) assays were carried out using 500-mL flasks with 400 mL of working volume with a substrate concentration of 10 g VS/L and inoculum to substrate (I/S) ratio of 2 in 36 ± 1 °C water bath. The concentrations for swine and buffalo manure were 5.1 and 5.0 % (TS basis), respectively. After the substrate and inoculum were added in flasks and mixed well, a N2 purge was applied at least 30 s to form anaerobic environment in the flasks. Rubber stoppers were then put into place to seal the flasks immediately. The flasks were shaken manually once a day once the fermentation has begun. All the tests including blanks which contained only the inoculum and positive blanks which contain the same concentrations of cellulose and inoculum were duplicated based on reliable repeatability obtained from previous study in our lab. The assays were conducted for 42–60 days. The cellulose conducted the BMP assays under the same conditions as the positive control. The results are averaged for each test.

The measurement of daily biogas production was implemented according to reference [20]. Daily biogas produced was collected in the gas-collecting cylinder by displacing saturated NaCl solution. The pressure of the produced biogas stored in the headspace of the cylinder was calculated by taking liquid column pressure and saturation vapor pressure in the headspace from the atmosphere pressure. The biogas production was then recalculated into standard volume at a standard temperature and pressure (273.15 K, 101.325 kPa). The methane was sampled on top of the gas-collecting cylinder.

Analytical Methods

The TS and VS were determined according to standard methods [21], so as to the chemical oxygen demand (COD) and total nitrogen (TN) [22]. The methane content in the biogas was measured with a gas chromatograph (GC, Agilent 7890A) [23]. The BMP assays were referring to the literature [24]. The ultimate analysis was determined by an elemental analyzer (Germany, Elementar, Vario EL III/Isoprime). The soluble saccharides were measured by the anthrone-sulfuric acid colorimetry [25].

Kinetic Models and Model Parameter Estimation

Kinetic Models

In this study, six models including logistic [16], exponential [17], Fitzhugh [18], cone [18], monomolecular [19], and Gompertz [16] models were selected to fit the experimental data. The domain for all selected models was t ≥ 0. The selected models for describing methane production are shown in Table 1. In these equations, Y is methane yield (mL CH4/g VS), P is methane yield potential (mL CH4/g VS), k is rate constants (1/day), t is digestion time (day), R m is maximum methane production rate (mL CH4/g VS/day), L is length of the lag phase (day), and n is shape factor, dimensionless.

Model parameters were estimated using the non-linear least squares fitting (NLSF) tool in OriginPro [26].

Model Parameter Estimation

Root mean square prediction error (RMSPE) and Akaike’s information criterion (AIC) were calculated to compare the selected models in this paper. The RMSPE values stand for the deviation between predicted and experimental values. RMSPE was estimated as described by Eq. (1) [27–29].

where P i is predicted methane yield, mL CH4/g VS, E i is measured methane yield, mL CH4/g VS, and n is the number of test points.

AIC was employed based on information technology to compare goodness-of-fit of models [27]; AIC was calculated by Eq. (2).

where RSS is residual sum of squares, n is number of test points, and N is number of model parameters.

Results and Discussion

Model Results of Methane Production from Swine Manure and Buffalo Manure

The Methane Yield Potential (P)

The methane productions of cellulose, swine, and buffalo manure were fitted by the six kinetic models so as to find out the kinetic parameters. Table 2 shows estimated parameters of the studied models. As mentioned, P is the methane yield potential and could be calculated through all the employed models. The observed BMP from cellulose in this study was 399 mL CH4/g VS, which was 96 % of the theoretical BMP. This indicated the reliability of the BMP assays in this study. The predicted methane production was 392–399 mL CH4/g VS, which approximated the experimental value. This suggested that the models were able to predict methane yield from cellulose according to the perspective of P. Both the predicted values and observed final methane yield of our experimental results (479 and 308 mL CH4/g VS) [30] showed that swine manure produced more methane than buffalo manure. For swine manure generated from fine commercial formula feed, there was plenty of organic matter which could be degraded by the microorganisms. However, the feed of buffalo was mainly corn stover in this study. The lignocellulosic feed was firstly digested by the ruminant’s stomach and then the residues were excreted to form manure. The digestive process of the rumen made the resistant lignocellulose residue take a large part in the buffalo manure, which made this substrate even harder for bacteria in AD process to hydrolyze it to much smaller molecules for subsequent acetogenesis and methanogenesis. Particularly, the lignin in the lignocellulose is a three-dimensional aromatic heteropolymer of p-hydroxyphenyl propanoid units connected by C–C and C–O–C links, which is very difficult to be degraded by microorganisms in nature. It was reported that the lignin in buffalo manure could hinder the anaerobic digestion during BMP assays [15]. This might be the reason why the methane yield of swine manure was higher than buffalo manure under the same I/S ratio and fermentation conditions. The swine manure was much more suitable to produce methane than buffalo manure based on the current experimental conditions. Besides, the predicted methane yield potential of swine manure from Gompertz model was most close to the observed data, while logistic model was the second. The similar results could be obtained for buffalo manure.

The Rate Constant (k/R m)

The k value in the equations represents the degradation rate. The k value of swine manure was bigger than buffalo manure and cellulose in all models except Gompertz which could not give out k. It showed that methane production from swine manure was much faster than methane production from buffalo manure. The lower rate constant of buffalo manure might be also due to the higher concentration of lignocellulose that was recalcitrant for biodegradation [31]. The k value of cellulose is slightly lower than the swine manure but considerably higher than buffalo manure. The reason might lie in the fact that the nitrogen and trace elements in swine manure prompt the rate of methane production. Instead of the k value, the R m, which represents the maximum methane production rate, could be acquired in Gompertz model. Obviously, the methane production rate of swine manure was much higher than buffalo manure, which was consistent with the degradation rate. Except for the reason of lignocellulosic composition in buffalo manure mentioned above, the other reason may attribute to the effect of C/N ratio. The carbon-to-nitrogen (C/N) ratios for swine and buffalo manure were 14.4 and 34.6, respectively; neither was satisfied for anaerobic digestion. Generally, the appropriate C/N ratio for effective biomethanation would be 20–30 with 25 as the ideal level [32]. A low C/N ratio can cause ammonia accumulation which is toxic to methanogens. On the other hand, a high C/N ratio brought by using crop residue may lead to high VFA accumulation that might poison methanogens [33]. The biogas plant using the continuous or semi-continuous feeding mode would face trouble if the C/N ratio was improper [34, 35]. As a result, exogenous nitrogen would be required to supplement for buffalo manure to achieve more efficient methane production. For swine manure, even better performance of methane production was expected to happen if the carbon content could be improved. Therefore, further researches on co-digestion of swine and buffalo manure is recommended, in which synergism effect might be shown.

The Lag Time (L)

In monomolecular model, higher methane productions of swine and buffalo manure were experimentally determined during the estimated lag phase. It was observed that the cumulative methane production fit well with the monomolecular equation because of the high correlation coefficient R 2 (0.996–0.997) between the experimental and predicted values. Lag phase was found 0.99, 0.73, and 0.34 days for cellulose, swine manure, and buffalo manure, respectively. The larger L might be due to substrate inhibition. However, faster anaerobic digestion for swine manure could be concluded according to the rate constants.

Gompertz model seemed to predict the methane yield potential correctly for these three substrates. However, it is worth noting that the parameter L in logistic and Gompertz for buffalo manure was negative. This might indicate that the mentioned Gompertz and logistic models were not accurate enough to predict the lag phase of buffalo manure under the studied conditions. As a result, these two models were not suitable for predicting the methane yield for buffalo manure, although there was high correlation coefficient R 2 (0.994–0.996) between the experimental and predicted values along with the parameter estimates. According to Pitt et al. [18], it was hard to explain methane production model parameters in some cases. Several parameters in models even could not allow to be compared for different feed stocks. Furthermore, the most proper model for predicting methane production is necessary to be tested by RMSPE and AIC.

Model Testing

The calculated values of RMSPE and AIC are shown in Table 3. The lower the AIC value, the more correct the model will be [27]. In Table 3, the lowest AIC for cellulose was monomolecular model; cone was the second. It was easy to find that the lowest AIC for swine manure was from logistic model, while Fitzhugh was the second one. Similarly, the lowest two AICs for buffalo manure were also from logistic and Fitzhugh model. As a result, logistic model is likely to be the best model to predict the methane yield in the selected models for swine manure. As mentioned above, The L value in logistic for buffalo manure was negative, which made logistic model inefficient in explaining the physical significance of some parameters. As a result, the Fitzhugh model was the best model to predict the methane yield in selected six models for buffalo manure.

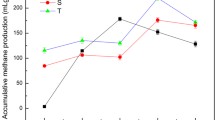

Both the logistic and Gompertz models are classic growth functions and are often employed for modeling in vitro gas production curves. As shown in Fig. 1, the methane production from swine manure is a sigmoidal shape, and the methane production from buffalo manure is a non-sigmoidal shape. The sigmoidal shape indicates that rate of gas production increased firstly before the maximum rate of fermentation was reached and then decreased, which may suggest the increased microbial numbers and activities during the early stages of incubation. However, the non-sigmoidal shape indicates that the rate of gas production decreased continually. Without the lag phase shown in the non-sigmoidal-shape curve, a stable growth pattern could be observed from methane production from buffalo manure. In fact, the negative L value for buffalo manure implied that the logistic and Gompertz models are not appropriate for predicting methane production from this kind of substrate. The insufficient quantity of the fitting points caused by incompletion of the digestion for buffalo manure in the experiment is another reason for the incapacity of logistic model to predict the methane production. Several curves in literatures fitting usually contain more than 60 points [16], but the methane yield for buffalo manure was still increasing after 60 days.

Although the assumptions underlying the logistic, Gompertz, and monomolecular models showed large differences, the biological meaning of L might be consistent to that of L in monomolecular and Gompertz. In the exponential models, it is assumed that no gas is produced until a discrete time lag, λ, has elapsed. The domain for these models is t ≥ λ, whereas models with no lag have a domain of t ≥ 0 (i.e., λ = 0). The logistic, Gompertz, and monomolecular contain a time parameter L, which is referred to as lag in some references, but is different from the discrete lag λ. Each model contains a rate constant, k, whose units are time−1, and some models contain a shape factor n [18].

The detailed equations for predicting methane production of cellulose, swine, and buffalo manure could be expressed as Y = 394.5(1 − e 0.270 − 0.272t), Y = 487.9\( \frac{1-{e}^{0.159-0.377t}}{1+{e}^{0.159-0.377t}} \) and Y = 340.4(1 − e −0.039t)1.093, respectively, where Y is methane yield (mL CH4/g VS), t is digestion time (day).

Figure 1 shows experimental and predicted methane yields for digestion of swine manure (a), buffalo manure (b), and cellulose (c). Figure 2 shows comparisons between experimental and predicted methane yields for digestion of swine manure (a), buffalo manure (b), and cellulose (c). According to Figs. 1 and 2, a very good fitness (R 2 > 0.99) could be obtained through linear fit between experimental and predicted methane yields from swine and buffalo manure. The two methane producing patterns were different when comparing buffalo and swine manure, because the physicochemical properties, chemical compositions, and biodegradation fractions of the two substrates were different [30]. The average residence time needed to reach more than 90 % of methane potential was only 9 days for swine manure, while 59 days was needed for buffalo manure. This implied that more digestion time was needed for fully digesting buffalo manure. The anaerobic digestion of buffalo manure demonstrated an inhibited pattern [24].

Conclusions

The model fitting results showed logistic and Fitzhugh models were the best in the selected models for predicting methane yields from swine and buffalo manure in this study, respectively. Swine manure showed much more degradable capacity and faster digestion speed than buffalo manure on biogas production. Based on the models, the predicted methane yield potential for swine and buffalo manure were 487.9 and 340.4 mL CH4/g VS, respectively, which were close to experimental values, respectively. Buffalo manure needs more than 60 days to achieve completely digestion. In addition, there exists an inhibited pattern without lag time of methane production from buffalo manure.

References

Li, L., Kong, X., Yang, F., Li, D., Yuan, Z., & Sun, Y. (2012). Biogas production potential and kinetics of microwave and conventional thermal pretreatment of grass. Appied Biochemistry and Biotechnology, 166, 1183–1191.

Sun, C., Liu, R., & Qin, G. (2010). Experiments on pretreatment and anaerobic digestion of asparagus stalk for biogas production (in Chinese with English abstract). Transactions of the CSAM, 41, 94–99.

Qin, G., Liu, R., & Sun, C. (2011). Effects of different concentrations of NaOH pretreatment on anaerobic digestion of rice straw for biogas production (in Chinese with English abstract). Transactions of the CSAE, 27(Supp.1), 59–63.

Calabrò, S., López, S., Piccolo, V., Dijkstra, J., Dhanoa, M. S., & France, J. (2005). Comparative analysis of gas production profiles obtained with buffalo and sheep ruminal fluid as the source of inoculum. Animal Feed Science and Technology, 123–124, 51–65.

Tuesorn, S., Wongwilaiwalin, S., Champreda, V., Leethochawalit, M., Nopharatana, A., Techkarnjanaruk, S., & Chaiprasert, P. (2013). Enhancement of biogas production from swine manure by a lignocellulolytic microbial consortium. Bioresource Technology, 144, 579–586.

Kafle, G. K., & Kim, S. H. (2013). Anaerobic treatment of apple waste with swine manure for biogas production: batch and continuous operation. Applied Energy, 103, 61–72.

Calabrò, S., Williams, B. A., Piccolo, V., Infascelli, F., & Tamminga, S. (2004). A comparison between buffalo (Bubalus bubalis) and cow (Bos taurus) rumen fluids in terms of the in vitro fermentation characteristics of three fibrous feedstuffs. Journal of the Science of Food and Agriculture, 84, 645–652.

Xue, B., Wang, L. Z., & Yan, T. (2014). Methane emission inventories for enteric fermentation and manure management of yak, buffalo and dairy and beef cattle in China from 1988 to 2009. Agriculture, Ecosystems & Environment, 195, 202–210.

Li, C., Champagne, P., & Anderson, B. C. (2011). Evaluating and modeling biogas production from municipal fats, oil and grease and synthetic kitchen waste in co-digestion. Bioresource Technology, 102, 9471–9480.

Zhong, W., Zhang, Z., Qiao, W., Fu, P., & Liu, M. (2011). Comparison of chemical and biological pretreatment of corn straw for biogas production by anaerobic digestion. Renewable Energy, 36, 1875–1879.

Lei, Z., Chen, J., Zhang, Z., & Sugiura, N. (2010). Methane production from rice straw with acclimated anaerobic sludge: effect of phosphate supplementation. Bioresource Technology, 101, 4343–4348.

Ellis, J. L., Kebreab, E., Odongo, N. E., McBride, B. W., Okine, E. K., & France, J. (2007). Prediction of methane production from dairy and beef cattle. Journal of Dairy Science, 90, 3456–3467.

Kebreab, E., Johnson, K. A., Archibeque, S. L., Pape, D., & Wirth, T. (2008). Model for estimating enteric methane emissions from United States dairy and feedlot cattle. Journal of Animal Science, 86, 2738–2748.

Pham, C. H., Triolo, J. M., & Sommer, S. G. (2014). Predicting methane production in simple and unheated biogas digesters at low temperatures. Applied Energy, 136, 1–6.

Patra, A. K. (2014). Prediction of enteric methane emission from buffaloes using statistical models. Agriculture, Ecosystems & Environment, 195, 139–148.

Zwietering, M. H., Jongenburger, L., Rombouts, F. M., & Van’t Riet, K. (1990). Modeling of the bacterial growth curve. Applied and Environmental Microbiology, 56, 1875–1881.

Veeken, A., & Hamelers, B. (1999). Effect of temperature on hydrolysis rates of selected biowaste components. Bioresource Technology, 69, 249–254.

Pitt, R. E., Cross, T. L., Pell, A. N., Schofield, P., & Doane, P. H. (1999). Use of in vitro gas production models in ruminal kinetics. Mathematical Biosciences, 159, 145–163.

Schulin-Zeuthen, M., Kebreab, E., Gerrits, W. J., Lopez, S., Fan, M. Z., Dias, R. S., & France, J. (2007). Meta-analysis of phosphorus balance data from growing pigs. Journal of Animal Science, 85, 1953–1961.

Walker, M., Zhang, Y., Heaven, S., & Banks, C. J. (2009). Potential errors in the quantitative evaluation of biogas production in anaerobic digestion processes. Bioresource Technology, 100, 6339–6346.

AOAC (1999). Official methods of analysis of the association of official agricultural chemists (16th ed., ). Arlington:AOAC International.

APHA (1998). Standard methods for the examination of water and wastewater. Washington:American Public Health Association.

Brown, D., & Li, Y. (2013). Solid state anaerobic co-digestion of yard waste and food waste for biogas production. Bioresource Technology, 127, 275–280.

Labatut, R. A., Angenent, L. T., & Scott, N. R. (2011). Biochemical methane potential and biodegradability of complex organic substrates. Bioresource Technology, 102, 2255–2264.

McDonald, P., & Henderson, A. (1964). Determination of water-soluble carbohydrates in grass. Journal of the Science of Food and Agriculture, 15, 395–398.

Johnson, M. L. (2008). Nonlinear least-squares fitting methods. Methods in Cell Biology, 84, 781–805.

Motulsky, H. J., & Christopoulos, A. (2003). Fitting models to biological data using linear and nonlinear regression, a practical guide to curve fitting. San Diego:Graph Pad Software Inc.

Wang, M., Tang, S. X., & Tan, Z. L. (2011). Modeling in vitro gas production kinetics: derivation of logistic-exponential (LE) equations and comparison of models. Animal Feed Science and Technology, 165, 137–150.

El-Mashad, H. M. (2013). Kinetics of methane production from the codigestion of switchgrass and Spirulina platensis algae. Bioresource Technology, 132, 305–312.

Sun, C., Liu, R., & Cao, W. (2014). Study on biochemical methane production from pig and buffalo manure (in Chinese with English abstract). China Biogas, 1, 49–52.

Thygesen, O., Triolo, J. M., & Sommer, S. G. (2014). Anaerobic digestion of pig manure fibres from commercial pig slurry separation units. Biosystems Engineering, 123, 91–96.

Weiland, P. (2010). Biogas production: current state and perspectives. Applied Microbiology and Biotechnology, 85, 849–860.

Wang, X., Yang, G., Feng, Y., Ren, G., & Han, X. (2012). Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresource Technology, 120, 78–83.

Banks, C. J., Zhang, Y., Jiang, Y., & Heaven, S. (2012). Trace element requirements for stable food waste digestion at elevated ammonia concentrations. Bioresource Technology, 104, 127–135.

Zhang, Y., Banks, C. J., & Heaven, S. (2012). Co-digestion of source segregated domestic food waste to improve process stability. Bioresource Technology, 114, 168–178.

Acknowledgments

Financial support from National Natural Science Foundation of China through contract (Grant No. 51376121) is greatly acknowledged. Besides, associate Professor Junmeng Cai from the School of Agriculture and Biology, Shanghai Jiao Tong University of China is greatly acknowledged for his valuable comments and suggestions to this paper. We also thank Bailonggang Sewage Treatment Plant (mesophilic) in Shanghai for providing inoculum and Instrumental Analysis Center of Shanghai Jiao Tong University for analysis of raw materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, C., Cao, W. & Liu, R. Kinetics of Methane Production from Swine Manure and Buffalo Manure. Appl Biochem Biotechnol 177, 985–995 (2015). https://doi.org/10.1007/s12010-015-1792-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1792-y