Abstract

Cellulose producing bacteria were isolated from fruit samples and kombucha tea (a fermented beverage) using CuSO4 solution in modified Watanabe and Yamanaka medium to inhibit yeasts and molds. Six bacterial strains showing cellulose production were isolated and identified by 16S rRNA gene sequencing as Gluconacetobacter xylinus strain DFBT, Ga. xylinus strain dfr-1, Gluconobacter oxydans strain dfr-2, G. oxydans strain dfr-3, Acetobacter orientalis strain dfr-4, and Gluconacetobacter intermedius strain dfr-5. All the cellulose-producing bacteria were checked for the cellulose yield. A potent cellulose-producing bacterium, i.e., Ga. xylinus strain DFBT based on yield (cellulose yield 5.6 g/L) was selected for further studies. Cellulose was also produced in non- conventional media such as pineapple juice medium and hydrolysed corn starch medium. A very high yield of 9.1 g/L cellulose was obtained in pineapple juice medium. Fourier transform infrared spectrometer (FT-IR) analysis of the bacterial cellulose showed the characteristic peaks. Soft cellulose with a very high water holding capacity was produced using limited aeration. Scanning electron microscopy (SEM) was used to analyze the surface characteristics of normal bacterial cellulose and soft cellulose. The structural analysis of the polymer was performed using 13C solid-state nuclear magnetic resonance (NMR). More interfibrillar space was observed in the case of soft cellulose as compared to normal cellulose. This soft cellulose can find potential applications in the food industry as it can be swallowed easily without chewing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose (BC) is a unique polymer with high crystallinity, nanoscale dimension, elasticity, mechanical strength, biocompatibility, and water holding capacity. Cellulose fibers are produced by certain bacteria belonging to the genera Acetobacter, Agrobacterium, Alcaligenes, Pseudomonas, Rhizobium, or Sarcina [1]. Acetobacter xylinum (or Gluconacetobacter xylinus) is nature’s most prolific cellulose producing bacterium. BC is produced as a highly hydrated and relatively pure cellulose membrane and therefore no chemical treatments are needed to remove lignin and hemicelluloses, as is the case with plant cellulose [2, 3]. Bacterial cellulose is attracting much attention because of its nanostructure, as a material of preference for nanotechnological applications, biomedical applications, as a food ingredient, and also a promising packaging material.

Two culture methods can be used to synthesize cellulose by Ga. xylinus. One is static culture in which a gelatinous pellicle is formed at the air-liquid interface. The pellicle grows in the downward direction [4]. The other is agitated culture, where pellet, irregular masses, or fibrillar cellulose structures are formed and are distributed in the medium. Under certain agitated condition, Ga. xylinus was observed to produce spherical cellulose beads. The BC produced in these agitated systems exhibits a lower degree of polymerization (DP), crystallinity, and Young’s modulus than that produced under static cultivation [5]. The less-organized form of BC may result from shear stress during agitation [6].

The formation of cellulose by laboratory bacterial cultures is an attractive biological phenomenon to obtain pure cellulose for several applications including food. By selecting the substrates, cultivation conditions, various additives, and finally the bacterial strain, it is possible to control the molar mass, molar mass distribution, and the supramolecular structure. Thus, it is possible to control important cellulose properties and also the course of biosynthesis [7]. However, the production is still a function of surface area to volume ratio.

Bacterial cellulose (BC) produced by the fermentation of coconut water is known as nata de coco, a dessert in the Philippines. BC can be used as a stabilizer, thickener, and dietary fiber in food [8]. BC is known to have cholesterol-lowering effect [9] and is also used as diet food. Often, cellulose-producing Acetobacter strains occur in the environment, i.e., fruits, vegetables, and fermented products along with yeast, fungi, and a milieu of other bacteria. Copper nanoparticles and CuO are known to function as antimicrobial agents [10, 11]. CuSO4 is also known to have antimicrobial properties to a certain extent [12]. Based on this fact, we have attempted to isolate cellulose-producing Acetobacter strains from fruit samples and kombucha tea using CuSO4 solution. Here, we have investigated the application of metal salts for their isolation. The medium used in this study to produce BC in the laboratory was formulated by Watanabe and Yamanaka. This medium is known to provide suitable growth conditions for the bacterium for cellulose production [13]. As a result, the BC formed was noticed to be relatively hard (highly dense) for human consumption. In the study, soft cellulose was produced by limiting the aeration to the cellulose-producing culture. The cellulose produced can be chewed easily and swallowed and is useful for many food applications. Soft cellulose with more water retention capacity is a form of hydrogel which is slippery in nature and suitable for edible purpose. In the present study, we have defined softness and the conditions required to produce it. Cellulose was also produced in non-conventional media such as pineapple juice and its twofold dilutions. Hydrolysed cornstarch medium was also used to check the cellulose production. The cellulose produced in this medium can be used for food application after autoclaving to remove the bacterial cells without harsh purification steps such as NaOH treatment.

Materials and Methods

Isolation of Cellulose-Producing Bacteria

Cellulose-producing bacteria were isolated from fruit samples such as apple, mango, banana, orange, watermelon (obtained from the Mysore region, India), and kombucha tea in the Watanabe and Yamanaka medium with slight modification containing g/L (50.0 sucrose, 5.0 yeast extract, 5.0 ammonium sulfate, 3.0 KH2PO4, 2.5 sodium acetate, 0.5 citric acid, 0.25 mL /L tween, and 15 agar, pH 5.5). Fruit samples were crushed in normal saline, serially diluted and plated on Watanabe and Yamanaka medium supplemented with sterile 10 mM CuSO4.5H2O to inhibit yeast and mold. The plates were incubated at 30 °C for 48 h. All the grown colonies were individually transferred to the test tubes containing 10.0 mL of the broth to confirm the cellulose production. The tubes showing the pellicle formation was subcultured five times to enrich for Gluconacetobacter colonies. The cultures were stored at 4 °C for further use.

Identification of Cellulose-Producing Bacteria

Two universal oligonucleotide primers, 27f (5’-AGAGTTTGATCCTGGCTCAG-3’) and 1542r (5’-AGAAAGGAGGTGATCCAGCC-3’), were used for amplification of the 16S rRNA gene in a thermocycler, Eppendorf. The PCR amplifications were conducted in a reaction mixture for 50 μl containing 5 μl 10× PCR buffer, 1.5 mM MgCl2, 0.2 mM dNTPs, 0.4 μM each primer, and 1 U Taq DNA polymerase. The amplified PCR products were purified using PCR purification kit, Quigen, cloned in p-drive vector, and sequenced at Ultra Lab Products, Bangalore. Further, the sequences were analyzed using BLAST homology search and submitted in the NCBI database using GenBank with accession nos.

Phylogenetic Analysis

The 16S rRNA gene sequence of the isolated strains were aligned with the 16S rRNA gene sequences of Gluconacetobacter species and other related taxa using CLUSTAL X software (version 1.82). The nucleotide sequences of the related taxa with their accession numbers were obtained from the GenBank database available at NCBI (Table 1). The similarity values of the 16S rRNA gene sequences were calculated from the multiple alignments. The software package MEGA (version 5.0) was used to construct a phylogenetic tree. The stability of the relationships was assessed by a bootstrap analysis of 1000 data sets.

Bacterial Cellulose Yield from Isolated Strains

Modified Watanabe and Yamanaka medium in g/L (50.0 sucrose, 5.0 yeast extract, 5.0 ammonium sulfate, 3.0 KH2PO4, 2.5 sodium acetate, 0.5 citric acid, 0.25 mL/L tween) was used to study the yield of cellulose from isolated bacterial strains. The pH of the medium was adjusted to 5.5. The medium was autoclaved at 121 °C for 15 min and inoculated with 10 % of 48-h-old culture grown in a test tube. Cellulose was harvested after 7 days and treated with 0.2 N NaOH to remove the bacterial and media protein contaminants. It was then washed with distilled water and dried in a hot air oven. Based on the yield, the most potent cellulose-producing bacteria, i.e., Gluconacetobacter. xylinum strain DFBT, was further studied.

Effect of Different Carbon Sources on Cellulose Production by Ga. xylinum

Cellulose production was studied by utilization of different carbon sources glucose/sucrose/mannitol/galactose/fructose/maltose/sorbitol/glycerol/trehalose/lactose replacing sucrose in the medium g/L (50.0 sucrose, 5.0 yeast extract, 5.0 ammonium sulfate, 3.0 KH2PO4, 2.5 sodium acetate, 0.5 citric acid, 0.25 mL/L tween) at 5 % (w/v) level. The pH of the medium was adjusted to 5.5 with acetic acid. Carbon sources were sterilized separately and added in the medium. All the experiments were carried out in sterile conditions. The flasks were kept at 30 °C for incubation in static condition for 2 weeks.

Cellulose Production in Non-Conventional Media

Cellulose production was carried out in pineapple juice and hydrolysed cornstarch medium separately. Pineapple was brought from a Mysore market and juice was extracted by blending the pulp in a laboratory blender (Waring, USA) and filtering with muslin cloth. The °Brix of the pineapple juice used was 10.5. Pineapple juice was diluted two times and four times to study the dilution effect on cellulose production. The pH of this medium was adjusted to 5.5 with 1 N NaOH. It was then autoclaved at 121 °C for 15 min. For the hydrolysed cornstarch medium, 50 g of cornstarch was gelatinized in 1 L distilled water at boiling temperature with constant stirring. It was then cooled to 65 °C and α-amylase (200 mg) and glucoamylase (100 mg) were added to hydrolyze the cornstarch for 2 h with constant stirring. The medium was dispensed equally in four 500-mL flasks. The pH of the medium was adjusted to 5.5 with 1 N HCl. It was then autoclaved at 121 °C for 15 min. The flasks were inoculated and incubated at 30 °C under static condition for 2 weeks.

Fourier Transform Infrared Spectrometer Analysis of Bacterial Cellulose

The surface properties of the BC were analyzed using Thermo Nicolet FT-IR spectrometer (Model 5700, Madison, WI). Fourier transform infrared spectrometer (FT-IR) spectra were recorded in a spectral range of 4000 to 500 cm−1 with a resolution of 4 cm−1, and analysis of the spectra was carried out using the software provided along with the instrument. A total of 32 scans were averaged to reduce the noise.

Production of Soft Cellulose

Cellulose was produced in a 2-L polypropylene bottle containing 1 L of the medium g/L (50.0 sucrose, 5.0 yeast extract, 5.0 ammonium sulfate, 3.0 KH2PO4, 2.5 sodium acetate, 0.5 citric acid, 0.25 mL/L tween), pH 5.5 under static condition at 30 °C for 4 weeks. The lid of the bottle was tightly closed to limit air supply.

Characterization of BC Membrane Using Scanning Electron Microscopy and NMR

The surface characteristic of the bacterial cellulose and soft cellulose produced was investigated using FEI (Nova nanosem 600) field emission scanning electron microscopy (SEM) (Netherlands). The purified cellulose films obtained after NaOH treatment were lyophilized and cut into 1-cm2 piece and sputter-coated with gold and examined at magnification of ×20,000 at an operating voltage of 15.0 kV. The chemical structure of bacterial cellulose was analyzed by 13C solid-state NMR spectroscopy (Jeol Resonance JNM-ECX400II-400 MHz). Microcrystalline cellulose (Sigma, USA) was taken as reference.

Results and Discussion

Cellulose-Producing Bacteria

Six cellulose-producing bacterial strains were obtained from fruits such as apple, banana, mango, orange, watermelon, and kombucha tea. The bacterial strains were identified by 16S rRNA gene sequencing and BLAST homology search in the NCBI database. The sequences of the bacterial strains were deposited in the Genbank database and the following accession numbers were obtained: HM100242.1 for Ga. xylinus strain DFBT, JN619368.1 for Ga. xylinus strain dfr-1, JQ080255.1 for Gluconobacter oxydans strain dfr-2, JQ080256.1 for G. oxydans strain dfr-3, JQ080257.1 for Acetobacter orientalis strain dfr-4, and JQ080258.1 for Ga. intermedius strain dfr-5. In the present study, a modified Watanabe and Yamanaka medium containing sodium acetate, citric acid, and tween 20 was used for cellulose production. Use of CuSO4 was found to be an effective method to purify Acetobacter strains. We have noticed in our earlier studies while working on A. xylinum that the organism is resistant to metal salts such as MgSO4, NiCl2, and CuSO4 (unpublished data). As a result, we have used CuSO4 solution to inhibit the growth of yeasts and molds which are rampant in the fruit samples. The cellulose-producing bacteria probably occur as endophytic organisms in fruit microflora along with various microorganisms without damaging the host. Endophytic microorganisms have been reported in several plants and organs including flowers, seeds, and fruits such as berries, papaya, grapes, etc. by various investigators [14–16]. The addition of CuSO4 in the Watanabe and Yamanaka medium followed by autoclaving results in formation of CuO which probably inhibited yeasts and molds and other bacteria but to a very lesser extent the Acetobacter. That is why the optimum concentration of CuSO4 at initial stages and subsequent addition has been specified at around 10 and 5 mM, respectively. There are few reports for the isolation of cellulose-producing bacteria from fruits and vegetables [17, 18].

Phylogenetic Analysis

The 16S rRNA sequences of the isolated strains were compared with several related taxa in the NCBI database. Gluconacetobacter rhaeticus strain JCM (AB645732.1) isolated from traditional Japanese fruit vinegar showed the highest similarity (99.0 %) to the isolated strain DFBT. Figure 1 shows the phylogenetic tree derived from the 16S rRNA gene sequences of 22 type-strains, which revealed that the isolated strains were a member of the genus Gluconacetobacter. As in the physiological characteristics, it was clear that the isolated strains were a member of the family Acetobacteracea and the genus Gluconacetobacter. Consequently, the isolated strains were named as Ga. xylinus strain DFBT, Ga. xylinus strain dfr-1, G. oxydans strain dfr-2, G. oxydans strain dfr-3, A. orientalis strain dfr-4, and G. intermedius strain dfr-5 for further studies based on their similarity index in the NCBI database.

Effect of Different Carbon Sources on Bacterial Cellulose Production by Ga. xylinus

Based on the yield of bacterial cellulose (data not reported), Ga. xylinum strain DFBT was selected for further studies. Sucrose was found to be the optimum carbon source, yielding 5.6 g/L (dry wt.) of cellulose, followed by glucose, 5.0 g/L. Other sugars gave a low yield of cellulose as shown in Fig. 2.

Cellulose Production in Non-Conventional Media

A very high yield of cellulose, i.e., 9.1 g/L, was produced by Ga. xylinus strain DFBT in two times diluted pineapple juice medium as shown in Table 2. But in four times diluted pineapple juice medium, only 3.15 g/L of cellulose was produced which is about one third of the cellulose produced in two times diluted pineapple juice. This indicates that cellulose production is not directly proportional to the strength of the medium. Pineapple juice used to produce cellulose does not contain other ingredients such as yeast extract, ammonium sulfate, KH2PO4, sodium acetate, citric acid, and tween present in the Watanabe and Yamanaka medium. The pH of the pineapple juice medium was maintained at 4.0 even after 2 weeks of fermentation by cellulose-producing bacteria. Cellulose produced in cornstarch medium was about 3.48 g/L.

FT-IR Analysis of Bacterial Cellulose

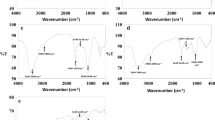

The FT-IR spectra of bacterial cellulose are shown in Fig. 3. For the pure cellulose spectrum, distinguish peaks of 3350 cm−1 and shouldering around 3400 to 3500 cm−1 indicates O-H stretching, 2800 to 2900 cm−1 indicates C-H stretching, 1160 cm−1 indicates C-O-C stretching, and 1035 to 1060 cm−1 indicates C-O stretching. Other fingerprint regions for cellulose are peaks around 1300 cm−1 which indicates C-H bending and around 1400 cm−1 which indicates CH2 bending [19]. The FT-IR spectra of bacterial cellulose grown in modified Watanabe and Yamanaka medium showed characteristic cellulose peaks at 3345 cm−1 for O-H stretching vibration, at 2891.5 cm−1 for C-H stretching vibration, at 1400 cm−1 for C-H bending vibration, and at 1030 to 1060 cm−1 for C-O-C and C-O-H stretching vibration of the sugar ring [20], thus confirming the purity of the cellulose produced. The shape of the curve is a signature of the origin of the cellulose. In addition, the spectra of bacterial cellulose from Ga. xylinum showed its own signature curve and this shape of curve was consistent and reproducible.

Production of Soft Cellulose

Soft cellulose was produced in modified Watanabe and Yamanaka medium in polypropylene bottle by limiting the air supply by tightly closing the lid. The cellulose production in this condition takes more time as compared to normal static culture cultivation; however, very transparent cellulose with high water holding capacity was produced, hence it can be called as a soft cellulose/hydrogel. This hydrogel finds several applications in food, cosmetics, and pharmaceutical industries. Soft cellulose is particularly useful as a source of dietary fiber in salads, low-calorie desserts, fabricated foods, and diet drinks where it can be used in small pieces and can be swallowed easily. Soft cellulose with high water retention floats in the water and fruit juices making it useful as a food additive for fruit juices. Strict aerobic conditions for the growth of bacteria only exits in thin, upper surface layer of the cellulose. More oxygen supply does not show any significant increase in the cellulose production [21]. Also, in case of agitated culture where oxygen supply is more, cellulose production is not significantly high [5]. This shows that an optimum concentration of oxygen is required for the cellulose production. If oxygen is in limited quantity, cellulose formed is less reticulated here we call as soft cellulose. The soft cellulose was also found suitable for preparation of spherical cellulose nanocrystals (data not reported) using cellulase enzyme.

Characterization of BC Membrane Using SEM and NMR

The morphological structures of BC fibers from purified BC samples and soft cellulose were analyzed by SEM. The analysis by SEM revealed that the cellulose produced in the limited oxygen supply has more interfibrillar space making it extra porous and soft (Fig. 4). This may be due to limited oxygen; less bacterial growth leads to the production of cellulose which is less reticulated with more water holding capacity. Whereas, the cellulose produced in normal oxygen supply has interwoven mat-like structure of the cellulose fibers with no apparent pores as shown in Fig. 5 as also observed by [22].

NMR was used to analyze the structural pattern of the bacterial cellulose produced in the modified Watanabe and Yamanaka medium which revealed that it has similar structural pattern as that of microcrystalline cellulose taken as a reference. This comprised of six characteristic peaks corresponding to six carbon atoms of the glucose molecule (monomeric unit of cellulose) (Fig. 6). Similar structural pattern for bacterial cellulose has also been reported by different researchers [23, 24].

Conclusion

Six cellulose-producing bacteria were isolated from fruit samples and kombucha tea and identified by ribotyping. Use of CuSO4 solution was found to be an effective method to purify Acetobacter strains, and it has not been reported yet. Out of the six strains isolated, Ga. xylinus was further optimized for cellulose production. Sucrose was found to be the best carbon source followed by glucose. FT-IR analysis of the membrane showed the characteristic cellulose peaks. NMR of bacterial cellulose revealed similar structural pattern to that of microcrystalline cellulose. FESEM analysis of soft cellulose revealed the increased interfibrillar spaces in the membrane. Our research found that a novel kind of soft cellulose can be produced in limited oxygen supply which can find several food applications and other industrial applications.

References

El-Saied, H., Basta, A. H., & Gobran, R. H. (2004). Research progress in friendly environmental technology for the production of cellulose products (bacterial cellulose and its application). Polymer-Plastics Technology and Engineering, 43, 797–820.

Wan, W. K., Hutter, J. L., Millon, L., & Guhados, G. (2006). Bacterial cellulose and its nanocomposites for biomedical applications. ACS Symposium Series, 938, 221–241.

Barud, H. S., Barrios, C., & Regiani, T. (2008). Self supported silver nanoparticles containing bacterial cellulose membranes. Materials Science and Engineering C: Biomimetic and Supramolecular Systems, 28, 515–518.

Borzani, W., & Desouza, S. J. (1995). Mechanism of the film thickness increasing during the bacterial production of cellulose on non-agitated liquid-media. Biotechnology Letters, 17(11), 1271–1272.

Czaja, W., Romanovicz, D., & Brown, R. M., Jr. (2004). Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose, 11, 403–411.

Watanabe, K., Hori, Y., Tabuchi, M., Morinaga, Y., Yoshinaga, F., Horii, F., Sugiyama, J., & Okano, T. (1994). Structural features of bacterial cellulose vary depending on the cultural conditions (pp. 45–50). Kyoto: Proc. Cellulose Society of Japan.

Klemm, D., Heublein, B., Fink, H. P., & Bohn, A. (2005). Cellulose: fascinating biopolymer and sustainable raw material. Angewandte Chemie International Edition, 44, 3358–3393.

Bajaj, I., Chawla, P., Singhal, R., & Survase, S. (2009). Microbial cellulose: fermentative production and applications. Microbial cellulose: fermentative production and applications. Food Technology and Biotechnology, 47(2), 107–124.

Chau, F., Yang, P., Yu, C.-M., & Yen, G.-C. (2008). Investigation on the lipid- and cholesterol-lowering abilities of biocellulose. Journal of Agricultural and Food Chemistry, 56(6), 2291–2295.

Ren, G., Hu, D., Cheng, E. W., Vargas-Reus, M. A., Reip, P., & Allaker, R. P. (2009). Characterisation of copper oxide nanoparticles for antimicrobial applications. International Journal of Antimicrobial Agents, 33(6), 587–590.

Ramyadevi, J., Jeyasubramanian, K., Marikani, A., Rajakumar, G., & Rahuman, A. A. (2012). Synthesis and antimicrobial activity of copper nanoparticles. Materials Letters, 71, 114–116.

Rathore, P., Hegde, A., Ginjupalli, K., & Upadhya, P. N. (2009). Evaluation of antifungal activity of additives to resilient liners: an in vitro pilot study. Artificial Organs, 23(1), 6–9.

Ramana, K. V., Tomar, A., & Singh, L. (2000). Effect of various carbon and nitrogen sources on cellulose synthesis by Acetobacter xylinum. World Journal of Microbiology and Biotechnology, 16(3), 245–248.

Muthukumarasamy, R., Revathi, G., Seshadri, S., & Lakshminarasimhan, C. (2002). Gluconacetobacter diazotrophicus (syn. Acetobacter diazotrophicus), a promising diazotrophic endophyte in tropics. Current Science, 83(2), 137–145.

Compant, S., Mitter, B., Colli-Mull, J. G., Gangl, H., & Sessitsch, A. (2011). Endophytes of grapevine flowers, berries, and seeds: identification of cultivable bacteria, comparison with other plant parts, and visualization of niches of colonization. Microbial Ecology, 62(1), 188–197.

Krishnan, P., Bhat, R., Kush, A., & Ravikumar, P. (2012). Isolation and functional characterization of bacterial endophytes from Carica papaya fruits. Journal of Applied Microbiology, 113(2), 308–317.

Jesus, E. G., Andres, R. M., & Magno, E. T. (1971). A study on the isolation and screening of microorganisms for production of diverse textured nata. The Philippine Journal of Science, 100, 41–52.

Jahan, F., Kumar, V., Rawat, G., & Saxena, R. K. (2012). Production of microbial cellulose by a bacterium isolated from fruit. Applied Biochemistry and Biotechnology, 167(5), 1157–1171.

Halib, N., Iqbal, M. C., Amin, M., & Ahmad, I. (2012). Physicochemical properties and characterization of nata de coco from local food industries as a source of cellulose. Sains Malaysiana, 41(2), 205–211.

Sun, Y., Lin, L., Deng, H., Li, J., He, B., Sun, R., & Ouyang, P. (2008). Structure of bamboo in formic acid. Bioresources, 3(2), 297–331.

Hornung, M., Ludwig, M., Gerrard, A. M., & Schmauder, H. P. (2006). Optimizing the production of bacterial cellulose in surface culture: evaluation of substrate mass transfer influences on the bioreaction (Part 1). Engineering in Life Science, 6(6), 537–545.

Goh, W. H., Rosma, A., Kaur, B., Fazilah, A., Karim, A. A., & Rajeev, B. (2012). Microstructure and physical properties of microbial cellulose produced during fermentation of black tea broth (Kombucha) II. International Food Research Journal, 19, 153–158.

Watanabe, K., Tabuchi, M., Morinaga, Y., & Yoshinaga, F. (1998). Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose, 5, 187–200.

Kai, A., & Ping, X. U. (1994). C.p./m.a.s. 13C N.M.R. study on microbial cellulose-fluorescent brightener complexes. Polymer, 35, 75–79.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neera, Ramana, K.V. & Batra, H.V. Occurrence of Cellulose-Producing Gluconacetobacter spp. in Fruit Samples and Kombucha Tea, and Production of the Biopolymer. Appl Biochem Biotechnol 176, 1162–1173 (2015). https://doi.org/10.1007/s12010-015-1637-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1637-8