Abstract

In the present study, a new biosensor based on laccase from Paraconiothyrium variabile was developed for catechol. The purified enzyme entrapped into the Fe3O4/polyaniline/chitosan (Fe3O4/polyaniline (PANI)/chitosan (CS)) biocomposite matrix film without the aid of other cross-linking reagents by a one-step electrodeposition on the surface of carbon paste electrode (CPE). The formed layer of biocomposite was characterized with scanning electron microscopy (SEM), electrochemical impedance spectroscopy (EIS), and cyclic voltammetry (CV). The biosensor was optimized with respect to biocomposite composition, enzyme loading, and solution pH by amperometry method. The biosensor exhibited noticeable eletrocatalytic ability toward catechol with a linear concentration range from 0.5 to 80 μM and a detection limit of 0.4 μM. The biosensor showed optimum response within 8 s, at pH 5, and 40 °C. The apparent Michaelis–Menten (K M app) was found to be 1.092 μM. The fabricated biosensor could be applied for determination of catechol in tea leaf samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Catechol and its derivatives are important phenolic compounds due to their antioxidation and antivirus properties which could affect the activities of some enzymes. They play a major role in several pathophysiological diseases such as atherosclerosis, cardiovascular, Parkinson’s, and Alzheimer’s diseases, and some cancers. Moreover, they are widely used as procurers in medicines, cosmetics, dyes, pesticides, and so on. They have also been recognized as important environmental pollutants owing to their high toxicity and low degradability in the ecological system. Therefore, a sensitive, rapid, and simple method for determination of catechol is of great interest. Common analytical techniques such as spectrophotometry [1] gas chromatography (GC) [2], high-performance liquid chromatography (HPLC) [3], synchronous fluorescence using partial least-squares (PLS) [4], capillary electrochromatography [5], and capillary zone electrophoresis [6] have been used for determination of catechol in various samples. Catechol has an excellent electrochemical activity, so that various electrochemical sensors for oxidation of phenolic compounds like catechol have been reported [7–9]. Specifically, amperometric biosensors have been adopted to detect catechol in food and environmental samples [10–13]. The electrochemical oxidation of phenolic compounds may induce the deactivation of surface of the bare working electrodes such as platinum and glassy carbon electrode by electrode fouling due to polymeric film formation [14]. Thus, various novel materials for modification electrodes at relatively low cost have been reported.

Laccase catalyzes the oxidation of various aromatic compounds, such as phenols by reducing molecular oxygen to water [15]. Laccase and tyrosinase are the most common enzymes used as biological recognition elements in polyphenolic biosensors [16–18], although tyrosinase-based biosensors have shown superior sensitivity than those of laccase-based, but laccase has long time stability to catalyze the oxidation of phenolic compounds [19, 20].

A number of biosensors for detection of phenolic compounds have been reported based on immobilization of laccase onto various supports. The nature of the immobilization matrix plays an important role in the elimination of interferences and offers improvements in the efficiency, sensitivity, and operational stability of the biosensors [15, 21]. There are also various methods for laccase immobilization such as physical adsorption or chemical interactions [22]. The entrapment method is a physical interaction between enzyme and the matrix [22–26]. Although this methodology is characterized by mass transfer limitation and low enzyme loading, but in this method, fouling of neither the enzyme nor chemical changes of the support is obtained [27].

Biocomposites are biocompatible materials which are added to a biomolecule or biopolymer, providing good environment for immobilization of enzymes and sustaining their bioactivity in electrode modification processes [28, 29]. It is worthy to note that chitosan (CS) has gained growing interest in immobilizing biomolecules, especially enzyme immobilization [30]. This compound has an excellent film-forming ability and high mechanical stability. Furthermore, it is nontoxic, biocompatible, and low-cost and has a remarkable affinity to proteins. Obviously, selection of proper nanoparticles as the catalyst plays a key role in immobilization of the enzymes. Magnetic–chitosan (CS–Fe3O4) and carbon nanotubes–chitosan (CNT–CS) composites are another laccase immobilization supports that have been tested for detection of phenols, but the enzyme was covalently bound to support via cross-linker that is not easy to be carried and time consuming [31–35]. The CS–Fe3O4 nanocomposite has also been utilized to immobilize enzyme in the absence of a cross-linking reagent, in which the enzyme incorporated into the composite film, remaining better catalytic activity and improving biosensors’ performance [36–38]. Recently, Fe3O4 coated with polyaniline (PANI) has been extensively used in electrode modification. Such a composite modified electrode combines the ability of Fe3O4 and conductive polymer to promote electron transfer reactions with the advantages of entrapping biological material [39]. To overcome the problem of enzyme leakage, one-step deposition of nanoparticles in CS film has been reported [40].

In this study, a new bisosensor-based nanobiocomposite was prepared for determination of catechol. A mixture of nanocomposite Fe3O4/PANI, CS, and the laccase enzyme was immobilized on a carbon paste electrode by a one-step cathodic potential electrodeposition. Such fabrication design not only simplifies preparation of the biocomposite film to prepare biosensor but also greatly enhances sensitivity and stability of the biosensor. Meanwhile, the thickness of the biocomposite is controllable. Further, the covalent immobilization of enzyme onto hybrid electrode is likely to overcome the problem of enzyme leakage. The fabricated biosensor was utilized to determine the concentration of catechol in tea leaf samples based on oxidation of catechol to phenoxy radicals.

Experimental

Materials

Extracellular laccase was purified from the submerged fermentation of the soil isolate ascomycete Paraconiothyrium variable [41, 42]. Chitosan (CS) and catechol were purchased from Sigma-Aldrich. FeCl3·6H2O, FeCl2·4H2O, aniline, ammonium peroxydisulfate (APS), sodium hydroxide, hydrochloric acid, ethanol, methanol, and acetone were purchased from Merck (Darmstadt, Germany). Aniline was purified under vacuum before use. Phosphate buffer solution (PBS, 0.05 M) was used as supporting electrolyte through the experiments using Na2HPO4 and NaH2PO4.

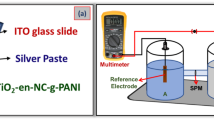

Apparatus

All electrochemical experiments and electrochemical impedance spectroscopic (EIS) measurements were performed using an potentiostat/galvanostat (Autolab PGSTAT-302N, Eco-Chemie, Utrecht, Netherlands, GPES/FRA software) equipped with a three-electrode system consisting of Fe3O4/polyaniline/laccase/CS-modified carbon paste electrode (Fe3O4/PANI/Lac/CS/CPE) as a working electrode, and Ag/AgCl and Pt wire as reference and auxiliary electrodes, respectively. Characterization of the electrode surfaces was performed by scanning electron microscopy (LEO Model 1450 VP, Carl Zeiss, UK). The high-performance liquid chromatography (HPLC) analyses were performed by a Shimadzu chromatographic system (Tokyo, Japan). Chromatographic separation was accompolished on a C18 column (250 × 4.6 mm, 5 μm) with the mobile phase of a mixture of methanol/acetic acid (50:50, v/v) at a flow rate of 1 mL min−1. The injection volume was 10 μL, and the effluent was monitored by the UV detector at 275 nm.

Preparation of Fe3O4/PANI Nanocomposite

Fe3O4 nanoparticles were synthesized by co-precipitation of Fe2+ and Fe3+ ions in the presence of alkaline solution under hydrothermal treatment according to Berger et al. [43]. Then, the Fe3O4 (0.25 g) nanoparticles were dispersed into a solution containing aniline (0.2 mL) and HCl (0.1 M). The APS (2.2 mmol) as an oxidant was added drop wise to the solution under stirring (300 rpm) at room temperature for 2 h and was incubated overnight. The resultant product was washed with deionized water, methanol, and ether three times and dried at 70 °C for 5 h under vacuum to obtain a green-black powder of Fe3O4/PANI nanocomposite [44].

Preparation of the Fe3O4/PANI/Lac/CS/CPE Biosensor

At first, the CPE was prepared through mixing 0.07 g of graphite powder with melted n-eicosane as a binder [45]. A portion of the composite mixture was tightly packed into the end of a 1-mL propylene tube (3 mm in diameter) and was left to dry in an ambient condition. A copper wire inserted into the carbon paste provided the electrical contact. The surface of the electrode was polished with a weighing paper until a shiny appearance was obtained, and then it was rinsed with deionized water. Prior to electrodeposition, the nanobiocomposite was prepared by mixing of Fe3O4/PANI nanoparticles (4 mg mL−1) and CS (0.2 %, w/w) and sonicated for 30 min and stirring for 2 h. Different concentrations of laccase (0.83 U mg−1) in the range of 1–10 mg mL−1 were added to the mixture and stirred at 4 °C for 1 h. The biosensor was prepared by electrodeposition of the biocomposite on the CPE surface at different applied potentials from −1.0 to −2.0 V (vs. Ag/AgCl) and different electrodeposition times (100–300 s). After rinsing the biosensor with PBS, it was kept in the buffer at 4 °C.

Optimization of Experimental Variables

In order to obtain optimum conditions of the enzyme electrode, different parameters such as solution pH, temperature, and composition of the electrode were investigated amperometrically.

The effect of pH on the performance of the biosensor was studied by incubating the electrode in catechol solution buffered (0.05 M PBS) at the pH range of 4.5–8. The effect of temperature on the performance of the biosensor was examined by incubation of the electrode in catechol solution at different temperatures (20–50 °C) at an interval of 5 °C.

Electrochemical Measurement

Cyclic voltammograms were recorded in the potential range from −0.8 to +0.90 V in PBS (0.05 M) at a scan rate of 50 mV s−1. The biosensor was employed for determination of catechol by amperometric measurements at the applied potential of +0.2 V (vs. Ag/AgCl) in steady-state condition. EIS studies were carried out in 0.5 mM Fe(CN)6 3−/Fe(CN)6 4− containing 0.1 M KCl solution. The frequency sweep was selected from 0.05 Hz to 100 kHz and amplitude of 10 mV.

Determination of Catechol Contents in Green and Black Tea Leaves

To validate the proposed method, the biosensor was employed for determination of catechol content in four commercial tea brands. Two grams of the dried tea leaves were boiled in 10 mL of distilled water and filtered, and the extracted solutions were diluted two times with PBS (pH 6.5). Determination of the catechol content in tea leaf samples was conducted by using the developed biosensor under the optimized condition. The measurements were carried out by interpolation of the corresponding amperometric signals into calibration plots constructed with catechol solutions. The results of the present method were compared with those determined by HPLC according to Qiao et al. [46].

Results and Discussion

Characterization of the Modified Carbon Paste Electrodes

The surface morphology of the bare CPE, Fe3O4/PANI/CS/CPE, and Fe3O4/PANI/Lac/CS/CPE electrodes was characterized by SEM studies (Fig. 1a–c). The SEM image of a typical bare CPE (Fig. 1a) showed a homogeneous surface, whereas electrodeposition of Fe3O4/PANI and CS on CPE surface displayed a uniform layer of nanocomposite on the electrode surface (Fig. 1b). The enterapment of laccase from P. variabile in Fe3O4/PANI/CS nanocomposite was confirmed by the SEM image in Fig. 1c.

Electrochemical impedance spectroscopy (EIS) and cyclic voltammetry(CV) were used for characterization of electrochemical behavior of the modified electrodes. To evaluate conductivity of CPE with different coating materials, the impedance measurements at CS/CPE, Fe3O4/PANI/CS/CPE, and Fe3O4/PANI/Lac/CS/CPE electrodes were carried out in 0.05 M PB solution containing 5 mM K4Fe(CN)6/K3Fe(CN)6 and 0.1 M KCl. The corresponding Nyquist plots are illustrated in Fig. 2a. The equivalent circuit was established to find the electron transfer resistant (R ct) values. The R ct values derived from the curves for CS/CPE, Fe3O4/PANI/CS/CPE, and Fe3O4/PANI/Lac/CS/CPE were 510, 240, and 330 Ω, respectively. As can be seen, the R ct significantly decreased at Fe3O4/PANI/CS/CPE electrode (curve b) that was lower than that at CS/CPE (curve a), indicating lower electron transfer resistance (R ct) and better electron conductivity pathway on the surface of CPE modified with Fe3O4/PANI nanocomposite. Meanwhile, Fe3O4/PANI/Lac/CS/CPE electrode (curve c) shows larger semicircle diameter at higher frequencies, most probably owing to poor electrical conductivity and high electron transfer resistance of immobilized enzyme at this biosensor.

To evaluate electrochemical behavior of the electrodes, CV method was employed in a 5.0 mM K4Fe(CN)6/K3Fe(CN)6 and 0.1 M KCl solution as the probe (Fig. 2b). The peak separation (ΔE p) of 270 mV at CS/CPE electrode (curve a) was observed indicating that CS acted as an inert blocking layer to hinder electron transfer. The significant increase in peak current at Fe3O4/PANI/CS/CPE (curve b) resulted from increasing in electrical conductivity and electrocatalytic properties of nanocomposite film deposited on the surface of CPE. The decrease in current at Fe3O4/PANI/Lac/CS/CPE (curve c) proved that the enzyme immobilized in nanocomposite matrix. These agree with the results obtained by the impedance experiments.

Electrochemical Response Toward Catechol at Different Electrodes

In the present study, catechol as a substrate was used for evaluation of the catalytic activity of laccase at Fe3O4/PANI/Lac/CS/CPE. Figure 3 displays the cyclic voltammograms of CPE/CS electrode (curve a), Fe3O4/PANI/CS/CPE (curve b), and Fe3O4/PANI/Lac/CS/CPE (curve c) in the potential range of −1.0 to 1.5 V in an unstirred PBS (0.05 M, pH = 7) containing catechol at concentration of 400 μM. A pair oxidation/reduction peak at 0.55 and −0.10 V (vs. Ag/AgCl) was exhibited at CS/CPE. Obviously, the electrochemical signal of catechol at Fe3O4/PANI/CS/CPE with increasing in current was seen at 0.55 V which was attributed to the catalytic property of Fe3O4/PANI composite toward the oxidation of catechol. However, two well-defined oxidation peaks at 0.2 and 0.55 V (vs. Ag/AgCl) at Fe3O4/PANI/Lac/CS/CPE were observed as gradually potentially increased from −1.0 to 1.5 V (vs. Ag/AgCl). The presence of the oxidation peak at 0.2 V at Fe3O4/PANI/Lac/CS/CPE resulted from the enzymatic reaction of laccase, while this peak did not observe at CS/CPE and Fe3O4/PANI/CS/CPE. It seems that the enzymatic reaction of catechol on Fe3O4/PANI/Lac/CS/CPE produced phenoxy radicals which are further evidence to oxidation of catechol to quinine [14]. In reverse scan, the reduction of quinone to catechol was occurred at −0.02 V at the biosensor surface. This suggested that the oxidation of catechol at 0.2 V at the Fe3O4/PANI/Lac/CS/CPE might take place more selective and less exposed to the possible interferents than that at the other two electrodes. The peak current at this potential increased linearly with increasing in the concentration of catechol, so this potential was selected for amperometric determination of catechol.

Optimization of Experimental Conditions

As described above, the performance of the laccase biosensor is based on the amperometric detection of the enzymatic product generated during laccase oxidation of catechol in the presence of the dissolved oxygen. The amount of laccase loading in the nanocomposite film will affect the current response of the biosensor. Thus, different enzyme electrodes were prepared to examine the effect of enzyme amount on the biosensor response. According to the obtained results, high oxidation peak current was achieved when the enzyme concentration increased up to 7 mg mL−1. Upon further increase in the amount of laccase, the oxidation peak current decreased most probably due to increase in charging current and prohibiting electron transfer to catechol at the surface of the biosensor (Fig. 4a).

Both the electrodeposition potential and time could control the biocomposite film thickness. As shown in Fig. 4b, the oxidation peak current increased with increase in electrodeposition time from 100 to 200 s to reach the maximum response and decreased thereafter. Higher biosensor responses and more acceptable calibration curves were achieved with electrodeposition potential at −1.5 V. When the potential was more negative than −1.5 V, the biocomposite layer became instable, and the favorable sensitivity of the biosensor was lost.

The effect of pH on the response of the biosensor was studied in 0.05 M PBS in the pH range of 5.0–7.5. The experimental results showed an increase in the oxidation current response up to pH 6.5. At lower pH, CS was dissolved in the solution, while at higher pH, the enzyme activity was decreased (Fig. 5a).

Another parameter that affects the biosensor performance is temperature. The optimum temperature was found to be 40 °C (Fig. 5b) that was in agreement with the previous report [47].

Evaluation of the Biosensor

The performance of the biosensor was evaluated in terms of the linearity, limit of detection (LOD), response time, reproducibility, and long-term stability. The steady-state current response to stepwise increasing catechol concentration is shown in Fig. 6. The amperometric current was linearly increased, while the concentration of catechol increased from 0.5 to 80 μM with a correlation coefficient of 0.995 (inset of Fig. 6) and a limit of detection of 0.4 μM (S/N = 3). The response time of the enzyme electrode was 8 s, indicating rapid diffusion of catechol to the biosensor surface. The reproducibility of the biosensor was evaluated based on the response of three different biosensors at the linear concentration range, and the relative standard deviation was calculated to be 7.8 %. Long-term stability of biosensor was studied based on the amperometric measurement of the biosensor response in various days. The enzyme electrode retained 90 % of its original response after 60 days storage in 0.05 M PBS (pH = 6.5) at 4 °C. The relationship between the current response and the concentration of the substrate followed the Michaelis–Menten kinetic mechanism. The apparent Michaelis–Menten constant (K app M ) was estimated to be 1.092 μM by the analysis of the slope and the intercept of the Lineweaver–Burk plot of 1/I vs. 1/C [48].

Table 1 shows the performance characteristics of the new biosensor compared with those reported for different amperometric biosensors. The K M app is lower than that of 256 and 300 μM from the previous results [47, 49]. The small K M app value reveals high enzyme activity and preserving enzyme catalytic specificity against catechol. As it can be seen, the obtained sensitivity of Fe3O4/PANI/Lac/CS/CPE was 126 μA mM−1 which was better than that of the compared biosensors [47, 49–51]. The linearity and limit of detection of the present biosensor were better than earlier reports [49, 50].

Interference Study

The selectivity of the biosensor was evaluated by measurement of the biosensor response to possible interferents under the optimized conditions. For this purpose, amperometric currents of binary solutions containing 10 μM catechol and the interferents such as gallic acid, quercetin, cysteine, ascorbic acid, uric acid, caffeine, and fructose each at 100 μM concentration level were measured. No change in the amperometric current response was observed for the studied interferents except for ascorbic acid, indicating that the proposed biosensor is highly selective toward catechol in the presence of a ten fold excess of the studied compounds (Fig. 7).

Determination of Catechol in Tea Samples

To show the ability of the biosensor for determination of catechol in tea, four tea brands were tested under the optimized conditions. The comparative evaluation of black (samples A–C) and green (sample D) tea leaves were performed in triplicate analysis for each type of tea. The samples were also analyzed by HPLC to obtain the catechol content (Table 2). The correlation coefficient of the results by the two methods was 0.990, indicating to the high accuracy of the method. Therefore, the biosensor is reliable for determination of catechol in tea leaves.

Conclusions

Fe3O4/PANI/Lac/CS nanobiocomposite has been prepared by a simple one-step electrodeposition approach on the surface of CPE for determination of catechol. The combination of Fe3O4/PANI and CS limited conformational alterations of enzyme and provided selective environment for maintaining the bioactivity of laccase. Combination of the hydrogen binding formation of biocomposite and phenoxy radical of catechol as well as good conductivity of Fe3O4/PANI advantages provided fast response of the laccase biosensor toward catechol. Excellent linearity, good selectivity, and accepted long-term stability are advantages of the biosensor. The developed biosensor could be used satisfactorily for determination of catechol in tea samples.

References

Usmani, Q. S., Beg, M. M., & Shukla, I. C. (1979). Analyst, 104, 148–151.

Ng, L. K., Lafontaine, P., & Harnois, J. (2000). Journal of Chromatography A, 873, 29–38.

Lee, B. L., Ong, H. Y., Shi, C. Y., & Ong, C. N. (1993). Journal of Chromatography A, 619, 259–266.

Pistonesi, M. F., Di-Nezio, M. S., Centurión, M. E., Palomeque, M. E., Lista, A. G., & Fernández, B. S. (2006). Talanta, 69, 1265–1268.

Guan, N., Zeng, Z., Wang, Y., Fu, E., & Cheng, J. (2000). Analytica Chimica Acta, 418, 145–151.

Xie, T., Liu, Q., Shi, Y., & Liu, Q. (2006). Journal of Chromatography A, 1109, 317–321.

Yin, H., Zhang, Q., Zhoud, Y., Ma, Q., Liu, T., Zhub, L., & Aia, S. (2011). Electrochimica Acta, 56, 2748–2753.

Wang, L., Huang, P., Bai, J., Wang, H., Zhang, L., & Zhao, Y. (2006). International Journal of Electrochemical Science, 1, 403–413.

Li, M., & Zhao, G.C. (2012) International Journal of Electrochemistry, DOI 243031, 1–8.

Sulak, M. T., Erhan, E., & Keskinler, B. (2010). Applied Biochemistry and Biotechnology, 160, 856–867.

Lin, H., Gan, T., & Wu, K. (2009). Food Chemistry, 113, 701–704.

Carralero Sanz, V., Luz Mena, M., Gonzalez-Cortes, A., Yanez-Sedeno, P., & Pingarron, J. M. (2005). Analytica Chimica Acta, 528, 1–8.

Liu, J., & Mattiasson, B. (2002). Water Research, 236, 3786–3802.

Enache, T. A., & Oliveira-Brett, A. M. (2011). Journal of Electroanalytical Chemistry, 655, 9–16.

Fernández-Fernández, M., Sanromán, M. A., & Moldes, D. (2013). Biotechnology Advances, 31, 1187.

Kaushik, A., Solankia, R. P., Pande, M. K., Kaneto, K., Ahmad, S., & Malhotram, D. B. (2010). Thin Solid Films, 519, 1160–1166.

Kaushik, A., Solanki, P. R., Ansari, A. A., Sumana, G., Ahmad, S., & Malhotram, D. B. (2009). Sensors and Actuators B, 138, 572–580.

Tsai, Y. C., Chen, S. Y., & Lee, C. A. (2008). Sensors and Actuators B, 135, 96–101.

Vianello, F., Ragusa, S., Cambria, M. T., & Rigo, A. (2006). Biosensors and Bioelectronics, 21, 2155–2160.

Jarosz-Wilkołazka, A., Ruzgas, T., & Gorton, L. (2004). Enzyme and Microbial Technology, 35, 238–241.

Fu, J., Qiao, H., Li, D., Luo, L., Chen, K., & Wei, Q. (2014). Sensors, 14, 3543–3556.

Martinez-Ortiz, J., Flores, R., & Vazquez-Duhalt, R. (2011). Biosensors and Bioelectronics, 26, 2626–2631.

Chawla, S., Rawal, R., Kuhad, S. R. C., & Pundir, C. S. (2011). Analytical Methods, 3, 709–714.

Ibarra-Escutia, P., Gomez, J. J., Calas-Blanchard, C., Marty, J. L., & Ramírez-Silva, M. T. (2010). Talanta, 15, 1636–1642.

Montereali, M. R., Seta, L. D., Vastarella, W., & Pilloton, R. (2010). Journal of Molecular Catalysis B, 64, 189–194.

Liu, Y., Zeng, Z., Zeng, G., Tang, L., Pang, Y., Li, Z., Liu, C., Lei, X., Wu, M., Ren, P., Liu, Z., Chen, M., & Xie, G. (2012). Bioresource Technology, 115, 21–26.

Brady, D., & Jordaan, J. (2009). Biotechnology Letters, 31, 1639–1650.

Cabaj, J., Sołoducho, J., Chyla, A., & Jedrychowska, A. J. (2011). Sensors and Actuators B, 157, 225–231.

Li, Y., Cao, X., Qian, X., Chen, Y., & Liu, S. (2012). Journal of Electroanalytical Chemistry, 686, 7–11.

Krajewskam, B. (2004). Enzyme and Microbial Technology, 35, 126–139.

Kalkan, N., Aksoy, S., Aksoy, E. A., & Hasirci, N. (2012). Journal of Applied Polymer Science, 123, 707–716.

Jiang, D.-S., Long, S. Y., Huang, J., Xiao, H. Y., & Zhou, J. Y. (2005). Biochemical Engineering Journal, 25, 15–23.

Bayramoglu, G., Yilmaz, M., & Yakup, A. M. (2010). Bioprocess and Biosystems Engineering, 33, 439–448.

Liu, Y., Qu, X., Guo, H., Chen, H., Liu, B., & Dong, S. (2006). Biosensors and Bioelectronics, 21, 2195–2201.

Chawla, S., Rawal, R., & Pundir, C. S. (2011). Journal of Biotechnology, 156, 39–45.

Chawla, S., Rawal, R., Sharma, S., & Pundir, C. S. (2012). Biochemical Engineering Journal, 68, 76–84.

Rossi, L. M., Quach, A. D., & Rosenzweig, Z. (2004). Analytical and Bioanalytical Chemistry, 380, 606–613.

Wei, H., & Wang, E. (2008). Analytical Chemistry, 80, 2250–2254.

Nguyen, B. H., Tran, L. D., Do, Q. P., Nguyen, H. L., Tran, N. H., & Nguyen, P. X. (2013). Material Science and Engineering C, 33, 2229–2234.

Delanoy, G., Li, Q., & Yu, J. (2005). International Journal of Biological Macromolecules, 35, 89–95.

Forootanfar, H., Faramarzi, M. A., Shahverdi, A. R., & TabatabaeiYazdi, M. (2011). Bioresource Technology, 102, 1808–1814.

Faramarzia, M. A., & Forootanfara, H. (2001). Colloids and Surfaces B: Biointerfaces, 87, 23–27.

Berger, P., Adelman, N., Beckman, K. J., Campbell, D. J., Ellis, A. B., & Lisensky, G. C. (1999). Journal of Chemical Education, 76, 943–948.

Mehdinia, A., Roohi, F., & Jabbari, A. (2011). Journal of Chromatography A, 1218, 4269–4274.

Sadeghi, S., & Motaharian, A. (2013). Material Science and Engineering C, 33, 4884–4891.

Qiao, J.-Q., Yuan, N., Tang, C.-J., Yang, J., Zhou, J., Lian, H.-Z., & Dong, L. (2012). Research on Chemical Intermediates, 38, 549–558.

Zhou-Hong, X., Liu-Hua, L., Bai, X., & Shi-Chung, H. (2013). Sensors and Actuators B, 181, 661–667.

Lineweaver, H., & Burk, D. (1934). Journal of American Chemical Society, 56, 658–666.

Xu, X., Lu, P., Zhou, Y., Zhao, Z., & Guo, M. (2009). Material Science and Engineering C, 29, 2160–2164.

Xu, X., Guo, M., Lu, P., & Wang, R. (2010). Material Science and Engineering C, 30, 722–729.

Li, D., Pang, Z., Chen, X., Luo, L., Cai, Y., & Wei, Q. (2014). Beilstein Journal of Nanotechnology, 5, 346–354.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sadeghi, S., Fooladi, E. & Malekaneh, M. A New Amperometric Biosensor Based on Fe3O4/Polyaniline/Laccase/Chitosan Biocomposite-Modified Carbon Paste Electrode for Determination of Catechol in Tea Leaves. Appl Biochem Biotechnol 175, 1603–1616 (2015). https://doi.org/10.1007/s12010-014-1380-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1380-6