Abstract

Coptotermes formosanus Shiraki is a well-known wood-feeding termite, which can degrade not only cellulose and hemicellulose polysaccharides, but also some aromatic lignin polymers with its enzyme complex to the woody biomass. In this study, a very abundant protein was discovered and purified, using a three-step column chromatography procedure, from the tissue homogenate of the salivary glands and the gut of C. formosanus. Mass spectrometric analysis and the following peptide searching against the mRNA database toward this termite species indicated that the novel protein was a hemocyanin enzyme, termed as Hemo1, which further exhibited a strong oxidase activity in the substrate bioassays toward ABTS [2,2′-Azino-bis (3-ethylbenzothiazoline-6-sulfonic acid)], as well as other aromatic analogues, such as catechol and veratryl alcohols. This oxidative protein was an acid-favored enzyme with a molecular weight at 82 kDa, and highly active at 80 °C. These findings indicated that the novel protein, hemocyanin, discovered from the gut system of C. formosanus, might be an important ligninolytic enzyme involved in the biomass pretreatment processing, which will potentially enhance the digestibility and utilization of biomass polysaccharides in termite digestive systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

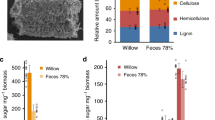

Lignocellulose from plants consisting of cellulose, hemi-cellulose, and lignin has been considered as an important resource for biofuels. Biological utilization of lignocellulose typically begins with a pretreatment process, followed by the hydrolysis and fermentation processes. Conventional physical and chemical pretreatments are usually energy intensive and environmentally unfriendly [1]. To alleviate the problem, much attention has recently been drawn to biological pretreatments, in which lignin is modified by oxidative metalloenzymes such as laccases and peroxidases, followed by the hydrolysis of the bonds between lignin and carbohydrates by feruloyl esterases [2, 3].

Lignin-modification enzymes have been found in fungi and insects. Examples include filamentous basidiomycetes (white- or brown-rot fungi) such as Phanerochaete chrysosporium [4, 5] as well as wood-feeding insects such as Coptotermes formosanus [6, 7]. Using the method of tetramethylammonium hydroxide thermochemolysis to probe lignin modification, Geib et al. [8] reported three types of lignin modification in lower termite Zootermopsis angusticollis: (1) side chain oxidation, (2) ring hydroxylation, and (3) ring demethoxylation. Ke et al. [9] reported that lignin undergoes structure change in the gut of C. formosanus as revealed by pyrolysis-gas chromatography/mass spectrometry and thermogravimetry. Despite these observations, enzymes responsible for lignin modification in the insect gut remain mostly unknown except for the well-studied laccases and peroxidases.

King et al. [10] identified a highly expressed oxidase, annotated as a hemocyanin, from a Limnoriid wood borer Limnoria quadripunctata. Lignin-decomposing function of this hemocyanin has been proposed in light of the lack of laccases and peroxidases in this species. Mainly found in the hemolymph of many arthropods and molluscs, hemocyanin is a copper protein, which serves as an oxygen transport molecule by binding 1 dioxygen molecule (O2) between the two copper atoms [11]. Interestingly, hemocyanins from insects such as silkworm Bombyx mori, moth Galleria mellonella [12], and tarantula Eurypelma californicum [13], as well as some crustaceans [14], have been found to exhibit phenol oxidase activity. Limited proteolysis or chemical denaturation may increase this activity. Since the basic structure units of lignin are phenol derivatives, the phenol oxidase activity may also oxidize lignin. However, experimental evidence to support this speculation remains absent.

In this paper, we report the purification of a major ABTS [2,2′-Azino-bis (3-ethylbenzothiazoline-6-sulfonic acid)] oxidase (Hemo1) from the tissue homogenate of main digestive organs (salivary gland and gut) of C. formosanus and its high homology to hemocyanin. Analysis of its enzymatic activities revealed that Hemo1 oxidized veratryl alcohol and catechol, providing experimental evidence that supports the lignin-modification activity of hemocyanin. Hemocyanin may thus serve to modify lignin in the insect’s gut to increase the accessibility of other wood-degrading enzymes such as cellulases and hemicellulases. Thus Hemo1 may be further explored as a candidate enzyme for biological pretreatment of lignin.

Materials and Methods

Termite

Wood-feeding termite, C. formosanus Shiraki, were originally collected from the campus of Zhongshan University, Guangzhou, People’s Republic China, and maintained in the laboratory at 25 ± 2 °C. A total of 3,000 worker termites were carefully dissected, and the salivary glands and guts were collected and kept frozen at −20 °C in 50 mM Na3PO4 buffer (pH 7.0) until use.

Protein Purification

The tissues of the digestive organs of C. formosanus, including the salivary glands and the gut system, were homogenized on ice using a homogenizer in the presence of 1 mM PMSF (phenylmethanesulfonyl fluoride) and subsequently sonicated. The homogenate was centrifuged at 12,000×g for 10 min at 4 °C, the supernatant collected and buffer exchanged into 20 mM Tris-Cl (pH 8.0) using a HiTrap desalting column (GE Healthcare, Chalfont, St. Giles, UK). The homogenate proteins were fractionated using cation-exchange chromatography (5-ml HiTrap Q HP column, GE Healthcare) with step-elution by 0 to1 M NaCl in 20 mM Tris-Cl, pH8.0. Fractions exhibiting high oxidase activities on ABTS were pooled and further purified using hydrophobic interaction chromatography (1-ml HiTrap Phenyl HP column, GE Healthcare) with step-elution by 1 to 0 M (NH4)2SO4 in 50 mM Na3PO4, pH 7.0. Fractions with high ABTS oxidase activity were pooled, buffer-exchanged into 20 mM Tris-HCl (pH 8.0) using the HiTrap desalting column, and further purified using anion-exchange chromatography (1-ml HiTrap DEAE FF column, GE Healthcare) with step-elution by 0 to1 M NaCl (in 20 mM Tris-HCl, pH 8.0). Highly active fractions were pooled and subject to SDS-PAGE (sodium dodecyl sulfate-polyacrylamide gel electrophoresis) and non-denaturing PAGE analyses to determine the protein purity. The protein content was determined by the BCA method using a BCA assay kit (Beyotime, Jiangsu, People’s Republic China).

Mass Spectrometric Analysis of the Purified Protein

The purified protein, termed Hemo1, was eluted from the SDA-PAGE gel and sent to Shanghai Boyuan Biological Technology Co., LTD (Shanghai, People’s Republic China) for MS analysis (ABI, MALDI-TOF/TOF 4800 mass spectrograph) after trypsinization [15]. Protein identification was performed using MAS-COT Distiller (http://www.matrixscience.com/, Matrix Science, UK) against the protein database translated from the mRNA sequences of C. formosanus’s gut (unpublished data) using a significance threshold of p < 0.05. The cDNA sequence of hemo1 was deposited in GenBank under the accession number: KF718963.

Enzyme Assays

For all enzyme assays, the reaction mixture consisted of 20 μl enzyme preparation, 200 μl substrate solution, 320 μl buffer (200 mM), and 360 μl water. Buffers used included: glycine-HCl, pH 1.5∼3.5, sodium acetate, pH 4.0∼5.5, and sodium phosphate, pH 6.0∼7.0, For protein purification, the enzyme assay was performed at 30 °C and pH 4.0 for 30 min, using ABTS as the substrate. The reaction was terminated by placing the assay tube on ice for 2 min before OD420 reading using a spectrophotometer [16]. For optimal pH determination, the enzyme assay was performed at 80 °C for 150 s in various buffers with pH ranging from 1.5 to 7.0. For optimal temperature determination, the enzyme assay was carried out at pH 2.5 for 150 s under various temperatures. For pH tolerance tests, the purified enzyme was pretreated in buffers with different pH at 80 °C for 1 h, and the remaining activity was determined at 80 °C, pH 2.5 for 150 s. For thermostability tests, the purified enzyme was pretreated at 80 °C, pH 2.5 for with various time intervals and the remaining activity determined under the same conditions for 150 s. Catechol oxidase activity [17] and veratryl alcohol (3,4-dimethoxybenzyl alcohol) oxidase activity [18] were determined at 80 °C, pH 2.5 for 150 s. The optical density of the oxidation product was measured at 420 nm (catechol oxidase) or 310 nm (veratryl alcohol oxidase) using a spectrophotometer. The substrate concentration of ABTS, veratryl alcohol, and catechol were 0.5, 1, and 50 mM, respectively; and the extinction coefficients of the oxidation products were 36,000, 9,256, and 3,450 M−1 cm−1, respectively. All the enzymatic activities showed in the manuscript were calculated based on a standard assay by subtracting a blank control in the absence of enzymes and subtracting an enzyme control in the absence of substrates. One unit of the specific enzyme activity (U) was defined as the number of micromoles of the oxidation product produced per minute per milligram protein. The K m value was measured using the Lineweaver–Burk method under optimal conditions.

Results

Purification of Hemo1

The tissue homogenate was obtained from the digestive organs of the wood-feeding termite, C. formosanus, and subject to SDS-PAGE analysis. As shown in Fig. 1a, a major protein of an apparent molecular weight of about 82 kDa was observed (lane 1). To determine the function of this protein, a three-column chromatography procedure was set up to purify the protein.

Purification of Hemo1 from the tissue extract of C. formosanus by the three-column chromatography procedure. At each step, the eluted fractions were examined for the ABTS oxidase activity. The highly active fractions were pooled and subject to gel electrophoresis analysis. a SDS-PAGE analysis. Lane 1: crude tissue extract; lane 2: high activity pool from the HiTrap Q HP column; lane 3: high activity pool from the HiTrap Phenyl HP column; lane 4: protein molecular weight standards; lane 5: another high activity pool from the HiTrap Phenyl HP column; lane 6: high activity pool from the HiTrap DEAE FF column. b Non-denaturing PAGE analysis. Lane 1: crude tissue extract; lane 2, high activity pool from the HiTrap DEAE FF column. Gels were stained by Coomassie blue for protein visualization

First, the tissue homogenate was fractionated by a cation-exchange column (HiTrap Q HP). The bound proteins were step-eluted with a 0–1 M of NaCl gradient and assayed for the ABTS oxidase activity. SDS-PAGE analysis of the pooled active fractions showed that the protein purity was substantially increased (lane 2, Fig. 1a). The pool was further purified by a hydrophobic interaction (HIC) column (HiTrap Phenyl HP). The bound proteins were step-eluted with a 1–0 M (NH4)2SO4 gradient and active fractions pooled. This chromatography step further increased the purity of the protein (Lanes 3 and 5, Fig. 1a). Finally, the protein was purified by an anion-exchange column (HiTrap DEAE FF column). The bound proteins were step-eluted with a 0–1 M NaCl gradient. After this step, the purified active component appeared homogeneous as analyzed by both SDS-PAGE (lane 6, Fig. 1a), and non-denaturing PAGE (lane 2, Fig. 1b). The activity of the final purified Hemo1 against ABTS was 6.4 times larger than that of the original tissue homogenate.

Mass Spectrometry and Bioinformatic Analyses of Hemo1

The identity of the purified protein was determined by peptide-mapping analysis using mass spectrometry. As shown in Table 1, the result of MALDI-TOF/TOF analysis revealed that the protein matched a hemocyanin from the transcriptome of C. formosanus with up to seven ions scores >25 (p < 0.05) and the sequence coverage of 23 %. Accordingly, we named the protein to be Hemo1. Based on its mRNA sequence, Hemo1 has 668 amino acid residues, with a calculated molecular weight of 82.3 kDa and pI value of 7.73. The apparent molecular weight of Hemo1 as determined by SDS-PAGE analysis (Fig. 1a) matches the expected size, which further confirms its identity of the purified protein to be the Hemo1.

BLAST search of the Hemo1 protein sequence against the NR database revealed that the best hit for Hemo1 is a hexamerin from Reticulitermes speratus (Genbank accession number: BAG48838.1; http://www.ncbi.nlm.nih.gov), with a similarity of 80 %. Hexamerins are hemocyanin-derived storage proteins that have lost the ability to bind copper ions and transport oxygen. Results of Pfam domain searches revealed three domains of hemocyanin: an alpha domain, a copper containing domain, and an Ig-like domain, with E values <10−45 (http://pfam.sanger.ac.uk).

The Optimal pH and Temperature of Hemo1

The pH dependence of the ABTS oxidase activity of the purified Hemo1 was determined at 80 °C for 150 s with pH ranging from 1.5 to 7.0. As shown in Fig. 2, Hemo1 was active mainly under acidic conditions (pH < 6), displaying the optimal pH of 2.5 under the assay conditions. After this pH, the activity declined with increasing pH. The activity finally disappeared at pH 7.0. The temperature dependence was determined at the optimal pH of 2.5 under the assay conditions with temperature ranging from 20 to 90 °C. Interestingly, the enzyme activity increased with increasing temperature until it peaked at the optimal temperature of 80 °C (Fig. 3).

pH dependence of the ABTS oxidase activity of the purified Hemo1. Enzyme assays were performed at 80 °C for 150 s. Glycine-HCl buffer were used for pH 1.5 to 3.5; acetate buffers for pH 4.0 to 5.0; and phosphate buffers for pH 6.0 to 7.0. No activity above pH 7.0 was detected. Error bars represent standard deviations (n = 3)

Thermostability and pH Tolerance of Hemo1

It is interesting that the Hemo1displayed high activity at high temperatures (80–90 °C). We thus examined if the enzyme is stable at its optimal temperature (80 °C) and optimal pH of 2.5. The ABTS oxidase activity was not stable under the assay conditions. It lost about 30 % of its activity after 1-h incubation and about 80 % of its activity after 4 h (Fig. 4). On the other hand, with 1-h incubation at 80 °C and different pH, Hemo1 retained about 50–70 % of its activity under acidic conditions with pH ranging from 1.5 to 4.0 (Fig. 5). It was most stable at pH 2.0.

Stability of the ABTS activity of the purified Hemo1 at different pH values. Hemo1 was pretreatment for 1 h at 80 °C in 100 mM buffer with pH ranging from 1.5 to 3.5 (Glycine-HCl) or at 4.0 (acetate buffer) before enzyme assay was performed at 80 °C, pH 2.5 for 150 s. Error bars represent standard deviations (n = 3)

Effect of Different Reagents

To determine the effects of various chemical additive on the enzyme activity of the purified Hemo1, the enzyme was incubated with different metal ions (1 mM Mg2+, Ca2+, Co2+, Cu2+, or Zn2+), a chelator (10 mM EDTA), or a detergent (0.1 % SDS) at room temperature for 10 min before the ABTS oxidase activity assay was performed at 80 °C (pH 2.5) for 150 s with the assay mixture containing the same amount of respective additive. As shown in Fig. 6, 1 mM Cu2+ and Zn2+ enhanced the enzymatic activity by about 60 and 20 %, respectively, while 1 mM Co2+ and 0.1 % SDS reduced the activity by about 30 and 40 %, respectively. The effect of 1 mM Mg2+, Ca2+, or 10 mM EDTA was statistically insignificant (p = 0.13) in a one-way ANOVA analysis (Excel 2007, Microsoft, USA).

Effects of metal ions, a denaturant (SDS), and chelator (EDTA) on the ABTS activity of the purified Hemo1. Hemo1 was incubated with 1 mM of Mg2+, Ca2+, Co2+, Cu2+, Zn2+, 0.1 % SDS, or10 mM EDTA for 10 min at room temperature before enzyme assay was performed at 80 °C, pH 2.5 for 150 s in the presence of the same amount of respective additive. Error bars represent standard deviations (n = 3)

Specific Activities on Different Substrates

To determine if Hemo1 has the capability to modify lignin, the oxidase activity against catechol and veratryl alcohol, the latter being the simplest lignin model compound. The activity against ABTS was also determined for comparison. Among the three substrates tested, Hemo1 exhibited the highest activity toward ABTS with the specific activity of 89.11 mU/mg and K m value of 44 μM (Table 2). Hemo1 also displayed a weak catechol oxidase activity and veratryl alcohol oxidase activity with the specific activities of 0.14 and 0.11 mU/mg, respectively.

Discussion

The discovered novel oxidase, Hemo1, identified from the gut system of a wood-feeding termite, C. formosanus, was a thermostable and versatile oxidase against various aromatic compounds. It is reported that the hemocyanin identified from tarantula Eurypelma californicum is a thermostable enzyme that can be active at 90 °C [19]. In this study, Hemo1 purified from C. formosanus was also found to be highly active at 90 °C. In addition, tarantula hemocyanin has been reported to primarily oxidize l-dopa and its derivatives (catechol derivatives) [13], but we found that this novel Hemo1 from C. formosanus exhibited a versatile oxidase function toward ABTS, catechol, as well as veratryl alcohols. Hemo1 was actually very abundant in the digestive system of C. formosanus (Fig. 1), which may indicated that Hemo1 is an inevitable enzyme that plays an important oxidase function to woody biomass.

Hemo1 might be involved in the biological pretreatment processing toward lignocellulosic biomass and may functionally cooperate with other lignolytic enzymes, such as laccases, peroxidases, and other oxidases, found in the gut system of C. formosanus. As a matter of fact, one of the reaction substrate of Hemo1, Veratryl alcohol, that has a higher redox potential than phenol [20], is the smallest lignin model compound typically used for assessing if an enzyme to modify lignin [21]. The veratryl alcohol oxidase activity exhibited by Hemo1 suggests that it may play a role in lignin modification in the gut system of C. formosanus to assist the in situ lignocellulose pretreatment process [22]. Our data also indicated that H2O2 at 0.1 mM did not have any effect on the enzymatic activities of Hemo1, suggesting that the enzyme uses oxygen as an oxidant, instead of H2O2. This property implies a sharp contrast to that of the recombinant laccase, RfLacA, from another wood-feeding termite, Reticulitermes flavipes [23], which can employ H2O2 as an oxidant. In addition, RfLacA does not oxidize ABTS while Hemo1 exhibited a high specific activity toward this substrate. Clearly, these two enzymes mentioned above exhibit important differences in substrate specificity. If these two types of enzymes co-exist in a termite’s gut system, it is likely that they may complement each other to enhance the lignin degradation processing.

From the evolutionary point of view, arthropod hemocyanins, arthropod phenol oxidases, crustacean pseudohemocyanins, and other insect storage hexamerins are closely related [24], which actually come into a protein superfamily. Hemocyanins are generally a kind of copper-containing proteins, consistent with our observations that 1 mM Cu2+ can significantly (p < 0.05, t test) enhance the ABTS oxidase activity of Hemo1 (Fig. 6). The oxidase activity of many hemocyanins indeed requires activation by detergent or partial proteolysis [24]. However, the native crustacean hemocyanins would exhibit the oxidase activities without adding any detergent or proteolysis [14]. Similarly, the ABTS oxidase activity of Hemo1 from C. formosanus did not require any activation processing by SDS treatment to enhance its activity. The limited chelating effect of EDTA to the activities of Hemo1 in Fig. 6 was probably due to the low pH value (2.5) greatly limiting its chelating effect, the interference of glycine buffer to EDTA, as well as the intrinsic stable binding between Hemo1 and copper ions.

Annotations of the mRNA sequence databases of C. formosanus and other wood-feeding termites, such as R. flavipes and Zootermopsis nevadensis, reveal that there are at least two hemocyanin-like proteins in these wood-feeding insects [25, 26], which suggested that hemocyanins indeed exist in these kinds of wood-feeding termites, and their lignin-modification functions for biomass pretreatment might be prevalence [27]. However, it is not clear whether or not all of these hemocyanin-like proteins have the similar functions to degrade the recalcitrant lignin compounds in woody biomass. More studies are needed for better understanding of their biological functions, particularly for why the unique duplicated hemocyanins exist in these wood-feeding insects.

Wood-feeding termites are among the most efficient natural biomass deconstructing systems, which can utilize not only cellulose and hemicellulose polysaccharides, but also some aromatic lignin polymers with its unique enzyme complex [27, 28]. The novel lignolytic enzyme, Hemo1, may play a specific and inevitable role in the biomass pretreatment processing in the gut system of C. formosanus. Examination of lignolytic enzyme constitutes and their responsible functions in the wood-feeding termites, in order to identify the novel mechanisms in biomass pretreatment processing, may be the main focus in the future to develop the nature-inspired technology for further improving managed industrial processing in biomass conversion [27].

References

Agbor, V. B., Cicek, N., Sparling, R., Berlin, A., & Levin, D. B. (2011). Biotechnology Advances, 29, 675–685.

Chen, S. L., Zhang, X. Y., Singh, D., Yu, H. B., & Yang, X. W. (2010). Biofuels, 1, 177–199.

Lundell, T. K., Makela, M. R., & Hilden, K. (2010). Journal of Basic Microbiology, 50, 5–20.

Ryu, S. H., Cho, M. K., Kim, M., Jung, S. M., & Seo, J. H. (2013). Applied Biochemistry and Biotechnology, 171, 1525–1534.

Zeng, J. J., Singh, D., & Chen, S. L. (2011). Bioresource Technology, 102, 3206–3214.

Ke, J., Laskar, D. D., Gao, D. F., & Chen, S. L. (2012). Biotechnology Biofuels, 5, 11.

Sethi, A., Slack, J. M., Kovaleva, E. S., Buchman, G. W., & Scharf, M. E. (2013). Insect Biochemical Molecular Biology, 43, 91–101.

Geib, S. M., Filley, T. R., Hatcher, P. G., Hoover, K., Carlson, J. E., Jimenez-Gasco, M. D., Nakagawa-Izumi, A., Sleighter, R. L., & Tien, M. (2008). Proceedings of the National Academy of Sciences of the United States of America, 105, 12932–12937.

Ke, J., Singh, D., Yang, X. W., & Chen, S. L. (2011). Biomass and Bioenergy, 35, 3617–3626.

King, A. J., Cragg, S. M., Li, Y., Dymond, J., Guille, M. J., Bowles, D. J., Bruce, N. C., Graham, I. A., & McQueen-Mason, S. J. (2010). Proceedings of the National Academy of Sciences of the United States of America, 107, 5345–5350.

Decker, H., & Tuczek, F. (2000). Trends Biochemical Science, 25, 392–397.

Kawabata, T., Yasuhara, Y., Masanori, O., Matsuura, S., & Ashida, M. (1995). Proceedings of the National Academy of Sciences of the United States of America, 92, 7774–7778.

Decker, H., & Rimke, T. (1998). The Journal of Biological Chemistry, 273, 25889–25892.

Jaenicke, E., & Decker, H. (2004). Micron, 35, 89–90.

Liao, J. L., & Huang, Y. J. (2011). Genomics, Proteomics & Bioinformatics, 9, 229–237.

Petruccioli, M., Frasconi, M., Quaratino, D., Covino, S., Favero, G., Mazzei, F., Fedrici, F., & D’Annibale, A. (2009). Journal of Biological Inorganic Chemistry, 14, 1153–1163.

Ogel, Z. B., Yuzugullu, Y., Mete, S., Bakir, U., Kaptan, Y., Sutay, D., & Demir, A. S. (2006). Applied Microbiology and Biotechnology, 71, 853–862.

Niku-paavola, M., Karhunen, E., Salola, P., & Raunio, V. (1988). Biochemistry Journal, 254, 877–884.

Sterner, R., Vogl, T., Hinz, H., Penz, F., Hoff, R., Föll, R., & Decker, H. (1995). FEBS Letters, 364, 9–12.

Huang, X. R., Wang, D., Liu, C. X., Hu, M., Qu, Y. B., & Gao, P. J. (2003). Biochemical and Biophysical Research Communications, 311, 491–494.

Timofeevski, S. L., Nie, G., Reading, N. S., & Aust, S. D. (1999). Biochemical and Biophysical Research Communications, 256, 500–504.

Scharf, M. E., & Boucias, D. G. (2010). Insect Sci., 17, 166–174.

Coy, M. R., Salem, T. Z., Denton, J. S., Kovaleva, E. S., Liu, Z., Barber, D. S., Campbell, J. H., Davis, D. C., Buchman, G. W., Boucias, D. G., & Scharf, M. E. (2010). Insect Biochemical Molecular Biology, 40, 723–732.

Burmester, T. (2001). Molecular and Biological Evolution, 18, 184–195.

Scharf, M. E., Wu-Scharf, D., Zhou, X., Pittendrigh, B. R., & Bennett, G. W. (2005). Insect Molecular Biology, 14, 31–44.

Terrapon, N., Li, C., Robertson, H. M., Ji, L., Meng, X., Booth, W., Chen, Z., Childers, C. P., Glastad, K. M., Gokhale, K., Gowin, J., Gronenberg, W., Hermansen, R. A., Hu, H., Hunt, B. G., Huylmans, A. K., Khalil, S. M., Mitchell, R. D., Munoz-Torres, M. C., Mustard, J. A., Pan, H., Reese, J. T., Scharf, M. E., Sun, F., Vogel, H., Xiao, J., Yang, W., Yang, Z., Yang, Z., Zhou, J., Zhu, J., Brent, C. S., Elsik, C. G., Goodisman, M. A., Liberles, D. A., Roe, R. M., Vargo, E. L., Vilcinskas, A., Wang, J., Bornberg-Bauer, E., Korb, J., Zhang, G., & Liebig, J. (2014). Nature Communication, 5, 3636.

Sun, J.Z., Ding, S.H. and Doran-Peterson, J. (2014). Biological conversion of biomass for fuels and chemicals: exploration from natural utilization systems (Sun, J.Z., Ding, S.H. and Doran-Peterson, J., ed.), RSC Publishing, Cambridge, UK, pp. 1–11.

Sun, J. Z., & Scharf, M. (2010). Insect Sci., 17, 163–165.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (31201752), the Startup Foundation of Jiangsu University (11JDG109) and the Priority Academic Program Development of Jiangsu Higher Education Institution. JHDW acknowledges the supports of a grant (DEFG02-94ER20155) from the Office of Science (BES) and a grant (DE-FG02-08ER64692) from the Office of Science (BER), the US Department of Energy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Haifang Qiu and Alei Geng contributed equally to this work.

Rights and permissions

About this article

Cite this article

Qiu, H., Geng, A., Zhu, D. et al. Purification and Characterization of a Hemocyanin (Hemo1) with Potential Lignin-Modification Activities from the Wood-Feeding Termite, Coptotermes formosanus Shiraki. Appl Biochem Biotechnol 175, 687–697 (2015). https://doi.org/10.1007/s12010-014-1326-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1326-z