Abstract

Multiwalled carbon nanotubes (CNT) doped polyaniline (Pani) nanocomposite has been electrochemically deposited onto indium tin oxide (ITO)-coated glass substrate for fabrication of uric acid biosensor. To achieve this, uricase (from Bacillus fastidiosus) has been covalently immobilized onto glutaraldehyde-modified CNT-Pani/ITO and characterized using cyclic voltammetry (CV), scanning electron microscopy (SEM), Fourier transform infrared (FTIR) spectroscopy, electrochemical impedance spectroscopy (EIS), etc. CV studies of CNT-Pani/ITO electrode reveals that the system obeys quasi-reversible electron transfer behavior with diffusion coefficient of 2.3346 × 10−8 cm s−1 in K3FeCN6. Fabricated uricase-CNT-Pani/ITO electrodes were tested for uric acid detection in buffer and spiked serum samples electrochemically. It was found that fabricated electrode was able to detect 0.01–1.0 mM uric acid using CV and 0.02–0.8 mM uric acid using differential pulse voltammetry (DPV). The enhanced electrochemical performance of this biosensor is due to the high enzyme loading synergistically connected to CNT-Pani nanocomposite leading to improved enzyme characteristics such as Km value of 4.85 × 10−3 mM L−1 (about 70 times less than the free enzyme), sensitivity of 43.2 μA mM−1 for CV-based detection and 8.38 μA mM−1 for DPV-based detection within response time of 60 s. Fabricated electrodes were able to maintain their electrochemical activity with 60 times reusability and were stable up to 28 weeks when stored at 4 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Elevated urate levels in human are of major concern worldwide. Urate test or uric acid determination is a routinely performed to access existence of disease or its state in case of gout/arthritis, kidney stone analysis/risk panel, effect of drugs/chemotherapy/radiation therapy leukemia, pneumonia, etc. Elevated uric acid levels from normal physiological range in human fluids (0.15–0.45 mM in serum and 1.4–4.4 mM in urine) are due to altered purine metabolism, and decreased levels are due to exposure of toxic compounds. Changing lifestyle pattern is witnessing rising hypertension cases, and it is being suspected to have relation with the elevated urate levels [1]. Consequently, uric acid measurement for diagnosis and treatment of these disorders is routinely required at a larger scale. In this context, a unique option lies in application of uricase enzyme for estimation of uric acid. Various uric acid biosensors have emerged in laboratories besides the available contemporary methods of uric acid determination to overcome their existing challenges [2, 3]. The available biosensors are providing immense opportunities to tune in various performances-related parameters through simple measurement, shorter response time, high sensitivity, and selectivity through application/integration of various “nano”-“bio” materials.

Biosensor fabrication process involves two important steps: selection of bio-element (here uricase for uric acid determination) along with immobilization surface to be interfaced and transduction of bio-recognition event to a measurable output. It has been noticed that most of the biosensors are amperometrically driven, and the measurements are being performed ≥0.5 V. This potential range is unfavorable towards the real-world measurements since most of the biological-electroactive molecules interfere in the analyte measurement. Interestingly, careful selection of immobilization support material in coherence to the bio-recognition event gives important key to resolve the challenges of this signal transduction. With the emergence of nanotechnology and available opportunities to tune in sensitivity, stability of bio-element and ease of fabrication, it is desired to design and choose a suitable functional material for enzyme immobilization [4]. Range of nanomaterials such as metal nanoparticles (gold, silver, zinc, etc.), carbon allotropes (carbon nanotubes, graphene, graphite, etc), nanostructured conducting polymers (polypyrrole, polyaniline, polyacrylate, etc.) are available to be integrated with the biological elements [5, 6]. Uses/applications of nanomaterials, conducting polymers (CPs) and their composites, towards fabrication in various biosensors are well cited. Carbon nanotubes ever since their discovery are most attractive due to their low cost, unique tunable mechanical and electric properties [7, 8]. Similarly, CPs also referred to as synthetic metals and their uniqueness lie in electrical and magnetic properties of a metal, while retaining the mechanical properties of a polymer. Here, polyaniline (Pani) is the second most widely studied member of intrinsically conducting organic polymers that has a rigid and planar backbone providing good conductivity and is insoluble in common organic solvents [5].

Yan Jiang et al. developed a selective uricase biosensor with electroactive intrinsic polyaniline synthesized in ionic liquid at high pH showing linear detection range from 1.0 × 10−3 to 1.0 m mol dm−3. The value of the Michaelis–Menton constant (K m) was found to be 7.83 m mol L−1 [9]. A polyaniline-uricase biosensor was developed by template process that uses generation of hydrogen peroxide and its consumption by peroxidase, subsequently measuring the dissolved oxygen concentration with shelf-life of about 75 days and the K m as 2.31 mol dm−3 [10]. Polyaniline-poly-n-butyl-methacrylate composite film has been prepared for estimation of uric acid via measuring the change in electrical resistance as a function of concentration of the uric acid (5–12 mg dL−1) [11]. Nanostructured polyaniline-uricase biosensor has been prepared that sensed uric acid in the range of 0.1–0.6 mM uric acid in 60 s response time, K m value 5.1 × 10−3 mM L−1 reusability (more than 30 times) and stability (>16 weeks) [2]. Recently, self-assembled monolayers (SAMs) of thio-substituted nucleo-bases and their derivatives (mercaptopyrimidine (MPM), mercaptopurine (MPU), 4-amino-2-mercaptopyrimidine (AMP), 6-thioguanine (TG), 4,6-diamino-2-mercaptopyrimidine (DMP)) on gold (Au) electrode have been used for simultaneous electro analysis of NADH, ethanol, and uric acid (UA). Among them, Au-AMP electrode shows linear response for uric acid concentration range (1–500 μM) with high sensitivity (0.78 ± 0.007 μAcm−2 μM−1). However, the separation between the two broad peaks (uric acid and NADH) is small (80–100 mV) [12]. A reagent less uricase/MWCNTs–SnO2 biosensor for uric acid determination has been reported in differential pulse voltammetry (DPV) measurements in 1.0 × 10−7–5.0 × 10−4 mol L−1 range and detection limit of 5.0 × 10−8 mol L−1 which retained 79.5 % activity when stored at 5 °C and reused for about 10 successive uses with 4.5 % loss [13]. Uricase-thionine-single-walled carbon nanotube/glassy carbon has been developed with a low detection limit (0.5 ± 0.05 μM), a wide linear range (0.002 to 2 mM), high sensitivity (~90 μAmM−1 cm−2), as well as good stability and repeatability [14]. Uricase-polyacrylic acid-multiwalled carbon nanotube was used to detect uricase in 0.3–10 μM with LOD of 110 nM [15]. Gold nanoparticle-CNT composite has been used for uric acid in range of 0.01–0.8 mM with LOD of 0.01 mM [16]. PDDA-uricase-ZnO-MWNTs multilayer uricase biosensor showed a wide linear response range of 0.005 to 1 mM with a linear sensitivity of 393 mA cm−2 M−1, a detection limit of 2.0 mM (3σ), and a long-term stability of 160 days can be obtained by using differential pulse voltammetry (DPV) [17]. Zinc oxide nanowires-based uric acid biosensor has been reported with sensitivity of 89.74 μA cm−1 mM−1 in the linear detection range of 0.1–0.59 mM [18].

In this work, we report immobilization of uricase to electrochemically prepared multiwalled carbon tube-polyaniline composite for its application towards detection of uric acid.

Methods

Chemicals and Reagents

Multiwalled carbon nanotubes (CNT), aniline (Ani), horse radish peroxidase (HRP, EC 1.11.1.7) having specific activity 200 U/mg, Tris buffer, indium tin oxide (ITO)-coated glass plates, o-dianisidine, uric acid, cholesterol, ascorbic acid, urea, and glucose were purchased from Sigma-Aldrich. Uricase was procured from Fluka as lyophilized powder having activity 16.2 U/mg (EC 1.7.3.3; from Bacillus fastidiosus). Aniline was distilled prior to being use. All other chemicals and solvents were of analytical grade and were used without any purification.

Preparation of CNT Doped Polyaniline onto Indium Tin Oxide (ITO)-Coated Glass Plates

In 1 M HCl, 1 mg ml−1 CNT was solubilized (chemical oxidation/carboxyl functionalization of CNT) through ultra-sonication for about 80 h [19, 20]. Thereafter, a monomer solution containing aniline (0.1 M) and 0.01 mg mL−1CNT in 1 M HCl was subjected to constant current of about 150 μA for about 15 min to deposit carbon nanotubes-polyaniline (CNT-Pani) composite on ITO coated glass substrates (1 cm2) using a three-electrode electrochemical cell consisting Ag/AgCl reference electrode and platinum counter electrode using chronopotentiometric technique with the intermittent washing steps using potentiostat-galvanostat (Autolab PGSTAT 302). It must be mentioned here that these CNT-Pani electrodes were prepared by controlling the chain length and morphology using two intermittent washing with 1 M HCl buffer after every 5 min of polymerization (i.e., total polymerization time of 15 min).

Immobilization of Uricase onto CNT-Pani Surface

Scheme 1 shows the enzyme interfacing with the CNT-Pani surface for fabrication of an electrochemical biosensor for uric acid. Five microliters (0.16 U) of uricase (1 mg/ml) was immobilized onto glutaraldehyde-activated CNT-Pani. The CNT-Pani was dipped in 0.5 % glutaraldehyde solution for 5 h to covalently link “uricase” through its amino group. After the successful immobilization of the enzyme, the electrodes were washed with Tris-Cl buffer (50 mM at pH 6.5) to remove the non-covalently bound enzyme on polymer surface. UV-visible measurements carried out to check presence of any unbound enzyme on “Tris-Cl buffer” collected after washing the electrode surface revealed that 98 % of uricase could be loaded onto CNT-Pani. The series of uricase-CNT-Pani electrodes were prepared and stored at 4 °C when not in use. The uricase-CNT-Pani electrodes were characterized using UV–VIS spectrometer (Shimadzu (model 160A), scanning electron microscopy (SEM, Leo 440), cyclic voltammetry (CV), differential pulse voltammetry (DPV), and impedance spectroscopy (Autolab Eco chemie, Netherlands)). Standard uric acid solutions were prepared in Tris-Cl buffer (50 mM at pH 6.5).

Uricase Measurements

UV-Visible Response Studies of Free Uricase and Uricase-CNT-Pani Electrodes

Uricase activity was studied for their UV visible response as a function substrate concentration (0.01–1.1 mM) at pH 6.5 and 10–50 °C temperature. These measurements were carried out with a UV–VIS spectrometer (Shimadzu 160A), and the entire process involves two-step biochemical reactions as indicated in Eqs. 1 and 2.

UV visible response was recorded at 405 nm after 60 s. To stop the reaction process, uricase functionalized CNT-Pani electrode was removed from substrate containing reaction mix, and the reaction mix was kept in ice to immediately stop the enzyme action for in case free enzyme. Reaction mix consisted of 2 ml Tris-Cl buffer containing 0.025 mg/ml HRP (horse radish peroxidase), 0.01 % o-dianisidine dye, and desired concentration of substrate uric acid.

Characterization and Response Studies of Uricase-CNT-Pani Electrodes

The electrochemical behavior of CNT-Pani and uricase-CNT-Pani electrodes were studied by using CV, DPV, and impedance measurements using a three-electrode cell comprising Ag/AgCl as a reference electrode, platinum foil as a counter electrode, and uricase-CNT-Pani electrode as working electrode in 50 mM Tris-Cl buffer of pH 6.5. CV and DPV of uricase-CNT-Pani electrodes were recorded in 50 mM Tris-Cl buffer containing desired uric acid concentration (0.01–1.1 mM) at scan rate of 30 mV s−1 after 60 s reaction time at 35 °C. Fabricated uricase-CNT-Pani electrode was attested for its electrochemical performance in presence of various interferents such as ascorbic acid, urea, cholesterol, and glucose. Uric acid estimation was also performed in blood serum samples obtained from volunteers using uricase-CNT-Pani electrodes through photometric and electrochemical methods with reference to respective standard curves. The serum samples were kept at 4 °C before analysis.

Results and Discussion

Electrochemical investigations of Pani, CNT-Pani, and Uricase-CNT-Pani electrodes

Figure 1a shows CV and impedance studies (inset) of CNT-Pani deposited onto ITO-coated glass plates recorded in Tris buffer 50 m M, pH 6.5 at 30 mVs−1. Where in CV of CNT-Pani reveals three characteristic redox peaks at about 266 and 565 and 755 mV describing the first two peaks for oxidation of aniline to radical cation (leucoemeraldine) and then to radical di-cation (emeraldine). The third peak may be attributed to the formation of emeraldine to (per) nigraniline [21]. These results indicate that negatively charged CNT is associated with the Pani as a dopant molecule. It is worth mentioning here that peak current of Pani-CNT is 6.8 × 10−5 A, which is higher than that of Pani electrode (3.2 × 10−5 A) [2]. Further to this, CV of uricase-CNT-Pani electrode indicates the successful immobilization of uricase due to absence of these oxidation peaks for CV. These results reveal the slow redox process occurring at the electrode surface due to slow electron transfer from the surface due to immobilization of uricase enzyme. Figure 1a inset contains the impedance spectroscopic studies of CNT-Pani and uricase-CNT-Pani electrodes in 50 mM Tris-Cl of pH 6.5 in the frequency range of 10 MHz to 105 Hz at a bias voltage of 0.13 V. In the Cole–Cole plot of dielectric spectroscopy, semicircle portion at higher frequency correspond to electrode transfer limited process whereas linear portion corresponds to diffusion. The value of electron transfer resistance depends on dielectric features at the electrode-electrolyte interface. Uricase-CNT-Pani electrode surface shows higher R CT (732 Ω) as compared to CNT-Pani electrodes (37.5 Ω), which can be attributed to the presence of obstructing layer of enzyme uricase on the conducting polymer surface for ion exchange [2]. It may be noted that these results are in agreement with the CV studies.

Figure 1b exhibits CV studies of CNT-Pani at various scan rates (10–120 mV s−1). It can be seen that anodic (Ipa) and cathodic peak (Ipc) current various linearly as a function of square root of scan rate v1/2 (Fig. 1b inset, Eq. 3) suggesting that the electrochemical process follows quasi-reversible electron transfer behavior (ΔE p = 1.44 V) and is diffusion controlled. The diffusion coefficient “D” has been calculated to be 2.3346 × 10−8 cm s−1 using Randal–Sevcik Eq. (4) [22].

[Where I p is the peak current, v is scan rate in V s−1, A is area of film in cm2 (0.25 cm2 in our case), C is the bulk concentration (5 mM for FeCN6 −3), “n” is number of electron transfer per molecule in oxidation process (here n = 1)]. The surface coverage/concentration (Γ) of electroactive species on CNT-Pani has been calculated using Brown-Anson model [23] and found to be 6.0517 × 10−7molcm−2 using Eq. (5) as given below:

Where R is gas constant (8.314 J/mol/K), T is the absolute temperature of the system (=25 °C), F is Faraday’s constant (96,584 C mol−1), Γ is the surface concentration of the film in mol cm−2.

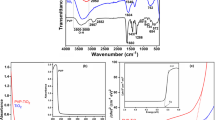

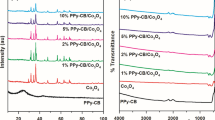

FTIR and SEM Studies of CNT-Pani and Uricase-CNT-Pani Electrodes

The Fourier transform infrared (FTIR) spectrum and SEM pictures of Pani [2], CNT-Pani, and Uricase-CNT-Pani electrode are shown in Fig. 2a–d, respectively. FTIR spectra are shown in Fig. 2a where peaks at 770 (C-H bend), 790, and 840 cm−1are for bending vibrations of C-H linkage in aniline in agreement to our earlier studies [2]. Dip seen at 1,291 cm−1 can be assigned to pyridine-type C-N bond representing presence of Pani [2, 24]. Peak at 1,490 cm−1 can be assigned to C=C of benzoid rings and 1,575 for aromatic and unsaturated structure of >C=C< bonds affirming presence of Pani [2, 25]. While peaks at 1,133 and 1,164 cm−1 for C-O bends and stretching vibrations in –carboxyl groups of CNT and polyaniline, respectively. Broad dip from 2,900–3,400 cm−1 is attributed to OH stretch present in CNT and 2,370 cm−1 peak is due to -OH stretch from strongly hydrogen bonded –COOH groups present on CNT [26]. Peak at 2,922 cm−1 is for asymmetric stretching of CH bond in Pani. However, peak at 3,034 and 3,219 cm−1 is due to OH asymmetric stretch in aromatic carbon. The additional peak observed in the spectra of uricase-CNT-Pani at 1,552 and 1,644 cm−1 are attributed to the primary and secondary amide linkages in enzyme molecules indicating the presence of uricase onto the CNT-Pani surface.

Figure 2b–d shows the scanning electron microscopic pictures of the Pani, CNT-Pani, and uricase-CNT-Pani electrodes, respectively. It can be seen that polyaniline exists as fibrous structure (Fig. 2b), which is colocated with brighter fibers of CNTs (Fig. 2c). It is worth noticing that presence of small globules structures present in uricase-CNT-Pani as shown in Fig. 2d confirms the immobilization of uricase onto CNT-Pani surface compared to CNT-Pani surface. It is introspected that negatively charged functional groups (-OH/-COOH) on CNT surface is providing sufficiently good doping to Pani that coexistence of both will be facilitating a promising immobilization support for electrochemical signal transduction.

Response Characteristics of free Uricase and Uricase-CNT-Pani Using Colorimetric Estimation

Colorimetric assay has been performed to assess enzyme activity of free uricase and uricase-CNT-Pani electrode at 405 nm using UV–VIS spectroscopy at varied pH of buffer, temperature, and uric acid concentration (0.01 to 1.1 mM). Uricase-CNT-Pani electrode was found to give maximum activity at pH 6.5 of Tris-Cl buffer (results not shown), and this is in agreement to a known trend that proteins generally work well at 1 pH strength higher than its pI (pI of uricase is 5.4) without any major change in confirmation. Besides this, the maximum activity of uricase at this pH may also be also assigned to use of positively charged matrix CNT-Pani that might be additionally buffering the surrounding negatively charged ions to sustain suitable microenvironment for uricase. Michaelis–Menton kinetic parameter (K m) was calculated as the values of enzymatic reaction from Lineweaver–Burk plot (Fig. 3a, b). The K m value of free and immobilized enzyme (uricase-CNT-Pani) were found to be 3.4 × 10−1 and 4.85 × 10−3 mM L−1, respectively (Fig. 3a, b). The results indicate improved enzyme affinity towards the substrate (uric acid) leading to favorably improved activity of the immobilized uricase. It is significantly noticed that the K m value of the immobilized uricase improved by about 70 times compared to free enzyme and 1.06 times compared to uricase-Pani [2]. This improved value can be assigned to CNT’s role as dopant which is contributing towards improved signal transduction and bringing in favorable changes in enzyme affinity to substrate and its performance. Uricase-CNT-Pani electrode has been studied for their thermal stability by measuring the absorbance at 405 nm at different temperatures ranging from 10 to 50 °C (Fig. 3c, d). It can be seen that the absorbance increased with the increase in the temperature up to 35 °C and started decreasing thereafter (Fig. 3c). This decrease in absorbance with increasing temperature beyond 40 °C can be due to the denaturation of enzyme through continuous heat denaturation that increases with rise in temperature. The activation energies in the lower and higher range were calculated (Fig. 3d) and found to be 13.9 and 34.65 kJ/mol, respectively, suggesting better activity of enzyme at lower temperature.

Electrochemical Estimation of Uric Acid Using Uricase-CNT-Pani Electrode

Figure 4a shows the cyclic voltammograms of uricase-CNT-Pani electrode for different uric acid concentrations (0.01–1.1 mM) wherein the oxidation peak observed at 0.45 V corresponding to the oxidation of hydrogen peroxide produced during the reaction between uricase enzyme and uric acid (Eq. 1).

The increase in the value of oxidation current with increase in urea concentration indicates the increase in the hydrogen peroxide concentration. Only single electrode was used to study the influence of different concentrations of uric acid on the electrochemical behavior. From the plot, it is clear that linear detection range of the uricase-CNT-Pani electrode has been found to be 0.01–1.0 mM of uric acid (Fig. 4a inset) with the sensitivity of 43.21 μA mM−1. Improved performance of this biosensor may be due to the positively charged matrix of CNT-Pani which is facilitating inflow of negatively charged ions including substrate uric acid and is providing suitable microenvironment for immobilized uricase leading to enhanced biomolecule-analyte interaction. This might also include favorable confirmatory changes to enzyme uricase. Figure 4b contains similar studies of uricase-CNT-Pani using DPV indicating detection range of 0.2–0.8 mM uric acid and sensitivity of 8.38 μA mM−1 at 0.227 V. These results indicate that measurement of uric acid is possible at a relatively lower potential using DPV measurement, which is very useful to lower down the influence of interferents present in real-world samples.

Response of Uricase-CNT-Pani Electrode in Serum

Table 1 summarizes the effect of interferents (2 mM urea, 5 mM glucose, 2 mM ascorbic acid, 150 mg/dl cholesterol) in electrochemical response (CV and DPV) of the uricase-CNT-Pani electrodes on detection of 0.2 mM uric acid. These results indicate that there is little or no variation in the response current in the peak at 450 mV for CV and 0.227 V for DPV. These results indicate that developed uricase-CNT-Pani electrode reflects little or no influence of interferents especially in case of DPV. Table 2 describes the response studies of the uricase-CNT-Pani electrodes in serum samples. These results reveal that these designed electrodes can be used for clinical diagnostics since no significant influence of serum interferents has been observed.

Besides this, it may be noted that the uricase-CNT-Pani electrodes have been found to have response time of 60 s and can retain the enzyme activity by 95 % after 28 weeks of storage at 4 °C. The enzyme electrode was reused for about 60 times for electrochemical measurements while retaining the enzyme activity at about 90 %. These results are showing improvement over our previous studies [2]. Since polyaniline has been reported as good thermal insulator for various enzymes [27, 28], this CNT-Pani composite is providing improved, conducive, and favorable microenvironment contributing improved enzyme stability and affinity for substrate. The comparison of present work with performance characteristics various uric acid biosensors reported literature has been described in Table 3.

Conclusions

Uricase has been successfully integrated with CNT-Pani matrix for fabrication of uric acid biosensor. Interestingly, it was revealed using FTIR and SEM studies that CNTs and Pani fibers are colocated in a way that CNTs are substituting the Cl− ions as dopants. Further studies of uricase-CNT-Pani electrodes have shown that value of the Michaelis–Menton constant (K m = 4.85 × 10−3 mM L−1) decreased about 70 times compared to free enzyme. Negatively charged CNT dopant-fibers appear to facilitate increased interaction of uricase with uric acid. These uricase-CNT-Pani electrodes give promising and improved performance in terms of response time (60 s), sensitivity (43.2 μA mM−1 in 0.01–1.0 mM using CV and 8.38 μA mM−1 in 0.02–0.8 mM using DPV) and stability (>28 weeks). Attempts are being made to attest the efficacy of the Pani-uricase electrodes using urine samples.

References

Poudel, B., Yadav, B. K., Kumar, A., Jha, B., & Raut, K. B. (2014). Journal of Tropical Biomedicine, 4, 59–64.

Arora, K., Sumana, G., Saxena, V., Gupta, R. K., Gupta, S. K., Yakhmi, J. V., et al. (2007). Analytica Chimica Acta, 594, 17–23.

Ali, S. M. U., Alvi, N. H., Ibupoto, Z., Nur, O., Willander, M., & Danielsson, B. (2011). Sensors and Actuators B, 152, 241–247.

Wanekaya, A. K., Chen, W., Myung, N. V., & Mulchandani, A. (2006). Electroanalysis, 18, 533–550.

Arora, K., Chand, S., & Malhotra, B. D. (2006). Analytica Chimica Acta, 568, 259–274.

Yang, D. S., Jung, D. J., & Choi, S. H. (2010). Radiation Physics and Chemistry, 79, 434–440.

Iiloma, S. (1991). Nature, 354, 56–58.

Heer, W. A., Charelain, A., & Ugarte, D. (1995). Science, 270, 1179–1180.

Jiang, Y., Wang, A., & Kan, J. (2007). Sensors and Actuators B, 124, 529–534.

Kan, J., Pan, X., & Chen, C. (2004). Biosensors and Bioelectronics, 19, 1635.

Castillo-Ortega, M. M., Rodríguez, D. E., Encinas, J. C., Plascencia, M., Mendez-Velarde, F. A., & Olayo, R. C. (2002). Sensors and Actuators B, 85, 19.

Behera, S., & Raj, C. R. (2007). Sensors and Actuators B, 128, 31–38.

Zhang, F. F., Xiao-Li Wang, X. L., Li, C. X., Li, X. H., Wan, Q., Xian, Y. Z., et al. (2005). Analytical and Bioanalytical Chemistry, 382, 1368–1373.

Chen, D., Wang, Q., Jin, J., Wu, P., Wang, H., Yu, S., et al. (2010). Analytical Chemistry, 82, 2448–2455.

Liu, A., Honma, I., & Zhou, H. (2007). Biosensors and Bioelectronics, 23, 74–80.

Chauhan, N., & Pundir, C. S. (2011). Analytical Biochemistry, 413, 97–103.

Yiting, W., Lei, Y., Ziqiang, Z., Jian, Z., & Jianzhong, Z. (2009). Analytical Letters, 42, 775–789.

Zhao, Y., Yan, X., Kang, Z., Lin, P., Fang, X., Lei, Y., et al. (2013). Microchimica Acta, 180, 759–766.

Jeykumari, D. R. S., Kumar, S. S., & Narayanan, S. S. (2005). Pramana Journal of Physics, 65, 731–738.

Datsyuk, V., Kalyva, M., Papagelis, K., Parthenios, J., Tasis, D., Siokou, A., et al. (2008). Carbon, 46, 833–840.

Pruneanu, S., Veress, E., Marian, I., & Oniciu, L. (1999). Journal of Material Science, 34, 2733–2739.

Randles, J. E. B. (1948). Transactions of Faraday Society, 44, 322–327.

Bard, A. J., & Faulkner, L. R. (2000). Electrochemical Methods: fundamentals and applications (2nd ed.). New York: Wiley.

Pengm, H., Mo, Z., Liao, S., Liang, H., Yang, L., Luo, F., et al. (2013). Science Reports, 3, 1765.

Silverstein, R. M., & Webster, F. X. (2002). Spectrometric identification of organic compounds sixth edition. India: Wiley. 165.

Saraf, R. (2013). International Journal of Nano Devices, 2, 1–6.

Gerard, M., Ramanathan, K., Chaubey, A., & Malhotra, B. D. (1999). Electroanalysis, 11, 450.

Stilwell, D. E., & Park, S. M. (1988). Journal of the Electrochemical Society, 135, 2491.

Piermarini, S., Migliorelli, D., Volpe, G., Massoud, R., Pierantozzi, A., Cortese, C., et al. (2013). Sensors and Actuators B, 179, 170–174.

Liu, Y., Yuan, M., Liu, L., & Guo, R. (2013). Sensors and Actuators B, 176, 592–597.

Rawal, R., Chawla, S., Chauhan, N., Dahiya, T., & Pundir, C. S. (2012). International Journal of Biological Macromolecules, 50, 112–118.

Lei, Y., Liu, X., Yan, X., Song, Y., Kang, Z., Luo, N., et al. (2012). Journal of Nanoscience and Nanotechnology, 12, 513–518.

Chu, H., Wei, X., Wu, M., Yan, J., & Tu, Y. (2012). Sensors and Actuators B, 163, 247–252.

Acknowledgments

We are grateful to Prof. Sopory, Vice Chancellor, JNU, and Prof. Bhudhani, Director, NPL, New Delhi, India for their constant encouragement and infrastructural support. DST-PURSE, DBT sponsored projects IYBA-2008 (BT/B1/12/045/2008) andRGYI-2009 (BT/PR13127/GBD/27/195/2009) are duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arora, K., Choudhary, M. & Malhotra, B.D. Enhancing Performance of Uricase Using Multiwalled Carbon Nanotube Doped Polyaniline. Appl Biochem Biotechnol 174, 1174–1187 (2014). https://doi.org/10.1007/s12010-014-0996-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-0996-x