Abstract

Label-free detection technique based on impedance was investigated for aflatoxin M1 (AFM1) and aflatoxin M2 (AFM2) analysis in milk products. The impedance change resulting from antigen-antibody interaction was studied using a two-electrode setup made up of silver (Ag) wire. Processed milk such as drinking yogurt and flavored milk samples were analyzed in a flow-based setup. Two microflow pumps were used to construct the flow system where analytes (AFM1 and AFM2) were injected and impedance was measured using functionalized Ag wire electrodes. The flow system was optimized by adjusting both inlet and outlet flows to maintain the reaction volume optimum for impedance measurements. Using Bode plot, the matrix effect was investigated for detection of AFM1 and AFM2 in various matrices. Good recoveries were obtained even at low-AFM1 concentrations in the range of 1–100 pg/mL. The influence of AFM2 on the detection of AFM1 was also investigated. The proposed method provides good scope for online monitoring of such hazardous toxins in milk products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aflatoxin M1 (AFM1) and Aflatoxin M2 (AFM2) are fungal metabolites found in milk and related milk products [1–3]. Contamination of milk with AFM1 and its ill effects on humans are well documented [4–8]. Moreover, from studies, it has been found that AFM1 is relatively stable during milk pasteurization and storage, as well as during the preparation of various dairy products [9–11]. As a result, these can be found in various milk products such as yogurt, flavored milk, infant formula milk powder, cheese, and other milk-based confectioneries including chocolates, sweets, and pastries [12–14]. Due to their carcinogenicity and severe toxicity, many international agencies have set maximum permissible limits of AFM1 in milk and related products [15–17]. Therefore, it is important to determine AFM1 and AFM2 levels in milk and milk products in order to protect consumers in various age groups, meeting the stringent regulatory standards set by these international agencies [18, 19].

There are few reports available on flow-based AFM1 detection and analysis. A bilayer lipid membrane based biosensor and related thin-film technology were investigated for AFM1 monitoring of milk using a flow injection system by Andreou and Nikolelis [20]. This was a very fast method (four samples per minute) and allowed a continuous monitoring of milk. But, the detection limit was around 200 pg/mL. Sibanda et al. [21] have developed a membrane-based flow-through enzyme immunoassay for detection of AFM1 in milk. The assay was coupled to an immunoaffinity column, and a detection limit at 50 pg/mL was achieved. However, the total assay time was found to be 30 min. In another report, Badea et al. [10] have developed a flow injection immunoassay with amperometric technique for AFM1 detection in milk. The detection limit of 11 pg/mL was obtained for milk samples at the rate of six samples in triplicate per hour. But, the immunoassay involved a complex procedure comprising of many steps. Anfossi et al. [22] have developed a high sensitive immunoassay-based lateral flow device for semiquantitative determination of AFM1 in milk. There, they have optimized the competitor design and the gold-labeling strategy to obtain the LOD at 20 ng/L. Direct detection of AFM1 in milk was obtained by acquiring images of the strips and correlating intensities of the colored lines with analyte concentrations. The one-step assay was completed in 17 min, including a very simple and rapid sample preparation. This method did not account for AFM1 analysis in milk products. Moreover, the individual test strips were disposable, thus not so economical. Therefore, there is a need for a simple, sensitive, and rapid method for flow-based AFM1 detection and analysis in milk with minimal pretreatment methods.

In this paper, we have investigated a flow-based label-free impedimetric immuno-sensing technique for analysis of AFM1 and AFM2 in milk products that facilitated scope for online monitoring. Earlier, we have reported a silver-wire-based impedance setup for analysis of AFM1 in milk sample [23]. Herein, using a flow-based setup, a label-free impedimetric technique has been demonstrated for analysis of AFM1 and AFM2 in different matrices such as certified reference material (ERM-BD-282), drinking yogurt, and flavored milk. The flow system was optimized by adjusting both inlet and outlet flow rates to maintain the sample volume optimum for measurement. The milk and related samples were artificially spiked with known concentrations of AFM1 and AFM2, and impedance was measured. In all cases, an increase in impedance value was observed with increased AFM1 concentration. This flow-based setup was used to study mixture of AFM1 and AFM2 in milk products. The short analysis time (10 min) of the proposed method provides a vast scope for online monitoring.

Materials and Methods

AFM1, Tween 20, certified reference material (CRM) ERM-BD282 (AFM1 in whole milk powder, <0.02 μg/kg), 11-mercaptoundecanoic acid (11-MUA), 1-ethyl-3-[3-dimethylaminopropyl]carbodiimide hydrochloride (EDC), and N-hydroxy succinimide (NHS) were purchased from Sigma–Aldrich (USA). Hydrogen peroxide (H2O2) 30 % (w/v), acetonitrile (ACN) HPLC grade, and sodium chloride (NaCl) were purchased from Merck (Germany). AFM2 was purchased from Fermentek, Israel. Ethyl alcohol 200 proof was purchased from TEDIA, USA. Sodium hypochlorite (4 %) solution was purchased from Fisher Scientific (India). All the AFM1 solutions were prepared inside a Glove box in a maintained inert (N2) atmosphere. AFM1 stock solution was prepared by dissolving the AFM1 powder in 5 % ACN (v/v) in phosphate-buffered saline (PBS) at a concentration of 5 μg/2 mL and stored at −20 °C. A wide dynamic range of working standard solutions in the range of 1–200 pg/mL were prepared by diluting the stock with 5 % ACN. Rat monoclonal antibody (mAb) [1C6] of AFM1 was purchased from Abcam (UK). The stock solution of mAb was prepared as described in our earlier paper [7].

Centrifugation, shaking, and filtration of the samples were done by Spinwin mini centrifuge, Spinix shaker, and syringe filter respectively purchased from Tarsons (India). Glove box, Cole-Parmer (USA) was used for the handling of AFM1 standard solution. Water produced in a Milli-Q system (Millipore, Bedford, MA, USA) was used for preparing all the solutions. Certified ultrahigh pure N2 (99.9 %) and a pH meter (SevenMulti Mettler Toledo, 8603, Switzerland) were used in various experimental steps. Ag wire (diameter = 0.25 mm) was procured from ACROS Organics, USA. The diameter of wire was reduced to 0.18 mm by dipping the wires in piranha solution for about 90 s. For flow injection analysis, a syringe pump and a multichannel peristaltic pump were used. The syringe pump and the peristaltic pump were purchased from Chemyx, USA, and Gilson, France, respectively. Impedance measurements were carried out using IVIUM CompactStat impedance analyzer, Netherlands.

Sample Preparation of Milk Products

The milk product analysis was carried out in commercially available drinking yogurt and flavored milk. The flavored milk sample was centrifuged at 6,000 rpm for 10 min. The upper fatty layer was removed by spatula, and the middle clear portion was diluted with PBST (1:1) and used. The drinking yogurt sample was only diluted with PBST (1:5) and used for analysis.

Experimental Procedure for Flow-Based Impedance Analysis

It is known from the literature that AFM2 is more prevalent in milk products than AFM1. The occurrence of AFM1 and AFM2 was analyzed by impedance in milk products such as drinking yogurt and flavored milk in a flow-based system. The flow system was designed in-house as shown in Fig. 1. The flow rate was optimized by adjusting both the inlet and outlet flow rates. The inlet to the microcell was governed by Chemyx micro syringe pump where two fluids (PBST and milk product sample) were injected, mixed, and channelized to the working cell. The flow rate of the inlet system was optimized to about 0.5 mL/min for a total syringe sample volume of 2 mL.

The sample was injected through the inlet pipe along with buffer where two solutions were mixed and directed to the cell. The milk products were spiked with known concentrations of AFM1 or AFM2 by micropipettes. The outlet system was governed by Gilson microflow pump where the flow rate was optimized to 2.4 rpm. These two flow rates resulted in maintaining a working volume of 0.5 mL in the cell. The functionalized antibody-coated Ag wires were dipped into the microcell by 1 cm and were separated by 1 mm. Electrochemical impedance spectroscopy (EIS) measurements were carried out at 5 mV applied potential with a frequency range of 1 Hz–100 KHz.

Results and Discussion

EIS Study of Various Milk Products

Using an earlier developed label-free EIS-based immunosensor, the impedimetric analysis was further extended to study the effect of various milk products such as standard ERM BD-282 milk, flavored milk, and drinking yogurt for quantitative analysis of AFM1 and AFM2. ERM BD-282 milk was reconstituted and spiked with known concentrations of AFM1 and AFM2. After the immobilization of mAb for AFM1, impedance spectroscopy measurements have been carried out with a 5 mV amplitude signal varying from 1 Hz to 100 KHz. AFM1 (25 pg/mL) was spiked in different milk samples, and impedance data were recorded as depicted in Fig. 2a. The response time was 2 min; however, the total analysis time was 10 min. For quantitative analysis, it is appropriate to measure changes in impedance at a single frequency. Figure 2a shows the change in impedance value at 1 Hz for 25 pg/mL of AFM1 spiked in different milk samples.

a Impedance spectra of the immunosensor after interaction of mAb with 25 pg/mL AFM1 spiked in ERM-BD 282, flavored milk, and drinking yogurt at room temperature (EIS: frequency range 1 Hz to 100 KHz at ac potential 5 mV). b Bode diagram of the immunosensor after interaction of mAb with 25 pg/mL AFM1 spiked in ERM-BD 282, flavored milk, and drinking yogurt at room temperature (EIS: frequency range 1 Hz to 100 KHz at ac potential 5 mV)

It is also evident from the Fig. 2a that the similar impedance response is obtained for ERM-BD282 and flavored milk, but a large change in impedance was observed for yogurt. Since the impedance spectroscopy allows the detection of capacitance changes at the interfaces. Capacitance changes can be derived from the imaginary part “Zim,” of the complex impedance spectra [24]. The change of imaginary part of impedance Zim provides better correlation to analyte concentration than the real part of impedance [25].

The frequency to monitor the antibody-antigen interaction was chosen in such a way that the system exhibited near-ideal capacitor behavior [26]. The influence of frequency was shown by Bode plot of phase angle and log of impedance magnitude versus log of frequency (Fig. 2b) for various milk samples spiked with 25 pg/mL of AFM1. The system exhibited near-ideal capacitor behavior in the region where the impedance curve was a straight line with a slope of about −1 and the phase angle was as close to −90° as possible [27]. This frequency was observed to be 52 Hz for ERM-BD282 milk and flavored milk, and the same was observed at 159 Hz for yogurt sample. Thus, it was observed that the frequency shift occurs for the same concentration of analyte in various matrices.

Validation of Sensor Operation in Milk Samples

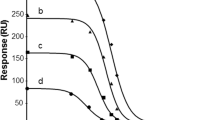

The sensor was validated for quantitative AFM1 analysis in the flow-based system. The EIS data were collected for different concentrations of AFM1 (1–100 pg/mL). Figure 3a represents Bode plot obtained for the ac impedance analysis of anti-AFM1 mAb following exposure to various AFM1 concentrations in flavored milk. Similar experiments were carried out for drinking yogurt and ERM-BD 282 milk sample.

a Bode diagram of the immunosensor after interaction of mAb with 1–50 pg/mL AFM1 spiked in flavored milk and drinking yogurt at room temperature (EIS: frequency range 1 Hz to 100 KHz at ac potential 5 mV). b Bode diagram of the immunosensor after interaction of mAb with 25–100 pg/mL AFM1 spiked in drinking yogurt at room temperature (EIS: frequency range 1 Hz to 100 KHz at ac potential 5 mV)

Figure 3b shows the Bode plot for the ac impedance analysis of anti-AFM1 mAb following exposure to various AFM1 concentrations in drinking yogurt. The interaction of antigen-antibody on functionalized electrode in the flow system creates a new charged layer as a capacitance that is in series with the double-layer capacitance. A decrease in total capacitance and hence increased impedance were observed at the lower applied frequency of 1 Hz, which confirms the binding of antigen-antibody. The change in total capacitance was confirmed from the frequency shift for near-ideal capacitor behavior for different concentrations of AFM1 as depicted in Fig. 3a, b. The sensitivity of the sensor was found to be 4.28 % in flavored milk and 0.44 % in drinking yogurt, respectively. For the same concentration of spiked AFM1, impedance change was obtained as 40 and 25 % in flavored milk and drinking yogurt, respectively.

Sensor Selectivity

The selectivity of the sensor toward AFM1 was studied in the frequency range of 1 Hz to 100 KHz using EIS at 5 mV applied potential in the flow-based system. In the optimized condition, the response signal for AFM1 binding was measured in 10 min. The mAb immobilized on the electrode showed partly cross-reactivity with AFM2 (a structural analog of AFM1). The cross-reactivity of mAb toward AFM2 was quantified experimentally using the presented setup at 1 pg/mL in ERM-BD 282. The impedance change for AFM2 was found to be lower as compared to that for AFM1 at 1 Hz. From Fig. 4, it is clearly evident that the sensor is highly selective toward AFM1 as against AFM2. The AFM1 and AFM2 at 1 pg/mL were distinguishable from each other. This verifies the excellent detection ability of the sensor at an ultralow concentration. This analysis provides the scope for simultaneous detection of these compounds by the sensor in flavored milk/drinking yogurt. The analytical figures of merit of the developed flow-based impedimetric setup are summarized in Table 1.

Conclusion

In this work, a label-free impedimetric immunosensor was developed for the analysis of aflatoxin M1 and aflatoxin M2 in a flow-based setup. The sensor could detect successfully the AFM1 and AFM2 at concentrations as low as 1 pg/mL under flow setup. The sensor was also extended for analysis of both AFM1 and AFM2 in a more complex matrix such as flavored milk and drinking yogurt. The developed method is also relatively simple and facilitates analysis in 10 min with response time of 2 min. The immunosensor was tested for its performance with regard to interferences arising from different matrices. It was observed that the sensor worked best for ERM-BD 282 and flavored milk which were almost similar in their constituents. But, when drinking yogurt was tested, there was a signal suppression observed which might be attributed to matrix interference. The sensor could selectively detect AFM1 in a milk product that also contains AFM2. This flow-based selective immunosensor provides a vast scope for online monitoring of AFM1 and AFM2 at milk collection centers.

References

Henry, S., Bosch, F. X., Bowers, J. C., Portier, C. J., Petersen, B. J., & Barraj, L. (1997). Aflatoxins (WHO Additives, series 40.) Joint Expert Committee on Food Additives (JECFA).

Shephard, G. S., Berthiller, F., Burdaspal, P. A., Crews, C., Jonker, M. A., Krska, R., et al. (2012). World Mycotoxin Journal, 1, 3–30.

Bognanno, M., Fauci, L., La Ritieni, A., Tafuri, A., De Lorenzo, A., Di Micari, P., et al. (2006). Molecular Nutrition & Food Research, 50, 300–305.

Van Egmond, H. P. (1989). Food Additives and Contaminants, 6, 139–188.

Thirumala-Devi, K., Mayo, M. A., Hall, A. J., Craufurd, P. Q., Wheeler, T. R., Waliyar, F., et al. (2002). Journal of Agricultural and Food Chemistry, 50, 933–937.

Rastogi, S., Dwivedi, P. D., Khanna, S. K., & Das, M. (2004). Food Control, 15, 287–290.

Kanungo, L., Pal, S., & Bhand, S. (2011). Biosensors and Bioelectronics, 26, 2601–2606.

Gurbay, A., Aydın, S., Girgin, G., Engin, A. B., & Sahin, G. (2006). Food Control, 17, 1–4.

Codex Committee on Food Additives and Contaminants (2001). CL CX/FAC 01/20, Comments submitted on the draft maximum level for aflatoxin M1 in milk.

Badea, M., Micheli, L., Messia, M. C., Candigliota, T., Marconi, E., Mottram, T., et al. (2004). Analytica Chimica Acta, 520, 141–148.

Anfossi, L., Calderara, M., Baggiani, C., Giovannoli, C., Arletti, E., & Giraudi, G. (2008). Journal of Agricultural and Food Chemistry, 56(6), 1852–1857.

Sharman, M., Patey, A. L., & Gilbert, J. (1989). Journal of Chromatography, 474, 457–461.

Martins, M. L., & Martins, H. M. (2000). Food Additives and Contaminants, 17, 871–874.

Kamkar, A. (2006). Food Control, 17, 768–775.

European Commission (EC). (2006). Commission Regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Official Journal of the European Union L, 364, 5–24.

FDA U.S. Food and Drug Administration (2011). Guidance for industry: action levels for poisonous or deleterious substances in human food and animal feed. 20/04/2011. Available from: http://www.fda.gov/Food/GuidanceComplianceRegulatoryInformation/GuidanceDocuments/ChemicalContaminantsandPesticides/ucm077969.htm.

Food safety and standards (contaminants, toxins and residues) regulations, 2011, F.No. 2-15015/30/2010.

Siddappa, V., Nanjegowda, D. K., & Viswanath, P. (2012). Food and Chemical Toxicology, 50(11), 4158–4162.

Kim, E. K., Shon, D. H., Ryu, D., Park, J. W., Hwang, H. J., & Kim, Y. B. (2000). Food Additives and Contaminants, 17, 59–64.

Andreou, V. G., & Nikolelis, D. P. (1998). Analytical Chemistry, 70, 2366–2371.

Sibanda, L., De Saeger, S., & van Peteghem, C. (1999). International Journal of Food Microbiology, 48, 203–209.

Anfossi, L., Baggiani, C., Giovannoli, C., Biagioli, F., D’Arco, G., & Giraudi, G. (2013). Analytica Chimica Acta, 772, 75–80.

Bacher, G., Pal, S., Kanungo, L., & Bhand, S. (2012). Sensors and Actuators B: Chemical, 168, 223–230.

Katz, E., & Willner, I. (2003). Electroanalysis, 15, 913–947.

Bart, M., Stigter, E. C. A., & Stapert, H. R. (2005). Biosensors and Bioelectronics, 21, 49–59.

Berney, H., West, J., & Haefele, E. (2000). Sensors and Actuators B: Chemical, 68, 100–108.

Wu, Z.-S., Li, J.-S., & Deng, T. (2005). Analytical Biochemistry, 337, 308–315.

Acknowledgments

This work is funded by National Agriculture Innovation Project (NAIP) No. C4/C10125, ICAR and The World Bank. LK acknowledges NAIP for the award of Research Associate Fellowship. GB acknowledges the Director of BITS Pilani K. K. Birla Goa Campus.

Author information

Authors and Affiliations

Corresponding author

Additional information

Lizy Kanungo and Gautam Bacher contributed equally to this work.

Rights and permissions

About this article

Cite this article

Kanungo, L., Bacher, G. & Bhand, S. Flow-Based Impedimetric Immunosensor for Aflatoxin Analysis in Milk Products. Appl Biochem Biotechnol 174, 1157–1165 (2014). https://doi.org/10.1007/s12010-014-0995-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-0995-y