Abstract

The indigenous microbial community utilizing aliphatic, aromatic, and polar components from the oily sludge as sole source of carbon and energy was selected from the soil samples of Ankleshwar, India for biosurfactant production. Evaluation of biosurfactant production was done using screening assays such as surface tension reduction, hemolytic activity, emulsification activity, drop-collapse assay, and cell surface hydrophobicity studies. Maximum biosurfactant (6.9 g/l) production was achieved after 5 days of growth from Bacillus subtilis DSVP23 which was identified by 16S RNA technique (NCBI GenBank accession no. EU679368). Composition of biosurfactant showed it to be lipopeptide in nature with 15.2% protein content and 18.0% lipid content. Functional group analysis was also done by using Fourier transform infrared spectroscopy which showed it to be a protein-bound lipid thereby imparting them special properties. Analysis by matrix-assisted laser desorption/ionization time-of-flight mass spectrometric and nuclear magnetic resonance revealed that the major constituents of lipopeptide are leucine and isoleucine. Gas chromatographic analysis data indicated that oily sludge components of chain length C12–C30 and aromatic hydrocarbons were degraded effectively by B. subtilis DSVP23 after 5 days of incubation. These results collectively points toward the importance of B. subtilis DSVP23 as a potential candidate for bioremediation studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biosurfactants are surface-active metabolites produced by microorganisms which when grown on water miscible or oily substrates remain adherent to microbial cell surfaces or are secreted in the culture medium [1–3]. A wide variety of microorganisms having the ability to produce biosurfactant are Bacillus subtilis, Pseudomonas aeruginosa, Candida antarctica, Acinetobacter radioresistensis, and Serratia sp. [4]. Microbial surfactants constitute a diverse group of molecules known to occur in a variety of chemical structures, such as glycolipids, lipopeptides, fatty acids, neutral lipids, phospholipids, and particulate structures [4]. The distinctive property of these amphipathic moieties that partition preferentially at the interface between fluid phases confers excellent detergency, emulsifying, foaming, and dispersing tracts, making them the most versatile agents [5]. Biosurfactant production would enhance oil dispersion into the aqueous phase and retard volatilization of low carbon atom-hydrocarbons (below C7), favoring biodegradation [6]. The hydrophobic compounds present in the surrounding vicinity of cell can alter cell membranes including cell surface hydrophobicity, which enhances adhesion of cells to hydrocarbons in the water–hydrocarbon interface and transportation through the cell membrane. In addition to the above, biosurfactant production, cell-to-cell, and cell-to-substrate interactions play a significant role in cleaning oil-polluted sites by degrading its hydrocarbon contents [7]. The effect of exogenously added microbial biosurfactants in enhancing the bioremediation of crude oil-polluted soils has been reported [9, 10]. The use of microorganisms in both in situ and on-site treatment processes involving breakdown of hazardous organic environmental contaminants avoids the economic and technical disadvantages. The accumulation of waste oily materials in bottom crude oil storage tanks and huge amounts of oil sludge’s from water oil separation systems in refineries poses severe problem because many of the standard treatment processes used to decontaminate soil and groundwater have been limited in their application, are expensive, or may be only partially effective [8]. Thus, evaluation of biosurfactant from oily sludge-contaminated soil may explore the efficient strains in biodegradation of crude petroleum oil.

Materials and Methods

Isolation of Microorganisms

Soil contaminated with oily sludge from Ankleshwar, Gujarat was used for isolation of bacterial colonies. Briefly, soil sample (10 g) was shaken with 200 ml distilled water for 30 min at 200 rpm and allowed to settle. The supernatant was centrifuged at 3,000 rpm for 5 min before plating out. Dilution of the supernatant samples was made to 10−3–10−5 times with sterile distilled water, and the cultures were then plated on nutrient agar plates to isolate individual colonies.

Medium and Growth Parameters

The isolated bacterial colonies were then purified and grown on “Pruthi and Cameotra” salt medium supplemented with crude oil (2%) at 30 °C, pH 7.2 [11, 12]. The medium contained the following nutrient amounts (in milligrams per liter), which were found optimal in biosurfactant synthesis: KH2PO4 2,000, Na2HPO4·2H2O 2,000, K2SO4 350, NaNO3 2,000, MgSO4·7H2O 150, NaCl 100, FeSO4·7H2O 50, CaCl2 50, and 1 ml of trace elements containing (in milligrams per liter): ZnSO4·7H2O 525, MnSO4·4H2O 200, CuSO4·5H2O 705, Na2MoO4·7H2O 15, CoCl2·6H2O 200, H3BO4 15, and NiSO4·6H2O 27.

Screening of Biosurfactant Producer

Surface Tension Measurement

Surface tension of the cell-free broth (50 ml) of the culture supernatant was measured by tensiometer (Sigma 703 KSV instruments Ltd., Finland) using Wilhelmy plate measurement technique as described earlier [13]. The surface tension of “Pruthi and Cameotra” salt medium at 30 °C was used as control. All the measurements were taken in triplicate.

Hemolytic Activity

Screening of isolated biosurfactant producing strain was determined by hemolytic activity. The fresh single colony of cultures was streaked on blood agar plates containing 5% (v/v) blood (Himedia, India), respectively, and incubated at 37 °C for 48–72 h.

Drop-Collapse Assay

The drop-collapse technique was performed in the 96-well microtiter (12.7 × 8.5 cm) plate (Greiner, Germany). Before use, each well was rinsed three times each with hot water, ethanol, and distilled water and dried. After preparation, each well was coated with a thin layer of 1.8 μl of 10 W-40 Pennzoil® which was spread as a thin coating over the bottom of the well. The coated wells were equilibrated for 24 h to ensure a uniform oil coating. A 5-μl aliquot of sample was delivered into the center of the well using a 25-μl glass syringe (Hamilton, Reno, NV, USA) by holding the syringe at an angle of 45°. The syringe was rinsed three times between each sample addition with water and then with acetone. Drop-collapse assay results were then determined visually after 1 min. If the drop remained beaded, the result was scored as negative. If the drop collapsed, the result was scored as positive. Samples were replicated five times, and each experiment was repeated three times [14].

Emulsification Activity

The cell-free broth of the culture supernatant was centrifuged and tested for its emulsifying ability by a modified method [15]. Briefly, cell-free broth (2 ml) was mixed into the screw cap test tube, and 3 ml of kerosene was then added. The mixture was vortexed at high speed for 2 min and left at room temperature. The emulsification activity, E 24 (%), was determined using the following equation after 24 h (for the stability of emulsion):

Cell Surface Hydrophobicity

Bacterial strains selected on basis of above screening methods were subjected to cell surface hydrophobicity technique for further assessment of biosurfactant production which includes the array of tests below.

Hydrophobic Interaction Chromatography

Phenyl Sepharose CL-4B, approximately 0.6 ml, was used as the column packing matrix which was equilibrated with a solution of 4.0 M NaCI in 0.5 M citrate buffer. Cell suspension was prepared in the same solution which served for equilibrating the gel, and 0.1 ml was introduced on the gel followed by 3 ml of the equilibrating solution. The elute (non-retained bacteria) was compared with the original bacterial suspension by measuring the absorbance at 540 nm and the results recorded as a percentage of retained bacteria (hydrophobic index).

Salt Aggregation Test

A bacterial suspension of 25 μl (approximately 1010 cfu/ml) in 0.002 M sodium phosphate buffer pH 6.8 was mixed with an equal volume of salt solution into 24-well tissue culture tray. The bacterial/salt mixture was gently rocked for 2 min at 25 °C, and visual reading was performed against a black background.

Adherence to Polystyrene: Replica Plate Test

Sterile disposable polystyrene (25 mm) disks were pressed firmly onto confluent agar surface growth, and the replica colonies obtained on the polystyrene surface were washed in running water for 2 min. The replica was fixed by dipping in methanol and staining with crystal violet. Greater than 50% coverage of the disk by adherence cells was scored as positive. This procedure was repeated at different time intervals so as to check the age-dependent hydrophobicity of the bacterial colonies [16].

Bacterial Adherence to Hydrocarbons

Bacterial adherence to hydrocarbons of the selected isolates was performed by dispensing the bacterial suspensions (1.2 ml) into 0.2 ml, hydrocarbons (dodecane, hexadecane, pristane) as described previously [16]. Results were recorded as the percentage absorbance of the aqueous phase after treatment relative to the initial absorbance of the bacterial suspension [17].

Biochemical and Molecular Characterization

The selected strain from the above evaluation tests was identified by microscopic and conventional biochemical tests in accordance with Bergey’s manual of systematic bacteriology [18].

Amplification of 16S rRNA Gene

Total bacterial genomic DNA was purified [19] and extracted for PCR amplification [20]. The identification of the selected bacterial isolate DSVP23 was performed using standard 16S rRNA-specific universal primers (Genescript, India) having forward primer (5′-AGAGTTTGATCCTGGCTCAG-3′) and reverse primer (5′-AAGGAGGTGATCCAGCCGCA-3′). A reaction mixture containing approximately 50 ng of template DNA, PCR buffer (10 mM Tris–HCl, pH 8.3; 50 mM KCl; 2.5 mM MgCl2; and 0.001% gelatin), a 0.2-mM concentration of each PCR primer, 0.2 mM conc. of each deoxynucleoside triphosphate, and 2.5 U of Taq DNA polymerase in a total volume of 50 μl was prepared. PCR conditions involved initial denaturation at 95 °C for 2 min, followed by 30 cycles of denaturation at 95 °C for 1 min, annealing for 1 min at 58 °C, and extension at 72 °C for 1 min; 5 μl of PCR product was electrophoresed on a 1% agarose gel containing 1 mM ethidium bromide for visualization of DNA in the amplified bands on a UV illuminator.

Phylogenetic Analyses

Partially sequenced amplified 16S rDNA fragment of about 1,500 bp size was compared with other gene sequences in GenBank using NCBI BLAST (www.ncbi.nlm.nih.gov) and aligned with gene sequence of our isolates using CLUSTALX software. The aligned sequences were used to construct a distance matrix, after the generation of 1,000 bootstrap sets, that was subsequently used to construct a phylogenetic tree using the neighbor-joining method (software MEGA) [21].

Extraction of Biosurfactant from Culture Broth

Culture broth of the isolated B. subtilis DSVP23 was centrifuged for 10 min at 6,000 rpm at 4 °C to obtain cell-free supernatants and crude was precipitated from the supernatant by adding 6 N HCl to obtain a final pH of 2.0. The acid precipitate was recovered by centrifugation (8,000 rpm for 15 min at 4 °C) and was further extracted with dichloromethane. The precipitate thus formed was collected by centrifugation for 10 min at 1,000 rpm at 4 °C and dried under a current of warm air. The product obtained after the extraction procedure was dried at 60 °C to a constant weight prior to get the yield of biosurfactant production.

Characterization of Biosurfactant

Determination of Protein Content

Protein content of cell-free broth was estimated by Lowry method using bovine serum albumin as standard [22].

Determination of Lipid Content

The biosurfactant was extracted by gently refluxing with diethyl ether for 1 h. This step was repeated thrice. The ether extract was dried with anhydrous Na2SO4 and clarified, followed by gravimetric estimation of the crude lipid.

Matrix-Assisted Laser Desorption/Ionization Mass Spectrometry

The 0.5 μl of purified biosurfactant was spotted onto an anchor chip positions on a matrix-assisted laser desorption/ionization (MALDI) plate. The 0.5 μl of matrix was added to the sample spot. The matrix tried was a saturated solution of 2,5-dihydroxybenzoic acid in water and 0.3 mg/ml α-cyano-4-hydroxycinnamic acid in acetone/ethanol (2:1, v/v). A peptide standard was also spotted for external calibration. The spots were left at room temperature to dry and analyzed on Applied Biosystems Voyager System 4402 Mass Spectrometer in delayed mode, with an acceleration voltage 20 kV.

Nuclear Magnetic Resonance Spectroscopy

One-dimensional 1H nuclear magnetic resonance (NMR) spectra were recorded at 298 K on a 500-MHz NMR spectrophotometer (Bruker, Germany). The samples were prepared as solutions in 100% CDCl3 using approximately 1–3 mg of biosurfactant.

Fourier Transform Infrared Spectroscopy

Dried biosurfactant was ground with KBr powder and was dispersed uniformly in a matrix of dry nujol (paraffin) mar, compressed to form an almost transparent disk for Fourier transform infrared spectroscopy (FTIR) spectra measurement in the frequency range of 4,000–500 cm−1. The biosurfactant sample was characterized using FTIR spectrophotometer (Thermo-Nicolet, USA) equipped with OMNIC software for data analysis.

Biodegradation Studies of B. subtilis DSVP23

B. subtilis DSVP23 inoculum 2% (v/v) was added to sterilized Erlenmeyer flasks (250 ml) containing 50 ml of sterilized “Pruthi and Cameotra” salt medium supplemented with 2% (w/v) oily sludge. The experimental flasks were then incubated for 7 days under shaking conditions (180 rpm) at 37 °C. Sampling was done after every 24 h for 7 days. Bacterial growth was estimated by determination of cell dry biomass. Cell-free broth was analyzed for change in pH and reduction in surface tension along with recovery of biosurfactant.

Gas Chromatography of Residual Oily Sludge

The aliphatic fraction was dissolved in 10 ml hexane and the aromatic fraction in 5 ml acetone for gas chromatography. These samples were then analyzed in gas chromatograph (Hewlett Packard 5890 Series II); 0.4 μl of these was injected into the respective columns of the gas chromatograph (Hewlett Packard 5890 series II) fitted with flame ionization detector.

Results

Isolation and Screening of Bacterial Isolates for Biosurfactant Production

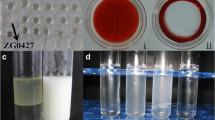

Among 26 bacterial isolates obtained, five isolates namely DSVP2, DSVP9, DSVP11, DSVP18, and DSVP23 were found to be potential biosurfactant producer when tested for hemolytic ability, emulsification activity, drop-collapse assay, and surface tension reduction as an index for biosurfactant production. Bacterial isolate DSVP23 screened was found to possess maximum biosurfactant production ability as shown in Table 1. The results were further confirmed by performing cell surface hydrophobicity studies comprising of batteries of assays (hydrophobic interaction chromatography (HIC), salt aggregation test (SAT), replica plate test (RP), and bacterial adherence to hydrocarbons (BATH)) as shown in Table 2.

Identification of the Isolate

On microscopic examination, bacterial isolate DSVP23 appeared as gram-positive, motile, rod-shaped, endospore-forming bacteria. By performing biochemical analysis using Bergey’s manual of systematic bacteriology, the strain was tentatively designated as B. subtilis. The PCR-amplified product yielded an amplicon of 1.5 kb which corresponds to 16S rRNA gene (Fig. 1). Alignment of the 16S rRNA gene sequences of bacterial isolate DSVP23 with sequences obtained by doing a BLAST searching revealed 100% similarity to B. subtilis (NCBI GenBank accession no. EU679368) (Fig. 2).

Characterization of Biosurfactant

Determination of Protein and Lipid Content of Biosurfactant

Biosurfactant was composed of 15.2% protein and 18.0% lipid respectively. The proportion of the surfactant ratio of protein and lipid remains constant in the acid precipitate at different periods of harvesting.

Matrix-Assisted Laser Desorption Ionization Time-of-Flight Mass Spectrometry

Data obtained from MALDI time-of-flight mass spectrometry (TOF-MS) of purified biosurfactant showed well-resolved groups of mass peaks at m/z 1,165.2, 1,022.7, 1,044.6, and 1,058.6 indicated it to be a lipopeptide with mixture of structural analogs (Fig. 3). Mass spectrometry confirmed isomers of surfactin in purified fractions. The mass peak at 1,044.6 was attributed to a surfactin isoform containing a β-hydroxy fatty acid with a chain of 14 carbon atoms.

Nuclear Magnetic Resonance

Results obtained with 500 MHz for 1H NMR (Fig. 4) clearly indicates that the molecule under investigation is of lipopeptide in nature. The spectrum confirms the presence of a long aliphatic chain (CH2 at 1.5–1.2 ppm), and peptide backbone amide-NH groups are in region from 7.95 to 7.2 ppm. A doublet signal obtained at 0.859 ppm corresponds to (CH3)2–CH group, specifying the terminal branching in the fatty acid component. The spectrum indicates the resonance of the following amino acids: valine with peptide CH at 4.6, CH2 at 1.7, and 2 CH3 at 0.9 ppm; leucine with peptide CH2 at 1.7, CH at 1.3, and 2 CH at 0.9 ppm; isoleucine with peptide CH at 4.2, CH at 2.2, CH2 at 1.9, and 2 CH3 at 0.9 ppm; aspartic acid or asparagines with peptide CH at 4.7 and CH2 at 2.8 ppm; and glutamic acid or glutaminepeptide CH at 4.3, internal CH2 at 1.9, and CH2 α to the carbonyl at 2.1 ppm.

Fourier Transform Infrared Spectroscopy

The spectra showed strong absorption bands of peptides at 3,343, 1,641, and 1,518 cm−1 resulting from N–H stretching, C=O stretching, and combined C–N stretching mode (Fig. 5). The predominant adsorption bands were 1,368, 1,451, and 2,960 cm−1, which indicate aliphatic chains (CH2, CH3) of sample. The intense band at 1,641 cm−1 corresponds to –CO–NH–R group. The absorption region at 1,737 cm−1 was due to an ester carbonyl band.

Biodegradation Studies of B. subtilis DSVP23

Biodegradation studies of B. subtilis DSVP23 carried for 7 days on “Pruthi and Cameotra” salt medium supplemented with 2% oily sludge showed maximum biomass (4.9 g/l), with simultaneous drop in pH. The maximum surface tension reduction of oily sludge (30.2 mN/m) and biosurfactant production (6.9 g/l) was observed after 5 days of incubation (Fig. 6).

Gas Chromatography

Gas chromatographic profiles obtained after 5 days of incubation revealed that it was able to degrade hydrocarbons of the oily sludge, compared with those of control (Fig. 7).

Gas chromatography profile of hydrocarbon degradation pattern by B. subtilis DSVP23 after 5 days: a Uninoculated control for aliphatic fraction. b Oily sludge (aliphatic fraction) degradation pattern. c Uninoculated control for aromatic fraction. d Oily sludge (aromatic fraction) degradation pattern

Discussion

Crude oil-contaminated soil samples used in the present investigation for isolation of bacterial colonies were gathered with a presumption that probability and capability of finding native bacterial population to mineralize crude oil hydrocarbons in crude oil is higher in such sites as has been recorded earlier [14, 23–27]. Screening of biosurfactant producing isolates was performed by using blood agar lysis, emulsification activity, drop-collapse test, and surface tension reduction assay. A total of five strains, namely DSVP2, DSVP9, DSVP11, DSVP18, and DSVP23, were selected on basis of above tests. Earlier researchers have documented these methods as rapid and reliable for screening and selection of microbes producing biosurfactants [28, 29]. Cell surface hydrophobicity studies were further employed for indirect confirmation of biosurfactant producing isolates. HIC, SAT, BATH, and RP assay procedures suggest that hydrophobic nature of cell surface is a prerequisite for the identification of biosurfactant producing strains. On comparative analysis, the hydrophobic properties of microorganisms confirmed that the five selected strains were active biosurfactant producers. Reports have recommended the use of cell surface hydrophobicity tests as a characteristic feature of biosurfactant producing microbes [17]. The sequencing of the 16S rRNA allowed the identification of potential biosurfactant producer (DSVP23) at species level with an identity from 97% to 100% comparing the sequences to those from the GenBank databases [30]. The groups of mass spectra peaks could be attributed to the isoform ensembles of surfactins, iturins, and fengycins, which represent the well-known biosurfactant families produced by B. subtilis [31]. Analysis of the 1H NMR spectra of isolated biosurfactant has led us to suggest their structural relatedness to lipopeptides from B. subtilis [32]. FTIR spectrum when compared with the previously reported spectrum for biosurfactants from Bacillus species, bands characteristic of C–N bond, amide II bond, and aliphatic chain and –OH/–NH groups were observed, indicating that this compound is a lipopeptide [2, 33–36]. GC analysis has been used to determine the ability of bacterial isolate B. subtilis DSVP23 to degrade oily sludge after 5 days of incubation. The gas chromatographic data indicate that isolate was able to consume almost all saturates and aromatics in the oily sludge when compared with controls. One possible explanation for this phenomenon could be that hydrocarbons, which cannot be used for growth by many soil organisms, can be oxidized if present as co-substrates in a system in which another substrate is available for growth [6]. Strain B. subtilis DSVP23 isolated from the oily sludge-contaminated soil was capable of utilizing oily sludge as carbon source. It was noticed that biosurfactant production by B. subtilis DSVP23 was growth-associated because a good correlation is observed between maximum yield of biosurfactant and biomass at 48 h of incubation (at late log phase) and surface-active compound was stable over time which is in good agreement to findings [16, 37]. Maximum biosurfactant production detected during late log growth phase values was coincident with least surface tension. Similar correlation was observed earlier during the growth of three Pseudomonas species on n-dodecane [16].

The ability of bacterial isolate B. subtilis DSVP23 to degrade hydrocarbons in mixed (oily sludge) forms suggests a probable use of bacteria for the treatment of other oil wastes. Besides this, ecofriendly biosurfactants are of considerable researcher’s interest for product formulations in detergent, cosmetic, and pharmaceutical applications.

References

Abouseouda, M., Maachi, R., Amranec, A., Boudergua, S., & Nabia, A. (2008). Desalination, 223, 143–151.

Das, K., & Mukherjee, A. K. (2007). Process Biochemistry, 42, 1191–1199.

Cunha, C. D., Rosario, M., Rosado, A. S., & Leite, S. G. F. (2004). Process Biochemistry, 39, 2277–2282.

Desai, J. D., & Banat, I. M. (1997). Microbiology and Molecular Biology Reviews, 61, 47–64.

Joshi, S. J., & Desai, A. J. (2010). Advances in experimental medicine and biology. In R. Sen (Ed.), Biosurfactants (Vol. 672, p. 222). New York: Springer.

Lima, A. S., & Alegre, R. M. (2009). Brazilian Archives of Biology and Technology, 52, 285–290.

Rocha, C. A., Pedregosa, A. M., & Laborda, F. (2011). AMB Express, 1, 9.

Das, K., & Mukherjee, A. K. (2007). Bioresource Technology, 98, 1339–1345.

Abalos, A., Vinas, M., & Sabate, J. (2004). Biodegradation, 15, 249–260.

Cubitto, M. A., Moran, A. C., Commendatore, M., Chiarello, M. N., Baldini, M. D., & Sineriz, F. (2004). Biodegradation, 15, 281–287.

Pruthi, V., & Cameotra, S. S. (2003). Journal of Surfactants and Detergents, 6, S12971–S12974.

Lal, B., & Khanna, S. (1996). Journal of Applied Bacteriology, 81, 355–362.

Dhote, M., Juwarkar, A., Kumar, A., Kanade, G. S., & Chakrabarti, T. (2010). World Journal of Microbiology and Biotechnology, 26, 329–335.

Bodour, A. A., & Miller-Maier, M. R. (1998). Journal of Microbiological Methods, 32, 273–280.

Noudeh, G. D., Noodeh, A. D., Moshafi, M. H., Behravan, E., Afzadi, M. A., & Sodagar, M. (2010). African Journal of Microbiology Research, 4, 1814–1822.

Pruthi, V., & Cameotra, S. S. (1997). Biotechnology Techniques, 11, 671–674.

Rosenberg, M., Gutnick, D., & Rosenberg, E. (1980). FEMS Microbiology Letters, 9, 29–33.

Sneath, P. H. A., Mair, N. S., & Sharpe, M. E. (1986). Bergey’s manual of systematic bacteriology (Vol. 2, pp. 999–1436). Baltimore: Williams & Wilkins.

De Clerck, E., Rodrıguez-Dıaz, M., Vanhoutte, T., Heyrman, J., Logan, N. A., & De Vos, P. (2004). International Journal of Systematic and Evolutionary Microbiology, 54, 941–946.

Pitcher, D. G., Saunders, N. A., & Owen, R. J. (1989). Letters in Applied Microbiology, 8, 151–156.

Kumar, S., Tamura, K., & Nei, M. (2004). Brief Bioinformatics, 5, 150–163.

Lowry, O. H., Rosebrought, N. J., Farr, A., & Randall, R. J. (1951). Journal of Biological Chemistry, 139, 265–274.

Okoh, A. I., & Trejo-Hernandez, M. R. (2006). African Journal of Biotechnology, 5, 2520–2525.

Emtiazi, G., & Shakarami, H. (2004). African Journal of Biotechnology, 4, 172–176.

Kasai, Y., Kishira, H., Sasaki, T., Syutsubo, K., Watanabe, K., & Harayama, S. (2002). Environmental Microbiology, 4, 141–147.

Okerentugba, P., & Ezeronye, O. (2003). African Journal of Biotechnology, 2, 288–292.

Batista, S. B., Mounteer, A. H., Amorim, F. R., & Tótola, M. R. (2006). Bioresource Technology, 97, 868–875.

Bodour, A. A., Guerrero-Barajas, C., Jiorle, B. V., Malcomson, M. E., Paull, A. K., Somogyi, A., Trinh, L. N., Bates, R. B., & Maier, R. M. (2004). Applied and Environmental Microbiology, 70, 114–120.

Youssef, N., Duncan, K., & Nagle, D. (2004). Journal of Microbiological Methods, 56, 339–347.

Ouoba, L. I., Thorsen, L., & Varnham, A. H. (2008). International Journal of Food Microbiology, 124, 224–230.

Yakimov, M. M., Timmis, K. N., Wray, V., & Fredrickson, H. L. (1995). Applied and Environmental Microbiology, 61, 1706–1713.

Nitschke, M., & Pastore, G. (2003). Applied Biochemistry and Biotechnology, 108, 295–301.

Vater, J., Kablitz, B., Wilde, C., Franke, P., Mehta, N., & Cameotra, S. S. (2002). Applied and Environmental Microbiology, 68, 6210–6219.

Makkar, R. S., & Cameotra, S. S. (1999). Journal of Surfactants and Detergents, 2, 237–241.

Joshi, S., Bharucha, C., Jha, S., Yadav, S., Nerurkar, A., & Desai, A. J. (2008). Bioresource Technology, 99, 195–199.

Makkar, R. S., & Cameotra, S. S. (1997). Journal of Industrial Microbiology and Biotechnology, 18, 37–42.

Mahanty, B., Pakshirajan, K., & Dasu, V. V. (2006). Applied Biochemistry and Biotechnology, 134, 129–141.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pemmaraju, S.C., Sharma, D., Singh, N. et al. Production of Microbial Surfactants from Oily Sludge-Contaminated Soil by Bacillus subtilis DSVP23. Appl Biochem Biotechnol 167, 1119–1131 (2012). https://doi.org/10.1007/s12010-012-9613-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9613-z