Abstract

Although a number of filamentous fungi, such as Trichoderma and Aspergillus, are well known as producers of cellulases, xylanases, and accessory cellulolytic enzymes, the search for new strains and new enzymes has become a priority with the increase in diversity of biomass sources. Moreover, according to the type of pretreatment applied, biomass of the same type may require different enzyme blends to be efficiently hydrolyzed. This study evaluated cellulases, xylanases, and β-glucosidases produced by two fungi, the thermotolerant Acrophialophora nainiana and Ceratocystis paradoxa. Cells were grown in submerged culture on three carbon sources: lactose, wheat bran, or steam-pretreated sugarcane bagasse, a commonly used cattle feed in Brazil. Xylanase and endo-1-4-β-glucanase (CMCase) highest production were found in A. nainiana growing on lactose and reached levels of 2,200 and 2,016 IU/L, respectively. C. paradoxa showed highest activity for xylanase when grown on wheat bran and for β-glucosidase when grown on steam-treated bagasse, at levels of 12,728 and 1,068 IU/mL, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The progressive depletion of world oil reserves, coupled with the accumulation of greenhouse gases responsible for global warming, is driving a search for renewable and economically feasible biofuels. Within this context, the use of alternative energy sources, including renewable raw materials such as biomass, has become a main target within the international sustainable development agenda.

Second-generation ethanol (from lignocellulosic biomass) has been regarded worldwide as a major alternative to the use of petroleum. Ethanol can be produced from biomass through its pretreatment, enzymatic hydrolysis, and the alcoholic fermentation of the resulting sugar syrups by yeast species [1–7]. A number of filamentous fungi are capable of degrading biomass through the production of enzymes such as cellulases (exoglucanases and endoglucanases), β-glucosidase, xylanases, and accessory biocatalysts. The thermotolerant fungus Acrophialophora nainiana shows a substantial xylanase activity when grown on lignocellulosic and xylan as carbon substrates [8] while Ceratocystis paradoxa is reported as a sugarcane phytopathogen [9].

In Brazil, sugarcane bagasse and straw are major residues of first-generation ethanol production from sucrose and are regarded as potential sources of sustainable biomass ethanol. Thus, further knowledge regarding enzymes for processing biomass has particular relevance in the sugarcane industry. The study of low-cost enzyme production is needed for the deployment of biomass ethanol technology, as this new process will compete with the already well-established and highly profitable sucrose ethanol market. The benefits of this new technology will range from the intensification of ethanol production per planted area to the social benefits embodied by the expansion of the biofuels production industry.

The aim of the present work was to study the production of cellulolytic enzymes, xylanases, and β-glucosidases by the fungi C. paradoxa and A. nainiana, in submerged fermentation, using different carbon sources.

Materials and Methods

Microorganisms, Maintenance, and Propagation

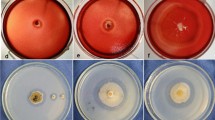

The fungi were cultured in Petri dishes containing potato dextrose agar for 7 days at 28 °C for C. paradoxa and at 40 °C for A. nainiana. Spore suspensions from sporulating cultures were obtained by addition of NaCl 0.90% (w/v) and lightly scraping the cultures. The suspensions were centrifuged at 2,568×g for 15 min in a Beckman-Coulter Allegra 6R centrifuge, and the spores were preserved in a solution of glycerol 20% (v/v) at −4 °C.

Fermentation Conditions

Cellulase production was carried out in 1,000-mL Erlenmeyer flasks containing 300 mL of modified Breccia growth medium (Table 1) for C. paradoxa and modified Mandels’ growth medium (Table 1) for A. nainiana. Lactose, wheat bran, and steam-pretreated sugarcane bagasse were tested as carbon sources for both microorganisms.

After sterilization, the culture media were inoculated with a 1% (v/v) of spore suspension to give a concentration of 106–107 spores/mL. Triplicate cultures were incubated for 7 days in a rotary shaker (New Brunswick model INNOVA 4340) at 200 rpm and 30 °C for C. paradoxa and 40 °C for A. nainiana. For comparison, Trichoderma reesei Rut C30 was also cultured in the modified Mandels’ medium (Table 1), using lactose as carbon source, at 30 °C and 200 rpm.

Samples of the culture supernatants, collected daily and centrifuged at 3,000 rpm for 15 min, were used for determination of enzyme activity (CMCase, FPase, β-glucosidase, and xylanase) and pH determination.

Enzyme Activity Assays

The filter paper (FPU), endo-1-4-β-glucanase (CMCase) and β-glucosidase (BGU) activities were based on standard IUPAC procedures and are expressed using international units (IU) [10].

FPase activity was based on the determination of reducing sugar concentration released during the degradation of a strip of filter paper. The reaction medium was formed by 0.5 mL of the fermentation supernatant (previously diluted in 50 mM sodium citrate buffer pH 4.8, when necessary), 1.0 mL of 50 mM sodium citrate buffer pH 4.8, and a strip of filter paper Whatman No. 1 measuring 1.0 × 6.0 cm (approximately 50 mg). The reaction mixture was incubated at 50 °C for 60 min under agitation, and the released reducing sugars measured afterwards. One filter paper unit (FPU) corresponded to the release of 2 mg of glucose equivalents (or 4% of initial substrate) in 60 min.

The CMCase activity was determined by measuring reducing sugars released during the degradation of carboxymethylcellulose (CMC). The reaction medium consisted of 0.5 mL of a 4% w/v CMC solution in 50 mM sodium citrate buffer pH 4.8 and 0.5 mL of the fermentation supernatant (previously diluted in 50 mM sodium citrate buffer pH 4.8, when necessary). The reaction mixture was incubated at 50 °C, under agitation, for 10 min, to ensure a sugar release constant rate. At the end of reaction, 0.5 mL was removed and immediately added to tubes containing 0.5 mL of 3,5-dinitro salicylic acid (DNS). The DNS reagent interrupted the enzymatic reaction and allowed the quantification of reducing sugars [11]. One unit of CMCase activity corresponded to the formation of 1 μmol of reducing sugar (glucose equivalent) per minute using carboxymethyl cellulose as substrate.

The activity of β-glucosidase was measured as glucose released using cellobiose as substrate. The reaction medium consisted of 0.5 mL of supernatant (previously diluted in 50 mM sodium citrate buffer pH 4.8, when necessary) and 0.5 mL of solution of the substrate (15 mM cellobiose solution in sodium citrate buffer pH 4.8, 50 mM). The reaction mixture was incubated at 50 °C for 30 min under agitation. The reaction was terminated by immersing the tubes in boiling water for 5 min. Glucose concentrations were measured using a Biochemistry Analyzer YSI 2700 Select. One unit of β-glucosidase activity corresponded to the formation of 1 μmol of glucose per minute using cellobiose as a substrate.

The xylanase activity was determined as previously described [12, 13]. For preparation of the substrate, 1 g xylan (oat spelts) was treated with 20 mL 1.0 M NaOH for 1 h under agitation, then 20 mL of 1.0 M HCl was added, with stirring. The solution was homogenized and made to a final volume of 100 mL with 50 mM sodium acetate pH 5.0, stirred for an hour, and then centrifuged for 20 min to remove the insoluble xylan [12]. To measure the enzyme activity, 100 μL of xylan was added to 50 μL of enzyme preparation. After incubation at 50 °C for 30 min, the concentration of reducing sugars was determined by the DNS method [11], using xylose as a standard. One unit of xylanase activity was defined as the formation of 1 μmol of reducing sugar (xylose equivalent) per minute.

Results and Discussion

The maximal enzyme activities produced by A. nainiana and C. paradoxa using lactose, wheat bran, and steam-treated sugarcane bagasse are presented in Table 2. Significant accumulation of FPase, CMCase, and xylanase activity were produced by A. nainiana in the lactose medium, at 144 ± 56 FPU/L, 2,016 ± 238 IU/L, and 2,200 ± 216 IU/L, respectively (Table 2). However, these levels were approximately 10-fold lower than those observed for T. reesei Rut C30, at 1,200 ± 137 FPU/L, 25,000 IU/L, and 15,000 ± 700 IU/L, respectively (Table 2). Nonetheless, the ratios of FPase/CMCase activity were equivalent in A. nainiana and T. reesei Rut C30, which suggests that further strain improvement in the thermotolerant A. nainiana microorganism will be beneficial. For wheat bran and steam-treated bagasse, the results for FPase and CMCase activities showed no significant differences. Xylanase activity was favored in the wheat bran medium and steam-treated bagasse medium, reaching 1,200 ± 135 and 1,067 ± 87 IU/L, respectively. Xylanase activity was also 10-fold lower in comparison to that of T. reesei Rut C30. The accumulation of β-glucosidase activity was insignificant for all carbon sources tested.

The pH profiles for A. nainiana shown in Fig. 1 indicate that the pH of all culture media remained constant until the 4th day of fermentation followed by a small increase most likely due to cell death followed by proteolysis and amino acids deamination. Low β-glucosidase levels were detected in the culture supernatant after the pH rise suggesting that the enzyme is located in the periplasmic cell space or is an internal biocatalyst.

The profile for enzyme accumulation by C. paradoxa using lactose, wheat bran, and pretreated sugarcane bagasse are presented in Table 2. The fungus was able to produce FPase in all media evaluated; nevertheless, peak values were approximately half of those observed for A. nainiana, at 107 ± 30 FPU/L for the lactose medium, 77 ± 7 FPU/L for the wheat bran medium, and 61 ± 8 FPU/L for the steam-treated sugarcane bagasse, respectively. CMCase accumulated only slightly in the lactose medium (data not shown), whereas peak concentrations reached 542 ± 101 and 538 ± 98 IU/L for wheat bran and bagasse, respectively (Table 2). C. paradoxa showed a consistent xylanase production for all tested carbon sources. Enzyme peak levels were 12,728 ± 1,422 IU/L on wheat bran, 9,966 ± 633 IU/L on bagasse, and 7,522 ± 917 IU/L on lactose, which compared well with the xylanase levels measured for T. reesei RUT C30 at 15,000 ± 700 IU/L (Table 2). The xylanase production trait may be related to its fungal phytopathogenicity towards sugarcane.

C. paradoxa also showed β-glucosidase accumulation to a level of 1,068 ± 22 IU/L with steam-treated sugarcane bagasse and 770 ± 65 IU/L with wheat bran. The production levels on steam-treated bagasse were higher than those observed for T. reesei RUT C30, at 800 ± 51 IU/L (Table 2). Nevertheless, although it is well known that T. reesei Rut C30 is deficient in β-glucosidase, these data may serve as an indicator of the fungal enzyme profile. Lactose repressed β-glucosidase production by C. paradoxa (Table 2). The pH profiles for C. paradoxa showed to be fairly constant as expected due to the buffering capacity of Breccia-modified medium (Fig. 2).

Conclusions

Similar to what is seen with T. reesei Rut C30, the thermotolerant A. nainiana was able to metabolize lactose. The fungus produced FPase, CMCase, and xylanase, but at peak levels approximately 10-fold lower than that observed for T. reesei Rut C30 culture. However, the FPase/CMCase and FPase/xylanase ratio were equivalent to those of T. reesei. A. nainiana can, therefore, be regarded as a candidate for strain improvements studies aiming the improvement of cellulases and xylanase production. The maximum enzyme concentrations in A. nainiana culture supernatants were in the range of 144 FPU/L for FPase, 2,016 IU/L for CMCase, and 2,200 IU/L for xylanase on lactose medium.

C. paradoxa was a poor FPase and CMCase producer in all studied medium, showing enzyme activities 10- and 40-fold lower, respectively, than those seen in T. reesei Rut C30 culture. Xylanase accumulation, however, using wheat bran was 85% of that observed for T. reesei Rut C30; β-glucosidase levels on the steam-pretreated sugarcane bagasse were equivalent to those observed for T. reesei.

Maximum enzyme concentrations in the C. paradoxa culture supernatants were in the range of 107 FPU/L for FPase on the lactose medium, approximately 540 IU/L for CMCase on the wheat bran or sugarcane bagasse medium, 12,728 IU/L for xylanase on the wheat bran medium, and 1,068 IU/L for β-glucosidase also on wheat bran medium. Lactose repressed the production of β-glucosidase.

Overall, the two fungal strains that were evaluated in this study showed relevant traits, such as a balanced FPAse/CMCase and FPAse/xylanase ratios for the thermotolerant A. nainiana whereas C. paradoxa showed to be a consistent xylanase producer; its xylanase complex concerning its β-xylosidase and arabinofuranosidase as well as feruroyl esterase activities will be addressed in further work. This study contributes new information and prospects on two cellulolytic strains in terms of its present and potential cellulolytic and xylanolytic biotechnological uses.

References

Azzam, A. M. (1989). Journal of Environmental Science and Health. Part B, 24(4), 421–433.

Bjerre, A. B., Olesen, A. B., & Fernqvist, T. (1996). Biotechnology and Bioengineering, 49, 568–577.

Cadoche, L., & López, G. D. (1989). Biological Wastes, 30, 153–157.

Dale, B. E., Henk, L. L., & Shiang, M. (1984). Developments in Industrial Microbiology, 26, 223–233.

Duff, S. J. B., & Murray, W. D. (1996). Bioresource Technology, 55, 1–33.

Reshamwala, S., Shawky, B. T., & Dale, B. E. (1995). Appl Biochem Biotechnol, 51/52, 43–55.

Wright, J. D. (1998). Chemical Engineering Progress, 84(8), 62–74.

Medeiros, R. G., Soffner, M. L. A., Thomé, J. A., Cacais, A. O. G., Estelles, R. S., Salles, B. C., et al. (2000). Biotechnology Progress, 16, 522–524.

Moutia, Y., & Saumtally, S. (1999). Technical report: Mauritius Sugar Industry Research Institute AMAS. Réduit: Food and Agricultural Research Council.

Ghose, T. K. (1987). Pure and Applied Chemistry, 59(2), 257–268.

Miller, L. (1959). Analytical Chemistry, 31, 426–428.

Filho, E. X. F., Puls, J., & Coughlan, M. P. (1993). Journal of Industrial Microbiology, 11, 171–180.

Cardoso, O. A. V., & Filho, E. X. F. (2003). FEMS Microbiology Letters, 223(2), 309–314.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barros, R.R.O., Oliveira, R.A., Gottschalk, L.M.F. et al. Production of Cellulolytic Enzymes by Fungi Acrophialophora nainiana and Ceratocystis paradoxa Using Different Carbon Sources. Appl Biochem Biotechnol 161, 448–454 (2010). https://doi.org/10.1007/s12010-009-8894-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-009-8894-3