Abstract

Lactic acid is an important product arising from the anaerobic fermentation of sugars. It is used in the pharmaceutical, cosmetic, chemical, and food industries as well as for biodegradable polymer and green solvent production. In this work, several bacterial strains were isolated from industrial ethanol fermentation, and the most efficient strain for lactic acid production was selected. The fermentation was conducted in a batch system under anaerobic conditions for 50 h at a temperature of 34 °C, a pH value of 5.0, and an initial sucrose concentration of 12 g/L using diluted sugarcane molasses. Throughout the process, pulses of molasses were added in order to avoid the cell growth inhibition due to high sugar concentration as well as increased lactic acid concentrations. At the end of the fermentation, about 90% of sucrose was consumed to produce lactic acid and cells. A kinetic model has been developed to simulate the batch lactic acid fermentation results. The data obtained from the fermentation were used for determining the kinetic parameters of the model. The developed model for lactic acid production, growth cell, and sugar consumption simulates the experimental data well.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lactic acid was first discovered in 1780 and has two stereoisomers called d(−)-lactic acid and l(+)-lactic acid. Lactic acid is used in the food, cosmetic, pharmaceutical, chemicals, and biodegradable polymer production. It is a naturally occurring organic acid that can be produced by fermentative or chemical synthesis. The chemical synthesis is mainly based on the hydrolysis of lactonitrile by strong acid, where a racemic mixture of the two forms [d(−) and l(+)] lactic acid is produced [1]. In fermentative process, the isomers either d(−) or l(+) of lactic acid, depending on the stereospecificity of the lactate dehydrogenase, are present in the cells. Racemic mixture may be formed when both l- and d-lactate dehydrogenase are present in the same cell or in rare cases by action of an inducible lactate racemic and combination with a constitutive l-lactate dehydrogenase [2].

The biotechnological production of lactic acid has received a significant interest, since it is an attractive process for both environmental viewpoint and economic, due the combination of the low cost of production from sugarcane fermentation and reduction of dependency of fossil-based feedstock and biocatalyst use.

Lactic acid is produced in fermentation using lactic acid bacteria (LAB) or fungi. The desirable characteristics of industrial microorganisms are their ability to rapidly and completely ferment cheap raw materials, requiring minimal amount of nitrogenous substances, providing high yields of preferred stereospecific lactic acid under conditions of low pH and high temperature and production of low amounts of cell mass and negligible amounts of other by-products [3]. The LAB are classified into homofermentative, which produce virtually a single product, lactic acid, and heterofermentative, the bacteria that produce other products such as ethanol, CO2, acetoin, diacetyl formate, or acetic acid along with lactic acid [4].

A number of different substrates have been used for the fermentative production of lactic acid by LAB. The carbon source for microbial production of lactic acid can be either sugar in pure form, such as glucose, sucrose, and lactose, or sugar-containing materials, such as molasses, whey, and sugarcane bagasse [5]. The purest product is obtained when a pure sugar is fermented, resulting in lower purification costs, but this is economically unfavorable because pure sugars are expensive and lactic acid is a cheap product [6].

In this work, several bacterial strains isolated from industrial ethanol fermentation were used to select the best strain to lactic acid production. In a next stage, fermentation was carried out using sucrose obtained from sugarcane molasses for lactic acid production. The sugarcane is a renewable carbon source, abundant and cheap, and is a major culture developed in Brazil. The production and yield are growing due to agriculture advances as well as the industrial process related to sugar and bioethanol production.

Materials and Methods

Screening

A total of sixty strains of LAB were isolated from samples of industrial ethanol fermentation obtained from different ethanol plants and belonging to bacteria culture collection of the Sugarcane Technology Center.

The strains were initially plated in Man–Rogosa–Sharpe (MRS) agar and incubated at 35 °C for 48 h. After incubation time, the stains were classified on the basis of their morphological characteristics (shape, color, and size). Next, the strains were cultivated in medium containing 4.0 g/L yeast extract, 5.0 g/L casein, 0.55 g/L K2HPO4, 0.425 g/L KCl, 0.125 g/L CaCl2, 0.125 g/L MgSO4, 0.0025 g/L MnSO4, and 0.0025 g/L FeCl3 at 35 °C without pH control. Three flasks were prepared with culture medium for each strain with different carbon source (glucose, fructose, and sucrose). Glucose, fructose, and sucrose were added to concentrations of 50 g/L. The pH and cell density were measured after 48 h of incubation, and the strains were classified on the basis of their by-product formation and gas production, cell growth, flocculation, pH and temperature tolerance, and ability to ferment sucrose, an abundant component of the sugarcane molasses.

The three best strains selected were used in a fractional experimental design 24 − 1 developed to determined the optimum conditions. The pH, cell density, and lactic acid concentration were measured after 24, 48, and 72 h. The yield and lactic acid end concentration were the dependent variables of the experimental design. After developing the experimental design, some experiments were repeated, and pure sucrose was replaced by sugarcane molasses. The best strain and the optimum condition were used in fermentative process for lactic acid production.

Microorganism

One milliliter of the selected culture was plated in MRS agar for activation and incubated for 48 h at 35 °C. A loop of this pre-culture was transferred under anaerobic conditions to test tube containing 10 mL of MRS medium and inoculated at 35 °C for 48 h. This culture suspension was inoculated into five test tubes with 10 mL of MRS fresh each and incubated for 24 h. Finally, the five aliquots of culture suspension were transferred to Erlenmeyer flasks containing 450 mL of MRS fresh and cultivated at 34 °C and 150 rpm for about 17 h. After incubation, 350 mL of this inoculum was used in the fermentation.

Fermentation

Fermentation was carried out in a 3-L New Brunswick Scientific BioFlo III bioreactor with 2.5-L working volume. Sugarcane molasses (54% sucrose w/w) without pre-treatment was diluted with distilled water to obtained sucrose initial concentration of 12 g/L approximately. The fermentation medium was enriched with 5 g/L of yeast extract.

The temperature was maintained at 34 °C, agitation speed at 200 rpm, and pH at 5.0 by adding 4 M NaOH. The fermentation was performed under anaerobic conditions. The LabVIEW® software was used for monitoring and controlling process parameters during fermentation.

After the sucrose is completely consumed, it was carried out a pulse of molasses diluted (12 g/L of sucrose) in the process, and in approximately 32 h, a synthetic molasses pulse was added in order to avoid the inhibition of the cell growth by high sucrose concentration as well as increase the lactic acid end concentration. The total time of fermentation was approximately 50 h, and the time of the batch was about 9 h. The experimental data obtained from batch fermentation with sucrose initial concentration of 12 g/L were used for the determination of kinetic parameters.

Analytic methods

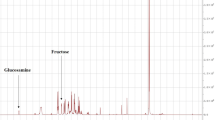

Samples were aseptically withdrawn from bioreactor at approximately 2-h intervals during fermentation and utilized to appraise the cell growth, lactic acid production, sucrose consumption, and by-product formations. The samples were centrifuged at 2,000 rpm for 20 min. The biomass was washed twice with distilled water and again centrifuged and dried at 75 °C for 48 h. The supernatants were used for determining the lactic acid, sucrose, and by-product (acetic acid and ethanol) concentration in high-performance liquid chromatography equipped with refractive index and UV-visible detectors connected in series and a Bio-Rad Aminex HPX-87H column (300 × 7.8 mm) at 37 °C, and 4 mM H2SO4 was used as mobile phase (pH 2.8) at a flow rate of 0.6 mL/min and sample injection volume of 25 μL. Lactic acid concentrations were also estimated from the sodium hydroxide consumption to maintain the fermentation pH constant.

Mathematical Model

In this work, an unstructured kinetic model was develop to represent the batch lactic acid fermentative production from sugarcane molasses using a LAB isolated from the industrial ethanol fermentation. The model has three kinetic equations that represent the biomass, lactic acid, and sucrose concentration and was based on the Luedeking–Piret model for growth-associated and non-growth-associated lactic acid production [7] and modified to include terms of product inhibition, substrate inhibition, and substrate limiting, as show in Eqs. 1, 2, and 3:

Biomass concentration

Sucrose concentration

Lactic acid concentration

Results and Discussion

A screening was performed using 60 strains of bacteria to select the best to be used in the lactic acid production. Initially, the isolated strains were classified on the basis of their morphological characteristics, by-product formation and gas production, ability to ferment sucrose, pH and temperature tolerance, and flocculation. Among the 60 strains studied, only three (strain 7, 25, and 27) showed satisfactory results, i.e., good cell growth, negligible CO2 production, sucrose consumption, and lactic acid production (pH decrease). Table 1 shows the decrease in pH value after 48 h of incubation at 35 °C of the three strains, and the cell viability is shown in Table 2.

The three selected strains were used in a fractional experimental design 24 − 1 to determine the fermentation optimum conditions as well as to select the best strain to lactic acid production. The experimental design was carried out in shake flasks stirred at 150 rpm, and the strains were cultivated in a synthetic medium using sucrose as carbohydrate source without pH control. The decrease in pH value can be considered as a factor to lactic acid production. Table 3 shows the parameters used in the experimental design 24 − 1.

The experimental design was realized using two central points, and the maximum sucrose concentration used was 45 g/L, whereas in the experiments initially carried out to evaluate the 60 strains, low sucrose consumption was possible perceive when a concentration of 50 g/L was used. Table 4 shows the fractional experimental design used and the lactic acid yield obtained in each run to three strains. The best experimental results were obtained in run 5: temperature (30 °C), sucrose concentration (15 g/L), yeast extract (7.5 g/L), and K2HPO4 (0.75 g/L) to the three strains. The highest yield was obtained with strains 25 and 27, but using strain 27, the acetic acid yield was of 13.5% and 9.7% with strain 25. The Pareto chart (Fig. 1a–c) was used to identify the effects of the parameters on the lactic acid yield after 48 h.

The Pareto chart (Fig. 1a–c) depicts that of the four parameters analyzed; only sucrose concentration and temperature were statistically significant for lactic acid yield at 5% significance level for the three strains, and both parameters negatively influence the lactic acid yield. Then, in order to maximize the lactic acid yield, the optimal conditions correspond to run 5, i.e., lower sucrose concentration and temperature. As K2HPO4 and yeast extract showed no significant influences on lactic acid yield, they can be used as central values. Due to lower acetic acid production by strain 25, this was selected for lactic acid production on higher scale. The sucrose concentration (p = 0.002) was the parameter that most influenced the lactic acid yield when strain 25 (Fig. 1b) was used. From the results obtained in the experimental design, new experiments were realized using sugarcane molasses instead of pure sucrose. The best result was obtained when 24.6 g/L of sugarcane molasses (∼12 g/L sucrose) and 5 g/L of yeast extract were used. This medium composition was used for the batch lactic acid production conducted in 3 L bioreactor. The K2HPO4 has no influence on the lactic acid yield when sugarcane molasses was used as carbon source, so that it was not used in such case. Figure 2 shows microscope photography of the selected strain.

The fermentation was performed with sucrose initial concentration of 12 g/L (diluted molasses), and throughout the process, pulses of molasses was carried out in order to avoid the inhibition of the cell growth by high sucrose concentration as well as increase the lactic acid end concentration. The pulse was added in the fermentation temperature, and the volume was kept constant through periodic withdrawal during the process. Figure 3 shows the changes in concentration of sucrose, lactic acid, and biomass, which occur during fermentation at pH and constant temperature under anaerobic conditions.

In the fermentation with sucrose concentration of about 36 g/L (initial concentration, pulses 1 and 2), as shown in Fig. 3, about 90.0% of sucrose was consumed to produce lactic acid and cells. The yield was calculated by determining the total amount of formed lactic acid per amount of consumed sucrose, as in Eq. 4. The lactic acid yield obtained with sugarcane molasses diluted was very similar with that obtained by synthetic molasses (83%).

The experimental data obtained from the initial 9 h of batch fermentation with a starting sucrose concentration of 12 g/L were used to approximate the kinetic parameters, and the evaluation of experimental data was carried out by approximating sigmoidal function. Figure 4 shows the experimental data of batch fermentation.

Fermentation time of 9 h approximately was required to complete sucrose consumption (batch process) with yield of 81%. Figure 5 shows that the quantity of base added is directly correlated with the production of lactic acid.

The kinetics of lactic acid production is associated with growth, as shown in Fig. 6a and b. The maximum lactic acid productivity obtained was of 2.49 g/L h, as shown in Fig. 6b. Figure 6c and d shows the relationship of growth rate to cell biomass concentration and to lactic acid concentration, respectively. The maximum growth rate (0.73 g/L h) was obtained when the lactic acid concentration was 8.5 g/L. For higher concentrations, a linear decay of the growth rate was observed (Fig. 6d). This evidences a product inhibition at high concentrations.

A kinetic model has been developed to represent in batch fermentation to produce lactic acid by strains isolated from industrial ethanol fermentation. The data obtained from the fermentation were used for determining the kinetic parameters of the model. Table 5 shows the parameters obtained in the batch fermentation to lactic acid production. The developed model allows good predictions for lactic acid production, growth cell, and sugar consumption compared with experimental data, as shown in Fig. 7. Some discrepancy has been observed between the model and the experimental data, which can be minimized by a model fitting procedure to experimental data.

Conclusions

In this work, the capacity of 60 strains isolated from industrial ethanol fermentation to lactic acid production were selected and evaluated. Among the strains, one that produces lactic acid from sugarcane molasses without pretreatment was selected. After screening the best strains, an experimental design was carried out to determine the optimum condition fermentation. From the results of the experimental design, it was possible to perceive that the yield of lactic acid is favored when using lower temperature and lower sucrose concentration to prevent the inhibition of the cell growth. Lactic acid was obtained by fermentation of sugarcane molasses, an economical substrate, using bacteria isolated from sugar and alcohol mill, adapted to the industrial environment, considering the biorefinery concept in order to develop an economically competitive biotechnological process. Batch fermentations were conducted at 34 °C, pH 5.0, 200 rpm, and sucrose initial concentration of 12 g/L obtained from diluted sugarcane molasses. Throughout the process, pulses of molasses was carried out to avoid the inhibition of the cell growth by high sucrose concentration as well as to increase the lactic acid end concentration. The yield of lactic acid obtained from diluted sugarcane molasses fermentation was of 0.83 g/g. The maximum growth rate was obtained in a lactic acid concentration of 8.5 g/L. For lactic acid concentrations above this value, a linear decrease in growth rate was observed. The ratio of α/β equals 6.0 justifies a growth-associated lactic acid formation. The model developed has been found to provide an adequate description of the fermentation kinetics.

Abbreviations

- K i :

-

Inhibition constant (L/g)

- K s :

-

Monod constant (h−1)

- P :

-

Lactic acid concentration (g/L)

- P 0 :

-

Lactic acid initial concentration (g/L)

- S :

-

Sucrose concentration (g/L)

- S 0 :

-

Sucrose initial concentration (g/L)

- X :

-

Biomass concentration (g/L)

- α :

-

Growth-associated constant for the Luedeking–Piret (g lactic acid/g biomass)

- β :

-

Non growth-associated constant for the Luedeking–Piret (g/h)

- µ max :

-

Maximum specific growth rate (h−1)

References

Datta, R. & Henry, M. (2006). Lactic acid: recent advances in products, processes and technologies—A review. Journal of Chemical Technology and Biotechnology, 81, 1119–1129.

Burgos-Rubio, C. N., Okos, M. R., & Wankat, P. C. (2000). Kinetic study of the conversion of different substrates to lactic acid using Lactobacillus bulgaricus. Biotechnology Progress, 16, 305–314.

Narayanan, N., Roychoudhury, P. K., & Srivastava, A. (2004). L (+) lactic acid fermentation and its product polymerization. Journal of Biotechnology, 7(2), 167–179.

John, R. P. & Nampoorthiri, K. M. (2007). Fermentative production of lactic acid from biomass: An overview on process developments and future perspectives. Applied Microbiology and Biotechnology, 74, 524–534.

Wee, Y. J., Kim, J. N., & Ryu, H. W. (2006). Biotechnological production of lactic acid and its recent applications. Food Technology and Biotechnology, 44(2), 163–172.

Pandey, A., Soccol, C. R., Rodriguez-Leon, J. A., & Nigam, P. (2001). Solid state fermentation in biotechnology: fundamentals and applications. New Delhi: Asiatech.

Luedeking, P. & Piret, E. L. (1959). A kinetic study of the lactic acid fermentation. Batch process at controlled pH. Journal of Biochemical and Microbiological Technology and Engineering, 1, 393–412.

Acknowledgements

The authors are thankful to the Fundação de Amparo a Pesquisa do Estado de São Paulo, Brazil (FAPESP), process number 06/07175-7 for the financial support. The authors want to thank also the Sugarcane Technology Center (CTC) and the Laboratory of Bioprocess of the School Foods Engineering of the State University of Campinas.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lunelli, B.H., Andrade, R.R., Atala, D.I.P. et al. Production of Lactic Acid from Sucrose: Strain Selection, Fermentation, and Kinetic Modeling. Appl Biochem Biotechnol 161, 227–237 (2010). https://doi.org/10.1007/s12010-009-8828-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-009-8828-0