Abstract

Mixed enzyme preparation having both xylanase and laccase activity was evaluated for its bleach enhancing ability of mixed wood pulp. The enzyme was produced through co-cultivation of mutant Penicillium oxalicum SAUE-3.510 and Pleurotus ostreatus MTCC 1804 under solid-state fermentation. Bleaching of pulp with mixed enzyme had resulted into a notable decrease in kappa number and increased brightness as compared to xylanase alone. Analysis of bleaching conditions had denoted that 8 IU g−1 of mixed enzyme preparation (xylanase/laccase, 22:1) had led into maximal removal of lignin from pulp when bleaching was performed at 10% pulp consistency (55 °C, pH 9.0) for 3 h. An overall improvement of 21%, 8%, 3%, and 5% respectively in kappa number, brightness, yellowness, and viscosity of pulp was achieved under derived bleaching conditions. Process of enzymatic bleaching was further ascertained by analyzing the changes occurring in polysaccharide and lignin by HPLC and FTIR. The UV absorption spectrum of the compounds released during enzymatic treatment had denoted a characteristic peak at 280 nm, indicating the presence of lignin in released coloring matter. The changes in fiber morphology following enzymatic delignification were studied by scanning electron microscopy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The removal of lignin is essentially required during paper manufacturing [1]. Lignin is a three dimensional polymer with a complex structure, present in all woody plants and other lignocellulosic residues which are used as raw material for paper manufacturing. It provides structural integrity to plant cell wall due to its linkages with cellulose and hemicellulose residues [2, 3]. The brown color of pulp is due to the presence of lignin which has to be removed during the process of paper-making for aesthetic reasons. Removal of this lignin by biological means is considered as biobleaching and is economical and environment friendly compared to conventional bleaching [4–6]. The xylanolytic and lignolytic enzyme systems of different microbes have been explored by several researchers. Xylanases hydrolyze xylan layer in the plant cell wall and affects the structural integrity and thus facilitating the removal of lignin in subsequent bleaching stages. At the same time it also attacks on the xylan which is reprecipitated on the surface of pulp fibers during chemical pulping thus enhancing bleaching by exposing lignin for the action of bleaching chemicals [7, 8]. Ligninases, unlike xylanases, directly and specifically attacks on lignin, oxidizes it, and make it water soluble. Laccase which is a major enzyme of ligninolytic enzyme system, attacking mainly the phenolic groups by concomitant reduction of oxygen to water through intermediate formation of phenoxy radicals [9]. Thus both xylanases and laccases have tremendous potential for bleaching of paper pulp. Bleach boosting of different kinds of paper pulps with help of either xylanase or laccase alone have been attempted by various groups. The application of xylanase for biobleaching of kraft pulp was evaluated by different groups [10–14]. Medeiros et al. [15] had studied the performance of fungal xylan-degrading enzyme preparations in ECF bleaching of eucalyptus pulp while Roncero et al. [16] applied xylanase in TCF bleaching of wheat straw pulp. Similarly laccase preparations had also been used for bleaching by various groups [17–20]. Simultaneous action of xylanase and laccase may prove to be a promising strategy for achieving higher degree of pulp bleaching. Due to action of xylanase, lignin is exposed which will be degraded and removed simultaneously due to presence of laccases, therefore, leading into improved level of delignification.

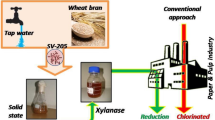

In the present work, mixed enzyme preparation consisting of xylanase and laccase was evaluated for its ability to bleach mixed wood pulp. The enzyme preparation was developed in our laboratory through co-cultivation of Penicillium oxalicum SAUE-3.510 and Pleurotus ostreatus MTCC 1804 under solid-state fermentation.

Material and Methods

Paper Pulp

The mixed wood pulp (Eucalyptus/Poplar, 60:40) corresponding to kappa number 14.1 (with 35.5% ISO brightness and viscosity 10.1 cp) obtained through kraft pulping from STAR Paper Mill, Saharanpur, (Uttar Pradesh), India. Pulp was washed, air dried, and stored in air tight polythene bags for further studies.

Production of Enzymes

The mutant P. oxalicum SAUE-3.510, developed in our laboratory through mixed mutagenesis, was used for xylanase production under solid-state fermentation condition using bagasse and black gram husk (3:1) as solid substrate. P. ostreatus MTCC 1804, used for laccase production was procured from Microbial Type Culture Collection Bank (MTCC) at Institute of Microbial Technology, Chandigarh, India. Mixed enzyme having both xylanase and laccase activities was produced by co-cultivation of P. oxalicum SAUE-3.510 and P. ostreatus using the similar solid support (bagasse and black gram husk, 3:1) under solid-state fermentation. The co-culturing was performed for 8 days followed by harvesting to obtain the mixed enzyme preparation.

Estimation of Xylanase

Xylanase was assayed by mixing the 500 μl of suitably diluted enzyme in 50 mM glycine–NaOH buffer (pH 9.0) with 0.5 ml of xylan solution (1%) in a final volume of 1 ml and incubating at 55 °C for 30 min. The reducing sugars released were measured by the dinitrosalicyclic method [21]. One unit of enzyme corresponds to 1 μmol of xylose released per minute under the assay conditions.

Estimation of Laccase

Laccase assay was performed using ABTS (2, 2′-azino-bis-(3-ethylbenz-thiazoline-6-sulphonic acid)) as substrate. Reaction was carried out by taking 50 mM Glycine–NaOH buffer at pH 9.0, enzyme extract and 1.0 mM of ABTS in a total volume of 1 ml. Reaction was monitored at 420 nm using UV-Vis spectrophotometer Cary 100 Bio (Varian Australia) at 25 °C [22].

Enzymatic Treatment of Pulp

Selection of Enzyme

The effect of enzyme (xylanase and laccase) on bleaching of mixed wood pulp was evaluated by treating the pulp with two different enzymes viz. xylanase and xylanase–laccase mixture (22:1) respectively (10 IU g−1of pulp, 55 °C, pH 9.0, 2 h). Enzymatic treatment was followed by measurement of kappa number and formation of paper pads for brightness measurement.

Derivation of Enzyme Dose

In order to find out the optimum dosage of mixed enzyme for achievement of maximum lignin removal, the pulp was treated with varying dosages of enzyme mixture ranging from 0–20 IU g−1 of pulp for 2 h.

Derivation of Treatment Time

The pulp samples were treated with derived dosage of enzyme mixture (8 IU g−1 of pulp) for varying time periods ranging from 0–5 h to obtain the suitable time for achieving maximum bleaching effects.

All the experiments were performed in triplicates using 10 g of pulp, in polythene bags at 55 °C, pH 9.0, and at 10% pulp consistency. After enzymatic treatment, pulp was washed with distilled water and the filtrate was collected for analyses. The reducing sugar released was measured by the dinitrosalicylic acid (DNS) [21], phenolic compounds generated were estimated by measuring the absorbance at λ 237 nm and release of hydrophobic compounds were determined by measuring the absorbance at λ 465 nm [23, 24].

Color Removal from the Pulp

After enzyme treatment and washing, absorbance of collected filtrate was determined spectrophotometrically from λ 200 nm to λ 400 nm to study the removal of lignin. The color of effluent is due to presence of lignin [14].

Physical and Chemical Characterization of Pulp

Following enzymatic treatment, pulp was washed and handsheets were prepared by standard test methods [25]. The effect of enzymatic treatment on the bleaching of pulp was assessed by estimating the kappa number (T236), viscosity (T230), and brightness (ISO standard 2469). Viscosity was determined by dissolving the pulp in cupriethylenediamine (CED) solution and measuring the viscosity with an Ostwald viscometer. Brightness of a handmade paper sheet was determined with an Elrepho instrument (Technobright ERIC-950, USA).

Scanning Electron Microscopy

Laboratory sheets prepared with treated and untreated pulp samples were examined with scanning electron microscope (SEM, LEO 435 VP, England) to analyze the fiber morphology following enzymatic treatment. Since cellulose is an insulator, the samples were coated with a gold film.

X-Ray Diffraction

Laboratory sheets were prepared according to standard test methods [25] and crystallinity of these sheets was measured through X-ray diffraction (XRD ) using a diffractometer (Bruker AXS D8 Adv, Germany) operated at 40 kV and 30 mA. The samples were scanned at 1° min−1 from 2θ = 5° to 50° [16].

Fourier-Transformed Infrared Spectroscopy

Lignin from treated and untreated pulp samples was extracted with methanol/tetrahydrofuran (1:1, v/v) solution in a soxhlet extractor for 3 h. Under these conditions, lignin from pulp samples was completely extracted [26]. These samples were embedded in KBr disk and subjected for fourier-transformed infrared spectra ( FTIR ) with a Perkin Elmer-1600 series spectrometer at room temperature. The assignment of absorbance peaks were based on published FTIR database for lignin [27].

High Performance Liquid Chromatography

The solubilization of lignin and carbohydrates in buffer (50 mM Glycine–NaOH, pH 9.0) during enzymatic treatment was monitored by HPLC (Waters 1500 series, Ireland). Carbohydrates were analyzed using a hydrocarbide column (4.6 × 250 mm) with RI detector and eluted with acetonitrile/water (70:30) using an injection volume of 20 μl and a runtime of 15 min. The peaks were analyzed by using xylooligomers as standard. The lignin degradation products (monophenols) were analyzed using Novo Pak C18 column at 40 °C using a mixture of acetonitrile–water–tetramethyl ammonium hydroxide-phosphoric acid (20:80:1:1) as eluent, and a UV-detector at 240 nm [28]. Prior to HPLC analysis, effluent samples were diluted 100 times with mobile phase and filtered through a 0.2 μm teflon syringe filter to remove impurities [1].

Results and Discussion

Selection of Enzyme for Biobleaching

The present work had demonstrated that an improved level of delignification may be achieved by using xylanase–laccase mixture as compared to xylanase alone. As compared to xylanase, mixed enzyme preparation proved to more effective for decreasing the kappa number and increasing the brightness. Higher decrease (≥5%) in kappa number was obtained by mixed enzyme preparation (12.7 ± 0.14) as compared to xylanase alone (13.4 ± 0.13). Similarly, brightness of the sheets when treated with mixed enzyme preparation was higher (38.3 ± 0.26 ISO) as compared to xylanase alone (37.0 ± 0.31 ISO) (Fig. 1). These observations denote that mixed enzyme preparation may be an effective alternative as compared to xylanase alone for biobleaching. This combination was used for further analysis. Synergistic action of xylanase and laccase that would have caused simultaneous dissociation and degradation of lignin into smaller phenolic compounds may have effected into better delignification of pulp. Moreover, laccase due to its size is generally not able to penetrate into the fiber wall [29], but xylanase action leads to porous cell wall and lignin therefore is exposed on surface for the action of laccase. The reaction products that are released by the xylanase (xylooligomers and xylose) may quench the radicals generated in the lignin structure by lignin modifying enzymes [9]. Thus, xylanase–laccase mixture impacts into a better delignification of pulp.

Derivation of Major Parameters for Enzymatic Biobleaching

The optimized dose of xylanase–laccase mixture for biobleaching of mixed wood pulp at 55 °C, pH 9.0 was found to 8 IU g−1 of pulp (Fig. 2a) which had led to a 12.8% decrease in the kappa number (12.2 ± 0.23). The maximum bleaching of mixed wood pulp was achieved after 3 h treatment with mixed enzyme preparation (Fig. 2b) that had resulted in a 20.7% decrease in kappa number (11.1 ± 0.44). Higher enzyme dose or longer periods of enzyme treatment did not result into any increase in the enzyme led bleaching effects (Fig. 2a, b).

After enzymatic treatment of pulp under above derived conditions, 21% reduction of kappa number, 8% increase in brightness, and 5% increase in pulp viscosity was obtained (Table 1). The release of phenolic compounds (λ 237 nm) and hydrophobic compounds (λ 465 nm) was also maximum along with an increase in release of reducing sugars at derived bleaching conditions (Fig. 2a, b). The correlation between release of chromophores (λ 237 nm), hydrophobic compounds (λ 465 nm), and reduction in kappa number coupled to the release of reducing sugars had suggested the dissociation of lignin and sugars from pulp fibers. Pulp upon pretreatment had its xylan layer degraded due to xylanase action releasing therefore the xylose and other reducing sugars. This led to the exposure of lignin for subsequent action of laccase while after degradation resulted into the release of chromophoric and phenolic compounds. Release of chromophores as well as hydrophobic compounds was maximum at the derived bleaching conditions and had become constant with increasing dose and reaction time. The release of reducing sugars, however, continued but at comparatively lower level. The later phenomenon may be due to xylanase-mediated hydrolysis of soluble xylooligosaccharides which were released due to initial depolymerization of the xylan [10, 11, 14].

Color Removal from the Pulp

Following bleaching of pulp with different doses of mixed enzyme preparation, effluents thus collected were scanned from λ 200–400 nm to detect the release of colored compounds. The peak at 280 nm in the UV spectra indicates the presence of lignin in the released color compounds and the color removal increased with the increase in enzyme dose (Fig. 3).

Effect of Enzymatic Treatment on Lignocellulosic Components

Analysis of Fiber Morphology

The fiber morphology was analyzed following enzymatic treatment of the pulp. The enzymatic treatment introduced greater porosity, swelling, separation, and peeling of pulp fibers (Fig. 4b) as compared to the smoother surface of untreated pulp (Fig. 4a). The swelling, separation, and loss in compactness in the pulp fibers render them more susceptible for chemical bleaching as it facilitates the entry of various chemicals during subsequent bleaching stages. This peeling appearance also coincides with the observations as obtained by Pham et al. [8], Torres et al. [30], and Roncero et al. [31, 32] of eucalyptus pulp bleached with xylanase. Garg et al. [10] had also observed the changes in the exterior of the fibers of birch kraft pulp treated with xylanase preparations that were free of cellulase activity. It is well known that during pulping process short xylan chains precipitated on the surface of pulp fibers act as physical barrier for the entry of bleaching chemicals in subsequent bleaching stages. The separation of this xylan leads to formation of grooves or cracks enabling the bleaching agents to penetrate more readily.

Analysis of Pulp Crystallinity

Analysis of pulp crystallinity is a significant criterion that is utilized to assess the pulp delignification during bleaching. As a result of enzymatic action, hemicellulose and lignin materials are removed, leaving high proportions of amorphous cellulose which leads to decreased pulp crystallinity [32]. The X-ray diffraction analysis of xylanase–laccase and xylanase-treated mixed wood pulp are shown in Fig. 5. The degree of pulp crystallinity was determined on the basis of peak width at half maximum. As shown in diffractograms it is maximum for xylanase–laccase-treated (XL) pulp, hence it is least crystalline.

Characterization of Lignin After Enzyme Treatment

Lignin is a three dimensional, highly branched polymer with a wide variety of functional groups providing active centers for chemical and biological interactions. Understanding the biodegradation of lignin, have significant implications in order to develop an environment friendly process for selective removal of lignin during paper-making. Much interest has focused on functional group analysis by various research groups [26, 33, 34]. The main functional groups in lignin are hydroxyl, methoxy, carbonyl, and carboxylic groups. The production of these groups depends on genetic origin and isolation process applied.

FTIR spectra xylanase–laccase and xylanase (X) treated pulp samples, showed characteristic and pronounced changes for the sample treated with mixed enzyme preparation (Fig. 6a–c). Peak at 3,400 cm−1 appeared due to presence of OH groups [35] in lignin in XL- and X-treated samples. However, intensity and peak variation was higher in XL-treated sample (Fig. 6c). Similar observations were recorded at peak intensity at 2,900 cm−1. The peak intensity at this wave number is attributed to presence of methyl/methylene (–CH) groups. A new, strong peak at 1,720 cm−1 in XL-treated pulp samples appeared while its intensity was lower in X and it was absent in the untreated pulp sample. This peak is attributed due to release of free carbonyl groups (C=O) due to action of enzyme on lignin’s aromatic ring [27]. In untreated samples these carbonyl groups remain associated with aromatic rings, hence resulted into no absorption. Besides this, more peaks generated at 1,600–1,400 cm−1 and 1,300–1,200 cm−1 wave numbers due to changes in the ratio of syringyl and guaiacol groups.

Analysis of Solubilized Products After Enzyme Treatment

The release of xylooligomers and monophenols due to degradation of xylan and lignin during enzymatic bleaching was analyzed by HPLC. Mixed enzyme preparation was more effective in degrading lignin as compared to the degradation when single enzyme preparation was used. Analysis had indicated that xylose was the major degradation product (Fig. 7a–d) and similarly catechol, syringaldazine, and other phenolic products were detected (Fig. 8a–d) under the above-defined treatment conditions. Xylanase attacks on xylan layer and degrade it into xylooligomers and eventually into monomeric sugar xylose. The disorganization of xylan layer facilitates the laccase to disorient the lignin layer and degrade the same into simpler constituents thus leading to bleaching of pulp for paper manufacture. Niku-Paavola et al. [9] had also studied the enzymatic delignification on pine kraft pulp and obtained the similar results.

Concluding Remarks

A mixed enzyme preparation developed through co-cultivation of mutant P. oxalicum SAUE-3.510 and P. ostreatus under solid-state fermentation proclaims its efficacy for biobleaching of mixed wood pulp as compared to xylanase from P. oxalicum SAUE-3.510. A synergistic action of xylanase and laccase had resulted into improved quality of pulp due to effective delignification that leads to new insights for ecofriendly bleaching technology by employing mixed enzyme preparation.

References

Barreca, A. M., Fabbrini, M., Galli, C., Gentili, P., & Ljunggren, S. (2003). Laccase/mediated oxidation of a lignin model for improved delignification procedures. Journal of Molecular Catalysis B, Enzymatic, 26, 105–110. doi:10.1016/j.molcatb.2003.08.001.

Uffen, R. L. (1997). Xylan degradation: a glimpse at Microbiol diversity. Journal of Industrial Microbiology & Biotechnology, 19, 1–6. doi:10.1038/sj.jim.2900417.

Record, E., Asther, M., Sigoillot, C., Pages, S., Punt, P. J., Haon, M., et al. (2003). Overproduction of the Aspergillus niger feruloyl esterase for pulp bleaching applications. Applied Microbiology and Biotechnology, 62, 349–355. doi:10.1007/s00253-003-1325-4.

Bajpai, P., & Bajpai, P. K. (1992). Biobleaching of kraft pulp. Proc Biochem, 27, 319–325. doi:10.1016/0032-9592(92)87009-6.

Ragauskus, A. J., Poll, K. N., & Cesternino, A. (1994). Effects of xylanase pretreatment procedures on non-chlorine bleaching. Enzyme and Microbial Technology, 16, 492–495. doi:10.1016/0141-0229(94)90019-1.

Tolan, J. S., & Guenette, M. (1997). Using enzymes in pulp bleaching: mill applications. Advances in Biochemical Engineering/Biotechnology, 157, 290–309.

Paice, M. G., Gurnagul, N., Page, D. H., & Jurasek, L. (1992). Mechanism of hemicellulose directed prebleaching of kraft pulp. Enzyme & Microbial Technology, 14, 272–276. doi:10.1016/0141-0229(92)90150-M.

Pham, P. L., Alric, I., & Delmas, M. (1995). Incorporation of xylanase in total chlorine free bleach sequences using ozone and hydrogen peroxide. Appita Journal, 48, 213–217.

Niku-Paavola, M. L., Ranua, M., Suurnakki, A., & Kantelinen, A. (1994). Effects of lignin modifying enzymes on pine kraft pulp. Bioresource Technology, 50, 73–77. doi:10.1016/0960-8524(94)90223-2.

Garg, A. P., Roberts, J. C., & Mc Carthy, A. J. (1998). Bleach boosting effect of cellulase free xylanase of Streptomyces thermoviolaceus and its comparison with two commercial enzyme prepartions on birchwood kraft pulp. Enzyme and Microbial Technology, 22, 594–598. doi:10.1016/S0141-0229(97)00250-0.

Beg, Q. K., Bhushan, B., Kapoor, M., & Hoondal, G. S. (2000). Production and characterization of thermostable xylanase and pectinase from a Streptomyces sp. QG-11–3. Journal of Industrial Microbiology & Biotechnology, 16, 211–213.

Atik, C., Imamoglu, S., & Bermek, H. (2006). Impact of xylanase pre-treatment on peroxide bleaching stage of biokraft pulp. International Biodeterioration & Biodegradation, 58, 22–26. doi:10.1016/j.ibiod.2006.04.003.

Sandrim, V. C., Rizzatti, A. C. S., Terenzi, H. F., Jorge, J. A., Milagres, A. M. F., & Polizeli, M. L. T. M. (2005). Purification and biochemical characterization of two xylanases produced by Aspergillus caespitosus and their potential for kraft pulp bleaching. Process Biochemistry, 40, 1823–1828. doi:10.1016/j.procbio.2004.06.061.

Khandeparkar, R., & Bhosle, N. B. (2007). Application of thermoalkalophilic xylanase from Arthrobacter sp. MTCC 5214 in biobleaching of kraft pulp. Bioresource Technology, 98, 897–903. doi:10.1016/j.biortech.2006.02.037.

Medeiros, R. G., Silva, F. G., Jr., Salles, B. C., Estelles, R. S., & Filho, E. X. F. (2002). The performance of fungal xylan-degrading enzyme preparations in elemental chlorine free bleaching for eucalyptus pulp. Journal of Industrial Microbiology & Biotechnology, 28, 204–206. doi:10.1038/sj.jim.7000227.

Roncero, M. B., Torres, A. L., Colom, J. F., & Vidal, T. (2003). TCF bleaching of wheat straw pulp using ozone and xylanase. Part A: paper quality assessment. Bioresource Technology, 87, 305–314. doi:10.1016/S0960-8524(02)00224-9.

Gronqvist, S., Buchert, J., Rantanen, K., Viikari, L., & Suurnakki, A. (2003). Activity of laccase on unbleached and bleached thermomechanical pulp. Enzyme & Microbial Technology, 32, 439–445. doi:10.1016/S0141-0229(02)00319-8.

Lund, M., Eriksson, M., & Felby, C. (2003). Reactivity of fungal laccase towards lignin in softwood kraft pulp. Holzforschung, 57, 21–26. doi:10.1515/HF.2003.004.

Camarero, S., Ibarra, D., Martinez, A. T., Romero, J., Gutlerrez, A., & Rio, J. C. D. (2007). Paper pulp delignification using laccase and natural mediators. Enzyme & Microbial Technology, 40, 1264–1271. doi:10.1016/j.enzmictec.2006.09.016.

Ibarra, D., Romero, J., Martinez, M. J., Martinez, A. T., & Camarero, S. (2006). Exploring the enzymatic parameters for optimal delignification of eucalyptus pulp by laccase mediator. Enzyme & Microbial Technology, 39, 1319–1327. doi:10.1016/j.enzmictec.2006.03.019.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428. doi:10.1021/ac60147a030.

de-Souza Cruz, P. B., Freer, J., Siika-aho, M., & Ferraz, A. (2004). Extraction and determination of enzyme produced by Cerriporiopsis subvermispora during biopulping of Pinus Taeda wood chips. Enzyme & Microbial Technology, 34, 228–234.

Patel, A. N., Grabski, A. C., & Jeffries, T. W. (1993). Chromophore release from kraft pulp by purified Streptomyces roseiscleroticus xylanase. Applied Microbiology & Biotechnology, 39, 405–412. doi:10.1007/BF00192102.

Gupta, S., Bhushan, B., & Hoondal, G. S. (2000). Isolation, purification and characterization of xylanase from Staphylococcus sp. SG-13 and its application in biobleaching of kraft pulp. Journal of Applied Microbiology, 88, 325–334. doi:10.1046/j.1365-2672.2000.00974.x.

TAPPI test methods. (1996). Technical association of the pulp and paper industry. Atlanta, GA: TAPPI press.

Geng, X., & Li, K. (2002). Degradation of nonphenolic lignin by the white-rot fungus Pycnoporus cinnabarinus. Applied Microbiology & Biotechnology, 60, 342–346. doi:10.1007/s00253-002-1124-3.

Buta, J. G., Zardrazil, F., & Gallettti, G. C. (1989). FT-IR determination of lignin degradation in wheat straw by white rot fungus Stropharia rugosoannulata with different oxygen concentrations. Journal of Agricultural & Food Chemistry, 37, 1382–1384. doi:10.1021/jf00089a038.

Niku-Paavola, M. L., Karhunen, E., Salola, P., & Raunio, V. (1988). Lignolytic enzymes of the white rot fungus Phlebia radiata. Journal of Biochemistry, 266, 36–43.

Goodell, B., Yamamoto, K., Jellison, J., Nakamura, M., Fujii, T., Takabe, K., et al. (1998). Laccase immunolabelling and microanalytical analysis of wood degraded by Lentinus edodes. Holzforschung, 52, 345–350.

Torres, A. L., Roncero, M. B., Colom, J. F., Pastor, F. I. J., Blanco, A., & Vidal, T. (2000). Effect of a novel enzyme on fibre morphology during ECF bleaching of oxygen delignified eucalyptus kraft pulps. Bioresource Technology, 74, 135–140. doi:10.1016/S0960-8524(99)00178-9.

Roncero, M. B., Torres, A. L., Colom, J. F., & Vidal, T. (2000). Using xylanase before oxygen delignification on TCF bleaching. Influence on fiber surfaces by SEM. Process Biochemistry, 36, 45–50. doi:10.1016/S0032-9592(00)00178-3.

Roncero, M. B., Torres, A. L., Colom, J. F., & Vidal, T. (2005). The effect of xylanase on lignocellulosic components during the bleaching of wood pulps. Bioresource Technology, 96, 21–30. doi:10.1016/j.biortech.2004.03.003.

Sealey, J., & Ragaukas, A. J. (1998). Residual lignin studies of laccase-delignified kraft pulps. Enzyme & Microbial Technology, 23, 422–426. doi:10.1016/S0141-0229(98)00056-8.

El Mansouri, N. E., & Salvado, J. (2007). Analytical methods for determining functional groups in various technical lignins. Industrial Crops & Products, 26, 116–124. doi:10.1016/j.indcrop. 2007.02.006.

Faix, O. (1992). Methods in lignin chemistry, Fourier transform infrared spectroscopy (Lin, S. Y., & Dence, C. W., ed.) (pp. 83–109). Berlin, Heidelberg: Springer.

Acknowledgements

Senior research fellowship awarded by Council of Scientific and Industrial Research, New Delhi, India to first author and national doctoral fellowship to second author by All India Council of Technical Education, New Delhi, India are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dwivedi, P., Vivekanand, V., Pareek, N. et al. Bleach Enhancement of Mixed Wood Pulp by Xylanase–Laccase Concoction Derived Through Co-culture Strategy. Appl Biochem Biotechnol 160, 255–268 (2010). https://doi.org/10.1007/s12010-009-8654-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-009-8654-4