Abstract

There is an increasing interest for the organic residues from various sectors of agriculture and industries over the past few decades. Their application in the field of fermentation technology has resulted in the production of bulk chemicals and value-added products such as amino acid, enzymes, mushroom, organic acids, single-cell protein, biologically active secondary metabolites, etc. (Ramachandran et al., Bioresource Technology 98:2000–2009, 2007). In this work, the production of extracellular xylanase by the fungus Penicillium canescens was investigated in solid-state fermentation using five agro-industrial substrates (soya oil cake, soya meal, wheat bran, whole wheat bran, and pulp beet). The best substrate was the soya oil cake. In order to optimize the production, the most effective cultivation conditions were investigated in Erlenmeyer flasks and in plastic bags with 5 and 100 g of soya oil cake, respectively. The initial moisture content, initial pH, and temperature of the culture affected the xylanase synthesis. The optimal fermentation medium was composed by soya oil cake crushed to 5 mm supplemented with 3% and 4% (w/w) of casein peptone and Na2HPO4.2H2O. After 7 days of incubation at 30 °C and under 80% of initial moisture, a xylanase production level of 18,895 ± 778 U/g (Erlenmeyer flasks) and 9,300 ± 589 U/g (plastic bags) was reached. The partially purified enzyme recovered by ammonium sulfate fractionation was completely stable at freezing and refrigeration temperatures up to 6 months and reasonably stable at room temperature for more than 3 months.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Xylan, the main type of hemicellulose, is a heterogeneous polysaccharide consisting of β-1,4-linked d-xylosyl residues on the back bone, but also contains arabinose, glucuronic acid, and arabinoglucuronic acids linked to the d-xylose back bone. Considering the complexity of the molecular structure, xylan requires two different enzyme activities for hydrolysis. These are 1/4-endo-xylanase (EC.3.2.1.8) and ¼-xylosidase (EC 3.2.1.37), which are responsible of the hydrolysis of main chain, the former attacking the internal main-chain linkages and the latter releasing xylosyl residues by endwise attack of xylooligosaccharides [2]. β-1,4-Endo-xylanase are carbohydrolases, which are used in industrial processes such as prebleaching of kraft pulp, improvement of the digestibility of animal feed, juice clarification, degumming of vegetal fibers (such as jute, ramie and hemp), and bioethanol production from lignocellulosic compounds [3–5]. Xylanases constitute the major commercial proportion of hemicellulases and have a world-wide market of around 200 millions dollars [6]. The sales trends are expected to increase owing to the fact that these enzymes have attracted increasing attention for their potential use in several new applications: coffee extraction, preparation of soluble coffee, protoplastation of plant cells, and production of alkyl glycosides for use as surfactants and washing of precision devices and semiconductors. Xylanases can be used alone or in conjunction with other enzymes and in particular with other hydrolases, but also with proteases, oxidases, isomerases, etc [7].

A variety of microorganisms, including bacteria, yeasts, and filamentous fungi have been reported to produce xylanases in submerged fermentation [3]. An alternative to this method is the use of the solid-state fermentation, which involves the growth of microorganisms on a wet solid substrate in the absence (or near absence) of free water [8]. Solid-state fermentation has gained renewed interest because of a number of economic and engineering advantages, including the simplicity of the equipment, the low moisture content, which prevents bacterial contamination, low energy consumption, minimization of the problems caused by the low gas distribution, and differential expression of metabolites [2]. For some specific processes, e.g., particular fungal enzyme production, the cost of solid-state fermentation technique is lower and the production is higher than submerged fermentation. Examples of this situation include cellulase production, which is estimated to be 100 times more economical with solid-state fermentation, and lipase production, which is 78% cheaper with solid-state fermentation. For all these economic and technical reasons, many researchers have recently focused their attention on the production of industrial enzymes and, in particular, on the reactor design, on the improvement of new solid supports [9].

The microbial production of xylanase is generally started after an induction step involving nutrient sources and cultivation condition. As the price of the substrate plays a crucial role in the overall processing cost, cheap substrates such as agro-industrial residues are used as carbonaceous sources in xylanase production [3]. Besides immobilizing the microorganisms, these supports supply the main nutrients needed for growth (mineral, vitamins, etc.). In the field of enzyme production, the soya oil cake has been slightly used contrary to wheat, corn, rice, sugar cane and beet, banana waste, potato, tea, coccus, apple and citrus fruits, wheat flours, and corn [9].

The filamentous fungus Penicillium canescens secretes a high level of xylanase (free cellulases), which gets a good potential for biobleaching of cellulose pulp [10]. The fermentation medium of P. canescens is simple in composition and not expensive, and the fermentation process can be easily upscaled. This observation makes the P. canescens strain economically and technological favorable for the production of extracellular xylanase.

This paper presents the potentialities of xylanase production by P. canescens on soya oil cake under solid-state fermentation in order to establish an economically feasible fermentative process. The experiments have been conducted in 250-ml Erlenmeyer flasks and in plastic bags to test the scale up of the process.

Materials and Methods

Carbon Sources

The agricultural substrates (soya oil cake 48, soya meal, wheat bran, whole wheat, and pulp beet) were supplied by the company (Ets Brichart S.A., Sombreffe, Belgium). Except the soya meal (whose particles size were lower than 1 mm), the other materials were chopped in a laboratory hammer mill (Gladiator, Mondelaers, Bruxelles, Belgium) to a 1-mm particle size before being used as carbon sources for xylanase production by P. canescens. The hammer mill was equipped with a 1-, 5-, and 10-mm-diameter grid.

Microorganism

P. canescens (supplied by G.I. Kvesidatse, Institute of Plant Biochemistry, Academy of Sciences, Tbilisi, Georgia) was maintained on dextrose-agar slants. The dextrose-agar media contained (percent, w/v) dextrose (0.2), yeast extract (0.2), and agar (1.2). The slants were inoculated with mycelia, incubated at 30 °C for 1 month, and were then maintained as a stock culture at 4 °C.

Inoculum

Spore suspension was used as the inoculum preparation. The spore suspension was prepared by adding 2 × 9 ml of sterile peptone saline solution (0.1% (w/v) of casein peptone, 0.5% (w/v) of NaCl, and 0.1% Tween 80) to the stock culture whose surface was gently scraped with a sterile wire loop. The spores were counted in a hemocytometer (Bürker Türk). The spore suspension was adjusted in order to obtain a spore count within the desired range.

Xylanase Production in 250-ml Erlenmeyer Flasks

Initially, 5 g of each of the individual carbon sources (soya oil cake, soya meal, wheat bran, whole wheat, and pulp beet) was chopped to 1-mm particle size, plus 25 ml of distilled water was placed in 250-ml Erlenmeyer flasks. The medium was autoclaved at 121 °C for 20 min and inoculated after cooling by 0.15 ml of the spore suspension to reach a concentration of 106 spores/g of carbon source. The fermentation was then performed at 30 °C under static conditions during 13 days. The most productive carbon source (soya oil cake) was then selected for a further 7-day study. A step by step optimization procedure with respect to supplementation in casein peptone (3% w/w, i.e., 150 mg), Na2HPO4.2H2O (4%, i.e., 200 mg), and initial growth moisture (66–90%) was employed.

The whole soya oil cake (size >10 mm) and the crushed soya oil cake (1-, 5-, 10-mm particles sizes) were used as carbon sources for xylanase production, respectively. The 5-mm soya oil cake size induced the maximal production. Twenty grams of the 5-mm soya oil cake was heated at 40 °C for 1 h in 100 ml of distilled water (or in 1–2% of sulfuric acid or NaOH solution). Afterward, the hydrolysates were removed. The treated soya oil cake was thoroughly washed three times in distilled water and dried at 37 °C for 1 h. Five grams was used for xylanase production. The fermentation medium was adjusted to neutral pH before autoclave. The xylanase production was compared to the control containing untreated 5-mm soya oil cake as carbon source. The experiments were conducted in triplicate and the mean value is selected.

Xylanase Production in Plastic Bags

The plastic bags (42 cm × 22.5 cm, 2.5 l) supplied by the company (SacO2 n.v., Rozenstraat, Eke, Belgium) contained a double line of filters (transverse and parallel pores of 1 mm of diameter), allowing gaseous exchange with the outside. The bags contained 100 g of 5-mm soya oil cake size mixed with a nutritive solution (3 g of casein peptone and 4 g of Na2HPO4.2H2O in 400 ml of distilled water). The media were sealed before autoclaving at 121 °C for 20 min. After cooling, the bags were opened. The media were aseptically shaken to obtain a bed height of 0.4 ± 0.1 cm and inoculated with 3 ml of the spore suspension to reach a concentration of 106 and 107 spores/g of soya oil cake, respectively. The plastic bags containing the medium were sealed, laid out horizontally on wooden trays in a temperature-controlled chamber at 30 °C. The process was led naturally (no control of temperature, aeration, moisture of culture inside the bag). The moisture content of the medium during fermentation was estimated by drying 15 g of sample to constant weight at 105 °C during 48 h. The experiments were conducted in triplicate, and the mean value is selected.

Enzyme Extraction and Assays

Enzyme Extraction

After the production, the fermented substrate from the flasks or the plastic bags was complemented with 75% (v/w) of distilled water. The solution obtained was centrifuged at 8,000×g for 15 min at 4 °C (Avanti™ J-25 I, Beckman, Palo Alto, USA) to remove the fermented residues. This supernatant was filtrated through a folded filter (∅ = 150 mm, 5951/2, Ref. No. 10311645, Schleilcher and Schuell, Dassel, Germany). Its pH was measured (pH-meter pH 330, Ser-Nr. 98410050, Germany). The clear supernatant was used as the enzymes extract (xylanase and protease), and its content in total extracellular protein, reducing sugars, and dextrose were assayed.

Xylanase Assay

Xylanase activity was measured according to Bailey et al. [11] using 1% birchwood xylan as substrate (X0502, EC 232-760-6, Sigma-Aldrich Chemie GmbH, Steinheim, Germany). Reducing sugars were assayed by the dinitrosalicylic acid method with xylose as standard [12]. One unit of xylanase activity is defined as the amount of enzyme releasing 1 μmol of reducing sugar equivalent to xylose per minute. Each test was done in triplicate, and the average value was validated when the variation between test values was less than 8.0%.

Protease Assay

The protease activity was measured according to Somkuti [13]. One milliliter of enzymatic extract was mixed with 4 ml of 0.5% (w/v) of Hammersten casein (Sigma) substrate in 0.05 M phosphate buffer, pH 6. The mixture was incubated at 30 °C for 30 min. The reaction was then halted by the addition of 5 ml of 5% tricholoacetic acid, after which the precipitate was removed by filtration (folded filter, ∅ = 150 mm, 5951/2, Ref. No. 10311645, Schleilcher and Schuell, Dassel, Germany). The absorbance of the filtrate was optically measured at 280 nm. One unit of protease was defined as the amount of enzyme required to liberate 1 mmol of tyrosine per minute at pH 6 and 30 °C. Each test was done in triplicate, and the average value was validated when the variation between test values was less than 8.0%.

Total Extracellular Protein Assay

The total extracellular protein was assayed with 0.1 ml of the enzymatic extract according to the method described by Smith et al. [14] using the bicinchoninic acid protein assay kit (Sigma). Bovine serum albumin (Sigma) was used as the standard for calibration. Standards and blanks were treated in the same manner. Each test was done in triplicate and the average value was evaluated. The variation between tests values was less than 8.0%.

Dextrose Assay

The dextrose assay was carried out by the sugar analyzer YSI (YSI 2700-D-Biochem, Yellow Springs Instruments CO, INC, OH, USA). Twenty five microliters of the enzymatic extract was injected into the YSI, and the concentration of dextrose (grams per liter) was automatically read.

Measurement of Reducing Sugars

The reducing sugar content of the enzymatic extract was measured by the dinitrosalicylic acid method with dextrose as standard.

Total Nitrogen Assay of the Carbon Sources

The total nitrogen content of the carbon sources was measured according to Kjeldahl method [15]. One gram of the chopped carbon source (1-mm particle size of soya oil cake, soya meal, wheat bran, whole wheat, or pulp beet) was submitted for digestion in the Kjeltec mineralizator (2020 Digestor, serial No. 399260301, Hoganas, Sweden) in the presence of a kjeltab pastille as catalyst, 10 ml of concentrated sulfuric acid, and 2 ml of hydrogen peroxide (30% w/v). The digestion was made by heating to 100, 185, 265, 335, and 440 °C for 20, 25, 20, 30, and 30 min, respectively. The resulting solutions were cooled at room temperature and diluted by adding 25 ml of distilled water. The solutions were then placed in the distillation–titration unit. Then, 50 ml of sodium hydroxide solution 50% (w/v) was automatically added, and the solutions were distilled for an additional 5 min. The ammonia collected in the receiving solution was automatically titrated by a mixture (sulfuric acid solution H2SO4 0.1 N in the presence of Tashiro mixture as indicator) until a colorimetric end point was detected. Glycine standard was used to check the concentration of the titrating solution. Blanks were treated in the same manner. Each test was done in triplicate, and the average value was evaluated. The nitrogen content was calculated by the following relation (1 ml H2SO4 = 1.4 mg nitrogen).

Storage Stability of the Partially Purified Xylanase

The crude xylanase was precipitated by 60% ammonium sulfate saturation with constant stirring at 4 °C for one night. The precipitate was recovered by centrifugation at 10,000×g for 15 min. The enzyme solution was desalted by dialysis for 24 h at 4 °C against 0.05 M citrate buffer, pH 6. The xylanase activity and protein estimation were carried out.

The storage stability of the partially purified xylanase was studied by keeping the enzyme solution in deep freeze (−20 °C), refrigeration (4 °C), and room temperature (27 °C), respectively, for 6 months. The enzyme solution was stored in sterile Eppendorf vials. Xylanase activity was assayed at regular intervals.

Results and Discussion

Optimization of Xylanase Production by P. canescens in 250-ml Erlenmeyer Flasks

Selection of Suitable Carbon Source and Optimal Duration of the Fermentation

Four agro-industrial substrates (soya oil cake, wheat bran, whole wheat, and pulp beet) chopped to 1-mm particle size and the soya meal (size <1 mm) were evaluated in flasks as potential inducers for xylanase production by P. canescens. Among them, the soya oil cake was found to be the most effective (Table 1). Maximum xylanase production (6,684 ± 334 U/g) was achieved after 7 days of cultivation with soya oil cake. Soya meal was also found to be a good substrate, which yielded 4,730 ± 206 U/g after 11 days of incubation. The soya meal was previously identified as being ideally suited for xylanase production by P. canescens [16] and by Bacillus pumilus [4].

With wheat bran and whole wheat, the xylanase synthesis appeared only at day 5. The xylanase level yielded 2,355 ± 121 U/g in 9 days for the wheat bran and 185 ± 9 U/g in 13 days for the whole wheat. With pulp beet, the weakest xylanase synthesis (212 ± 8 U/g) appeared at day 13. The variations of the xylanase production observed for these various substrates were probably related to the differences in their composition and their degree of degradability, including the presence of some additional nutrients in the carbon sources [17]. The nitrogen content N or protein N × 6.25 of these five substrates would be the prevalent factor in the induction of the xylanase production by P. canescens. The total nitrogen content of the substrates was measured by Kjeldahl method. The soya oil cake 48 and soya meal constitutes an important source of nitrogen (about 7%). The other substrates have a relatively low content in nitrogen (Table 2). In addition to proteins (42.5–45.8%, w/w), the soya oil cake 48 is an excellent source of energy (4,180 kcal/kg). This substrate showed a rich amino-acid profile with tryptophan (0.57–0.62%), threonine (1.67–1.79%), lysine (2.70–2.90%), and methionine-cystein (1.27–1.37%). The soya oil cake 48 contains also cellulose (5.6–7.4%) and minerals such as calcium (0.3%) and phosphor (0.69%), which are required for initiation of growth and propagation of the microorganism [18].

The reducing sugar content in the enzymatic extracts issued from the soya oil cake (49.4 ± 5.7 mg/g) and the soya meal (58.9 ± 7.9 mg/g) is relatively low at the beginning of the culture and only slightly increased during fermentation (Fig. 1a). At day 13, the highest values of reducing sugars (70.3 ± 6.6 and 184.25 ± 17.17 mg/g in the extract issued from the soya oil cake and the soya meal, respectively) appeared. However, the reducing sugar content in the enzymatic extracts from the pulp beet, whole wheat, and wheat bran first increased and then drastically decreased. The highest values observed were 996.4 ± 46 mg/g (for the extract issued from pulp beet at day 7), 939 ± 7.9 mg/g (for the extract issued from whole wheat at day 9), and 471.05 ± 38.8 mg/g (for the extract issued from wheat bran at day 3). The drop of the reducing sugar content in the pulp beet, whole wheat, and wheat bran can be attributed to consumption by the Penicillium strain. From our experiments, oil cakes are ideally suited nutrient support in solid-state fermentation, rendering both carbon and nitrogen sources. Oil cakes have been previously reported to be a good substrate for fungal enzyme production [1]. The soya oil cake 48 and the duration of 7 days will be used for further studies. The enzyme production could be further enhanced by optimization of physiological and biological conditions [10].

Profile of a reducing sugar content (milligrams per gram carbon source) and b dextrose content (milligrams per gram of carbon source) in the enzymatic extract during xylanase production at 30 °C. The fermentation medium contained 5 g of 1 mm carbon source plus 25 ml of distilled water and 106 spores/g of soya oil cake as inoculum. The experiments were conducted in triplicate and the average value was selected. Vertical errors bars represent standard deviation. Soya meal (open triangle), pulp beet (open rhombus), soya oil cake (closed triangle), wheat bran (closed square), whole wheat (closed rhombus)

Dextrose is the main carbon catabolic repressor of the xylanases synthesis by the Penicillia strains [19, 20] and the general repressor of the enzymes synthesized by P. canescens [21]. The dextrose content of the enzyme source issued from the soya oil cake and the soya meal was relatively weak (0.86 ± 0.04 and 1 ± 0.06 mg/g) at the beginning of the fermentation, but reached 1.6 ± 0.09 and 4.06 ± 0.25 mg/g at day 13 (Fig. 1b). In the enzyme source issued from the pulp beet, the dextrose content is relatively high before the beginning of the fermentation (7.48 ± 0.43 mg/g) and then decreased during fermentation to reach 1.38 ± 0.06 mg/g after 13 days. From this result and those already reported [21], it is strongly possible that the xylanase synthesis on the pulp beet appeared after the consumption of dextrose by the Penicillium strain. In the wheat bran, the dextrose content was first increased until day 7 (to reach 6.9 ± 0.36 mg/mg) and then decreased (to reach 2.26 ± 0.07 mg/mg at day 13). In the whole wheat, the dextrose content increased until day 13 to reach 18.28 ± 0.98 mg/g. The slow release of dextrose from the soya oil cake could also explain the better xylanase yield obtained with this substrate.

The pH of the enzyme source was measured during the fermentation and shows a tendency to increase during the solid-state fermentation. The pH variation was caused by the microorganism’s metabolic activity and may change according to the specific metabolic route. The pH increase may be caused by organic acid consumption such as citric, acetic, and lactic, or the release of ammonium salts resulting from the hydrolysis of protein and urea [2]. The soya meal and the soya oil cake induced a relative neutral pH, which seems to be very favorable for the xylanase production. However, the pH of the enzyme source issued from the whole wheat (less than 6), wheat bran (between 5 and 6), and the pulp beet (less than 5) was relatively low.

The extracellular protein (micrograms per milligram of carbon source) varied according to the nature of the substrate and the time of incubation. There was a regular increase in the content of extracellular protein for all the substrates. Better extracellular protein (109 ± 4.8 and 116 ± 4.14 μg/mg) was obtained with soya oil cake and soya meal after 7 and 11 days of fermentation, respectively. This can be explained by the high protein content of these two substrates.

Influence of Additives on Xylanase Production

The influence of various additives such mineral salts or pure sugars on xylanase production by P. canescens have been previously tested. The supplementation of low concentration of phosphorus Na2HPO4.2H2O (at 4%, w/w) was enhanced by 36% of the xylanase production [22]. In the same way, additional organic nitrogen source such as casein peptone (at 3%), in the substrate enhanced P. canescens growth and xylanase production by more than 25% (Fig. 2). This result is in accordance with those already reported by Gaspar et al. and Bakri et al. [16, 23]. Thus, in submerged fermentation, the supplementation in yeast extract (0.5% w/v) induced sevenfold more xylanase production by P. canescens. On wheat straw, the supplementation in yeast extract or casein peptone enhanced the xylanase production. The combination of the two organic nitrogen sources (yeast extract and casein peptone) caused the optimal xylanase production [23]. Organic nitrogen sources contain elements (vitamins, amino acids…) that are necessary for the excretion of xylanase by P. canescens [23].

Effect of supplementation in casein peptone on xylanase production at 30 °C. The fermentation medium contained 5 g of 1 mm soya oil cake size, 0% or 3% (w/w) of casein peptone, 25 ml of distilled water, and 106 spores/g of soya oil cake as inoculum. Without casein peptone (open triangle), with 3% casein peptone (closed triangle)

In the present work, the combination of 3% casein peptone and 4% source of phosphorus di sodic Na2HPO4.2H2O to the 5 g of soya oil cake has the potential to neutralize the fermentation medium. In this condition (the initial fermentation pH was 7.01 ± 0.2), 9,670 ± 298 U/g of xylanase was produced. A modification of the initial pH to 5, 6, 7.5, or 8 (by adjusting with a solution of NaOH 1% or HCl 37%) reduced the xylanase production to 6,440 ± 278, 7,427 ± 376, 6,786 ± 279, and 7,640 ± 521 U/g, respectively. Xylanase of P. canescens exhibits a pH-dependent behavior with an optimal stability at neutral pH [24]. In general, all the xylanases from the genus Penicillium are tightly regulated by the pH, expressing their transcripts at neutral pH only [20]. Similar reports were done during xylanase synthesis by Thermomyces lanuginosus in solid-state fermentation [25].

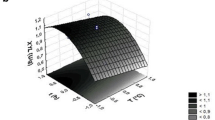

Influence of Incubation Temperature and Moisture Content on Xylanase Production

The environmental physicochemical parameters such as the incubation temperature and the moisture content are of primary importance in solid-state fermentation. These parameters affect dramatically the enzyme production by modulating the growth of the microorganism [26]. Among the three temperatures (23, 30, and at 37 °C) investigated, the optimal temperature for xylanase biosynthesis by P. canescens was 30 °C [22].

The influence of the initial moisture content was assayed in the range of 66–90%. The maximum xylanase production (10,045 ± 535 U/g) was reached with 80% initial moisture content, followed by 75% (7,685 ± 492 U/g), 83% (7,507 ± 300 U/g), 86% (7,124 ± 430 U/g), 66% (6,972 ± 244 U/g), and 90% (5,574 ± 112 U/g). Thus, initial moisture content higher or lower than 80% is detrimental to the microbial growth and, subsequently, to xylanase production. Low moisture content in solid-state fermentation decreased the metabolic and enzymatic activity owing to the reduction of the solubility of nutrients. A level of moisture higher than the optimum causes a decrease in porosity, an alteration in substrate particle structure, a gummy texture, a lower oxygen transfer, and an enhancement of the formation of aerial mycelia [8, 27].

Impact of Several Pre-treatment of Soya Oil Cake on Xylanase Production

In order to optimize the surface/volume ratio, which is necessary for the accessibility of the substrate by the Penicillium strain, the diffusion of oxygen, heat, and exo-enzymes, the crushed soya oil cake (sizes of 1, 5, 10 mm) and the whole soya oil cake (size >10 mm) were employed as carbonaceous substrates. The results indicated that the micronization (1 mm size) or the macronisation (size >5 mm) of the soya oil cake had a negative effect on xylanase production. Soya oil cake with a mean size of 5 mm (18,895 ± 778 U/g) for xylanase production was better, followed by 10 mm size (15,892 ± 802 U/g), whole soya oil cake (14,485 ± 1,090 U/g), and 1 mm size (11,496 ± 981 U/g). The micronization of the soya oil cake induces agglomeration and settling of the solid substrate, leading to a reduction of the global transfer phenomena inside the substrate. However, the macronisation, while providing a better aeration efficiency (due to increased interparticle space), may result in poor accessibility of the nutrients and limited surface for microbial spreading.

In front of these results, an optimal fermentation medium (5 g of 5 mm soya oil cake, 20 ml of distilled water, 3% and 4% of casein peptone and Na2HPO4.2H2O, respectively) was formulated with the following parameters: temperature of 30 °C and 7 days cultivation.

The 5 mm soya oil cake was subjected to hot distilled water, acid, and alkali treatments before being used as carbonaceous substrates. Heat treatment did not affect xylanase production, whereas the other treatments significantly reduced xylanase production. Reduction was more important, i.e., 77% and 87% in the case of the acid treatment and 27% and 42% in the alkali treatment. Such negative effects of agro-industrial substrates treatments on xylanase production have been reported in other studies. With wheat straw, alkali treatment caused a reduction in xylanase production by Aspergillus ochraceus [28]. These treatments led to the repression in xylanase synthesis due to a rapid consumption of the substrate, concurrent release of monomeric sugars, structural denaturation of the substrate, and removal of the major part of the hemicelluloses from the substrates [23, 28].

Scaling Up of the Xylanase Production

Plastic bags are often used as bioreactors in solid-state fermentation processes [29, 30]. For the purpose of scaling up, the fermentation was carried out in static conditions with autoclavable plastic bags (42 cm × 22.5 cm, 2.5 l). The temperature and moisture content of the medium were difficult to control throughout the whole fermentation process. To avoid important change at the level of the transfer characteristics (heat and oxygen), the depth of the culture medium (0.4 ± 0.1 cm) was identical to that used for the experiments carried out in flask. The fermentation was led with a charge of 100 g of soya oil cake in plastic bags, 80% of initial moisture content, 3% and 4% of casein peptone and Na2HPO4.2H2O, respectively. With an inoculum of 106 spores/g, the growth of the Penicillium strain was slow. After 7 days, the xylanase production reached a level of 6,938 ± 786 U/g. A part of the mycelia in the medium were dead or inactivated, causing an incomplete colonization of the medium. The water content of the medium (74 ± 3%) remained constant during fermentation. In order to overcome the problems associated with the cellular mortality, an inoculum of 107 spores/g was tried. In these conditions, the Penicillium strain colonized the whole medium, and the xylanase production reached 9,300 ± 589 U/g after 7 days. Comparing the maximal xylanase levels obtained in Erlenmeyer flasks (18,895 ± 778 U/g) and plastic bags (9,300 ± 589 U/g), it was found that the latter afforded 20 times more fermentation medium (100 g of soya oil cake) than in Erlenmeyer flasks (5 g of soya oil cake). The process may have the potential to be scaled up. In similar natural conditions, the xylanase level was comparable to the maximal produced xylanase (10,200 U/g) for a multi-layer packed bed reactor culturing by P. canescens [31]. Many problems occur in solid-state fermentation when the scale of the process increases. Notably, the transfer phenomena are strongly affected by the scale of the process. In our case, the oxygen transfer inside the plastic bags is expected to be very low. In order to improve the oxygen transfer effectively, maybe it would be interesting, for example, to supplement to the plastic bags a softened forced aeration (low and intermittent humidified air flow rate). Such system was tried during solid-state fermentation process developed for γ-linoleic acid production with Thamnidium elegans on apple pomace [30].

Storage Stability of the Partially Purified Xylanase

For industrial applications, storage of the enzymes without appreciable loss of activity is one of the key factors [28]. The production of protease affects the storage of the enzyme, which can be rectified by using proteolytic inhibitors or by using a protein purification method [32]. Ammonium sulfate fractionation (60% saturation) of crude xylanase yielded 80% of recovery of the enzyme with 1.39-fold purification. For 3 months, the partially purified xylanase retained its full activity at room temperature (27 °C), refrigerated temperature (4 °C), and deep freeze temperature (−20 °C). After 6 months, the enzyme still retained full activity at refrigerated and at deep freeze temperatures, while a loss (8–10%) was obtained at 27 °C. In another study, Aspergillus foetidus xylanase lost 5–10% of its activity at room and refrigeration temperatures after 1 and 4 weeks [28].

The decrease of the enzymatic activities during the storage is mainly attributed to the presence of proteolytic enzymes [4, 28]. P. canescens secretes only trace amounts of proteases, decreasing the occurrence of proteolysis [24]. Thus, P. canescens xylanase can be interesting for some applications, i.e., in bread making, since protease liquefies the dough [16]. Thus, in spite of its great content in protein, the enzymatic extract issued from the soya oil cake fermented medium contained only 9.74 ± 0.99 U/g of proteolytic activity. These results clearly indicate that suitable storage of the enzyme would be relatively easy.

Conclusion

Oil cakes have been widely used as a substrate for the production of fungal industrial enzymes, antibiotics, biopesticides, vitamins, and other biochemicals. The present work has established for the first time the feasibility of using soya oil cake 48, rich in nitrogen, as a substrate for xylanase production by P. canescens in solid-state fermentation. This substrate dominates the oil cake market, and its share of production is projected to rise an increase of 66% by 2010 [1]. The composition of the medium and the environmental parameters (neutral pH and 80% moisture content) were shown to be very important for the production. In previous works, wheat straw + 8% (w/w) of xylan induced a xylanase production of 9,632 U/g after 12 days [23]. In this work, the duration of the process was 7 days. The production cost was low because the process requires only supplementation of 3% casein peptone and 4% of Na2HPO4.2H2O. The study demonstrated the importance of the soya oil cake size since particle size of 5 mm enhanced the production. The storage stability of the enzyme was relatively good at room temperature (27 °C), refrigerated temperature (4 °C), and deep freeze temperature (−20 °C) for up to 6 months. The high level of xylanase (18,895 ± 778 U/g) obtained in cost-effective conditions and the good storage stability of the enzyme show the commercial potentialities of the P. canescens xylanase. To increase the scale of the process, tests were carried out with plastic bags containing 100 g of soya oil cake (depth culture medium of 0.4 ± 0.1 cm). A relatively good xylanase production of 9,300 ± 589 U/g was reached. In front of these results, the soya oil cake 48 is a suitable substrate for xylanase production by P. canescens.

References

Ramachandran, S., Sudheer, K. S., Christian, L., Carlos, R. S., & Ashok, P. (2007). Bioresource Technology, 98, 2000–2009. doi:10.1016/j.biortech.2006.08.002.

Leite, R. S. R., Daniela, A. B., Eduardo, D. S. M., Dênis, S., Eleni, G., & Roberto, S. (2007). Applied Biochemistry and Biotechnology, 136–140, 281–288. doi:10.1007/s12010-007-9058-y.

Ximenes, E. A., Bruce, S. D., Michael, R. L., Nathan, M., Michael, A. C., & Xin, L. (2007). Applied Biochemistry and Biotechnology, 136–140, 171–183. doi:10.1007/s12010-007-9049-z.

Asha, C. P., & Prema, P. (2007). Bioresource Technology, 98, 485–490. doi:10.1016/j.biortech.2006.02.033.

Karin, Ö., Vehmaanperä, J., Siika-Aho, M., Galbe, M., Viikari, M., & Zacchi, G. (2007). Enzyme and Microbial Technology, 40, 607–613. doi:10.1016/j.enzmictec.2006.05.014.

Katapodis, P., Vassiliki, C., Dimitris, K., & Paul, C. (2007). Biochemical Engineering Journal, 35, 136–141. doi:10.1016/j.bej.2007.01.007.

Collins, T., Charles, G., & Georges, F. (2005). FEMS Microbiology Reviews, 29, 3–23. doi:10.1016/j.femsre.2004.06.005.

Rodrigues, T. H. S., Alcilene, M. A. D., Gustavo, A. S. P., & Luciana, R. B. G. (2007). Applied Biochemistry and Biotechnology, 136–140, 675–687. doi:10.1007/s12010-007-9088-5.

Botella, C., de Ory, I., Webb, C., Cantero, D., & Blandino, A. (2005). Biochemical Engineering Journal, 26, 100–106. doi:10.1016/j.bej.2005.04.020.

Sinitsyna, O. A., Bukhtoyarov, F. E., Gusakov, A. V., Okunev, O. N., Serebryany, V. A., Vavilova, E. A., et al. (2003). Biochem, 68(12), 1313–1319.

Bailey, M. J., Biely, P., & Poutanen, K. (1992). Journal of Biotechnology, 23, 257–270. doi:10.1016/0168-1656(92)90074-J.

Miller, G. L. (1959). Analytical Chemistry, 31, 426–428. doi:10.1021/ac60147a030.

Somkuti, G. A. (1974). Journal of Dairy Science, 57(8), 898–899.

Smith, P. K., Krohn, R. I., Hermanson, G. T., Mallia, A. K., Gartner, F. H., Provenzano, M. D., et al. (1985). Analytical Biochemistry, 150, 70–85. doi:10.1016/0003-2697(85)90442-7.

Alejandro, M., Roser, R., Ramon, C., & Isidre, C. (2002). Talanta, 57, 1019–1026. doi:10.1016/S0039-9140(02)00136-4.

Gaspar, A., Cosson, T., Roques, C., & Thonart, P. H. (1997). Applied Biochemistry and Biotechnology, 67, 45–58. doi:10.1007/BF02787840.

Yang, S. Q., Yan, Q. J., Jiang, Z. Q., Li, L. T., Tian, H. M., & Wang, Y. Z. (2006). Bioresearch Technology, 97(15), 1794–1800.

Dawance, J. P. (1990). Engineer thesis, Gembloux Agricultural University, Belgium.

Chávez, R., Schachter, K., Navarro, C., Peirano, A., Bull, P., & Eyzaguirre, J. (2004). Biological Research, 37, 107–113.

Renato, C., Paulina, B., & Jaime, E. (2006). Journal of Biotechnology, 123(4), 413–433. doi:10.1016/j.jbiotec.2005.12.036.

Nikolaev, I. V., & Vinetski, Y. P. (1998). Biochemistry, 63(11), 1294–1298.

Assamoi, A. A., Delvigne, F., Aldric, J.-M., Destain, J., & Thonart, P. (2008). Biotechnology Agron. Soc. Environ, 12(2), 111–118.

Yasser, B., Philippe, J., & Thonart, P. (2003). Applied Biochemistry and Biotechnology, 105–108, 737–747.

Sinitsyna, O. A., Bukhtoyarov, F. E., Gusakov, A. V., Okunev, O. N., Bekkarevitch, A. O., Vinetsky, Y. P., et al. (2003). Biochemistry, 68(11), 1200–1209.

Lew, C., Sadhvir, B., Suren, S., Judit, S., & George, S. (2005). Process Biochem, 40, 3230–3235. doi:10.1016/j.procbio.2005.03.027.

Xiros, C., Evangelos, T., Petros, K., & Paul, C. (2008). Ind. Crops Prod., 28(2), 213–224.

Panagiotou, G., Granouillet, P., & Olsson, L. (2006). Applied Microbiology and Biotechnology, 72, 1117–1124. doi:10.1007/s00253-006-0394-6.

Amita, R. S., & Datta, M. (2005). Process Biochem, 40, 1763–1771. doi:10.1016/j.procbio.2004.06.041.

Viccini, G., Michael, M., Deise, M. F. C., Rosa, V.-S., & David, A. M. (2007). Process Biochem, 42, 275–278. doi:10.1016/j.procbio.2006.07.006.

Miroslav, S., Elena, C., Silvia, S., & Flavio, Z. (2000). Bioresource Technology, 73, 41–45. doi:10.1016/S0960-8524(99)00132-7.

Assamoi, A. A., Destain, J., Delvigne, F., & Thonart, P. (2008). Applied Biochemistry and Biotechnology, 145, 83–99. doi:10.1007/s12010-007-8077-z.

Poorna, C. A., & Prema, P. (2006). Biochemical Engineering Journal, 32, 106–112. doi:10.1016/j.bej.2006.09.016.

Acknowledgments

We are very grateful to Frank Delvigne (unite de Bio-Industries) for his helpful assistance during the revision of this manuscript. We also thank the Government of Côte d’Ivoire for financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Antoine, A.A., Jacqueline, D. & Thonart, P. Xylanase Production by Penicillium canescens on Soya Oil Cake in Solid-State Fermentation. Appl Biochem Biotechnol 160, 50–62 (2010). https://doi.org/10.1007/s12010-008-8496-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8496-5