Abstract

Kefir grains originate from the Caucasus region and are used for preparing beverages using sugar solution, milk, and fruit juice. As long as they are formed by a microbial consortium useful in the intestine, the produced drinks can be called probiotics. The aim of this study was to determine the antimicrobial activity during kefir fermentation in sugar broth. Fermentations with three kinds of carbohydrates (molasses, demerara sugar, and brown sugar) as carbon source were carried out. Brown sugar promoted the greatest antimicrobial activities, producing inhibition halos corresponding to 35, 14, 12, 14, and 14 mm for Candida albicans, Salmonella typhi, Shigella sonnei, Staphylococcus aureus, and Escherichia coli, respectively. Different carbon source concentrations and the time of fermentation influenced the size of the inhibition halos of the pathogenic microorganisms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Kefir is a natural mixed culture used for centuries in the Caucasus Mountains of Russia, which lie between the Black Sea and the Caspian Sea. It is a self-carbonated and slightly refreshing beverage that can be made with fruit juice, molasses, sugar, and any kind of milk such as cow, goat, sheep, camel, buffalo, or soy milk [1, 2]. The fermentation is initiated by white or yellow grains resembling cooked rice or small cauliflower heads. The grains are insoluble in water, gelatinous and with irregular size, and tend to precipitate at the bottom of the fermentation broth [3, 4]. These grains are composed of a matrix of different exopolysaccharides, denominated kefiran [5, 6]. The size of kefir grains ranges between 0.3 and 3.5 cm in diameter, and its chemical composition is (% w/w): water (89–90), lipids (0.2), proteins (3.0), sugar (6.0), and ash (0.7) [7]. These grains can be persevered by freezing, lyophilization, and refrigeration.

Kefir beverage differs from other fermented ones as it is not the result of the metabolic activity of a single species but is made from kefir grains, which are composed of various microorganisms. In kefir grains, there is a symbiotic association of microorganisms belonging to a diverse spectrum of species and genera including lactic acid bacteria (Lactobacillus, Lactococcus, and Leuconostoc), yeast (Kluyveromyces, Candida, Saccharomyces, and Pichia), and sometimes acetic acid bacteria (Acetobacter) [8, 9]. The presence of Torulaspora, Torula, and Debaryomyces in kefir grains has also been reported [4, 10].

The microbes in kefir grains are able to produce lactic acid, acetic acid, ethanol, peptides (bacteriocins), and other biologically active components that increase the storage capability of milk and inhibit the growth of undesirable and pathogenic microbes [9]. There are data to show that many lactobacilli are capable of producing a wide range of antimicrobial compounds that may be used in the treatment and prevention of vaginal infections [11].

The behavior of three selected food-borne pathogens, Escherichia coli, Listeria monocytogenes, and Yersinia enterocolitica, was monitored after being added to fermented and pasteurized kefir. The microorganism concentration increased in 1-day-fermented kefir, but only E. coli increased in 2-day-fermented kefir during fermentation. Y. enterocolitica was the most susceptible strain that was present in 1-day-fermented kefir for at least 14 days [12]. Lactic acid bacteria, also present in the kefir consortium, are known to produce antimicrobial compounds such as bacteriocins. This microorganism showed good antimicrobial activity against the Gram-positive microorganisms Bacillus cereus, Staphylococcus aureus, and L. monocytogenes as well as the Gram-negative microorganisms Pseudomonas aeruginosa, Vibrio parahaemolyticus, and Aeromonas hydrophila [13]. Other authors produced bacteriocins with bacilli homo-fermentative, catalase negative and microaerophilic in nature, with the antimicrobial compound showing a broad inhibitory spectrum against L. dyacetilactis and B. cereus [14].

Some studies refer to kefir’s antimicrobial activity and suggest that the probiotic might influence the gastrointestinal disorders of humans, such as with ulcers and diarrhea [14]. Supposedly, some inhibitory compounds of the kefir beverage, such as bacteriocins, hydrogen peroxide, and organic acids might be responsible for killing pathogenic microorganisms. In addition, kefir might also promote competitive adhesion to the gastrointestinal epithelium surface [15]. Lactobacillus isolated from kefir showed antimicrobial activity against Enterobacteria and verified that ingestion of kefir specifically lowered microbial populations of Enterbacteriaceae and Clostridia [1].

The northeast of Brazil has the largest infant mortality rate of the country (in 2005, there were 31.5 deaths/1,000 births, and the forecast for 2008 is 26.4 deaths/1,000 births) [16]. The Community Organization Pastoral da Criança distributes kefir grains to mothers with children affected with gastrointestinal diseases and recommends the addition of approximately 1.2 g of kefir grains in aqueous brown sugar solution (10 g/l), giving the children the fermented broth 24 h later. The Brazilian northeast region has a strong alcohol–sugar cane industry. Products and by-products of this industry are readily available in the regional market. In the sugarcane-to-sugar process, molasses can be obtained, which is a thick by-product containing 46.0% sugar, 3.0% protein, 65.0% nitrogen-free extract, and 8.1% ash [17]. In the sugar production process, mainly during the extraction and refining steps, clarifier, de-surfactant, precipitator, and preservatives are added, which remain after the refining step. Brown sugar is a sucrose sugar product with a distinctive brown color due to the presence of 3.5% molasses (light brown sugar) and up to 6.5% molasses (dark brown sugar). Opposite to refined sugar, brown sugar has no refining step in the processing [18]. Demerara sugar is an intermediate sugar between refined and brown sugar. This sugar is a partially refined soft sugar consisting of sugar crystals with some residual molasses or produced by the addition of molasses to refined white sugar.

The price of brown sugar in the local market is $2.98 per kilogram; however, demerara sugar and molasses cost $1.49 and $0.60 per kilogram, respectively. Kefir grows better in sugar with no or limited refining step. The goal of this study was to analyze the antimicrobial activity of kefir grains in the same conditions recommended by the Community Organization Pastoral da Criança in different kinds and concentrations of sugar in order to combat pathogenic microorganisms that cause gastrointestinal disorders and buccal candidiasis.

Materials and Methods

Kefir Culture

The kefir grains used in this study, obtained from the Community Organization Pastoral da Criança in Aracaju, Sergipe, Brazil were maintained at the Laboratory of Bioprocess Engineering from the Institute of Science and Technology in Aracaju, Sergipe, Brazil. Kefir grains were grown at room temperature in a brown sugar solution (10 g/l). The solution was sterilized at 121 °C for 15 min.

Fermentation Process

The kefir grains were cultivated in 250-ml Erlenmeyer flasks containing 200 ml of different sugar solutions (10 g/l) of brown sugar, demerara, and molasses, as well as in pH 6.0 (adjusted to 5.0 using HCl 0.1 M and NaOH 0.1 M) and at room temperature. Subsequently, the fermentation procedures were repeated using brown sugar and molasses concentrations (2, 5, 8, 10, 12, and 15 g/l). An initial amount of 1.2 g (0.12 g on dry weight bases) of kefir grains (0.38 ± 0.10 mm) was inoculated in each flask.

Assays

The pH value was determined using a digital pH meter. Biomass was assayed for moisture content by drying at 105 °C until constant weight. Reducing and non-reducing sugar were determined by the Lane–Eynon methods. All determinations were performed in triplicate (the standard deviations were <0.2) [19].

Antimicrobial Activity

When fermentation reached the desired endpoint, the broths were used to determine the antimicrobial activity. Ketoconazole (50 μg/ml) and Chloramphenicol (30 μg/ml) were used as antimicrobial compounds for fungi and bacteria (control), respectively. They were chosen based on their availability at the Centers of Basic Assistance in Health of the Brazilian Public Health System. The target microorganisms, E. coli (CCT-0355), S. typhi (CCT-1511), Staphylococcos aureus (ATCC-6533), Shigella sonnei (CCT-1484), and C. albicans (ATCC-76645) were grown in Bushell–Hass medium (composition, g/L: MgSO4, 0.2; CaCl2, 0.02; KH2PO4, 1.0; (NH4)2HPO4, 1.0; KNO3, 1.0; and FeCl3, 0.05) until a similar optical density of 0.5 (MacFallen scale). Suspensions (1 ml) of these target microorganisms were uniformly spread on the plates (Müller–Hinton medium and Sabouraud medium for bacteria and fungi, respectively), and wells of 6 mm in diameter were formed with a sterile glass tube by means of a vacuum pump. Samples of fermented broth (50 μl) were then transferred into the wells in the agar plates previously inoculated with the target microorganisms. The plates were then incubated at 37 °C. The diameter of inhibition halo was measured after 24–48 h [20]. All determinations were performed in triplicate (the standard deviations were <1.5).

Results and Discussion

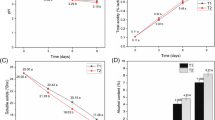

During the fermentation process, a gradual increase in the acidification broth from pH 6.91 to 2.12 was observed for all sugars used in this investigation (Fig. 1). Some authors have also verified a decrease of pH after 18 h of fermentation when kefir lyophilized grains were used, even though the minor pH value had been 4.88 [9]. Other authors utilized kefir grains (2.50 g/l) in sugar cane broth (12% w/v)-to-ethanol production and demonstrated that the pH changed from an initial 4.95 to 4.48 after 7 days of fermentation [21]. The acidity increase was due to the conversion of the carbohydrates to alcohol (action of yeasts of the consortium) and to the subsequent formation of organic acids, such as acetic acid (action of bacteria of the consortium).

The non-reducing sugar was probably converted enzimatically to reducing sugar, and this carbohydrate concentration increased until the end of fermentation. Each sugar substrate was assessed by the determination of the produced biomass and residual sugar (reducing and non-reducing sugar) at the end of fermentation, and the by-product as acetic and lactic acid (checked by monitoring the value of pH). It was observed that the conversion of initial sugar in these products and by-products was 11.06%, 28.19%, and 77.04% for demerara sugar, brown sugar, and molasses, respectively. However, the biomass yield had an opposite evolution of 0.58, 0.27, and 0.15 g/g, respectively. The pH value, at the end of fermentation, was 2.12, 2.79, and 3.28 g/g for demerara sugar, brown sugar, and molasses, respectively. Conversion of sucrose and glucose mixtures using kefir grains were above 98.7%, and the biomass yield was between 0.43 and 0.65 g/g [2]. The residual sugar at the end of fermentation was due to the possible inhibitory effects of the fermentation by-products (alcohols and acids, amongst others), the presence of unfermented sugar, the sugar refining step, or other nutrient starvation, since the media used in this study had the same composition with that recommended by the Community Organization Pastoral da Criança, containing only sugar. This finding corroborates the data found in literature [18].

Table 1 shows the action of fermentation broth on different pathogenic microorganisms, which were used as target microorganisms (E. coli, S. sonei, and S. thyphi) and are known to promote gastrointestinal disorders like diarrhea. This disease is still the most prevalent and important public health problem in developing countries despite advances in knowledge, understanding, and management that have developed during recent years [22]. Usually, the problem is associated with the ingestion of food contaminated with infectious or toxigenic microorganisms (S. aureus and S. sonei) and is a major cause of morbidity and a serious cause of death throughout the world [23, 24]. The yeast C. albicans is present in the human buccal cavity of children. The interaction of this microorganism with mucosal cells is believed to be one of the critical initial events in the development of candidiasis [25, 26]. In this research, the effect of type and sugar concentration on antimicrobial activity, using the target microorganisms cited, was investigated. It was observed that the largest amount of pathogenic microorganisms was inhibited in the fermentation broth of brown sugar after 144 h. The inhibition halo zones for C. albicans, S. typhi, S. sonnei, E. coli, and S. aureus were 28, 12, 12, 12, and 14 mm, respectively, as shown in Table 1. Ketoconazole promoted a halo zone for fungal inhibition lower than those submitted to the fermented broth, and chloramphenicol presented a halo zone of bacterial inhibition of 16 mm, with this value being very close to what is found when using fermented broth (12 mm). The bacteria used as target microorganisms were resistant because S. typhi, S. sonnei, and E. coli were not inhibited with this antimicrobial agent.

A medium consisting of sugar only is not efficient for biomass production in fermentation carried out under oxygen-limited conditions (no agitation or air supply) where alcoholic and lactic acid fermentation should be favored over biomass production. Therefore, the products of sucrose fermentation, apart from biomass, would be ethanol and lactic acid. The presence of these organic acids in the fermented broth can be considered as being responsible for the inhibition of the pathogens. In fermentation with kombucha, the antimicrobial activity observed was due to organic acids, primarily acetic acid, and was eliminated when samples were neutralized [27]. In this work, fermented broth containing demerara sugar had the lowest pH value; however, the halo zone of inhibition for this broth was not observed. Probably, the low pH value, due to organic acid production, was not the only factor responsible for the pathogen inhibition, suggesting that bacteriocin production occurred. Demerara sugar solution led to the highest biomass yield and presented a small halo zone of inhibition for C. albicans (14 mm) or none for bacteria. On the other hand, molasses and brown sugar (unrefined products) presented the largest halo zone of inhibition.

Illustratively, Fig. 2 shows the monitoring of the halo size for C. albicans with the three carbohydrate sources used in this work during the fermentation process. It was observed that after 24 h of fermentation (when the highest pH value was registered), the highest values of inhibition halos were verified. The data reported herein corroborate with the suggestion that the antimicrobial activity might be attributed to antimicrobial substances secreted (bacteriocins) during the fermentation and not simply to low pH values. Nevertheless, the chemical structure of the antimicrobial compound produced has not been determined so far. Bacteriocins which have been produced by lactobacilli, as those present in kefir grains, have shown a broad inhibitory spectrum against different target microorganisms [14].

Brown sugar concentration influences expressively the antimicrobial activity, and the best results were observed in the case of the smallest and largest concentrations tested (2 and 15 g/l). In addition, antimicrobial activity for all pathogenic microorganisms used in this work was verified in the case of 15 g/l concentration. The greatest inhibition was obtained for C. albicans (28 mm). The profile of pH values, as well as the concentration of reducing and non-reducing sugars, followed the same trend independently of the concentrations, which ranged from 2 to 15 g/l (Fig. 3).

The kefir grains entered into stationary phase at approximately 48 h of fermentation, although the greatest antimicrobial activity was found at 144 h of fermentation when 2 g/l of brown sugar (14 mm, S. sonnei), 12 g/l (14 mm, E. coli; 16 mm, S. aureus), and 15 g/l (28 mm, C. albicans; 12 mm, S. typhi) was used, as shown in Table 2. The kefir grains used in this work produced a 2.5 pH value, 0.37 to 6.10 g/l residual non-reducing sugar after 168 h of fermentation. When kombucha colonies were used, the total acid after 9 h was 3.3%, and the highest antimicrobial activity observed in the fermentation process was 16 mm in 35 g/l dry black tea and 16 mm in 17 g/l dry black tea for E. coli and Salmonella, respectively [27].

Molasses demonstrated the largest inhibition halo to pathogenic microorganisms at 168 h of fermentation. The pH, as in the previous fermentations, had the same reduction profile. This source of carbohydrate was more easily assimilated (between 30% and 53% of reducing sugars was consumed in the first 24 h of fermentation). Consequently, excellent hydrolysis occurred in reducing sugars, leading to their conversion in biomass (Fig. 3). An antibiotic action was not effective against S. typhi. The strongest effect in antimicrobial activity was observed in the case of high molasses concentrations (14 mm for E. coli, 12 mm for S. aureus, 12 mm for S. sonnei), except for C. albicans (30 mm in 2% of carbohydrate), as shown in Table 3. When 55% (w/v) of commercial sugar was used with kombucha colonies, the inhibition halo zone of S. typhi (32 mm at 21 h of fermentation) and E. coli (16 mm at 14 h of fermentation) was observed [28].

Conclusion

Kefir grains promoted the hydrolysis of non-reducing sugars, which are converted into organic acids and substances capable of producing inhibition halos in experiments with pathogenic microorganisms. Brown sugar was the most effective carbohydrate source with antimicrobial action, mainly against C. albicans (35 mm halo zone).

References

Santos, A., San Mauro, M., Sanchez, A., Torres, J. M., & Marquina, D. (2003). Systematic and Applied Microbiology, 26, 434–437. doi:10.1078/072320203322497464.

Harta, O., Iconomopoulou, M., Bekatorou, A., Nigam, P., Kontominas, M., & Koutinas, A. A. (2004). Food Chemistry, 88, 237–242. doi:10.1016/j.foodchem.2003.12.043.

Plessas, S., Trantallidi, M., Bekatorou, A., Kanellaki, M., Nigam, P., & Koutinas, A. A. (2007). Food Chemistry, 105, 187–194. doi:10.1016/j.foodchem.2007.03.065.

Loretan, T., Mosert, J. F., & Viljoen, B. C. (2003). South African Journal of Science, 99, 92–94.

Marquina, D., Santos, A., Corpas, I., Muñoz, J., Zazo, J., & Peinado, J. M. (2002). Letters in Applied Microbiology, 35, 136–140. doi:10.1046/j.1472-765X.2002.01155.x.

Rivière, J. W. M., & Kooiman, P. (1967). Archives of Microbiology, 59, 269–278. doi:10.1007/BF00406340.

Garrote, G. L., Abraham, A. G., & Antoni, G. L. (1997). Lebensmittel-Wissenschaft und-Technologie, 30, 77–84.

Paraskevopoulou, A., Athanasiadis, I., Blekas, G., Koutinas, A. A., Kanellaki, M., & Kiosseoglou, V. (2003). Food Hydrocolloids, 17, 615–620. doi:10.1016/S0268-005X(02)00122-4.

Witthuhn, R. C., Schoeman, T., & Britz, T. J. (2005). International Dairy Journal, 15, 383–389. doi:10.1016/j.idairyj.2004.07.016.

Simova, E., Beshkova, D., Angelov, A., Hristozova, T., Frengova, G., & Spasov, Z. (2002). Journal of Industrial Microbiology & Biotechnology, 28, 1–6.

Farnwork, E. R. (2005). Food Science & Technology, 2(1), 1–17.

Gumez, C., & Goven, A. (2003). Food Science & Technology International, 9(5), 365–369. doi:10.1177/1082013203039252.

Pal, V., Jamuna, M., & Jeevaratnam, K. (2005). Journal of Culture Collections, 4, 53–60.

Jamuna, M., & Jeevaratnam, K. (2004). Journal of General and Applied Microbiology, 50, 79–90.

Zubillaga, M., Weill, R., Postaire, E., Goldman, C., Caro, R., & Boccio, J. (2001). Nutrition Research, 21, 569–579. doi:10.1016/S0271-5317(01)00281-0.

UNICEF. (2007). Sobrevivência Infantil. Halteras Press, p. 126.

Curlian, L.V. (1983). National Feed Igredientes, pp. 1–11.

Mendonça, C. R., Rodrigues, R. S., & Zambiazi, R. C. (2000). CieÃncia Rural, 30(6), 1053–1058. doi:10.1590/S0103-84782000000600022.

AOAC (1998). Official methods of analysis.(16th ed.). Arlington, VA: Association of Official Analytical Chemists.

Sreeramulu, G., Zhu, Y., & Knol, W. (2000). Journal of Agricultural and Food Chemistry, 48, 2589–2594. doi:10.1021/jf991333m.

Dornelles, A. S., & Rodrigues, S. (2005). In: Simpósio Nacional de Bioprocessos, Conference Proceedings; Recife, Brazil, 2005, pp. 1–7.

Fagundes Neto, U., & Scaletsky, I. C. A. (2000). Sao Paulo Medical Journal, 118(1), 21–29. doi:10.1590/S1516-31802000000100006.

Alcoba-Flórez, J., Pérez-Roth, E., González-Linares, S., & Méndez-Álvarez, S. (2005). International Microbiology, 8, 133–136.

Bremer, P. J.; Fletcher, G.; Osborne, C. (2004). New Zealand for Crop and Food Researcher Limited, pp. 1–6.

Vieira, J. D. G., Ribeiro, E. L., Campos, C. C., Pimenta, F. C., Toledo, O. A., Nagato, G. M., et al. (2005). Revista da Sociedade Brasileira de Medicina Tropica, 38(5), 383–386.

Bailey, A., Wadsworth, E., & Calderone, R. (1995). Infection and Immunity, 63(2), 569–572.

Greenwalt, C. J., Ledford, R. A., & Steinkraus, K. H. (1998). Lebensmittel-Wissenschaft + [i.e. Und] Technologie. Food Science + Technology. Science + Technologie Alimentaire, 31, 291–296. doi:10.1006/fstl.1997.0354.

Lima, A. S., Rodrigues, S. A., Xavier Filho, L., Batista, R. A., & Santos Júnior, R. J.(2005). Simpósio Nacional de Bioprocessos, Conference Proceedings. Recife, Brazil, pp. 1–7.

Acknowledgments

The authors thank Fundação de Amparo a Pesquisa do Estado de Sergipe (FAP-SE) for the financial support of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, K.R., Rodrigues, S.A., Filho, L.X. et al. Antimicrobial Activity of Broth Fermented with Kefir Grains. Appl Biochem Biotechnol 152, 316–325 (2009). https://doi.org/10.1007/s12010-008-8303-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8303-3

, brown sugar; and

, brown sugar; and  , molasses) for C. albicans

, molasses) for C. albicans