Abstract

Biosorption of copper (II) and cadmium (II) by live Phanerochaete chrysosporium immobilized by growing onto polyurethane foam material in individual packed bed columns over two successive cycles of sorption–desorption were investigated in this study. Initial pH and concentrations of the metals in their respective solutions were set optimum to each of those: 4.6 and 35 mg·l−1 in case of copper and 5.3 and 11 mg·l−1 for cadmium. The breakthrough curves obtained for the two metals during sorption in both the cycles exhibited a constant pattern at various bed depths in the columns. The maximum yield of the columns in removing these metals were found to be, respectively, 57% and 43% for copper and cadmium indicating that copper biosorption by the immobilized fungus in its column was better than for cadmium. Recovery values of the sorbed copper and cadmium metals from the respective loaded columns by using 0.1 N HCl as eluant was observed to be quite high at more than 65% and 75%, respectively, at the end of desorption in both the cycles. Breakthrough models of bed-depth service time, Adams–Bohart, Wolborska, and Clark were fitted to the experimental data on sorption of copper and cadmium in the columns, and only the Clark model could fit the sorption performance of the columns well over the entire range of ratios of concentrations of effluent to influent, i.e., C/C 0 for both copper and cadmium biosorption. The kinetic coefficients of mass transfer and other suitable parameters in the system were determined by applying the experimental data at C/C 0 ratios lower than 0.5 to the other three models.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The intensification of industrial activity in the recent years is greatly contributing to an increasing discharge of toxic compounds in the natural environment, particularly in aquatic systems. Among the widely found toxic compounds, heavy metals bear a special significance because of their highly toxic nature even at very low concentrations. Increased usage of these heavy metals has even resulted in their depletion from their natural resources. Moreover, stricter environmental regulations have led to an increased and urgent need for controlling heavy metal discharge into the environment. The major industries that are responsible for the discharge of wastewater containing metals include mining, metallurgy, electroplating, and refining industries.

The conventional treatment techniques employed to remove heavy metals from wastewaters before their final discharge into the environment are physico-chemical processes, including precipitation, coagulation, membrane processes, ion exchange, adsorption [1]. However, the main drawbacks of these techniques rest in being either too costly or ineffective. The use of biological material for removing and recovering heavy metals from contaminated industrial effluents has emerged as a potential alternative method to the conventional ones [2]. Many microorganisms have been shown to be capable of concentrating heavy metals from their aqueous environment, and the term biosorption is used to describe for such passive, non-metabolically mediated process of metal binding by living or dead biomass [3]. Filamentous fungi may be better suited for this purpose than other microbial groups owing to their high tolerance towards metals, intracellular metal uptake, and wall-binding capacities [4].

Fungal species such as Rhizopus arrhizus, Aspergillus niger, Mucor miehei, etc. have been extensively studied for heavy metals biosorption, and the process mechanism seems to be species specific [5–7]. However, relatively only a few studies have been reported with Phanerochaete chrysosporium, which is a well-known white-rot fungus and a strong degrader of various xenobiotics, in detoxifying heavy metal-bearing wastewaters. Using biomass of P. chrysosporium has already shown promising results on the removal of select heavy metals from their aqueous constituents, but most of these studies are confined to experiments in simple batch shake flasks [8, 9].

The ultimate success of these studies, however, lies in developing engineering systems employing these microbes in treating large quantities of contaminated water on a continuous basis. Among the available reactor types for biosorption, packed bed columns offer several advantages, viz., simple to operate, high process yield, and easy scale-up. For this, the use of free microorganisms is technically and economically not feasible for small- and medium-flow treatment application due to high costs involved in the process [10]. In such cases, immobilized microbial cell system in fixed bed columns could provide additional advantages over freely suspended cells. The advantages include ease of regeneration and reuse of the biomass, easy solid–liquid separation operation, and minimal clogging in the fixed bed [11]. Although biosorption studies dealing with fixed bed columns involving immobilized biomass is not totally new, they are limited in using either dead, inactivated or resting biomass in miniscule columns. Moreover, immobilized live biomass have not been evaluated much of their efficiency, particularly in packed columns, for heavy-metal removal, which seems to offer dual advantages of high biosorption efficiency and more easy regeneration of the column [12–16]. In fact, in our earlier work [15], live P. chrysosporium immobilized by growing onto a suitable biosupport material in individual packed bed columns was demonstrated to remove copper and cadmium from synthetic metal solutions. However, the previous study involved merely the sorption of metals in a continuously operated column with no further cycles tested. Therefore, the present work was aimed at investigating and comparing the regeneration and reuse of the live immobilized P. chrysosporium in the biosorption of copper and cadmium in individual packed bed columns operated under continuous mode. To analyze the performance of these columns in the removal of the metals, several parameters as outlined below were used.

The loading behavior of the metal ions to be removed from solution in a packed bed is usually expressed in terms of the ratio of effluent to initial metal concentrations C/C 0 as a function of time (t) or volume (V) of the eluate for a given bed height (z) and is termed the isoplane or breakthrough curve.

The maximum (equlibrium) capacity C max of a packed bed column is calculated from area under the plot of adsorbed metal concentration versus time or, in other words, from the area behind the breakthrough curve; this is more conveniently expressed as:

where C ads is the adsorbed metal concentration (mg·l−1) and Q is the flow rate at which metal solution is passed into the column for a time period t until column bed saturation. For an easy comparison of columns in treating metals, another convenient parameter on sorption yield (Y), obtained from the ratio of maximum equilibrium capacity (C max) for a given metal to total metal loaded, is used. On the other hand, the total metal loaded in the column is obtained from a product of solution metal concentration and volume treated in the column.

Equation 2 below gives the fundamental equation according to the Adams–Bohart and the Thomas models describing the relationship between C/C 0 and t in a flowing system [17, 18].

where z is the bed depth (cm), the linear flow rate (cm·min−1) u is defined as the ratio of the flow rate Q (ml·min−1) to the cross-sectional area S c (cm2), k is the adsorption rate constant (l·mg·min−1), and N 0 is the saturation concentration (mg·l−1).

For describing the concentration distribution in the bed for low concentration range (low C/C 0) in the breakthrough curve, the following relationship by Wolborska could be used [19]:

where β is the kinetic coefficient of external mass transfer (1·min−1).

The expression of the Wolborska solution is equivalent to the Adams–Bohart relation if the constant k is equal to β/N 0, and the parameters in these two models can be determined from a plot of ln(C/C 0) against t for a given bed height and flow rate. Apparently, the terms k and N 0 seem to be fixed only for particular values of z and Q in a column.

One of the most successful models used in analyzing breakthrough data from column tests has been the bed depth-service time (BDST) model, which shares a common basis of theories with the Adams–Bohart model [20]. This model is described by the following equation:

where t b is the service time at breakthrough (min), and C b is the effluent concentration at breakthrough (mg·l−1). A straight line obtained by plotting t b versus z yields the values of saturation concentration of bed (N 0) and kinetic constant k from its slope and intercept, respectively. The value of N 0 can also be calculated in a more convenient way as follows. At 50% breakthrough, C 0/C = 2 and t b = t 0.5, the final term in the BDST equation becomes zero resulting in the following relationship:

Thus a plot of time at 50% breakthrough against bed height should be a straight line passing through the origin, allowing N 0 to be calculated.

Clark [21] used the mass transfer concept in combination with the Freundlich isotherm to define a new simulation of breakthrough curves and obtained the following equation [21]:

where n is the Freundlich constant, and v m, the migration velocity of the concentration fronts in the bed (cm·min−1), is determined by the following equation:

The values of A and r for a particular sorption process in a packed bed column could be determined by using Eqs. 8 and 9 for predicting the breakthrough curve as per relationship between C/C 0 and t in Eq. 7.

Materials and Methods

Chemicals and Reagents

The metal salts CuSO4·5 H2O and 3 CdSO4·7 H2O and other chemicals used were of analytical grade and obtained from s.d. Fine Chemicals, India. The media components for growing the fungal culture were obtained from HiMedia Laboratories, India.

Microorganism and Culture Medium

The fungal culture P. chrysosporium ATCC 24725 used in this study was maintained on malt agar slants, and the culture medium for its growth consisted of dextrose (15 g·l−1) and soya peptone (3 g·l−1) in distilled water, pH 5.6.

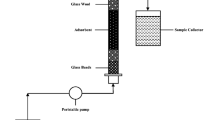

Biosorption Experiments in Packed Bed Columns

Two identical packed bed columns were used to investigate the sorption of copper and cadmium individually by the immobilized fungus. The fungus was immobilized via attachment by growing on polyurethane foam (PUF) cubes in the columns, as described elsewhere in Dias et al. [10]. The columns were constructed using Plexiglas material of height 33 cm and internal diameter 10 cm, each with both ends closed with rubber stoppers. The columns were randomly packed with PUF (0.6–0.8 mm average pore size) cubes of dimension 1 × 1 × 1 cm, and the bed was kept in place by the use of perforated plates at both ends of the columns. To study the effect of bed depth on the metal sorption, ports were provided at different heights of the columns, and liquid samples were collected from these ports.

Although no attempts were made to quantify the biomass in the study, visible biofilm growth was observed on the biosupport material within 10 days of passing the growth medium into the columns under batch recirculation mode. After ascertaining the fungal biomass immobilized onto PUF cubes in the columns, continuous biosorption experiments were performed by passing individual metal solutions into the respective columns in an up-flow mode using peristaltic pumps (Watson Marlow, 502 S Model, UK). A uniform distribution of the liquids through the bed was achieved with the aid of a distributor system located at its bottom. Samples were collected from the sampling ports at different heights of the bed at varying intervals of time and analyzed for residual metal concentrations. The respective concentration and pH in the feed solution was 35 mg·l−1 and 4.6 for copper and 11 mg·l−1 and 5.3 for cadmium. The flow rate in the copper and cadmium loading columns were set at 125 ml·min−1. The values of individual metal concentration and pH were selected on the basis of our previous study [8, 22], and the flow rate of 125 ml·min−1 represented sorption equilibrium time of 30 min in the columns. Also, the feed concentrations were used corresponding to a nearly linear isotherm relationship where the self-sharpening effect was not expected [23]. Following exhaustion of the columns, 0.1 N HCl solution was passed to regenerate the sorbed metals from the respective columns. This sorption–desorption cycle was repeated to study the efficiency of the column in the second cycle of operation. Preliminary investigations in the column with PUF material containing no biomass, however, revealed no effect on the adsorption of metal by the support material.

Metal Analyses

The concentration of copper or cadmium in the samples was determined using a Flame Atomic Absorption Spectrophotometer, SOLAAR 969 (UNICAM, UK) at their respective absorbance maxima. The operating conditions were as recommended in the manufacturer’s operating manual, and all analyses were done in the linear range of concentration with an accuracy of ±3%.

Results and Discussion

Biosorption of Copper and Cadmium in Individual Packed Bed Columns

The resulting breakthrough curves obtained during sorption in the two cycles for both the metals are presented in Figs. 1, 2, 3 and 4. These figures manifest a constant pattern of breakthrough curves in sorption of the metals over the entire range of bed depths in the individual columns; however, the breakthrough curves seemed to become less steep with increase in bed depth in the columns. The service time to 10% breakthrough in both the cycles was more for higher bed depth in the columns; for instance, in the first cycle of sorption in the copper biosorption column, the service time to 10% breakthrough at 8.5 cm bed depth was 15 min compared to a maximum of 80 min at 32.5 cm bed depth. Similarly, in the biosorption column for cadmium, the maximum service time to 10% breakthrough was observed to be 80 min at 32.5 cm bed depth. These observations were found consistent with those of the literature [24–26]. Quite expectedly, the volume treated also followed an increasing trend with bed depths in the columns due to more availability of the immobilized biomass with the bed depths.

Like in the first cycle of sorption in the columns, an increase in bed depth resulted in higher service time to 10% breakthrough for both the metals in the second cycle (Figs. 2 and 4). However, in this second cycle, the service time to 10% column breakthrough slightly decreased by about 5 min at 32.5 cm bed depth in case of both copper and cadmium biosorption columns. It is to be mentioned here that the columns were not washed after the first elution operation; instead, full-strength feed of the metals was initiated immediately in the respective columns. The slopes of these breakthrough curves obtained in the second sorption cycle had a slightly flatter profile compared to those obtained in the first sorption cycle in both the columns. This probably would have been due to some changes, particularly in the packed bed density and flow patterns within the columns during the preceding desorption phase with 0.1 N HCl. This could also account for the slight decrease in breakthrough time in the second cycle, as mentioned before. However, this specific observation needs more investigations to confirm. Nevertheless, an increasing length of the breakthrough curve accompanied by a decreasing slope at the breakthrough point proves approximately steady capacities of the columns. Volesky et al. [23] observed this phenomenon in their study involving dried biomass of brown marine alga, Sargassam filipendula, where an adsorption column using the biosorbent was investigated on its performance over two or more cycles of sorption and desorption. They attributed a shortening of breakthrough time with number of cycles due to a slight change in the column overall adsorption rate and not due to diminishing equilibrium uptake capacity. This may also mean that, while sorbing sites of the biomass were still available, they became less easily accessible for sorption.

The breakthrough curves resulting from sorption of the metals in the two cycles of operations were further analyzed as a function of bed depth in the columns; Table 1 summarizes the sorption parameters, viz., maximum equilibrium capacity C max (mg), metal loading (mg), and sorption yield (%) of the columns treating copper and cadmium. As mentioned earlier, the maximum equilibrium capacity of the column was calculated from area under the plot of adsorbed metal concentration versus time, and subsequently, the other two parameters were also calculated. The values of the parameters for both the metals were found to be generally high. Compared to the yield values of sorption in the first cycle, its values in the second cycle were higher for both the metals. However, yield values of copper in the two cycles were greater than those of cadmium. Similarly, the maximum equilibrium capacities at the end of the second cycle were unaltered or in some cases even better than in the previous cycle (Table 1). The yield values obtained in the study were compared with those seen in literature, which revealed a better significance of the current sorption system. For example, in the sorption of Cr (VI) by chitin in a packed column, Sag and Aktay [25] reported a maximum yield of only 17% under similar operating conditions of initial metal concentrations and residence time in their column. All these results indicated a very high potential of the immobilized live fungus in the columns to continuously treat a large volume of the metal-bearing solutions.

Regeneration of the Metal-Loaded Columns with 0.1 N HCl

It is understood that, from an application point of view, the volume of desorbing solution, which is necessary to regenerate the column and recover the metals, should be kept as low as possible for the ease of process handling. This is utmost possible when both sorption and desorption are carried out in the same column. In the present study, 0.1 N HCl was used for desorbing copper and cadmium from the respective metal-loaded columns. Figures 5 and 6 show desorption curves for the metals at different column bed depths in the two cycles of continuous operations, which typically show initially a steep rise followed by an equally shaped fall until negligible concentration of metals were detected in the effluent [23, 27, 28]. In the second sorption–desorption cycle, the sorption performance was necessarily related to the desorbing efficiency in the previous cycle, which was at least 64% for copper and 75% for cadmium (Table 2). These desorption efficiencies for the two metals were almost similar to the values obtained in our earlier study conducted in batch [22]. The desorption was carried out for 30 min at the same flow rate followed in the sorption phase and was found well sufficient for desorbing a maximum concentration of the metals from the loaded columns. As noted earlier, the columns at the end of the first desorption cycle were initiated immediately with a full-strength feed of the metal solutions. It is also worth making a point here that despite this continuous operation, the uptake capacity and column performance in the second sorption phase was unaltered and remained almost the same (Table 1). In order to assure a much higher desorption efficiency of the metals in a single process, this desorption phase may, however, have to be optimized further.

Application of Breakthrough Models to Evaluate and Predict the Experimental Data

Experimental evaluation of the performance of a packed bed column in biosorption is generally possible only with small laboratory columns, similar to the ones employed in the present study mainly because of cost considerations. However, the data collected from such laboratory studies can very well be utilized for predicting and evaluating the performance of practical size columns by applying suitable mathematical models developed for such purposes. Several models have been reported in the literature for predicting the breakthrough performance in packed bed adsorption, and an outline of some important and successful models were presented earlier in this paper. The results of fitting the experimental breakthrough data obtained in this study to these models are discussed further.

BDST Model

Bed depth service time model (Eq. 4) gives an idea of the efficiency of the column under constant operating conditions for achieving a desired breakthrough level. Based on the data obtained at a flow rate 125 ml·min−1 for copper and cadmium, plotting service time to 50% breakthrough (t 0.5) against bed depth (z) gave a linear relationship with determination coefficient (R 2) greater than 0.98 in all the cases. The calculated sorption capacity (N 0) of copper and cadmium loading columns obtained from the linear plots were found to be 184.2 and 60.2 mg·l−1, respectively, in the first cycle of operation; these values were slightly higher for both the metals in the second sorption cycle. Further, by applying the BDST model equation to the experimental data at 10% breakthrough point, a linear relationship was again obtained by plotting time to 10% breakthrough (t 0.1) against z. From the slope and the intercept of these linear plots, the adsorption rate constant k and N 0 corresponding to various bed depths in the two columns were calculated and are given in Table 3, which indicates a higher value of sorption rate constant in case of cadmium than copper. The values of these two parameters were found to be in good agreement with our previous study on batch kinetics of biosorption of copper and cadmium by the free fungus [9]. Similar to these findings, Tran and Roddick [28] observed that by fitting the adsorption data on uranium (VI) and lead onto silica gel in a column to BDST model, the estimated adsorption capacity values for uranium and lead were in good agreement with the experimentally determined values. Under the conditions adopted in the present study, it could be said that BDST model applied well to the experimental data for both service times to 10% and 50% breakthrough for the metals.

Adams–Bohart and Wolborska Models

Adams–Bohart and the related Wolborska models (Eqs. 2 and 3) express the breakthrough phenomenon in terms of the adsorption capacity and either the rate constant (k) or mass transfer coefficient (β). Both the model expressions can be linearized to give a relationship between ln(C/C 0) and time from which the model parameters can be calculated. It was observed that the model predictions agreed very closely with the experimental data giving a linear relationship up to a breakthrough level of 50% in both the first and second sorption cycles for the metals. The values of the Adams–Bohart and Wolborska model parameters corresponding to the experimental conditions together with R 2 values, presented in Tables 4 and 5, indicate closeness of fit between the experimental and predicted breakthrough up to 50% service time in the first and second sorption cycles. The values shown in these tables were obtained after applying the respective model equations to the experimental data for varying bed depths in the copper and cadmium biosorption columns. It was observed that the k value predicted by Adams–Bohart model was quite high for cadmium sorption compared to those of copper, a trend consistent with the previously tested BDST model. However, the sorption capacity (N 0) values for both the metals predicted by Adams–Bohart and Wolborska models were higher than those predicted by BDST model, but the values matched well between the two similar models. These N 0 values for both the metals were almost the same in the second cycle of sorption. With respect to the kinetic constant (k) values obtained from Adams–Bohart model, its values were slightly less for both the metals in the second cycle. Also, the values of the mass transfer coefficient β obtained from Wolborska model were slightly less in the second sorption cycle for the metals (Tables 4 and 5).

Clark Model

Clark model may be considered a more refined model for breakthrough, as it considers both the mass transfer and equilibrium adsorption in the process. In our earlier work dealing with a batch study on sorption of copper and cadmium on to P. chrysosporium biomass, it was found that the Freundlich model provided a good fit to the experimental equilibrium data [9], and the obtained Freundlich constants were adopted in the current study to calculate the Clark model parameters in analyzing copper and cadmium sorption in their respective columns. The values of A and r in Clark model (Eq. 7) were determined for the 10% breakthrough data for the metals employing a least square method in Matlab 7.1. The best-fit equations of copper and cadmium sorption for different column bed depths in the two cycles of operation are presented in Table 6. Plotting C/C 0 against time according to these equations gave the breakthrough curves predicted by Clark model (Figs. 7, 8, 9 and 10). It is evident that the experimental breakthrough curves for both the metals at different bed depths for the two cycles of operation were well predicted by the Clark model over the entire time period. The low values of integral sum of errors (ISE; presented in Table 7), calculated between the experimental and predicted breakthrough curves due to the Clark model, also indicate a reasonably good fit of the model. The r coefficient related to the mass transfer in the process varied in the range of 0.0523 to 0.1035 1 min−1 for copper and 0.0867 to 0.1752 1 min−1 for cadmium in the first cycle of sorption (Table 7). These values of r coefficient slightly decreased in the second cycle of sorption for the two metals; nevertheless, the values followed the same trend with bed depth in the columns in both the cycles. Sag and Aktay [25] have reported similar order of magnitude for the r coefficient in chromium (VI) sorption by chitin in a packed column. The parameter results obtained from Clark model are in good agreement with those of Guibal et al. [29] and Tran and Roddick [28] as well.

These results of fitting the experimental breakthrough data to the various models reveal variation of the estimated sorption kinetic parameters and mass transfer coefficient with the bed depth and with each sorption cycle in the metal biosorption columns. Despite maintaining the hydraulic conditions in the biosorption columns the same, such variation in the intrinsic sorption kinetic parameters and mass transfer coefficient is quite unlikely. Hence, it could be said that although the models, particularly the Clark model, described the experimental data accurately from a mathematical point of view, the kinetic reaction and mass transfer phenomenon in the sorption of the metals due to these models are still unclear. Therefore, it is necessary to exercise proper care while considering these models for scaling up of such biosorption processes.

Compared to the biosorption studies reported in the literature, which have used either dead, inactivated or resting biomass, this study shows good potential of the live immobilized fungus employing a packed bed column in removing heavy metals from contaminated wastewaters. An added advantage of using such live immobilized biomass in columns seems to be in easy regeneration and reuse of the column by allowing the biomass to further grow and immobilize, when needed, for further uptake of metals.

Conclusion

Biosorption of copper (II) and cadmium (II) by live biomass of P. chrysosporium immobilized by growing onto polyurethane foam material was studied in individual packed columns over two sorption–desorption cycles. The breakthrough curves obtained at various bed depths in the columns exhibited a constant pattern with both the metals. Comparison of sorption parameters of the individual columns in sorption of copper and cadmium indicated better performance towards copper uptake by the fungus. For both the metals, the values of sorption parameters in the second cycle were unaltered or in some cases slightly better than those obtained in the first cycle.

Several models were applied to simulate the breakthrough behavior of the metals in the columns, and suitable kinetic parameters involved in sorption of copper and cadmium in their respective columns were estimated from these models by fitting the experimental data. Among the four models tested, the Clark model could predict the breakthrough curves over the entire region for all depths in the columns. This was valid for both the metals in the two-sorption cycles evaluated in the study. The other three models could, however, perfectly fit the breakthrough region only up to 50% service time in the columns for both the metal cases. The best-fitting Clark model also allowed the determination of generalized logistic function of the breakthrough curves obtained in the study.

Acid elution using 0.1 N HCl was found successful in desorbing a high percentage of the metals from the respective metal-laden immobilized biomass in the columns. Overall, regenerative biosorption system using live immobilized P. chrysosporium in packed columns appears feasible under relatively simple operative conditions in detoxifying metal-bearing wastewaters.

Abbreviations

- C :

-

residual metal concentration, mg·l−1

- C b :

-

metal concentration at breakthrough, mg·l−1

- C ads :

-

adsorbed metal concentration, mg·l−1

- C eq :

-

residual metal concentration at equilibrium, mg·l−1

- C max :

-

maximum (equilibrium) capacity of column, mg

- C 0 :

-

initial metal concentration, mg·l−1

- k :

-

kinetic constant in bed depth service time, Adams–Bohart, and Wolborska breakthrough models, l·mg−1·min−1

- N 0 :

-

saturation concentration, mg·l−1

- Q :

-

flow rate, ml·min−1

- r :

-

coefficient of mass transfer in Clark model for breakthrough, 1·min−1

- t :

-

time, min

- t b :

-

service time to breakthrough, min

- u :

-

linear flow rate, cm·min−1

- v m :

-

migration velocity of the concentration front in Clark model for breakthrough, cm·min−1

- W :

-

metal loading into column, mg

- Y :

-

sorption yield, %

- z :

-

bed depth, cm

- β :

-

external mass transfer coefficient in Wolborska breakthrough model, 1·min−1

References

Lameiras, S., Quintelas, C., & Tavares, T. (2008). Bioresource Technology, 99, 801–806.

Tsezos, M. (2007). Advances in Materials Research, 20 & 21, 589–596.

Yesim, K., Arpa, C., Tan, S., Denizli, A., Genc, P., & Arica, M. Y. (2002). Process Biochemistry, 37, 601–610.

Volesky, B., & Holan, Z. R. (1995). Biotechnology Progress, 11, 235–250.

Kapoor, A., Viraraghavan, T., & Roy Cullimore, D. (1999). Bioresource Technology, 70, 95–104.

Ahluwalia, S. S., & Goyal, D. (2007). Microbial and plant derived biomass for removal of heavy metals from wastewater. Bioresource Technology, 98, 2243–2257.

Pradhan, S., Singh, S., & Rai, L. C. (2007). Bioresource Technology, 98, 595–601.

Gopal, M., Pakshirajan, K., & Swaminathan, T. (2002). Applied Biochemistry and Biotechnology, 102, 227–237.

Pakshirajan, K., & Swaminathan, T. (2002). In R. Devi, & N. Ashan (Eds.), Water and environmental management series pp. 1043–1052. UK: IWA Publishing.

Dias, M. A., Lacerda, I. C. A., Pimentel, P. F., de Castro, H. F., & Rosa, C. A. (2002). Letters in Applied Microbiology, 34, 46–50.

Arica, M. Y., Sharif, F. A., Alaeddinoglu, N. G., Hasaren, N., & Hasaren, V. (1993). Journal of Chemical Technology and Biotechnology (Oxford, Oxfordshire: 1986), 58, 281–285.

Chao, S., & Jian, Y. (1998). Water Research, 32, 2746–2752.

Yesim, K., Arpa, C., Tan, S., Denizli, A., Genc, P., & Arica, M. Y. (2002). Process Biochemistry, 37, 601–610.

Tsekovaa, K., & Petrov, G. (2002). Zeitschrift fuÉr Naturforschung Section C Biosciences, 57, 629–633.

Pakshirajan, K., & Swaminathan, T. (2006). Soil Sediment Contamination, 15, 187–197.

Iqbal, M., Saeed, A., & Zafar, S. I. (2007). Journal of Hazardous Materials, 148, 47–55.

Bohart, G., & Adams, E. Q. (1920). Journal of the American Chemical Society, 42, 523–544.

Thomas, A. C. (1944). Journal of the American Chemical Society, 66, 1664–1666.

Wolborska, A. (1989). Water Research, 23, 85–91.

Hutchins, R. A. (1973). Chemical Engineering Journal, 80, 133–138.

Clark, R. M. (1987). Environmental Science & Technology, 21, 573–580.

Pakshirajan, K., & Swaminathan, T. (2006). Proceedings of the fourth international symposium on southeast asian water environment (pp. 269–276). Bangkok, Thailand.

Volesky, B., Weber, J., & Park, J. M. (2003). Water Research, 37, 297–306.

Antonio, S., Ballester, A., Blazquez, M. L., Gonzalez, F., Munoz, J., & Hammaini, A. (1999). FEMS Microbiology Reviews, 23, 527–536.

Sag, Y., & Aktay, Y. (2001). Process Biochemistry, 36, 1187–1197.

Valdman, E., Erijman, L., Pessoa, F. L. P., & Leite, S. G. F. (2001). Process Biochemistry, 36, 869–873.

Fritz, J. S., & Schmitt, D. H. (1966). Talanta, 13, 123–128.

Tran, H. H., & Roddick, A. (1999). Water Research, 33, 3001–3011.

Guibal, E., Lorenzelli, R., Vincent, T., & Le Cloirec, P. (1995). Environmental Technology, 16, 101–114.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pakshirajan, K., Swaminathan, T. Biosorption of Copper and Cadmium in Packed Bed Columns with Live Immobilized Fungal Biomass of Phanerochaete chrysosporium . Appl Biochem Biotechnol 157, 159–173 (2009). https://doi.org/10.1007/s12010-008-8283-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8283-3