Abstract

In this paper, two new strians, Issatchenkia occidentalis (Lj-3, CCTCC M 2006097) and Issatchenkia orienalis (S-7, CCTCC M 2006098), isolated from different environments on solid media, were used in the detoxification process of the hemicellulosic hydrolysate of sugarcane bagasse. High-pressure liquid chromatography elution curve of UV-absorption compounds represented by acetic acid, furfural, and guaiacol (toxic compounds found in the hemicellulosic hydrolysate) showed that several chromatographic peaks were evidently diminished for the case of detoxified hydrolysate with isolate strains compared to the high peaks resulted for no detoxified hydrolysate. It was clear that these inhibitors were degraded by the two new isolates during their cultivation process. Fermentation results for the biodetoxified hydrolysate showed an increase in xylitol productivity (Q p) by 1.97 and 1.95 times (2.03 and 2.01 g l−1 h−1) and in xylitol yield (Y p) by 1.72 and 1.65 times (0.93 and 0.89 g xylitol per gram xylose) for hydrolysate treated with S-7 and Lj-3, respectively, in comparison with no detoxified hydrolysate (1.03 g l−1 h−1 and 0.54 g xylitol per gram xylose). This present work demonstrated the importance of Issatchenkia yeast in providing an effective biological detoxification approach to remove inhibitors and improve hydrolysate fermentability, leading to a high xylitol productivity and yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agricultural biomass, such as sugarcane bagasse, offers an abundant and low cost feedstock for high value added products such as xylitol. Xylitol is a polyalcohol and is as sweet as sucrose. Unlike the other sweeteners, xylitol is anticariogenic and has a pleasant taste and no unpleasant aftertaste [1, 2]. Currently, xylitol production is carried out by the chemical reduction of high-purified xylose derived from hemicellulosic hydrolysate of xylan-rich material. This process includes a series of extensive purification steps resulting in its high cost [3]. For this reason, the use of xylitol has been limited by its high price. The biological synthesis of xylitol is a promising alternative to the chemical process because it does not require initial xylose purification as the chemical method does and can simplify the xylitol separation steps [1, 4].

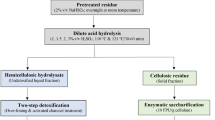

Carbohydrates contained in the lignocellulosic matrix are first released from hemicellulose and cellulose by hydrolysis pretreatment and then fermented for the bioproduction of different important products. Several methods have been reported in the literature for pretreatment of lignocellulosic materials [5]. Many of these pretreatments use a mineral acid as a catalyst. Pretreating with diluted acid completely hydrolyzes the hemicellulose fraction and liberates its correspondent sugar monomer [6]. The main drawback of acid treatment is that it is nonspecific and leads to the formation, in addition to sugars, of unwanted compounds that are inhibitory to xylitol-producing microorganisms [7]. Acid hydrolysate comprises a complex mixture of components in which more that 35 potential microbial inhibitors have been identified. These compounds can be divided into three major groups: organic acids (acetic acid, formic, and levulinic acids), furan (furfural and 5-hydroxylmethylfurfural), and phenolic compounds. They derive from sugar degradation or soluble lignin [8].

Many physical or chemical detoxification methods have been explored extensively to overcome the negative effect of inhibitors in hydrolysate. However, even if several methods are being deemed to be the best effective, such as concentration by evaporation [9], activated charcoal adsorption [10], overlime [11], cation- and anion-exchange resins [12], or their combination [13, 14], all have limitations. In general, they produce wastes and are costly; furthermore, the hydrolysate cannot reach the same fermentability degree of a synthetic pure medium [15]. In contrast, biological detoxification represents an improvement compared to these protocols because little waste is generated and it could be performed directly in the fermentation vessel before fermentation [16].

In this study, we reported two new yeast strains that could degrade the microbial inhibitors present in the hemicellulosic hydrolysate. After an experimental evaluation of their application value and thorough identification of their taxonomical position, we developed a new application concept of biodetoxification. Through the analysis of the obtained experimental results, these two new isolated strains were shown to be strongly efficient in improving hemicellulosic hydrolysate fermentability for xylitol bioproduction.

Material and Methods

Preparation of the Hemicellulosic Hydrolysate

Dried sugarcane bagasse was impregnated for 12 h with sulfuric acid (98% purity) of 2.5% (w/v) at a solid/liquid ratio of 1:6 and then hydrolyzed at 105 °C for 2.5 h in a 10-l stainless steel reactor (Guilin Chemical Machinery Co., Ltd). The resulting hydrolysate was centrifuged and concentrated by evaporation under vacuum (Buchi Rotavapor, R200, Switzerland) to one third of the initial volume at 70 °C.

Finally, it was neutralized with CaCO3 powder to the pH of 6 where the resulting precipitate was removed by vacuum filtration.

Culture Media

The culture media used for selection of microorganisms with detoxification activity was prepared by adding concentrated sugarcane bagasse hydrolysate (rich in toxic compounds) as the only carbon source and was supplemented by urea 2 g l−1 and a basic media (A) containing: (NH4)2SO4 2 g l−1, MgSO4·7H2O 0.2 g l−1, K2HPO4 4 g l−1, KH2PO4 6 g l−1, and yeast extract 0.5 g l−1. Finally, the enriched media were plated with supplement of agar 20 g l−1.

Selective Enrichment Culture and Microorganism Isolation

Microorganisms were isolated from wastewater and sludge samples obtained from xylose and paper-pulp industrial plants, areas considered rich in toxic compounds such as furfural and phenolic compounds, and kept at 4 °C until further test was done. A sample of 1 g (or 1 ml) was transferred into a 250-ml shake flask containing 25 ml of the enrichment culture (described in “Culture Media”) and was cultivated at 30 °C and 200 rpm for 48 h. One milliliter of the resulting culture broth was transferred to another shake flask containing new medium and continued to be cultivated for 48 h at the same conditions. After four generations following the procedure described above, the culture broths were lined on agar plates and cultivated at 30 °C for 5 days. Fast-growing colonies were selected first and transferred to a plate medium using pure xylose (30 g l−1) as the only carbon source. The isolates that did not grow on xylose plate and were able to grow on concentrated sugarcane bagasse hydrolysate (rich in toxic compounds) were chosen and preserved on malt extract agar slant tubes.

Detoxification Assays

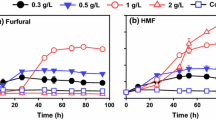

For inoculum preparation, overnight cultures of the selected strains S-7 and Lj-3 were grown on the liquid media (A) supplemented with glucose 30 g l−1. Cells from each culture were collected by centrifugation. The biodetoxification efficacy of selected and inoculated strains was assessed in defined media supplemented with toxic compounds (acetic acid 2 g l−1, furfural 20 mg l−1, and guaiacol 10 mg l−1) and basic salts solution containing (NH4)2SO4 5 g l−1, KH2PO4 1 g l−1, MgSO4·7H2O 0.5 g l−1, CaCl2 0.1 g l−1, NaCl 0.1 g l−1, yeast extract 0.2 g l−1, and urea 2 g l−1. Culture media was incubated at 200 rpm and 30 °C for 60 h. Samples for analysis were taken periodically. Concentrations of acetic acid, furfural, and guaiacol were determined by high-pressure liquid chromatography (HPLC) analysis.

Biodetoxification of Hemicellulosic Hydrolysate and Xylitol Production

The isolates used for the biodetoxification process of sugarcane bagasse hydrolysate were inoculated into a growth medium containing glucose 50 g l−1 besides basic media (A). The cultivation was carried out in 250-ml flasks containing 60 ml of growth medium at 200 rpm and 30 °C for 12 h. Fifteen percent (v/v) of the culture broth was transferred to a 250-ml flask containing 60 ml of neutralized sugarcane bagasse hydrolysate and urea 2 g l−1. After cultivating at 30 °C and 200 rpm for 48 h, the detoxicated hydrolysate were centrifuged to remove the microbial cells and then concentrated to 150 (grams of xylose per liter) under vacuum at 70 °C. They were stored at 4 °C before further test.

Yeast strain Candida tropicalis CCTCC M 205067 (CCTCC China Center for Type Culture Collection) was chosen for the xylitol fermentation in this study. The inoculum was cultivated in growth medium containing yeast extract 5 g l−1, glucose 15 g l−1, and xylose 15 g l−1 in addition to basic salt solution. The flasks were maintained under agitation of 200 rpm at 30 °C for 24 h. After centrifugation at 2,200×g for 20 min, the cells were recovered and rinsed twice with sterile water.

The fermentation medium was prepared by supplementing the biodetoxified sugarcane bagasse hydrolysate, with a beginning xylose concentration of 150 g l−1, with urea 5 g l−1, yeast extract 5 g l−1, and basic salt solution. Xylitol fermentation was performed under the following condition: 250-ml flasks contained 60 ml medium including 5% inoculum (v/v) at 30 °C and 200 rpm. The initial pH value of fermentation media was set at 6–7 with a supplement of xylose about 150 g l−1. All chemicals used in medium preparation and sugarcane bagasse hydrolysis were purchased from China National Medicines Corporation Ltd., Shang Hai.

Analytical Methods

Soluble solid contents were measured by manual saccharometer (WY080T, Wanchen Optics Instrument Factory, China). The concentration of xylose, glucose, and xylitol were determined using a WATERS 510 HPLC system with water 510 pump, a Waters 410 index refraction detector, a BC-100 carbohydrate Ca2+ column (Benson Polymeric, USA). The column was eluted with distilled water at a temperature of 85 °C and a flow rate of 0.5 ml min−1. For furfural, acetic acid and guaiacol analysis, a WATERS 486 UV-detector (USA) with a column of ZORBAX XDB-C18 (Agilent, USA) with an elution system of MeOH–H3PO4 (0.2%, w/w) = 75:25 (v/v) and a flow rate of 1.0 ml min−1 and 20-μl injection volume was used. Samples were previously filtered through a Sep Pak C18 filter and injected in the chromatograph. Identification and quantification of the experimentally obtained peaks (representing the inhibitors) were done by considering the retention times and peak heights and comparing them to a previously constructed peak model belonging to a well-defined control group. The detection wavelength was set at 198 nm.

Cell concentration for inoculation was determined by spectrophotometry (Beckman DU 640 B spectrophotometer). The yeast cells in fermentation broth was collected by centrifugation and then diluted with water to its initial volume. Its densities were determined by a calibration curve relating absorbance at 600 nm and represented as cell dry weight (g l−1).

Results

Identification of Isolates

At present, D1 and D2 26S ribosomal DNA (rDNA) sequences are used from almost all yeasts for species identification or phylogenetic analysis. Peterson and Kurtzman [15] correlated the biological species concept with the phylogenetic species concept by the extent of nucleotide substitutions in 26S rDNA sequences. Their study demonstrated that strains of a single biological species show less than 1% substitution in this region. Sequence analysis of the D1 and D2 regions of the 26S rDNA is the most reliable and simplest method for identification.

Cells used for DNA extraction were grown for approximately 24 h at 28 °C in 50 ml of YM Broth consisting of 3 g of yeast extract, 3 g of malt extract, 5 g of peptone, 10 g of glucose, and 1 g of agar per liter of distilled water and stored in a freezer (−4 °C) until use. DNA isolation for polymerase chain reaction (PCR) was performed by a modified version of the sodium dodecyl sulfate protocol [16]. The cells were suspended in 100 μl of extraction buffer [100 mM Tris–HCl (pH 8.5), 30 mM EDTA, 0.5% sodium dodecyl sulfate], fragmented with ultrasound processing for 5 min after storage at −80 °C for 10 min, and finally extracted by using chloroform and isopentanol (24:1 = v/v). Cells were centrifuged at 12,000 rpm to remove the precipitate. To the aqueous phase, 0.5 ml of isopropanol was added and stored at −20 °C for 30 min. Subsequently, DNA concentration took place by centrifugation at 12,000 rpm. The pellet was washed gently with 70% ethanol and resuspended in 50 ml TE buffer [10 mM Tris–HCl, 1 mM EDTA (pH 8.0)]. Dilute DNA samples were prepared for PCR by adding 4 μl of the genomic stocks to 1 ml of 0.1× TE buffer. The divergent domain at the 5′ end of the LSU rDNA gene [17] was symmetrically amplified with primers NL-1(5′-GCATATCAATAAGCGGAGGAAAAG-3′) and NL-4(5′-GGTCCGTGTTTCAAGACGG-3′) [18]. Amplification was performed for 32 PCR cycles with denaturation at 94 °C for 30 s, annealing at 62 °C for 1 min, and extension at 72 °C for 2 min. Visualization of the amplified DNA was performed following Geneclean treatment by electrophoresis in 1% agarose in 1× TAE buffer [0.04 M trisacetate, 0.001 M EDTA (pH 8.0)] and staining with ethidium bromide (8 × 10−5 mg/ml).

The PCR products were directly sequenced with primers NL-1 and NL-4 using the ABI TaqDyiDeoxy, Terminator Cycle Sequencing kit/ABI Model 377 automated DNA sequencer (Shanghai Sangon Biological Engineering Technology & Service Co., Shanghai City, China). Sequence data of isolates were revised by MEGA3.1, Clustalx (1.83) and Chromas [19]. The obtained sequence was compared with the known sequences in GenBank nucleotide sequence databases through nucleotide-nucleotide BLAST. The two new isolated strains were identified as S-7 and Lj-3. A homology tree for each isolate, for similarity comparison, was drawn with DNAMAN 5.22 software package (Lynnon Corporation, USA).

Molecule Character and Nucleotide Sequence Accession Number

Different yeasts can be assayed at the species level by PCR amplification and sequencing of D1/D2 domain of 26S rDNA [18]. After amplification of 26S rDNA domains D1/D2 by PCR and sequencing with the ABI Taq-DyeDeoxy Terminator Cycle sequencing kit/ABI Model 377 automated DNA sequencer, the nucleotide sequence of D1/D2 domain of isolates S-7 and Lj-3 were compared with other known sequences in GenBank + EMBL + DDBJ + PDB nucleotide sequence databases by a BLAST search [33]. Results showed that sequence of S-7, coded as EF030708, was between 99% and 100% identity to the sequences of the list number AB363785, AY707865, AF335979, AF335979, AJ749825, AY529499, AY529498, EU285533, EU293415, AM159103 belonging to Issatchenkia orientalis, whereas Lj-3 sequence coded as EF030710 was also between 99% and 100% identity to the sequences of the list number AB281316, EF620920, DQ869065, EF550236, AB281315, EF564403, EF564402, EF564381, U76348 belonging to Issatchenkia occidentalis.

Apparently, not only the results of the conventional morphological, physiological, and biochemical tests but also the similarity comparison of the nucleotide sequence of D1/D2 domain of 26S rDNA showed the new isolate S-7 to be the I. orientalis and Lj-3 to be I. occidentalis.

These new strains have been submitted to China Center for Type Culture Collection. Isolate I. orientalis S-7 was provided an accession number of CCTCC M 206098 and I. occidentalis Lj-3 of CCTCC M 206097.

Nucleotide sequence of S-7 and Lj-3 of D1/D2 domain of 26S rDNA were registered in the GenBank nucleotide sequence databases under accession numbers EF030708 for CCTCC M 206098 and EF0307010 for CCTCC M 206097, respectively.

Morphological, Physiological, and Biochemical Characterization

The colony appearances of S-7 and Lj-3 and their cellular morphology are shown in Figs. 1 and 2. The characterization of different compounds that are considered as nitrogen or carbon sources for these two new strains are expressed in Table 1. These characteristics were entirely similar to those of I. orientalis and I. occidentalis, respectively, as described by Barnett et al. [20].

Isolates with Detoxification Activity

By using selective enrichment culture, ten isolates were picked up from 60 samples taken from different environments of xylose and paper-pulp manufacturing industries (Table 2). All of the isolates were able to grow faster on plates containing sugarcane bagasse hemicellulosic hydrolysate (medium rich in furfural, guaiacol, and acetic acid), but apparently did not grow on the plates using xylose as the only carbon source.

All of the isolates were able to improve xylose fermentability from sugarcane bagasse hydrolysate for xylitol production; however, two isolates I. orientalis (S-7) and I. occidentalis (Lj-3) showed the best results, as shown clearly in Table 2.

Variation of UV-Absorption Compounds

HPLC elution curve of UV-absorption compounds represented by acetic acid, furfural, and guaiacol (toxic compounds) showed that several chromatographic peaks corresponding to these toxic compounds were diminished completely in the biodetoxified defined medium (chromatograms C and D) using the two novel isolate strains S-7 and Lj-3 compared to the high peaks found in the original no detoxified defined medium (chromatograms A and C). Chromatograms are clearly shown in Fig. 3. It is clear that several inhibitors (acetic acid, furfural, and guaiacol) were degraded by the two new isolates (S-7 and Lj-3), with detoxification activity, during its cultivation process. Chromatogram A (considered as the inhibitors control group) showed three high peaks that represented the toxic compounds (inhibitors): peak 1—acetic acid, peak 2—furfural, and peak 3—guaiacol. Chromatogram B (medium control group), meanwhile, showed two peaks that belonged to the culture medium (A) without inhibitors where peaks 4 and 5 represented the nutrients found in the medium. A defined medium (A) supplemented with inhibitors was represented by chromatogram C where five peaks were clearly present (combination of chromatograms A and B): peaks 1, 2, and 3—corresponded to the inhibitors (acetic acid, furfural, and guaiacol, respectively) and peaks 4 and 5—for the culture medium. The biodetoxified medium, using the two new strains (Lj-3 and S-7), is represented by the chromatograms D and E, respectively. In these chromatograms, the three high inhibitors peaks (shown in chromatogram C) have almost disappeared, indicating that all the inhibitors were efficiently degraded and therefore removed from the culture medium. On the other hand, two new peaks, 6 and 7, appeared in chromatograms D and E. Such peaks probably belong to the degradation products of furfural and guaiacol. More experimental studies concerning the products that were formed during the inhibitors degradation, by using these two new strains, are being carried out in our laboratories at the moment.

HPLC elution curves for A inhibitors; B culture medium; C culture medium supplemented with inhibitors; D, E Biodetoxified medium (degradation of inhibitors in culture medium by Lj-3 and S-7, respectively). Peaks: 1 acetic acid; 2 furfural; 3 guaiacol; 4, 5 culture medium components; 6 furfural degradation product; 7 guaiacol degradation product

The degrading ratios of UV-absorption toxic compounds can be determined by the comparison of their absorption peak area variations between the control group (represented by the no detoxified defined medium) and the biodetoxified medium. Based on the initial content of acetic acid, furfural, and guaiacol, their degradation ratios after the biodetoxification process reached close to 100% for both S-7 and Lj-3 strains, as shown in Table 3. From these results, it was concluded that the two new isolates posses a remarkable capacity to degrade acetic acid, fufural, and guaiacol, compounds considered as strong inhibitors for the cellular growth during xylitol production.

Hemicellulosic Hydrolysate Biodetoxification and Fermentation Assay

Sugarcane bagasse hemicellulosic hydrolysate was detoxified by the two new strains with S-7 and Lj-3. Obtained results are represented in Fig. 4. Chromatogram (A) shows three high peaks corresponding to the toxic compounds (inhibitors) found in the original no detoxified hemicellulosic hydrolysate, which are acetic acid, furfural, and guaiacol. The biodetoxified hydrolysate, using the two new strains Lj-3 and S-7, is represented by the chromatograms B and C, respectively. In these chromatograms, the three high inhibitors peaks (shown in chromatogram A) have almost disappeared, indicating that all the inhibitors were efficiently degraded. Such results were similar to those observed for the biodetoxified-defined medium (“Variation of UV-Absorption Compounds”).

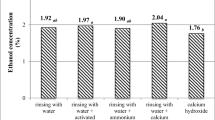

Detoxified sugarcane bagasse hemicellulosic hydrolysate with S-7 and L-3 strains was fermented by the yeast strain C. tropicalis CCTCC M 205067 using an initial xylose concentration of 150 g l−1 and cell density of 1.5 g l−1. Obtained results represented in Table 4 showed an increase in xylitol productivity (Q p) by 1.97 and 1.95 times (2.03 and 2.01 g l−1 h−1) and xylitol yield (Y p) by 1.72 and 1.65 times (0.93 and 0.89 g xylitol per gram xylose) for S-7 and Lj-3, respectively, compared with fermentation results obtained from hydrolysate without detoxification, medium rich in acetic acid, furfural, and guaiacol, productivity = 1.03 g l−1 h−1 and yield = 0.54 g xylitol per gram xylose. All experiments were run in triplicate. Figure 5 shows the influence of the biodetoxification process using the two new strains, S-7 and Lj-3, on the fermentability of the biodetoxified hemicellulosic hydrolysate in comparison with the fermentation results obtained for the no detoxified hydrolysate (considered as blank group).

Discussion

In this paper, two new strains (S-7 and Lj-3) were isolated with high degradation capacity of the main inhibitors for cellular growth in xylitol production. These inhibitors found in the sugarcane bagasse hydrolysate (also known as toxic compounds) were identified in our laboratories as furfural, acetic acid, and guaiacol.

Chemical composition of inhibitors resulting from dilute-acid hemicellulosic hydrolysates is very complex to be studied. More than 35 potential inhibitors have been identified in hydrolysates [21], although some of physical and chemical methods, such as vacuum evaporation, precipitation with overliming, activated charcoal adsorption, and ion exchange resin have been proven to be effective in removing inhibitors, as each physical or chemical detoxification method is specific to certain types of compounds. A vacuum evaporation process will raise the concentration of most of inhibitors in the concentrated hemicellulosic hydrolysate, including volatile acetic acid, except furfural [22]. Using such concentrated hydrolysate containing high concentration of multi-inhibitors in a fermentation process which the microorganisms used must have a degrading activity or good tolerance on these multi-inhibitors. Better results can be obtained only by combining two or more different methods [13]; however, the combinations of different detoxification methods would increase the xylitol fermentation cost. Some advantages of the fermentation process would be weakened by the cost raised in detoxification process. The toxicity of inhibitor is still a major factor limiting bioconversion processes that utilize hydrolysates [4].

Jönsson et al. [23] used laccase and peroxidase of the white-rot fungus Trametes versicolor to treat wood hydrolysate. It increased glucose consumption and ethanol productivity. However, the degradation of complex inhibitor components present in the hydrolysates needs complex enzymes acting on them and changing their composition; the costs of such enzymatic detoxification are clearly expensive. Adaptation of a microorganism to the hydrolysate is another biological method for improving the fermentation of hemicellulosic hydrolysate medium [24].

Biodetoxification, degrading inhibitors by microorganism, may be the most promising new route for hydrolysate treatment or an important extension to enhance the detoxification effects of physical and chemical methods. Lopéz et al. [14] isolated a new strain, Coniochaeta ligniaria NRRL 30616, which can metabolize furfural and 5-hydroxymethylfurfural. The hydrolysate of corn stover treated with C. ligniaria NRRL 30616 yields 1.66% ethanol in 80 h. In contrast, no ethanol was obtained in fermentations of untreated hydrolysate [25]. According to Lόpez et al. [24], bacteria Escherichia coli, Pseudomonas putida, and Rhodococcus erythropolis grew anaerobically on furfural. These data show that some microorganisms have a specific metabolism which can degrade multi-inhibitors in hydrolysate.

According to the results shown in Fig. 4, it was clear that I. orientalis S-7 and I. occidentalis Lj-3 have such activities simultaneously degrading furfural, acetic acid, and some phenolic compounds like guaiacol. Such detoxification mechanism of Issatchenkia strains was described in the work of Patrícia et al. [26] where the authors found that I. occidentalis involve an enzyme activity in azo-dye reduction. The dye reduction products 1-amino-2-naphthol can be used as a carbon and nitrogen source and N,N-dimethyl-p-phenylenediamine as a nitrogen source by this yeast. Also, a paper published by Tamaki et al. [27] showed that there is a glutathione-related detoxification system in the yeast I. orientalis where it can degrade S-(2-nitrophenyl) glutathione and S-(2-nitrophenyl) cysteine without suppressing its cell growth. Many researchers demonstrated that this yeast can rapidly degrade a series of volatile fatty acids, including acetic, propionic, butyric, and lactic acid [28–31].

Hydrolysate detoxification by I. orientalis S-7 and I. occidentalis Lj-3 was shown to be more efficient than other treatments. For example, overliming only presented decreases of 51% of the total furans and 50% of volume loss during treatment [32]. In contrast, isolate S-7 and Lj-3 completely removed the furfural, guaiacol, and acetic acid and did not cause any volume loss of the treated hydrolysate, thus contributing significantly to the efficiency and viability of the biodetoxification process. Moreover, biological detoxification with S-7 and Lj-3 can be used not only in the biotechnological process for xylitol production but also in the biomass-to-ethanol conversion [14]. This work demonstrated the importance of Issatchenkia as a microorganism, which contains metabolic degrading system of multi-inhibitors in hemicellulosic hydrolysate, thus providing an effective detoxification process to remove inhibitors and improve hydrolysate fermentability.

Conclusions

Two new yeast strains, I. orientalis S-7 and I. occidentalis Lj-3, isolated and identified in this study, considered as a new discovery and have not been reported in any published paper until now, proved to be an efficient alternative for the biological treatment of lignocellulosic hydrolysates. The biodetoxification of hemicellulosic hydrolysate in a single batch fermentation process, using the two strains S-7 and Lj-3, has favored a high xylitol productivity (Q p = 2.03 g l−1 h−1) and yield (Y p = 0.93 g xylitol per gram xylose), values that are considered an exclusivity of this work. This biodetoxification process offers many advantages over other detoxification treatments, including the complete depletion of furfural, acetic acid, and guaiacol, the possibility of performing detoxification in one step without additional manipulation, and no observed volume loss in the treated hydrolysate. Biodetoxification of lignicellulosic hydrolysates using S-7 and Lj-3 offers a promising alternative for diverse bioproducts production.

References

Sarrouh, B. F., Santos, D. T., & Silva, S. S. (2007). BTJ, 2(6), 759–763.

Silva, S. S., Converti, A., Zilli, M., Sene, L., & Felipe, M. G. A. (2001). Applied Biochemistry and Biotechnology, 57, 738–743.

Silva, S. S., & Afschar, A. S. (1994). Bioprocess Engineering, 11, 129–34.

Silva, S. S., Santos, J. C., Carvalho, W., Aracava, K. K., & Vitolo, M. (2003). Process Biochemistry, 38(6), 903–907.

Hsu, T. (1996) Handbook on bioethanol production and utilization. In: Wyman CE (Ed) Washington, DC: Taylor and Francis, pp. 179–212

Sun, Y., & Cheng, J. (2002). Bioresource Technology, 83, 1–11.

Parajó, J. C., Dominguez, H., & Dominguez, J. M. (1998). Bioresource Technology, 66, 25–40.

Palmqvist, E., & Hahn-Hagerdal, B. (2000). Bioresource Technology, 74, 25–33.

Berson, R. E., Young, J. S., & Kamer, S. N. (2005). Applied Biochemistry and Biotechnology, 123, 923–934.

Agblevor, F. A., Fu, J., & Hames, B. (2004). Applied Biochemistry and Biotechnology, 119, 97–120.

Carvalhero, F., Duarte, L. C., & Lopes, S. (2005). Process Biochemistry, 40, 1215–1223.

Mussatto, S. I., & Roberto, I. C. (2004). Bioresource Technology, 93, 1–10.

Carvalho, G. B. M., Mussatto, S. I., & Cândido, E. J. (2006). Journal of Chemical Technology and Biotechnology, 81, 152–157.

López, M. J., Nichols, N. N., Deien, B. B., Moreno, J., & Bothast, R. J. (2004). Applied Microbiology and Biotechnology, 64, 125–131.

Peterson, S. W., & Kurtzman, C. P. (1991). Systematic and Applied Microbiology, 14, 124–129.

Raeder, U., & Broda, P. (1985). Applied Microbiology, 1, 17–20.

Guadet, J., Julien, J., Lafey, J. F., & Brygoo, Y. (1989). Molecular Biology and Evolution, 6, 227–242.

Kurtzman, C. P., & Robnett, C. J. (1997). Journal of Clinical Microbiology, 35, 1216–1223.

Thompson, J. D., Higgins, D. G., & Gibson, T. J. (1994). Nucleic Acids Research, 22, 4673–4680.

Barnett, J. A., Payne, R. W., Yarrow, D. (1990) Yeasts: characteristics and identification. (pp. 683–684) Cambridge: Cambridge University Press.

Luo, C., Brink, D. L., & Blanch, H. W. (2002). Biomass Bioenergy, 22, 125–130.

Jönsson, L. J., Palmqvist, E., Nilvebrant, N. O., & Hahn-Hägerdal, B. (1998). Applied Microbiology and Biotechnology, 49, 691–697.

Rodrigues, R. C. L. B., Felipe, M. G. A., Almeida e Silva, J. B., Vitolo, M., & Gómez, P. V. (2001). Brazilian Journal of Chemical Engineering, 18(3), 299–311.

Silva, C. J. S. M., & Roberto, I. C. (2001). Letters in Applied Microbiology, 32, 248–252.

Nichols, N. N., Dien, B. S., & Guisado, G. M. (2005). Applied Biochemistry and Biotechnology, 124, 379–390.

Patrícia, A., Ramalho, M., & Helena, C. (2004). Applied and Environmental Microbiology, 70(4), 2279–2288.

Tamaki, H., Kumagai, H., & Shimada, Y. (1991). Agricultural and Biological Chemistry, 55(4), 951–956.

Arroyo, L. F. N., Duran, Q. M. C., & Garrido, F. A. (2006). Journal of Food Protection, 69(6), 1354–1364.

Lee, J. H., Lim, Y. B., & Park, K. M. (2003). Asian–Australasian Journal of Animal Sciences, 16(7), 1011–1014.

Middelhoven, W. J. (2001) Methods in biotechnology. In: Spencer, J. F. T., Spencer, R. (Eds.) Food microbiology protocols (pp. 209–224). New York: Humana.

Costas, M, Deive, F. J., & Longo, M. A. (2004). Process Biochemistry, 39, 2109–2114.

Martinez, A., Rodriguez, M. E., Wells, M. L., York, S. W., Preston, J. F., & Ingram, L. O. (2001). Biotechnology Progress, 17, 287–293.

Altschul, S. F., Madden, T. L., Schaffer, A. A., Zhang, J., Zhang, Z., Miller, W., et al. (1997). Nucleic Acids Research, 25(17), 3389–3402.

Acknowledgements

This research was supported by the National Nature Science Foundation of China (No.30450007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou-Rui, Z., Xiang-Xiang, Q., Silva, S.S. et al. Novel Isolates for Biological Detoxification of Lignocellulosic Hydrolysate. Appl Biochem Biotechnol 152, 199–212 (2009). https://doi.org/10.1007/s12010-008-8249-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8249-5