Abstract

The immobilization of horseradish peroxidase (HRP) on composite membrane has been investigated. This membrane was prepared by coating nonwoven polyester fabric with chitosan glutamate in the presence of glutraldehyde as a crosslinking agent. The physico-chemical properties of soluble and immobilized HRP were evaluated. The soluble HRP lost 90% of its activity after 4 weeks of storage at 4°C, whereas the immobilized enzyme retained 85% of its original activity at the same time. A reusability study of immobilized HRP showed that the enzyme retained 54% of its activity after 10 cycles of reuse. Soluble and immobilized HRP showed the same pH optima at pH 5.5. The immobilized enzyme had significant stability at different pH values, where it had maximum stability at pH 3.0 and 6.0. The kinetic properties indicated that the immobilized enzyme had more affinity toward substrates than soluble enzyme. The soluble and immobilized enzymes had temperature optima at 30 and 40°C and were stable up to 40 and 50°C, respectively. The stability of HRP against metal ion inactivation was improved after immobilization. Immobilized HRP exhibited high resistance to proteolysis by trypsin. The immobilized HRP was more resistant to inactivation induced by urea, Triton X-100, and organic solvents compared to its soluble counterpart. The immobilized HRP showed very high yield of immobilization and markedly high stabilization against several forms of denaturants that offer potential for several applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plant peroxidases are receiving increasing attention due to their extensive potential in clinical, biochemical, biotechnological, and industrial applications and in the synthesis of useful compounds [1–4]. These enzymes could also be exploited for the detoxification and remediation of various aromatic pollutants such as phenols, aromatic amines, 2,4,6-trinitrotoluene, and dyes, etc., present in wastewater/industrial effluents coming out from several industries such as textile, dyes, printing, paper, and pulp [5–8].

The immobilized enzymes have several advantages over the soluble enzymes, such as enhanced stability, easier product recovery and purification, protection of enzymes against denaturants, proteolysis, and reduced susceptibility to contamination [9]. Many methods have been applied for the immobilization of peroxidases. There have been a variety of approaches taken in the development of peroxidase immobilization techniques, such as adsorption [10–12], entrapment in a porous matrix [13], covalent binding [14], and electrochemical copolymerization [15, 16]. Many electrochemical techniques focus on the reduction of hydrogen peroxide based on the immobilized horseradish peroxidase (HRP) electrodes [17–20].

Chitosan, as one of the most promising natural polymers, with advantages such as biodegradability, chemical inertness, nontoxicity, biocompatibility, high mechanical strength, good film-forming properties, and low cost [21, 22], has been widely used for the immobilization of enzymes with the silica sol-gel method. Several enzymes, such as urease [23], lipase [24], tyrosinase [25], and HRP [26], have been immobilized on the matrix containing chitosan by silica sol-gel method. On the other hand, among the support materials that have been developed, nonwoven fabrics offer various advantages. Fabrics are fiber-based materials with high porosity (>95%) and large average pore size. Fibers can be formed from synthetic crystalline polymers or natural polymers in small diameter (approx. 10–40 mm), and they can be randomly arrayed (nonwoven) or knitted (woven) to form a three-dimensional matrix [27]. Whereas biodegradable fabrics are used in the development of artificial tissue substitutes in tissue engineering, nondegradable fabrics are preferred for the production of cellular biologicals [28].

The goal of this work is to develop a method for immobilizing HRP to be compatible with its further application. For that purpose, HRP was immobilized on composite membrane (chitosan/nonwoven polyester fabric membrane). The biochemical properties of immobilized enzyme were evaluated and compared with those of the soluble enzyme.

Materials and Methods

Horseradish Peroxidase

Previously, we partially purified Japanese HRP, where 1 mg of enzyme contained 900 units of peroxidase activity [29].

Chemicals

Chitosan was obtained from Aldrich. Hydrogen peroxide, guaiacol, glutraldehyde, polyethylene glycol, Triton X-100, and urea were purchased from Sigma Chemical. Dioxane, dimethylsulfoxide, and isopropanol are compounds from Merck. Other chemicals were of analytical grade.

Peroxidase Assay

Peroxidase activity was carried out according to Miranda et al. [30]. The reaction mixture contained, in 1 ml, 8 mM H2O2, 40 mM guaiacol, 50 mM sodium acetate buffer, pH 5.5, and the least amount of enzyme preparation. The change of absorbance at 470 nm due to guaiacol oxidation was followed at 30-s intervals at room temperature. One unit of peroxidase activity is defined as the amount of enzyme that increases the OD 1.0 per minute under standard assay conditions.

Preparation of Chitosan Glutamate/Cellulose Composite Membrane

Water soluble chitosan glutamate used for the preparation of composite membrane was prepared in a previous study [31]. The chitosan glutamate/cellulose composite membranes were prepared by the phase inversion method. The nonwoven polyester fabric (1.58 g) was subsequently stored in the chitosan glutamate solution overnight. Eight milliliters of chitosan glutamate solution containing an appropriate amount of polyethylene glycol as porogen and appropriate amount of glutraldhyde was poured over a pretreated nonwoven polyester fabric placed in a Petri-dish (100 mm diameter) and allowed to evaporate for 8 h at room temperature. The membranes were then immersed overnight in 1 M NaOH to extract the porogen and to generate a micropourous membrane. This was followed by washing several times with distilled water until the pH of the washing solution was the same as that of distilled water. Finally, the membranes were treated with a 10% glycerol solution to protect the composite membrane from shrinkage.

Immobilization Procedure

The enzyme immobilization was carried out by gently mixing end-over-end at room temperature overnight the chitosan-nonwoven fabric, previously washed repeatedly with distilled water, with the enzyme (5 mg contained 4,500 units) dissolved in 50 ml of 50 mM sodium acetate buffer pH 5.0 or sodium phosphate pH 7.0 or 8.0. Aliquots of the supernatant were drawn up and dried at room temperature to verify the advancement of the immobilization.

Effect of pH on Soluble and Immobilized HRP

The activities of soluble and immobilized HRP preparations were measured in buffers of various pH values (3.0–8.5). For pH stability, the enzyme was incubated at 4°C for 24 h at the same different pH values followed by dialysis against 50 mM sodium acetate buffer, pH 5.5.

Effect of Temperature on Soluble and Immobilized HRP

For measuring optimum temperature, the activities of soluble and immobilized HRP preparations were measured at various temperatures (20–80°C) under standard assay conditions. The thermal stability was carried out by preincubating the reaction mixture at various temperatures for 15 min prior to substrate addition, followed by cooling in ice bath. Activity of free and immobilized enzyme at zero time was taken as 100% activity.

Determination of Km

The Km values for enzyme were determined using H2O2 and guaiacol concentrations ranging from 1.6 to 8 mM and 8 to 40 mM, respectively.

Results and Discussion

Immobilization of Peroxidase on Composite Membrane

In the present selection of a suitable protocol, it is important to consider the time required for an efficient immobilization, as well as the percentage of enzymatic activity retained [32]. In the present study, HRP was immobilized on composite membrane in different pH values, 0.05 M sodium acetate buffer pH 5.0 or sodium phosphate buffer pH 7.0 or 8.0, and allowed to stand overnight. At pH 5.0, 100% of the original peroxidase activity was retained, whereas 37 and 9% of initial activity was retained at pH 7.0 and 8.0, respectively.

The soluble and immobilized HRP was stored at 4°C and measured at intervals of 1 week. As shown in Table 1, the soluble HRP lost 90% of its activity after 4 weeks of storage at 4°C, whereas the immobilized HRP retained 85% of its original activity at the same time. A reusability study was carried out by measuring the activity of the immobilized HRP (stored dry at 4°C) successive times, with several washes by 0.05 M sodium acetate buffer, pH 5.0. The maximum activity in the range of 100% was obtained at the beginning of the reusability experiments. After 10 cycles of reuse, a decrease of 46% in relative activity was recorded (Table 2). The excellent long-term stability should be attributed to the covalent interactions between the −COOH and NH2 groups in composite membrane and HRP, which prevented the loss of enzyme, and the biochemical environment provided by the chitosan and nonwoven-fabric, which prevented the denaturation of enzyme.

Physico-Chemieal Properties of Soluble and Immobilized Peroxidase

pH Optima

Figure 1 shows the pH-activity profile of soluble and immobilized HRP. Soluble and immobilized HRP preparations showed the same pH optima at pH 5.5. However, immobilized enzyme maintained a higher relative activity than soluble enzyme at both lower and higher pH levels, indicating that the immobilized peroxidase was less sensitive to pH changes than the soluble peroxidase. It is worth mentioning that the immobilized enzyme activities between 55 and 38% of the initial level were retained at pH around 3.0 and 8.5, which may be interesting for a wide range of applications. This effect was in agreement with general observations of immobilized enzyme on different supports, except pH optimum, as immobilization of peroxidases on sol-gel/chitosan [33], glutaraldehyde-agarose gel [34], O-carboxymethylated chitosan/sol-gel [35], and concanavalin A-cellulose [9], with pH optima at 7.4, 7.0, 4.5, and 5.0.

pH optimum of soluble and immobilized HRP. The reaction mixture contained, in 1.0 ml, 8 mM H2O2, 40 mM guaiacol, 0.1 unit of enzyme and 50 mM sodium citrate buffer (pH 3.0–4.0), sodium acetate buffer (pH 5.0–5.5), sodium phosphate buffer (pH 6.0–8.0), and Tris–HCl buffer (pH 8.6). Each point represents the average of two experiments

pH Stability

The pH stability of soluble and immobilized HRP was studied (Fig. 2). The enzyme was incubated at 4°C for 24 h at different pH values followed by dialysis against 50 mM sodium acetate buffer, pH 5.5. The immobilized enzyme had significant stability compared to soluble enzyme at different pH values examined. The immobilized enzyme had maximum stability at pH 3.0 and 6.0, where the enzyme retained the most of its activity. However, the effect of pH on the stability of free and immobilized manganese peroxidases from Phanerochaete chrysosporium and Bjerkandera after 1 h of incubation was determined, where between 40 and 60% of their activities were retained at pH around 3.5 and 6.0 [34].

pH stability of soluble and immobilized HRP. The enzyme was incubated at 4°C for 24 h at different pH values followed by dialysis against 50 mM sodium acetate buffer, pH 5.5. The residual soluble and immobilized enzyme activity was assayed under standard assay conditions. Each point represents the average of two experiments

Km

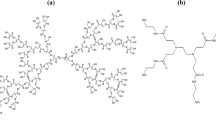

In most cases, immobilization affects the diffusion of the substrate towards the active site of the enzyme, this being reflected by the considerable increase in the apparent affinity constant (Km), when compared with that corresponding to the free enzyme [34]. In the present study, the calculated Km values of soluble and immobilized HRP were 5.5 and 3.6 for hydrogen peroxide and 16.6 and 9.0 mM for guiacol, respectively (Fig. 3a,b). The results indicated that the immobilized enzyme had more affinity toward substrates than soluble enzyme. On the contrary, the Km values of P. chrysosporium and Bjerkandera peroxidases were slightly increased with immobilization, which indicated a further influence of mass transfer resistance, where the Km values for soluble enzyme ranged from 62 to 70 μM H2O2 and for immobilized enzymes from 75 to 101 μM [34]. The Km value of the H2O2 biosensor was determined by steady-state amperometric response and found to be 1.30 μmol [33].

Effect of Temperature

Figure 4 shows the temperature optima curves for the soluble and immobilized HRP preparations. The soluble enzyme had an optimum temperature of approximately 30°C, whereas the temperature optimum of immobilized enzyme was shifted to 40°C. This indicated that the immobilized peroxidase resisted denaturation due to temperature rise. However, soluble and ConA-cellulose bound turnip peroxidase preparations showed the same temperature optima at 30°C, and the immobilized enzyme retained greater fractions of catalytic activity at higher temperatures as compared to free enzyme [9]. The effect of immobilization on stability at several temperatures was evaluated in experiments in which soluble and immobilized HRP were incubated for 15 min at temperatures ranging from 20 to 70°C (Fig. 5). The results showed that the soluble and immobilized HRP were stable up to 40 and 50°C, respectively. Whereas the soluble form exhibited a complete loss of activity upon incubation for 15 min at 70°C, the immobilized enzyme retained 25% of its activity. Therefore, the immobilization led to a considerable increase of thermostability. Also, immobilized HRP on cellulose membrane retained full activity at least for 2 h at 60°C, whereas the activity of free enzyme was reduced to almost zero at the same temperature [36]. In the same manner, immobilized turnip peroxidase incubated at 60°C for 2 h retained 54% of the initial enzyme activity, whereas the soluble enzyme lost nearly 83% of the original activity under similar incubation conditions [9].

Temperature optima of soluble and immobilized HRP. The enzyme activity was measured at different temperatures ranging from 20 to 60°C. The reaction mixture contained, in 1.0 ml, 50 mM sodium acetate buffer, pH 5.5, 8 mM H2O2, 40 mM guaiacol, and 0.1 unit of enzyme. Each point represents the average of two experiments

Effect of temperature on the thermal stability of soluble and immobilized HRP. The reaction mixture contained, in 1.0 ml, 50 mM sodium acetate buffer, pH 5.5, 8 mM H2O2, 40 mM guaiacol, and 0.1 unit of enzyme. The reaction mixture was preincubated at various temperatures for 15 min prior to substrate addition, followed by cooling in ice bath. Activity of soluble and immobilized enzyme at zero time was taken as 100% activity. Each point represents the average of two experiments

Inactivation by Heavy Metal Ions

The effect of heavy metal ions at the concentration of 10 mM on soluble and immobilized HRP was investigated (Table 3). For soluble enzyme, most of metal ions caused a slightly inhibitory effect (6–11% inhibition), whereas Cu2+ and Hg2+ caused great activation and inhibition percents, respectively. On the contrary, most metal ions caused activation effects for immobilized enzyme, except for Mn2+, Fe2+, and Hg2+, which caused inhibitory effects. The improved stability of the immobilized HRP may protect the enzyme against metal ion inactivation. This protection may result from the structural changes introduced in peroxidase by the applied immobilization procedure and, consequently, lower accessibility of the inhibiting ion to the essential SH groups of the enzyme active site. The same results were reported by Lobarzewski et al. [37], where the ions Mn2+, Cu2+, Ca2+, and Zn2+ stimulated the activity of the immobilized peroxidase more effectively than the preparation of soluble proteins. Although the Hg caused some decrease in peroxidase activity, immobilization of proteins partially protected them from harm from these ions.

Inactivation by Protease

Figure 6 shows the stability of soluble and immobilized HRP in the presence the increasing concentration (0.5–2.5 mg) of trypsin per milliliter of incubation volume. Soluble enzyme was more inactivated in the presence of increasing concentrations of trypsin than immobilized enzyme. The soluble and immobilized HRP retained 44 and 52% of their activities in the presence of 2.5 mg trypsin. It has been reported that Con A-Sephadex [8] and DEAE-cellulose [38] bound bitter ground peroxidase exhibited high resistance to proteolysis by trypsin.

Effect of trypsin concentration on the activity of soluble and immobilized HRP. Soluble and immobilized HRP were independently incubated with increasing concentrations of trypsin (0.5–2.5 mg) in a total volume of 1.0 ml of 50 mM sodium acetate buffer, pH 5.5 at 37°C for 1 h. Activity of enzyme was assayed according to the procedure described in the text

Effect of Urea, Triton X-100, and Organic Solvents

Immobilized HRP was more resistant to inactivation induced by 4.0 M urea compared to its soluble counterpart. Exposure of soluble enzyme with 4.0 M urea for 1 h resulted in the loss of 70% activity, whereas the immobilized enzyme retained 60% of the initial activity (Table 4). On the other hand, industrial effluents and wastewater sometimes contain detergents and organic solvents together with other aromatic pollutants, and such compounds can affect the activity of enzymes during wastewater treatment. However, it is necessary to investigate the role of these compounds on the activity of the immobilized enzymes. The immobilized HRP preparation was more resistant to denaturation induced by Triton X-100; this preparation retained 75% of the initial activity in the presence of 10% Triton, whereas the soluble HRP retained only 54% of the original activity under similar exposure (Table 4). The enhancement of enzyme activity by lower concentrations of detergents and stabilization of immobilized peroxidase against high concentrations of this type of detergent had already been reported by some workers [8, 9, 38].

The presence of organic solvents in wastewater necessitates the investigation of the stability of enzymes against inactivation induced by exposure of such organic solvents. The immobilized HRP was markedly more stable when it was exposed to 10% dioxane, DMSO, and propanol for 1 h (Table 4). There have been reports that immobilization of enzymes by multipoint attachment protects them from denaturation induced by organic solvents in cosolvent mixtures [39, 40].

Conclusion

HRP immobilized on chitosan/nonwoven fabric polyester membrane showed very high yield of immobilization and good reusability, and it was more stable to the denaturation induced by pH, heat, metal ions, urea, proteolytic enzymes, and water-miscible organic solvents. In the future, this immobilized enzyme preparation could be exploited for several industrial and environmental purposes.

References

Ryu, K., McEldon, J. M., Pokora, A. R., Cyrus, W., & Dordick, J. S. (1993). Biotechnology and Bioengineering, 42, 807–814.

Lobarzewsky, J., & Ginalska, G. (1995). Plant Peroxidase Newsletter, 6, 3–7.

Duran, N., & Esposito, E. (2000). Applied Catalysis. B, Environmental, 28, 83–99.

Kim, G.-Y., & Moon, S.-H. (2005). Korean Journal of Chemical Engineering, 22, 52–60.

McEldon, J. P., & Dordick, J. S. (1996). Biotechnology Progress, 12, 555–558.

Husain, Q., & Jan, U. (2000). Journal of Scientific & Industrial Research, 59, 286–293.

Lee, K. B., Gu, M. B., & Moon, S. H. (2003). Water Research, 37, 983–988.

Akhtar, S., Khan, A. A., & Husain, Q. (2005). Chemosphere, 60, 291–301.

Kulshrestha, Y., & Husain, Q. (2006). Biomolecular Engineering, 23, 291–297.

Zhang, J. Z., Li, B., Wang, Z. X., Cheng, G. J., & Dong, S. J. (1999). Analytica Chimica Acta, 388, 71–78.

Chen, W. B., & Pardue, H. L. (2000). Analytica Chimica Acta, 409, 123–130.

Xiao, Y., Ju, H.-X., & Chen, H.-Y. (2000). Analytical Biochemistry, 278, 22–28.

Liu, B. H., Yan, F., Kong, J. L., & Deng, J. Q. (1999). Analytica Chimica Acta, 386, 31–39.

Yabuki, S., Mizutani, F., & Hirata, Y. (2000). Sensors and Actuators B, 65, 49–51.

Fortier, G., Brassard, E., & Belanger, D. (1990). Biosensors & Bioelectronics, 5, 473–490.

Sergereva, T. A., Lavrik, N. V., Rachkov, A. E., Kazantseva, Z. I., Piletsky, S. A., & El’skaya, A. V. (1999). Analytica Chimica Acta, 391, 289–297.

Tatsuma, T., Gondaira, M., & Watanabe, T. (1992). Analytical Chemistry, 64, 1183–1187.

Vreeke, M., Maidan, R., & Heller, A. (1992). Analytical Chemistry, 64, 3084–3090.

Coche-Guerente, L., Cosnier, S., Innocent, C., & Mailley, P. (1995). Analytica Chimica Acta, 311, 23–30.

Xiao, Y., Ju, H.-X., & Chen, H.-Y. (1999). Analytica Chimica Acta, 391, 73–82.

Huang, R. Y. M., Moon, G. Y., & Pal, R. (2001). Journal of Membrane Science, 184, 1–15.

Krajewska, B. (2004). Enzyme and Microbial Technology, 35, 126–139.

Chellapandian, M., & Krishnan, M. R. V. (1998). Process Biochemistry, 33, 595–600.

Itoyama, K., Tokura, S., & Hayashi, T. (1994). Biotechnology Progress, 10, 225–229.

Carvalho, G. M., Alves, T. L., & Freire, D. M. (2000). Applied Biochemistry and Biotechnology, 84, 791–800.

Miao, Y., & Tan, S. N. (2001). Analytica Chimica Acta, 437, 87–93.

Shalaby, S. W. (1996). In B. D. Ratner, A. S. Hoffman, & F. Schoen (Eds.), Biomaterials science: An introduction to materials in medicine (pp. 118–124). San Diego: Academic Press.

Gumusderelioglu, M., & Turkoglu, H. (2002). Biomaterials, 23, 3927–3935.

Mohamed, S. A., Mohamed, T. M., El-Badry, M. O., & Fahmy, A. S. (2007). Bulletin of the National Research Center, 32, 53–65.

Miranda, M. V., Fernandez Lahor, H. M., & Cascone, O. (1995). Applied Biochemistry and Biotechnology, 53, 147–154.

Aly, A. S. (1998). Die Makromolekulare Chemie, 259, 13–18.

Guisan, J. M., Bastida, A., Cuesta, C., Fernandez-Lafuente, R., & Rosell, C. M. (1991). Biotechnology and Bioengineering, 38, 1144–1152.

Wang, G., Xu, J.-J., Chen, H.-Y., & Lu, Z.-H. (2003). Biosensors & Bioelectronics, 18, 335–343.

Mielgo, I., Palma, C., Guisan, J. M., Fernandez-Lafuente, R., Moreira, M. T., Feijoo, G., et al. (2003). Enzyme and Microbial Technology, 32, 769–775.

Xu, Q., Mao, C., Liu, N.-N., Zhu, J.-J., & Shen, J. (2006). Reactive Functional Polymers, 66, 863–870.

Bora, U., Kannan, K., & Nahar, P. (2005). Journal of Membrane Science, 250, 215–222.

Lobarzewski, J., Brzyska, M., & Wojcik, A. (1990). Journal of Molecular Catalysis, 59, 373–383.

Kulshrestha, Y., & Husain, Q. (2006). Enzyme and Microbial Technology, 38, 470–477.

Mozhaev, V. V., Seregeeva, M. V., Belova, A. B., & Khmelnitsky, Y. L. (1990). Biotechnology and Bioengineering, 35, 653–659.

Fernandez-Lafuente, R., Wood, A. N. P., & Cowan, D. A. (1995). Biotechnology Techniques, 9, 1–6.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohamed, S.A., Aly, A.S., Mohamed, T.M. et al. Immobilization of Horseradish Peroxidase on Nonwoven Polyester Fabric Coated with Chitosan. Appl Biochem Biotechnol 144, 169–179 (2008). https://doi.org/10.1007/s12010-007-8026-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-007-8026-x