Abstract

Driving cycles currently available cannot be used for the eco-design of vehicles power trains because those cycles do not describe local driving patterns. The main difficulty in obtaining a representative driving cycle is the lack of a repeatable and reproducible methodology to ensure that the resulting cycle is representative of local conditions. We developed a methodology to address this need, based on simultaneous data of speed, altitude, fuel consumption and tail pipe emissions. The methodology consists of three steps: (i) route selection; (ii) obtaining a representative sample of real cycles from vehicles driven in the region of interest; (iii) identification of the typical driving cycle as the one out of the real cycles sampled, whose characteristic parameters have the minimum weighted differences with respect to the average values of all cycles sampled. This method does not require the measurement of fuel consumption nor the emission of pollutants. However, by following this method, a vehicle that reproduces the resulting cycle exhibits a fuel consumption, and tailpipe emissions similar to the average of these variables shown by the entire population of vehicles with the same technology being driven in that region. We applied it to a fleet of 15 buses of the same technology covering the same routes over 8 months, in an area of high altitude with flat and hilly terrain. Measured fuel consumption and tailpipe emissions for the resulting driving cycle were within the 4% of difference with respect to the average values of all cycles sampled.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A typical driving cycle (TDC) is a time series of speeds representing the average driving pattern of drivers in a given region. Implicitly, it describes the average workload cycle demanded to the vehicle engine by drivers in that region. Therefore, a TDC has important applications, such as vehicle powertrain design, determination of fuel consumption, and determination of vehicle tail pipe emissions [1, 2].

-

Vehicle powertrain design: the expected driving cycle of a vehicle defines the external dynamic loads that the engine must supply. To size the engine and appropriate transmission ratios requires knowledge of the vehicle’s work cycle. Not knowing the expected driving pattern of the vehicle means designing a powertrain for any condition, leading to overdesign and higher fuel consumption.

-

Determination of fuel consumption: Vehicle buyers expect the manufacturer to specify a vehicle’s specific fuel consumption (SFC), in liters per kilometers or miles per gallon, obtained experimentally by repeatable procedures with results that can be replicated. However, fuel consumption depends on how the vehicle is driven. Automakers use a single arbitrary driving cycle as a basis for comparison. But the value obtained does not predict the driver’s actual fuel consumption, which depends on the local average driving pattern.

-

Determination of vehicle emissions: Environmental authorities require knowledge of environmental performance for vehicles sold in their jurisdiction, restricting vehicles with high fuel consumption and forcing automakers to develop new technologies to control vehicle emissions. However, vehicle emissions also depend on driving habits, topography, road conditions or infrastructure, environmental conditions and fuel characteristics such as sulfur content and additives. As in the case of fuel consumption, a single work cycle is used for comparison purposes. Environmental authorities define a maximum emission index (EI) as grams of contaminant per kilometer driven, that manufacturers must meet. Much effort goes into adjusting a vehicle’s engine to meet these legal requirements, yet with a different work cycle a vehicle’s environmental performance may worsen. A vehicle’s emission rating may not represent actual emissions in a given driving region.

The design of efficient powertrains and adequate measurement of both fuel consumption and vehicle emissions for a given region and application require, at a minimum, good knowledge of the typical driving pattern for the region or application of interest. The key characteristic is the representative nature of the cycle for these applications.

The process of obtaining driving cycles involves 3 phases:

-

Instrumentation of one or several vehicles to record its/their speed at 1 Hz. Cost and technology limitations have limited the number of vehicles sampled and has inhibited the monitoring of engine operating conditions (engine RPM, load, and temperature) and vehicle fuel consumption and tailpipe emissions.

-

Representative sampling of real cycles. Due to limitations in the number of vehicles instrumented, most works have used the chasing car technique to sample cycles in the city’s primary roads. The duration of the monitoring campaign has been also limited to short periods of time. The implications of performing a “representative sampling of cycles” has not been faced nor discussed yet.

-

Data analysis to build a representative driving cycle. Most recent works related to driving cycles have focused on this phase. There are 2 trends:

Transient cycles which are time series of vehicle’s speed. The most commonly used cycle in this category is the Urban Dynamometer Driving Schedule (UDDS), which is based on the FTP-72 driving cycle [3, 4]. Currently UDDS and FTP-75 are used worldwide to compare emissions from gasoline and diesel vehicles, respectively. Within this trend, each sampled cycle is divided into micro-routes (known as micro-trips) which are sections between two consecutive stops. Then, some authors elaborate a speed-acceleration frequency distribution (SAFD) plot, and build the driving cycle as a collection of micro-trips that reproduces the SAFD, sometimes via a Monte Carlo method [5,6,7]. Other authors define a set of statistics (also known as statistic parameters or characteristic parameters) that influences tailpipe emissions. Among the parameters most used are the average value for running speed, cruise, positive acceleration, idling time, and positive kinetic energy [8]. They define a cycle performance value (PV) function that is the summation of the weighted differences of the cycle characteristic parameter with respect to the average values of the cycles sampled. Finally, the cycle or set of micro-trips that minimizes PV is chosen as the representative driving cycle [9]. It has not been defined yet how to identify the characteristic parameters nor the values for the weighting factors. The major limitation to the micro-trip based methods is that the micro-trip does not differentiate various types of driving conditions such as roadway type or Level of Service (LOS) [10].

Steady state or stationary cycles that are time series artificially made up of constant phases of acceleration, speed and deceleration. Currently, the most commonly used stationary cycle is New European Driving Cycle (NEDC) [11]. It was originally developed in 1970 and is based on average use of vehicles in European cities. Stationary cycles are characterized by their simplicity and therefore have the advantage that when replicating this type of cycles on a chassis dynamometer it is easier to control acceleration ramp up and engine loads. They were designed as set of simple speed versus time ramps considering the following reasons: (i) while transient cycles were built from experimental measurements of speed over time, the methodology used to arrive at a unique cycle was arbitrary and not representative of typical driving patterns in a region; (ii) acceleration triggers fuel consumption and emissions; (iii) the same speed and acceleration profiles can be obtained under different engine load conditions. Thus to compare energy and environmental performance a transient cycle is just as arbitrary as one with simple geometry. The resulting fuel consumption and vehicle emissions from steady state cycle have no correlation with those obtained from transient cycles, since very different vehicle workloads are imposed.

While many driving cycles have been reported, still there is no a reproducible and repeatable methodology to determine them. Those methodologies do not take into account effects of high altitude (<1000 m above sea level) or highly variable topographies. No methodology has been developed based on simultaneous data of speed, fuel consumption and tailpipe emissions [5, 7].

Currently, with the advances in information technology, driving cycle samples are now easy to obtain via GPS, and therefore obtaining a representative sample of driving cycles is not any longer a limitation. However, a need still exists for a methodology to process data and obtain cycles that can be considered typical or representative. An explicit definition of representativeness for driving cycles should be stated.

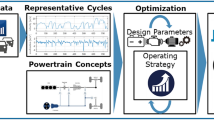

To enable the design for energy efficiency of vehicles power trains, we addressed these needs. We conducted analytical and experimental work to develop a reproducible and repeatable methodology to obtain a TDC based on simultaneous data of speed, position, altitude, instantaneous fuel consumption and tailpipe emissions. We called our proposed methodology as MWD-CP (minimum weighted differences of characteristic parameters). This paper describes the proposed methodology and reports results applying such methodology for the case of transit busses serving a single route. Work conducted to develop this methodology is described in a companion paper.

2 The MWD-CP methodology

Taking into consideration that the intended use of TDCs is mainly for the eco-design of power trains and to evaluate vehicle fuel consumption and environmental performance, we redefined a TDC as the time series of speeds representing the average driving pattern of drivers in a given region such that when reproduced by a vehicle, it shows fuel consumption, engine loads and vehicle emissions close to the average of these variables for the entire population of vehicles being driven in that region with the same technology.

This section describes the Minimum Weighted Differences of Characteristic Parameters (MWD-CP) methodology, which was developed to obtain TDC, based only on GPS data. The methodology has three phases: route selection, sampling of driving cycles and selection of the representative cycle.

2.1 Route selection

Phases 1 and 2 aim to representatively sample cycles of vehicles driven in the region or application of interest. Full sampling would require continuous recording (\(\sim \)1 Hz) of speed versus time of a representative fraction of the vehicle driven in the region for about year. Soon, technology advances may enable such massive data collection, but today we must simplify the process by choosing the primary routes used by drivers. We recommend using criteria such as traffic to select the most relevant routes.

2.2 Sampling of driving cycles

A statistical representative sample of the vehicles moving in the region of interest must be equipped with instruments that measure speed and altitude at a minimum frequency of 1 Hz, non-invasively and located unobtrusively so as not to affect the driver’s normal habits. GPS technology satisfies these requirements. Table 1 shows today’s available measurement alternatives and their advantages and disadvantages.

Then, a representative sample of cycles should be obtained. Table 2 shows the different driving cycle sampling techniques. The chasing car technique consists of arbitrarily selecting a vehicle and following it with an instrument-equipped vehicle. In the expert driver technique, the driver is asked to drive selected routes in a normal way, and as fast and safely as possible in order to test extreme conditions. Finally, the daily driver technique seeks to eliminate data collection influence on the driver’s normal habits. This is the recommended technique but it is also the most expensive. We suggest sampling at different times of day, different days of the week and different months with drivers following their own regular schedule, to include daily, weekly and seasonal variations in driving patterns.

2.3 Selection of the representative cycle

The objective of this phase is to choose among the many cycles sampled the one that represent them in terms of fuel consumption and tailpipe emissions. The technique used to choose that cycle is the key point of our proposed methodology.

2.3.1 Expressing each sampled cycle in terms of characteristic parameters

As a first step, each cycle sampled is described by a set of characteristic parameters, also known in the literature as Performance values (PV). This step is needed to substantially reduce the large amount of speed data to a set that (i) uniquely describes the cycle, (ii) has a physical interpretation, (iii) can be used to compare cycles, and (iv) influences fuel consumption.

Table 3 lists the characteristic parameters that we recommend. They are the average value for idle time, road grade, variations in potential energy, power dissipation due to drag forces, power associated to inertia forces, maximum acceleration, number of stops and maximum altitude. We showed in a companion paper that those parameters predict well fuel consumption. \(P_{ij }\) is the value for parameter i obtained for cycle j. The arithmetic average is calculated for each parameter across all cycles in the sample (\(\bar{P}_{i})\).

2.3.2 Weighting factors

The second step is to compare each characteristic parameter with respect to the average value of the same parameter for all the cycles sampled (\(\left| {P_{ij} -\bar{P}_{i} } \right| )\), and then add the differences obtained for each parameter.

However, some parameters are more relevant than others in the prediction of fuel consumption. Therefore, the summation of differences should be weighted according to the relevance of each parameter in the determination of fuel consumption.

We found that for a general cycle, characteristic of roads located on flat and hilly terrain, the most relevant parameter is \(V Sin \, \theta \), which is associated with increases in the potential energy of a vehicle due to large altitude variations and high vehicle weight. For the urban 1 cycle, characteristic of roads where there is constant heavy traffic running at low speeds, the most relevant parameter is \(V^{3}\), which is associated with aerodynamic forces. For the urban 2 cycle, characteristic of less congested roads in the city outskirts, the most relevant parameter is \(a_{+}V\), which is associated with inertial forces. This means that vehicles show more pronounced or prolonged acceleration patterns. In all three cycles, idle time is the second most relevant parameter for fuel consumption.

2.3.3 Typical driving cycle

Finally, as described in Eq. 1, the cycle (C) with the smallest sum of weighted differences is selected as representative of all the cycles in the sample, and therefore as the TDC.

3 Application to transit buses serving a single route

Aiming to illustrate the applicability of the MWD-CP methodology, we looked for a region of general characteristics, and a set of vehicles of the same technology.

3.1 Route

We looked for routes covering a region of general characteristics. However, for the purpose of our work was irrelevant the number of routes chosen. Then, aiming to facilitate the experimental work, we decided to select a single route that fulfill the requirements of generality, i.e., located at high altitude (>1000 m above sea level) whose topography included significant altitude changes (>500 m), with urban and suburban traffic.

We chose the Toluca-Mexico City route (TOL-MEX) via the Mexican federal tolled highway MEX-15D. Fig. 1a shows location and primary characteristics of this route. It has a span of 72.4 km, altitude between 2200 and 3100 m above sea level, with maximum road grade of about 8%. It is a mixed route, having both urban and suburban sections, with high traffic (\(\sim \)33,632 daily vehicles), made of 3 or 4 lanes in each direction that have been very well maintained.

We considered three cases: (i) “General cycle” which includes the complete 72.4 km route and comprises both urban and suburban areas, hilly areas and highways; (ii) “Urban 1 Cycle” which comprises the last flat 17.4 km of the general cycle, completely urban and on flat terrain inside Mexico City, which is characterized by a low traffic flow; and (iii) “ Urban 2 Cycle” which includes the first flat 14 km of the TOL-MEX road and comprises the urban and suburban areas from Toluca center to the city’s outskirts and is characterized by a medium traffic flow.

3.2 Instrumentation

For this study, 15 buses with the technology illustrated in Fig. 1b were equipped with the instrumentation described in Table 4.

State of the art on GPS technology was used to monitor vehicle position and altitude. Algorithms were developed to identify events where data was missing or atypical. Trips with less than 90% of data availability were discarded. It was verified that speed reported by GPS was equivalent to the one reported by the OBD system. GPS altitude was compared with actual altimetry manual measurements and an additional algorithm was developed to correct frequent errors in GPS reported altitude.

It was essential for our study to measure instantaneous fuel consumption. Automotive diesel technology determines this by controlling fuel injection time, which is available in the ECU (Engine Control Unit). We used OBD technologies for extracting, storing and reporting this information.

We used a portable emissions measurement system (PEMS) that measures the CO and \(\hbox {CO}_{2}\) mass emission via the nondispersive infrared method, and the NO and \(\hbox {NO}_{2}\) mass emission via the nondispersive ultraviolet method. Both of them are the USEPA’s recommended methods for measuring these pollutant concentrations.

3.3 Data acquisition

The buses were driven by the company’s regularly assigned drivers. We monitored the driving patterns minimizing any disruption to normal transport service and vehicle operation. Systematically, second by second we recorded data for variables in each cycle as described in Table 4. We sampled 1100 cycles in 8 months.

3.4 Data processing

We applied the MWD-CP methodology, which includes only GPS data. Table 5 describes the obtained TDC for general, urban 1, and urban 2 roads. Fig. 1g shows the TDC for the general road. Fig. reff1c–f show the measurements obtained for speed, altitude, fuel consumption, tailpipe emissions and speed, as function of distance, for the TDC of the general route. This cycle had a specific fuel consumption SFC = 0.34 l/km (Fuel economy FE = 2.94 km/l), which is within the confidence interval for the average fuel consumption across all sampled cycles of 0.35 ± 0.04 l/km (FE = 2.88 ± 0.37 km/l) and a relative difference smaller than 4.4%. Same observation was obtained for emissions of pollutants. Table 5 shows the average values obtained for the emission index of each air pollutant.

These results confirm that TDC, obtained through the MWD-CP methodology, can indeed be used to determine average fuel consumption over the represented cycle population.

4 Conclusions

We defined the representativeness of a driving cycle in terms of fuel consumption, engine loads and atmospheric emissions such that a typical cycle is the one whose fuel consumption and environmental emissions when is followed by a vehicle are equal to the average values for drivers using the same type of vehicle technology on a daily basis in the given region.

We proposed the minimum weighted differences of characteristic parameters methodology (MWD-CP) as an alternate way to identify the typical cycle based only on altitude and speed data collected from a representative sample of cycles.

Our methodology consists of representing an individual cycle with the following characteristic parameters: Speed on hilly terrain \((V Sin \,\theta \)), power associated with drag force \((V^{3})\), power associated with inertial force \((a_{+}V\)), total idle time (t), average road grade (\(\theta \)), maximum acceleration (\(a_{max})\), number of stops (N) and maximum altitude (\(H_{max})\). These parameters are statistically correlated with fuel consumption and their relative importance or weight depends on the topography and road characteristics of the region of study.

We applied our method to a controlled sample of vehicles on a single route at high altitude that includes both flat and hilly terrain. We measured speed, altitude, fuel consumption and environmental emissions with a frequency of 1 Hz during 8 months.

Measured fuel consumption and tailpipe emissions for the resulting TOL-MEX typical driving cycle were 2.88 ± 0.37 km/l, 861.6 ± 104.9 gr \(\hbox {CO}_{2}\) /km and 5.72 ± 0.53 gr NO/km. These values were within the 4.4% of difference with respect to the average values of all cycles sampled. We found that the cycle selected as representative in the controlled sample satisfies the condition of representativeness described above, i.e. fuel consumption and environmental emissions for the selected cycle are within the confidence intervals of mean consumption and emissions.

The MWD-CP methodology to obtain TDC allows the eco-design of vehicles power train within an interactive design environment.

References

Nutramon, T., Supachart, C.: Influence of driving cycles on exhaust emissions and fuel consumption of gasoline passenger car in Bangkok. J. Environ. Sci. 21, 604–611 (2009)

Ashtari, A., Bibeau, E., Shahidinejad, S.: Using large driving record samples and a stochastic approach for real-world driving cycle construction: winnipeg driving cycle. Transp. Sci. 48, 170–1183 (2014)

Jaikumar, R., Shiva Nagendra, S.M., Sivanandan, R.: Modeling of real time exhaust emissions of passenger cars under heterogeneous treffic conditions. Atmos. Pollut. Res. 8, 80–88 (2017)

Hung, W.T., Tong, H.Y., Lee, C.P., Ha, K., Pao, L.Y.: Development of a practical driving cycle construction methodology: a case study in Hong Kong. Transp. Res. Part D 12, 115–128 (2007)

Bishop, J.D.K., Axon, C.J., McCulloch, M.D.: A robust, data-driven methodology for real-world driving cycle development. Transp. Res. Part D 17, 389–397 (2012)

Hung, W.T., Tong, H.Y., Lee, C.P., Ha, K., Pao, L.Y.: Development of a practical driving cycle construction methodology: a case study in Hong Kong. Transp. Res. Part D 12, 115–128 (2007)

Xiao, Z., Dui-Jia, Z., Jun-Min, S.: A synthesis of methodologies and practices for developing driving cycles. Energy Proce. 16, 1868–1873 (2012)

Galgamuwa, U., Perera, L., Bandara, S.: Developing a general methodology for driving cycle construction: comparison of various established driving cycles in the world to propose a general approach. J. Transp. Technol. 5, 191–203 (2015)

Lin, J., Niemeier, D.A.: Regional driving characteristics, regional driving cycles. Transp. Res. Part D 8, 361–381 (2003)

Dai, Z., Niemeier, D., Eisinger, D.: Driving Cycles a New Cycle-Building Method that Better Represents Real-World Emissions. University of California, California (2008)

Dukulis, I., Pirs, V.: Development of Driving Cycles for Dynamometer Control Software Corresponding to Peculiarities of Latvia. Latvia University of Agriculture, pp. 95–102 (2009)

Acknowledgements

This study was financed by the National Mexican Council for Science and Technology (CONACYT), by companies Flecha Roja, Autotransporte Azteca and DIDCOM, and by the Tecnológico de Monterrey. The authors thank the contribution of Mr. Pedro Gómez, engineers Arcelia Hernández and Fernando Chanocua from company Flecha Roja, engineers Yojanan Cornejo and Vicente García from DIDCOM and MSc. Gustavo Alvarez from the Automotive Engineering Research Center—CIMA of the Tecnológico de Monterrey.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huertas, J.I., Díaz, J., Cordero, D. et al. A new methodology to determine typical driving cycles for the design of vehicles power trains. Int J Interact Des Manuf 12, 319–326 (2018). https://doi.org/10.1007/s12008-017-0379-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-017-0379-y