Abstract

To improve the UV resistance of cotton fabrics, three different carbon dots doped with boron and nitrogen (BN-CDs) were prepared by a one-step hydrothermal synthesis method using citric acid, ammonium citrate and glucose as different carbon sources, and ethylenediamine and borax as nitrogen and boron sources, respectively. Three types of blended aqueous solutions (BN-CDs/WPU) with BN-CDs and water-based polyurethane were sprayed on the surface of cotton fabric, and then the cotton fabric was rolled and dried. The structure and optical properties of BN-CDs were characterized by Fourier transform infrared spectroscopy, transmission electron microscopy, X-ray diffraction, X-ray photoelectron spectroscopy, ultraviolet-visible spectrophotometry, and fluorescence spectrophotometry. The structure and ultraviolet screening capability of cotton fabrics after finishing with BN-CD/WPU blend solution were characterized. Results showed that the prepared BN-CDs were graphite-like nanocrystals with an approximately 0.3-nm crystal plane spacing. All BN-CDs had rich hydroxyl groups and amine groups on the surface, which made the BN-CDs soluble in water. BN-CDs had a strong absorption peak in the ultraviolet region and emitted bright blue fluorescence independent of excitation wavelengths. Cotton fabrics finished with BN-CDs/WPU all showed a high ultraviolet protection factor (UPF), an excellent level of protection, and good washing durability. In particular, in cotton fabrics treated with BN-CDs prepared using citric acid as a carbon source, the UPF value was still as high as 50.1 even after washing 10 times, and the fabrics maintained good elasticity and morphological characteristics. Results thus showed that BN-CDs can be used as UV absorption agents for finishing cotton fabrics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Proper sunlight exposure is beneficial to human health, while excessive ultraviolet radiation can cause skin burns and erythemal; accelerate skin aging; and even cause skin cancer.1,2 Ultraviolet radiation from the sun that reaches the ground can be divided into three segments according to the wavelength of radiation: longwave UVA (315–400 nm), medium wave UVB (280–315 nm) and shortwave UVC (200–280 nm).3 The ozone layer in the stratosphere has a strong absorption capacity for the high-energy parts of the UVC and UVB sections, which thus effectively do not reach the surface of the Earth. Only approximately 2% of UVB and 98% of UVA can reach the surface of the earth. Therefore, the ultraviolet radiation protection of cotton fabrics is primarily aimed at UVB and UVA.

Currently, there are two primary methods for the production of textiles with UV screening capability. One is the incorporation of ultraviolet reflecting agents or absorbents in the production of synthetic fibers by blending, core nitration and other methods. Common ultraviolet reflectors are primarily silica particles,4,5 nanometal organic frameworks,6 graphene oxide,7 zinc oxide nanoparticles,8 etc. Common ultraviolet absorbents contain benzotriazole reactive dyes,9 rare earth metal organic complex light conversion agents10 and tea extracts.11 The preparation method of this type of ultraviolet absorbing fabric has the disadvantages of high technical requirements and high cost, and is not easy to use with natural fibers. The second method is using the coating method,12 sol-gel technology,13 printing method14 and other methods to give textiles UV screening capability during the finishing processing of cotton fabrics. The UV-resistant cotton fabrics treated with one of these methods exhibit poor fastness to washing and will have a certain degree of influence on the surface morphology of the cotton fabric.

Carbon dots (CDs) are a new type of fluorescent nanomaterial that have received extensive attention due to their high fluorescence and downconverted fluorescence emission characteristics.15 Due to advantages of high fluorescence intensity, strong photobleaching resistance, good biocompatibility, low toxicity, and good light stability,16 CDs are widely used in biosensors,17 chemical sensors18 and cell imaging19 and other fields. Currently, few studies have investigated using CDs as ultraviolet absorbers in textiles. Due to the strong UV absorption properties of many CDs, they can be used as ultraviolet absorbing finishing agents for cotton fabrics. In this paper, boron and nitrogen co-doped carbon dots (BN-CDs) of three different carbon sources were prepared by a one-pot hydrothermal synthesis. The effect of BN-CDs on the UV screening ability of cotton fabrics was investigated by characterizing the UPF values of cotton fabrics treated with a mixture of BN-CDs and water-based polyurethane (WPU) solutions.

Experimental section

Experimental materials

Citric acid monohydrate, glucose, ammonium citrate, ethylenediamine, and borax were all analytically pure and purchased from China National Pharmaceutical Group Corporation. Water-based polyurethane (WPU, homemade, all monomers purchased from China National Pharmaceutical Group Corporation) was used. Plain cotton white gray cloth (Qingdao Coastal Textile Co. Ltd.) with an area density of 135 g/m2; a thickness of 0.24 mm; and warp and weft densities of 298 and 312/(10 cm), respectively, was also used.

Synthesis of BN-CDs

Citric acid monohydrate (0.42 g, ammonium citrate or glucose), 0.042 g of borax and 0.5 mL of ethylenediamine were dissolved in 80 mL of deionized water, transferred to a 100-mL polytetrafluoroethylene autoclave (Henan-Nuo Pharmaceutical Chemical Container Limited Company), sealed, and put in an oven at 180°C for 5 h. Then, the mixture was naturally cooled to room temperature to obtain BN-CDs solutions with different carbon sources. The obtained solution was put into a dialysis bag (MW 1000 Da) for dialysis for 48 h and then freeze-dried in vacuum to obtain a light yellow powder. The three BN-CDs solutions were recorded as C1, C2, and C3 in the order of carbon sources: citric acid, ammonium citrate, and glucose.

Cotton fabric treatment

A method reported in the literature was used to synthesize water-based polyurethane (WPU) and formulate it into a 2% WPU aqueous solution.20 An equal volume of BN-CDs solution and WPU solution was evenly stirred to obtain a mixed solution of BN-CDs/WPU. Cotton fabrics were finished with different aqueous solutions of BN-CDs (C1, C2, C3) mixed with WPU. First, the cotton fabrics (4 cm × 4 cm) were washed with deionized water and dried in an oven at 80°C for 120 min, and 10 mL of BN-CDs/WPU mixed aqueous solution was placed into a vacuum sprayer. BN-CDs/WPU mixed solutions were sprayed into cotton fabric samples, placed in a 50°C oven to dry to semidry, removed, rolled on a small rolling mill five times, placed in a 50°C oven to dry, and sprayed. This operation was repeated until the spraying solution was finished. The three samples are denoted as F1, F2, and F3 in the order of carbon sources (citric acid, ammonium citrate, and glucose), and the water-washed blank cotton fabric is designated F0.

UPF value test and protection level assessment

The UV protection effect of the fabric is measured in accordance with the Australian/New Zealand standard AS/NZS4399-1996 “Evaluation and classification of solar protective clothing”.21 According to the ultraviolet protection factor (UPF), there are three classes: providing good protection (UPF: 15–24), providing very good protection (UPF: 25–39) and providing great protection (UPF > 40).

Characterization and testing

The UV absorption spectrum of BN-CDs was characterized by a UV2100 ultraviolet-visible spectrophotometer (Beifen-Ruili, China).

The excitation and emission spectra of BN-CDs were characterized by a WFY-28 fluorescence spectrophotometer (Tianjin-Tuopu, China).

The structural characterization of BN-CDs and finished cotton fabrics was performed using a VERTEX 70 Fourier transform infrared spectrometer (Bruker, Germany).

The particle size and structure of BN-CDs were observed with a Tecnai G2 F30 transmission electron microscope (TE, FEI, USA).

The surface morphology of cotton cloth after finishing with BN-CDs/WPU was observed with a JSM-IT300 electron microscope (SEM, JEOL, Japan).

The structure and composition of the samples were studied using a German Bruker AXS D2 X-ray diffractometer (Cu target Kα ray, λ = 0.15406 nm, scanning range 10°–80°).

Thermo Scientific Company X-ray photoelectron spectroscopy (K-alpha) was used to test the structure and elemental composition of the samples.

The ultraviolet protection factor (UPF) of the cotton fabric was tested using the HD902C ultraviolet transmittance tester (Nantong Hongda, China). Ten different positions were taken for each sample for testing, and the average value was recorded.

The durability of the samples was assessed by testing their UPF values after 1, 2, 5 and 10 household laundry washes. The household laundry test was conducted according to the AATCC61-2001 standard, and each washing time was 5 min. After washing and drying, the UV protection coefficient of the dried samples was measured again.

The change in the quality of cotton fabric after finishing and after washing was calculated as follows:

where mo is the mass (g) of the original fabric and mi is the mass (g) of the fabric after finishing or after washing.

Results and discussion

Structural analysis of BN-CDs

Figure 1 shows the infrared spectra of three BN-CDs. The primary functional groups of the prepared BN-CDs exist. The broad peaks of C1, C2, and C3 at 3384, 3405, and 3386 cm−1, respectively, can be attributed to the stretching vibrations of –NH and –OH. The peaks at 1652, 1647, and 1647 cm−1 can all be attributed to the –C=ON– stretching vibration, and the peaks at 1567, 1563, 1561 cm−1 can all be attributed to the –C=N stretching vibration. The peaks at 1041, 1045, and 1047 cm−1 can all be attributed to the vibrational vibration of C–O, and the peaks at 791, 627, and 647 cm−1, respectively, can all be attributed to the out-of-plane bending vibration peaks that are primarily –NH and –OH. The peaks of C1, C2, and C3 at 1394, 1389, and 1391 cm−1 can be attributed to the stretching vibration of B–O, and the peaks at 1120, 1080, and 1080 cm−1 can be attributed to the stretching vibration of C–B. The peaks at 1154 and 1180 cm−1 in C1 and C2 can be attributed to B–O–H bending vibrations. The peaks at 1154 and 1180 cm−1 in C1 and C2 can all be attributed to B–O–H bending vibrations. The peaks at 1482 and 1498 cm−1 in C1 and C3 can be attributed to the stretching vibration of C–N.22,23 These results showed that the surface of the three prepared BN-CDs contained a large number of amine groups, carboxyl groups and oxygen-containing functional groups, which can interact with the hydroxyl groups on the surface of cotton fabrics to enhance the interaction between BN-CDs and cotton fabrics.

Figure 2 shows the transmission electron micrograph of BN-CDs. The prepared BN-CDs all have a near spherical morphology with dimensions in the range of 5–8 nm. The high-resolution transmission electron micrographs in the lower right corner show that BN-CDs have a lattice parameter of approximately 0.30 nm, which is near the interlayer distance between the graphene layers (002 facet). Based on these results, the prepared BN-CDs may be graphite-like nanoparticles with abundant hydroxyl and amine groups on the surface.24

Figure 3 shows the XRD pattern of BN-CDs. The three types of BN-CDs have broad-scale diffraction peaks at 2d of 26.20°, 25.10° and 24.70° with crystal plane spacings of 0.344 nm, 0.347 nm and 0.354 nm, respectively, which can be designated the graphite (002) crystal plane.25 These results are consistent with those of TEM characterization. The low crystallinity of these three BN-CDs is primarily caused by the large number of functional groups on the surface of the carbon quantum dots, resulting in increased crystalline surface spacing.

To describe the structure and element composition of three different BN-CDs in more detail, we performed a detailed characterization analysis of the element composition of BN-CDs using XPS. As shown in Fig. 4, the XPS wide scan spectra of BN-CDs of three different carbon sources have strong absorption peaks at 191.7, 284.6, 400.3, and 530.4 eV that correspond to the peaks of B1s, C1s, N1s and O1s. These results indicate that we successfully prepared boron–nitrogen co-doped fluorescent carbon quantum dots.

XPS results show that BN-CDs of three different carbon sources are primarily composed of four elements, C, N, O and B, which is consistent with the infrared spectrum detection results, further indicating that there are a large number of hydrophilic functional groups containing nitrogen, oxygen and boron on the surface of the three carbon quantum dots. However, the proportions of the four elements in the three carbon quantum dots are different. As shown in Table 1, the proportions of C, N, O and B in C1 are 67.98%, 16.53%, 13.9% and 1.59%, while the proportions of C, N, O and B in C2 are 66.12%, 11.04%, 21.44% and 1.39%, respectively. The proportions of C, N, O and B in C3 are 64.9%, 11%, 22.6% and 1.5%, respectively. The different element contents of the three carbon quantum dots indicate that the contents of various groups on the surface of carbon quantum dots are different. C1 has the highest nitrogen content and the lowest oxygen content, while C3 has the lowest nitrogen content and the highest oxygen content, and C2 has the middle nitrogen content and oxygen content.

The high-resolution C1s, N1s, O1s and B1s XPS spectra of the three BN-CDs carbon sources are shown in Fig. 5. The high-resolution spectra of C1s of BN-CDs (Figs. 5a, 5b, 5c) show that there are three peak values at 284.3, 285.7 and 287.8 eV. Ascribed to C–C/C=C, C–N and C–O, carbon is shown to exist in the three different environments. The N1s high-resolution spectrum of BN-CDs (Figs. 5d, 5e, 5f) consists of two peaks centered on 399.1 and 400.7 eV, indicating that nitrogen exists in two forms of C–N–C and N–H, respectively. The O1s high-resolution spectrum of BN-CDs (Fig. 5g, 5h, 5i) consists of two peaks at 530.8 and 531.8 eV, indicating that oxygen exists in the form of C=O and C–OH/C–O–C, respectively. The B1s high-resolution spectrograms of BN-CDs (Fig. 5j, 5k, 5l) have peaks of 191.5 and 192.1 eV, indicating that boron primarily exists in the form of B–O and B–N/B–C. XPS results were consistent with those of FTIR analysis. Based on this characterization data, the prepared BN-CDs may be graphite-like nanocrystals with rich hydroxyl and amine groups on the surface.24

Photoluminescence characteristics of BN-CDs

Figure 6 shows the ultraviolet-visible absorption spectra and fluorescence emission spectra of the BN-CDs aqueous solution. The prepared BN-CDs exhibit good UV screening capabilities in the range of 200–400 nm, which shows that the prepared BN-CDs can be used as ultraviolet-shielding materials. There are two strong absorption peaks at 240 and 347 nm, which can be attributed to the π → π* transition of the conjugated double bond C=C and the n → π* transition of C=O, respectively.22 These results are consistent with the oxygen-containing groups on the surface of BN-CDs in Fig. 1 and the graphite-like structure in Fig. 2. Three BN-CDs aqueous solutions showed strong emission peaks at 435 nm when they were excited at 380 nm.

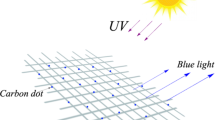

Figure 7 shows the fluorescence emission spectra of BN-CDs at different excitation wavelengths. Even if the excitation wavelength increases from 340 to 380 nm, the emission peak of the BN-CDs is nearly at 435 nm. Thus, the photoluminescence behavior independent of the excitation wavelength may be related to the surface defect state rather than the interband transition.26 Due to this downconverted fluorescence emission, BN-CDs can be used as ultraviolet absorbers for cotton fabrics. When ultraviolet light is irradiated onto BN-CDs, BN-CDs convert it into visible light.27 The inset shows photographs of aqueous solutions of BN-CDs under sunlight and 365-nm UV light. The C1 and C2 solutions are pale yellow, and the C3 solution is dark red when exposed to sunlight. Irradiated by 365-nm ultraviolet light, C1 and C2 solutions emit strong blue light, and C3 solution emits strong green–blue light.

Infrared spectrum of cotton fabric samples

Figure 8 shows the IR spectra of blank cotton fabrics and cotton fabrics after finishing with the three BN-CDs/WPU solutions and after 10 washes. The absorption spectrum in Fig. 8a primarily shows three characteristic peaks near 3294, 2865 and 1615 cm−1, which can be attributed to the O–H stretching vibration, C–H asymmetric stretching vibration and C=O stretching vibration of cotton cellulose, respectively. The absorption band between 1500 and 1200 cm−1 corresponds to the characteristic vibrations of C–H, O–H, C–O and C–O–C of cotton cellulose.28 The spectra of F1, F2 and F3 are similar, showing a strong absorption peak at 1725 cm−1, which can be attributed to the C–H stretching vibration and C=O stretching vibration in the WPU on the surface of the cotton fabric. There is a strong absorption peak at 1538 cm−1 due to the bending vibration of –C=O–N– in the BN-CDs. Results thus showed that BN-CDs successfully adhered to the surface of the cotton fabric after finishing with the three BN-CDs/WPU solutions, and there was no chemical reaction between BN-CDs/WPU and cotton cellulose.

The spectra of F1, F2 and F3 in Figs. 8b and 8a are similar, and the bending vibration of –C=O–N– at 1538 cm−1 is markedly reduced. After 10 washings, the amount of BN-CDs attached to the surface of the cotton fabric decreased because the combination of BN-CDs and WPU with the surface of cotton fabric has a physical effect. After washing, some of the BN-CDs fell off, resulting in weaker absorption peak intensity, but the absorption peak was still present, indicating that after multiple washings, the BN-CDs still adhered to the cotton fabric.

Surface morphology of cotton fabric samples

Figure 9 shows the SEM images of F0, F1, F2, and F3. F0 has a relatively smooth surface, but F1, F2 and F3 have a relatively rough surface with a thin layer of WPU on the surface. Due to the intermolecular hydrogen bonding among BN-CDs, cellulose and WPU, the WPU coating can improve the wash fastness of BN-CDs on the surface of cotton fabric.

UV protection of cotton fabric samples

Table 2 shows the UPF values of cotton fabric samples (F1, F2, F3) before and after water washing. The blank cotton fabric has a UPF value of approximately 31.2 (a very good anti-UV fabric). Cotton fabrics finished with three BN-CDs/WPU aqueous solutions of C1, C2, and C3 have UPF values of up to 97.1, 194.9, and 163.9, respectively, all of which provide excellent protection against UV fabrics. Finished cotton fabrics F1, F2 and F3 emit bright blue light under 365-nm UV light, as shown in Fig. 10. After washing once, the UPF values of F1, F2, and F3 all showed a marked decrease, which may be due to washing away the excessive BN-CDs solution absorbed on the surface of cotton fabric. After subsequent water washing, the UPF values of F1 and F2 tended to be stable. After ten washes with water, the UPF values of F1 and F2 were 1.61 and 1.55 times that of blank cotton fabrics, respectively, thus indicating that F1 and F2 remained excellent UV protection fabrics. In subsequent washings of F3, the UPF value continued to decrease primarily because BN-CQD does not chemically react with the surface of the cotton fabric and is primarily attached to the surface of the cotton fabric in the form of physical adsorption. The bond is thus weak, leading to BN-CQD easily falling off during washing. However, the UPF of cotton fabric treated with C3 was still as high as 79.9 after 10 washings, which was related to the dark-brown color of BN-CDs prepared by a glucose carbon source. The surface morphology of cotton fabric after C3 finishing was poor, and the color of the cotton fabric appeared black. Therefore, the use of C1 and C2 finishing cotton fabrics is more conducive to application in the field of clothing fabrics. F1, F2 and F3 still emit blue light under 365-nm UV light (Fig. 10) after 10 washes.

Figure 11 shows the rate of change in mass of the finished cotton fabrics with the number of washing times. After finishing cotton fabrics with BN-CDs/WPU solutions, the mass changes of cotton fabrics were relatively large. Compared with blank cotton fabrics, the masses of F1, F2, and F3 increased by 43.34%, 45.03%, and 43.25%, respectively, indicating that BN-CDs successfully attached to the cotton fabric in the presence of WPU. After the first and second water washings, the rate of change in mass dropped abruptly because the water washing removed a portion of the BN-CDs and WPU attaching to the surface of the cotton fabrics. In subsequent water washings, the mass of F1, F2, and F3 decreased slowly. Particularly for F1, the mass exhibited a relatively stable trend. Compared with the blank cotton fabric after washing 10 times, the mass change rate of the cotton fabrics finished with three BN-CDs/WPU solutions was 29.71%, 28.41% and 27.81%, respectively. Thus, a large number of BN-CDs were still attached to the surface of cotton fabric, which corresponded with the measured UPF value reported above.

Conclusions

Three boron–nitrogen-doped carbon dots were prepared with a one-step hydrothermal synthesis that used citric acid, ammonium citrate or glucose as a carbon source, and ethylenediamine and borax as nitrogen and boron sources, respectively. These BN-CDs exhibited PL behavior that was independent of excitation wavelength, emitted blue and green–blue luminescence under 365-nm ultraviolet light, and exhibited strong absorption peaks in the ultraviolet region. The BN-CDs/WPU-finished cotton fabric exhibited excellent UV protection. Compared with the BN-CDs prepared with ammonium citrate and glucose as carbon sources, the fabric treated with BN-CDs using citric acid as a carbon source achieved the best performance. After 10 washes, the UPF value of the fabric was 50.1 with good flexibility and morphology.

References

Wang, Q, Hauser, PJ, “Developing a Novel UV Protection Process for Cotton Based on Layer-by-Layer Self-Assembly.” Carbohydr. Polym., 81 (2) 491–496 (2010)

Mishra, A, Butola, BS, “Deposition of Ag Doped TiO2 on Cotton Fabric for Wash Durable UV Protective and Antibacterial Properties at Very Low Silver Concentration.” Cellulose, 24 (8) 3555–3571 (2017)

Qu, L, Tian, M, Hu, X, et al. “Functionalization of Cotton Fabric at Low Graphene Nanoplate Content for Ultrastrong Ultraviolet Blocking.” Carbon, 80 565–574 (2014)

Ronghui, G, Yani, L, et al. “Microwave-Assisted Synthesis of Silver Nanoparticles on Cotton Fabric Modified with 3-Aminopropy-Ltrimethoxysilane.” J. Appl. Polym. Sci., 130 3862–3868 (2013)

Ruixue, LI, Xiaolin, S, Xingya, Z, “Study on Anti-UV Property of Cotton Fibers by In-Situ Generation of TiO2.” J. Text. Res., 37 (3) 78–81 (2016)

Emam, HE, Abdelhameed, RM, “Anti UV Radiation Textiles Designed by Embracing with Nano MIL (Ti, In)–Metal Organic Framework.” ACS Appl. Mater. Interfaces, 9 (33) 28034–28045 (2017)

Tang, X, Tian, M, Qu, L, et al. “Functionalization of Cotton Fabric with Graphene Oxide Nanosheet and Polyaniline for Conductive and UV Blocking Properties.” Synth. Metals, 202 82–88 (2015)

Shaheen, TI, El-Nagger, ME, et al. “Durable Antibacterial and UV Protections of In Situ Synthesized Zinc Oxide Nanoparticles onto Cotton Fabrics.” Int. J. Biol. Macromol., 83 426–432 (2015)

Guoliang, G, Peng, Z, Defeng, Z, “Synthesis and Application Properties of Anti-UV Radiation Reactive Dyes Containing Benzotriazole Groups.” J. Dalian Univ. Technol., 49 (1) 24–27 (2009)

Hechun, C, Guibo, Y, “Synthesis of Dual Ligand Rare-Earth Light Conversion Agent and Its Application on UV-Protection Fabric.” J. Text. Res., 35 (5) 83–86 (2014)

Bonet-Aracil, MÁ, Díaz-García, P, Bou-Belda, E, et al. “UV Protection from Cotton Fabrics Dyed with Different Tea Extracts.” Dyes Pigments, 134 448–452 (2016)

Tran Thi, VH, Lee, BK, “Development of Multifunctional Self-Cleaning and UV Blocking Cotton Fabric with Modification of Photoactive ZnO Coating Via Microwave Method.” J. Photochem. Photobiol. A: Chem., 338 13–22 (2017)

Kowalczyk, D, Brzeziński, S, Kamińska, I, “Multifunctional Nanocoating Finishing of Polyester/Cotton Woven Fabric by the Sol–Gel Method.” Text. Res. J., 88 (8) 946–957 (2016)

Hakeim, OA, Abdelghaffar, F, Haroun, AA, “UV-Protection of Cellulosic Fabric Prints Using Hyperbranched Polyester-Stabilized Titania Coating.” Prog. Organ. Coat., 136 105295 (2016)

Lim, SY, Shen, W, Gao, Z, “Carbon Quantum Dots and Their Applications.” Chem. Soc. Rev, 44 (1) 362–381 (2015)

Tao, S, Zhu, S, et al. “The Polymeric Characteristics and Photoluminescence Mechanism in Polymer Carbon Dots: A Review.” Mater. Today Chem., 6 13–25 (2017)

Meshik, X, Farid, S, Choi, M, et al. “Biomedical Applications of Quantum Dots, Nucleic Acid-Based Aptamers, and Nanostructures in Biosensors.” Crit. Rev. Biomed. Eng., 43 (4) 277–296 (2015)

Ya-Jun, D, Chen, FU, Jing, W, “Synthesis of a New Kind Carbon Quantum Dots and Application in Copper Ion Detection.” Sci. Technol. Eng., 16 (11) 132–135 (2016)

Chan, KK, Yap, SH, Yong, KT, “Biogreen Synthesis of Carbon Dots for Biotechnology and Nanomedicine Applications.” Nano-Micro Lett., 10 (04) 268–313 (2018)

Zhou, X, Li, Y, Fang, C, et al. “Recent Advances in Synthesis of Waterborne Polyurethane and Their Application in Water-Based Ink: A Review.” J. Mater. Sci. Technol., 31 (7) 708–722 (2015)

Hebeish, A, Sharaf, S, Farouk, A, “Utilization of Chitosan Nanoparticles as a Green Finish in Multifunctionalization of Cotton Textile.” Int. J. Biol. Macromol., 60 (9) 10–17 (2013)

Li, Z, Yu, H, Bian, T, et al. “Highly Luminescent Nitrogen-Doped Carbon Quantum Dots as Effective Fluorescent Probes for Mercuric and Iodide Ions.” J. Mater. Chem. C, 3 (9) 1922–1928 (2015)

Yushan, L, Wei, L, Peng, W, et al. “Hydrothermal Synthesis of Nitrogen and Boron Co-Doped Carbon Quantum Dots for Application in Acetone and Dopamine Sensors and Multicolor Cellular Imaging.” Sens. Actuators: B. Chem., 281 34–43 (2019)

Zhang, YQ, Ma, DK, Zhuang, Y, et al. “One-Pot Synthesis of N-Doped Carbon Dots with Tunable Luminescence Properties.” J. Mater. Chem., 22 (33) 16714–16718 (2012)

Dong, Y, Shao, J, Chen, C, et al. “Blue Luminescent Graphene Quantum Dots and Graphene Oxide Prepared by Tuning the Carbonization Degree of Citric Acid.” Carbon, 50 4738–4743 (2012)

Chen, X, Zhang, W, Wang, Q, Fan, J, “C8-Structured Carbon Quantum Dots: Synthesis, Blue and Green Double Luminescence, and Origins of Surface Defects.” Carbon, 79 165–173 (2012)

Zuo, D, Liang, N, Xu, J, Chen, D, Zhang, H, “UV Protection from Cotton Fabrics Finished with Boron and Nitrogen Co-Doped Carbon Dots.” Cellulose, 26 4205–4212 (2019)

Rajaboopathi, S, Thambidurai, S, “Evaluation of UPF and Antibacterial Activity of Cotton Fabric Coated with Colloidal Seaweed Extract Functionalized Silver Nanoparticles.” J. Photochem. Photobiol. B Biol., 183 75–87 (2019)

Acknowledgments

This study was supported by the National College Students Innovation and Entrepreneurship Training Program (201910495025).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, S., Wang, C., Zhang, H. et al. Study on the ultraviolet absorbing properties of cotton fabric finished with boron and nitrogen co-doped carbon dots. J Coat Technol Res 19, 1077–1086 (2022). https://doi.org/10.1007/s11998-021-00586-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-021-00586-7