Abstract

This work aims at investigating the dispersibility of a modified hydrophilic nanosilica using methacryloxy propyltrimethoxysilane (MPTMS) in an organic phase, which contains UV-curable urethane acrylate oligomers and monomers with different functionalities. Through a Taguchi design of experiment, the impacts of influencing parameters such as silane coupling agent to silica ratio, hydrolysis ratio as well as treating bath pH were investigated. The optimum condition in which the maximum percentage of modification occurred was observed at higher stoichiometric levels of silane:silica ratio and alkaline pH conditions. Furthermore, statistical analysis demonstrated that hydrolysis ratio was not very significant. Low amounts of turbidity of prepared hybrid coatings indicated that modified particles with higher grafting contents had better dispersion stability in the acrylate resin.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Inorganic nanoparticles such as SiO2, TiO2, ZnO, and CaCO3 are widely used to improve the characteristic performances of organic coatings. Among these, nanosilica has attracted increasing interest due to its moderate hardness in applications where scratch and abrasion resistance are of prime importance.1,2 Furthermore, it has a low refractive index, so the transparency of the coatings would not be affected.3–6

As silica contains a large number of silanol groups on its surface in the form of vicinal, geminal, and isolated, it can be considered a very polar filler. Therefore, it is less dispersible in nonpolar media. Moreover, the surface silanol groups have a great affinity to form hydrogen bonding with each other, resulting in strong filler–filler interaction.

Infrared spectrometry has demonstrated the presence of single and/or associated hydroxyl groups on the surface of nanosilica (Fig. 1).7 These hydrophilic groups have a high surface energy and tend to adhere to each other. This leads to aggregations in the nonpolar organic compounds.3,4,8

Different types of hydroxyls and water absorbed molecules on the surface of nanosilica7

In order to modify nanosilica for improved dispersibilty in nonpolar media, a surface treatment using various methods has been reported.4,5,8,9 Use of appropriate modifying substances and the method by which treatment is performed seem very important.10 Silane coupling agents (CAs) are often used to modify the silica surface due to their bifunctional structure.11–14 These have reactive groups for both the filler and the matrix and may form a chemical link between two phases.15 Silanol groups that are formed and built in the structure of silane CA after its hydrolysis may form hydrogen bonding with the hydroxyl groups of nanosilica surface. Moreover, they have functional groups such as isocyanate, amine, epoxy, vinyl, and methacrylic.

Methacryloxy propyltrimethoxysilane (MPTMS) is one of the most widely used compounds for this purpose. This CA is able to form a chemical bond between the filler and UV-curable urethane–acrylate coatings.15–17 The mechanical properties of coatings could be enhanced by such chemical bonds.

Sol–gel processing is the most commonly used method to achieve such a modification. This process is based on hydrolysis and condensation reactions between the silane CAs and nanosilica in a polar media.

There are various factors affecting this process, including the type of silane CA,3,4 treating bath pH and hydrolysis ratio (ratio of water to silane),3,18 treatment time,8 pretreatment method,3,4,13 and the temperature of reaction.19 All of these factors may determine the final grafting of CAs on the surface of nanosilica.

It has been claimed by Xhanthos18 that the treating bath pH and hydrolysis ratio are the most important factors affecting the treatment process. The final result of the treatment reaction is the partial blocking of the nanosilica hydroxyl groups. This leads to particles with less hydrophilic surface and better compatibility with nonpolar media, e.g., organic polymers.15,16

Jesionowski and Krysztafkiewicz4 suggested a novel process for treatment of nanosilica with methacrylic silane in the course of its formation during precipitation from sodium metasilicate solution using acidic conditions in glycerin. In that work the ratio of CA to silica was changed between 1 and 10 parts per 100 parts of silica. These seem to be much less than the stoichiometric content of CA to react with the existing surface silanols.

The low reactivity of methacrylic silane in acidic conditions and low concentrations in the sol–gel process were not taken into consideration in that work. In another work, nanosilica surface treatment using amino and epoxy silane CAs was investigated by Sun et al.8 They explored an optimum condition for the treatment of nanosilica by investigating the type of CA and its concentration, treatment time, and predispersion method. It was found that long reaction time was necessary for the completion of the treatment reaction between silane and silica in acidic conditions.

Furthermore, Sun et al.11 studied the application of the treated nanosilica with dimethyldichlorosilane (DMCS) and MPTMS by evaluating the dispersion and interfacial compatibility of these particles in a PVC matrix. It was claimed that the compatibility between the functional groups coupled on the surface of nanosilica and the functional groups of the matrix is necessary to have an effective interfacial interaction for improved mechanical properties of the polymeric matrix.

Rostami et al.13 studied the effect of treating bath pH on two different types of silane CAs. They reported that the treatment methods included pH variations from very acidic (1–2), slightly acidic (4–6), and alkaline (8–10). These ranges of pHs had been chosen due to their influences on hydrolysis reaction, condensation of silane with itself and with the particle, as well as to their effects on protonation of amino functional groups of silane molecules used.

Through a design of experiment (DOE) using Taguchi method, the impact of influencing parameters such as molar ratio of precursors, hydrolysis ratio, post-curing temperature, post-curing time, and weight percentage of inorganic to organic part on the abrasion resistance of sol–gel based UV-curable nanocomposite films were investigated by Yahyaei et al.20

It was revealed that molar ratio of tetraethyl orthosilicate:methacrylic silane CA and inorganic to organic weight ratio were the most significant parameters, whereas thermal post-curing did not have any considerable effect on the mechanical properties.

Taguchi DOE is a suitable method for analysis of high quality systems. It provides appropriate designs that control the experimental conditions within a couple of variations. By learning and applying this technique, engineers, scientists, and researchers can significantly reduce the time required for experimental investigations.

The objective of the present work is to investigate the impact of factors affecting the surface treatment of a hydrophilic nanosilica using an acrylic silane. The parameters studied include treating bath pH, hydrolysis ratio, and silane CA concentration. In order to achieve the optimum conditions for the treatment reaction, a DOE was used. Particles were characterized utilizing different techniques to reveal their surface chemistry. To study the effectiveness of surface treatment, the behavior of particles in a UV-curable urethane acrylate resin was also investigated.

Experimental

Materials and methods

Hydrophilic nanosilica (OX50), having a specific surface area of 200 m2/g and particle diameter of 40 nm was obtained from Degussa Co. The pH of the 4 wt% silica dispersion (according to ISO 787-9) and the number of hydroxyl groups of silica21 are 3.7–4.7 and 4.6 OH nm−2, respectively.

According to ISO 787-9, pH of all particles involving acidic or alkaline active functional groups can be measured very easily. A mechanical homogenizer (IKA) was used to disperse 4 g of silica particles in the mixture of 32 g deionized water and 4 g ethanol for a short period of time of approximately 1–2 min. Suspensions were allowed to stand for 5 min, after which the nearest 0.1 unit of the measured pH was reported. The magnitude of the hydroxyl number of silica surface is the number of OH groups per unit surface area and when the surface is hydroxylated to the maximum degree, it can be considered as a physico-chemical constant. This constant has a quantitative amount: αOH,AVE = 4.6 (least-squares method) and αOH,AVE = 4.9 nm−2 (arithmetical mean).

MPTMS, 97% in ethanol, was purchased from Degussa Co. All other chemical reagents, including ethanol, hydrochloric acid, acetic acid, and caustic soda were obtained from Merck Co. All materials were used as received.

Surface treatment procedure

The variables studied included treating bath pH, hydrolysis ratio, and silane concentration. Each of these variables was investigated at three levels according to Table 1. A Taguchi DOE was utilized to statistically analyze the data. Accordingly, the number of experiments was reduced using Taguchi DOE from 27 to 9. In the Taguchi method three factors including (i) CA concentration, (ii) hydrolysis ratio, and (iii) treating bath pH, were investigated and three levels were selected for each factor. These variations are the most significant parameters affecting the final percentage of silane on the nanosilica surface. Consequently, 33 = 27 experiments should be tested to achieve an optimum condition for the treatment reaction between silane CA and nanosilica surface. Using Taguchi and Minitab 15 software an L9 orthogonal array instead of an L27 was proposed. This reduces the number of experiments from 27 to 9.

Minitab 15 software was utilized to analyze the L9 orthogonal array proposed by the Taguchi method, as shown in Table 2. The amount of silica and silane were calculated according to the stoichiometric value and hydrolysis ratio of 1 (h = 1) as equation (1)22:

where M is the amount of silane (in g), S sSi is the surface area of silica (in m2/g), m Si is weight of silica used (in g), and M Silane is the molecular weight of silane. OH·No is the number of hydroxyl groups per nm2 of silica, NA is the Avogadro number and 1018 is a factor converting m2 to nm2.

A mixture of deionized (DI) water and absolute ethanol was used as the medium for silica powder treatment. Hydrochloric acid, acetic acid, and caustic soda were used to adjust the pH. A mechanical homogenizer (IKA) was used for all samples at 19,000 rpm. All reactions lasted for 3 h. The resulting slurries were first centrifuged at 4500 rpm, followed by washing for three times with ethanol. In each washing stage the suspensions were centrifuged. Then the sedimented particles were dispersed in water:ethanol (50:50) solution and dried using a spray dryer at 120°C to collect the variously treated silicas.

Particle characterization

The pH for each powder in the mixture of ethanol and water was determined according to ISO 787-9 standard. Apparent densities were measured using a helium pycnometer. To study the functionalization of silane CA on nanosilica surface, a Perkin Elmer Spectrum One Fourier Transform Infrared (FTIR) spectrometer was used. The IR spectra of samples were recorded using KBr. To investigate the efficacy of surface treatment, thermogravimetric analysis (TGA) was performed utilizing a TGA-DTA Pyris Diamond SII Analyzer in a nitrogen atmosphere at a heating rate of 10°C/min from room temperature to 600°C.

Elemental analysis for carbon and hydrogen content on the modified and unmodified silica samples was employed according to ASTM D5291 by a Foss-Herueus CHN-D-Rapid Analyzer. Turbidity of dispersed silica powders in ethanol was determined using a HACH 2100 AN Turbid meter. Moreover, the spectra of samples at 5 nm scan intervals were measured in the range of 250–800 nm by the aid of a UV–vis spectrophotometer (Cray 100 scan).

Preparation of particle-loaded films

Films were prepared by mixing the organic phase as listed in Table 3 with various amounts of untreated and treated nanosilica particles. The weight percents of silica in the final samples were 3, 5, and 7%. These mixtures were applied on a precleaned glass using a doctor blade with 40 ± 5 μm thickness. Curing process of the prepared films was performed using a UV cabinet equipped with a conveyor having 1.13 mJ/cm2 irradiation illuminator. Pure urethane acrylate film was named as UAc and all the particle containing samples were labeled according to the weight percent of the corresponding nanosilica.

Results and discussion

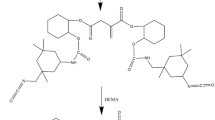

Silica has a polar surface and therefore shows poor interaction with the organic polymers in which it is dispersed. Silane CAs could enhance the compatibility between the fillers and the organic coatings by grafting functional groups on their surface. Determining the quantitative amount of silane grafted on the surface of nanosilica and exploring the condition for treatment reaction are the main tasks of this work. There are two different scenarios for the grafting of MPTMS on the surface of nanosilica.15 MPTMS can be oriented as a rod with a perpendicular orientation to the surface, or it can be oriented parallel to the surface, which may be formed by hydrogen bonding between MPTMS carbonyl and a hydroxyl group of the nanosilica (Fig. 2). It has been estimated that greater content of MPTMS is needed for the former case.15

Grafted MPTMS with perpendicular and parallel orientations15

MPTMS has three alkoxy groups, which can self-condense with each other upon hydrolysis. In this case, an oligomeric layer of silane can be grafted on the surface of nanosilica. Figure 3 shows schematic reactions of silane grafting on the surface of metal oxide fillers such as nanosilica. The hydrolysis of alkoxy group of a silane molecule is given in Scheme A in Fig. 3. This reaction may occur for alkoxy groups irrespectively. Not only hydrolyzed MPTMS molecules may form hydrogen bonding with the silanol groups of silica, these molecules can also form homo-condensates with each other easily as manifested in Scheme C in this figure. These two reactions compete with each other in the treatment reaction of silane on the nanosilica surface. Furthermore, if the homo-condensation is faster than grafting reaction, the MPTMS may no longer be available for reaction with inorganic surface.15

Reaction schemes for the grafting of MPTMS onto metal oxide particles15

Extensive studies have been carried out on the surface treatment of nanosilica.3,4,8,23 Rostami et al.13,24 investigated the effects of treating bath pH and hydrolysis ratio on the surface properties of amino and epoxy silane treated nanosilica particles. It was revealed that in all pH conditions, silica was more or less chemically grafted onto silane. When the pH of treating bath was adjusted at 1–2 prior and during the reaction, 58% grafting was reported by them, as obtained by CHN and TGA. At very alkaline conditions, however, the grafting content declined to 29%. The difference in grafting was discussed based on silane hydrolysis and condensation with the silica surface.

As mentioned above, the aim of this work is to explore the optimum conditions of nanosilica surface treatment through the changes of three variable factors including; treating bath pH, hydrolysis ratio, and silane to silica concentration ratio. Each of these factors was investigated in three different levels. With the use of an L9 orthogonal array according to the Tagouchi DOE, the number of experiments was reduced from 27 to 9. The various conditions of nanosilica treatment and the prediction of the quantitative amount of silane grafted on the silica surface are listed in Table 4. The quantitative amount of the silane grafted on the surface of nanosilica was marked with QSa in this table in which “a” refers to the number of the treated sample.

Effect of treatment pH

According to Table 2, sample 1 was treated at acidic pH (pH 1–2), hydrolysis ratio of 1/3 and silane to silica concentration ratio lower than the stoichiometric content. Silica and MPTMS isoelectric point are about 3 and 4.4–4.8, respectively. At pH 1–2, both silica surface and silanol groups in silane are positively charged, so they may not show affinity to each other. At this pH, silane has high reactivity (Fig. 4),18 so it can be hydrolyzed into silanol and then condensed with silica. Nanosilica hydroxyl groups and hydrolyzed silane interact with each other through hydrogen bonding, resulting in condensation and formation of Si–O–Si networks. The silane treatment reaction was conducted at acidic pH, so it may be expected that a monomeric form of silane layer is grafted on the surface of silica (similar to Scheme B in Fig. 3).

Reactivity of silanes and silanols18

In sample 2, synthesis reaction was performed at isoelectric pH (pH 4–5) condition. So, silica surface is negatively charged and silane molecules have no charges.7 Zeta potential can be directly related to the magnitude and sign of the surface charge, because the surface potential is not directly measurable. Isoelectric point is considered as a pH with zero zeta potential. A more negative value for zeta potential means a more basic character and vice versa, as mentioned in reference 7. The isoelectric point of silica is approximately 3.7–4.7. At the selected pH for sample 2 (pH 4–5), which is a bit higher than that of the isoelectric point of silica, the silica surface is negatively charged. Regarding methacrylic silane, it should be noted that its isoelectric point is approximately between 4.4 and 4.8 which is placed in the range of selected pH for sample 2. So, its zeta potential measured is zero, demonstrating no positive or negative charge on the silane surface. The effect of pH on the stability of the formed silanols on the methacrylic silane CA surface is different from that of the stability of alkoxy silanes. Silanols are most stable at around pH 3, and their reactivity is higher at pHs lower than 1.5 and higher than 4.5 (Fig. 4). Condensation of silanols leads to oligomers formation and, as a result, two- and three-dimensional networks will be formed. With respect to the silane hydrolysis and condensation, different reactivities can be expected in diverse pH ranges. At very low pH, silanes hydrolyze very fast. The as-formed silanols are relatively stable and, within a period of time, form coordinated networks. At neutral pH, silanes hydrolyze very slowly to silanols, which are unstable. Therefore, in both cases, there is a slow reaction in the change from silanes to siloxane networks. At alkaline pHs (pH > 8), silanes become highly reactive and form silanols very quickly. These silanols are very unstable and condense very fast to give uncoordinated siloxane networks (Fig. 4). At the pH conditions used for sample 2, silane has low reactivity and its hydrolysis seems very slow.

Sample 3 experiences an alkaline condition (pH 9–10). At this condition, both silica surface and silane molecules are negatively charged. It may be expected that these two similarly charged entities tend to repel each other. However, at alkaline conditions, silane has high reactivity (Fig. 4), and its methoxy groups are easily converted to silanol groups. The as-formed silanol groups from silane can either react with other silanol groups of silica surface or with neighboring hydrolyzed silane molecules to form siloxane bonds (similar to Scheme C in Fig. 3). In this way, the negative charge of the silane molecules could be reduced. Then, the nanosilica particles could approach the as-formed silanol groups of MPTMS and condense with each other to form a stable functionalization on the silica surface. It can be expected that there would be an oligomeric layer of silane on the surface of nanosilica.

In sample 6, the silane concentration is the same as sample 3 and the treating bath pH is acidic. The difference between these two samples can be corresponded to the monomeric grafting of silane on the surface of silica. In this sample, both the silica surface and silane molecules are positively charged and repel each other. Therefore, the surface charge of the silane cannot be reduced. So, the grafted extent of silane is lower than that of sample 3.

Effects of silane concentration and hydrolysis ratio

The action of alkoxysilanes starts with hydrolysis. The rate of hydrolysis depends on the pH as well as on the type of organo- and silicon functional groups. The silicon functional group has a significant influence on the hydrolysis rate. The order of reactivity is as follows: propoxy \(\ll\) ethoxy < methoxy. Typically, a large excess of water is used as reactant; under these conditions, the hydrolysis of alkoxysilanes is found to be a (pseudo) first-order reaction. According to Table 2, sample 1 was treated at a hydrolysis ratio of 1/3 and silane to silica concentration ratio lower than the stoichiometric content. Also, in the treatment reaction of this sample the concentration of the employed silane is not sufficient and MPTMS intrinsically has low reactivity for grafting. Therefore, it can be expected that a greater amount of MPTMS is needed to have an effective interaction with the hydroxyl groups of nanosilica surface and this sample may contain less MPTMS molecules grafted on its surface. Compared with the treating bath pH, the effect of hydrolysis ratio was not significant. It can be related to the formation of water molecules in the silane reaction mechanism depicted in Fig. 3. On the other hand, the concentration of the silane in sample 2 is at stoichiometric level; therefore, it may be expected that in comparison with the previous sample there would be greater amount of silane molecules grafted on the surface of nanosilica.

In sample 3, the silane concentration is greater than the stoichiometric content (silane:silica 10:1). So, more effective interaction would occur between silanol groups of silica surface and silanol molecules that are formed on the MPTMS molecules. At this condition one can predict that the quantitative extent of grafted silane on the surface of silica is higher than that of the two former samples.

In sample 4, the silane concentration is the same as sample 1. So, it may be expected that the grafted extent of silane on the surface of silica should be similar. However, this sample was formed at isoelectric pH condition in which silane has low reactivity. Therefore, it can be predicted that the content of grafted silane on the silica surface may be lower than for sample 1. Sample 5 was treated at the stoichiometric level of silane concentration with treating bath pH being alkaline. At alkaline pH conditions, silane has high reactivity and the grafted extent of silane can be much more than sample 2.

Particle analysis

The pH of different particles is given in Table 5. In comparison with the pH of the untreated nanosilica (pH 4.1), those of treated particles are higher. This can be attributed to the presence of methacrylic silane groups on the surface of nanosilica particles. The silica surface particles have been covered with hydroxyl groups. This means that the untreated one has an acidic characteristic. When the methacrylic silane molecules are grafted on the silica surface, its surface would become less acidic; the extent of which can be related to the quantitative amount of the grafted silane on the surface. As shown in Table 5, samples 3, 6, and 9 (especially sample 3), which might have the greater amount of grafted silane on their surface, have become more alkaline.

A similar trend in grafting content was also seen using density measurements. The density of untreated nanosilica is 2.2623 g/cm3. The densities of treated particles are also shown in Table 5. It is apparent from the results in Table 5 that the density of all treated particles has decreased. It can be explained that the presence of an organic layer would increase the volume of the treated nanoparticles. Consequently, the mass per unit volume (ρ) of treated nanoparticles decreases. Sample 3 has the lowest density. This is in agreement with the result of pH measurements. Also, it can be observed that the densities of the treated nanoparticles which have the lower amount of grafted silane on their surfaces are closer to that of pristine silica particle. The lowest density is observed for sample 3, which may mean that this sample has the highest amount of grafted silane on its surface.

In Fig. 5, the main effects for data deduced from the pH studies are presented. This figure has been obtained according to the Taguchi DOE using the Minitab software. According to this plot, hydrolysis ratio does not have a significant effect on grafting methacrylic silane on the surface. However, by increasing silane CA concentration, pH of treated particles increases. Also, the main effect plot for data deduced from density measurements is in agreement with the results shown in Fig. 5.

Structural studies using FTIR analysis

The FTIR spectra for untreated nanosilica particles and sample 3 are shown in Fig. 6. The peak observed at 1600–1630 cm−1 can be assigned to the physically adsorbed water. The peak at 3200–3500 cm−1 can be attributed to the vibration frequency of OH groups overlapped with that of silanol group vibration peaks on the silica surface. There is a peak at 1050–1150 cm−1 corresponding to Si–O–Si bond which can be observed in the spectrum of untreated nanosilica. The presence of this peak in the spectrum of treated samples indicates that the original structure of nanosilica has not changed. The silanol vibration frequency in the spectrum of sample 3 can be assigned to the presence of unreacted silanol groups on the surface of this sample. In comparison with the spectrum of the untreated nanosilica, the adsorption peak at 1708 cm−1 and 2920–2980 cm−1 appearing in the spectrum of MPTMS treated nanosilica represents the stretching mode of C=O and C–H in MPTMS, indicating that the CA has chemically coated the surface of the nanosilica particles. It is observed that the strongest peak corresponding to functional groups of MPTMS is in the spectrum of sample 3. This is in agreement with the results of pH and density of particles.

In order to quantitatively characterize the results of FTIR studies, the ratio of carbonyl peak to that of siloxane peak in the spectra of all samples has been calculated. The result of this characterization is shown in Table 6.

TGA of particles

The surface grafting of the nanosilica particles was also characterized by TGA. It can be seen from Fig. 7 that the treated nanosilica particles have weight losses prior to 200°C. This corresponds to the elimination of physically absorbed water and volatiles such as alcohols.25 There are also weight losses in the temperature range of 200–250°C, corresponding to the formed hydrogen bonding between silanol groups of silica samples and water molecules.

The weight loss in the temperature range of 250–600°C manifests the condensation of the rest of silanol groups on the surface of treated nanosilica. Furthermore, this weight loss can be attributed to the debonding and degradation of grafted MPTMS functional groups on the surface of nanosilica particles. The total weight loss was calculated for all treated samples. According to these calculations, samples 3 and 6 have the greatest total weight losses, respectively. It can be predicted that the content of the grafted silane may be the highest on the surface of these samples. Moreover, as these samples have the greatest amount of ash content at 600°C, it can be expected that the organic contents of these samples are greater. These results are also in accord with the results of pH, density and FTIR measurements.

Elemental analysis of the particles

To obtain the quantitative extent of the grafted MPTMS on the surface of nanosilica, C,H,O analysis was employed. The C and H contents for three selected samples are shown in Table 7. It can be seen that sample 3 has the highest total amount of C and H content, meaning that this sample has the highest extent of silane on its surface. A simple supposition was employed to calculate the efficiency of the treatment reaction as follows. Each mole of silane contains 7 mol of carbon. Therefore, by dividing the carbon contents shown in Table 7 to the atomic number of carbon (12), the moles of carbon on the surface of treated nanosilica can be obtained. This is equal to the number of grafted silane molecules on the surface of nanosilica. The initial amount of silane used per 100 g of silica is 1.71 g for samples 5 and 8 and is 17.1 g for sample 3. By dividing moles of carbon to the starting silane used, the reaction efficiency has been calculated.

Performance of particles in urethane acrylate matrix

The Nephelometric Turbidity Unit (NTU) is related to the size, shape, and concentration of particles in the suspension. In this method the concentration of particles in solvent is similar. The rate of sedimentation is related to density and surface chemistry of particles. If particles have a good interaction with solvent, they have a low rate of settling. It should be noted that higher dispersibility of particle in solvents is directly related to the interaction of particle with its media. Therefore, in turbidimetric measurements those particles are considered to have more reaction with the solvents that have higher NTU values. It means that the slope of reduction in NTU can more reliably be used as an indication of dispersion stability. Figure 8 shows the NTUs of treated and untreated nanosilica particles in ethanol. The pristine nanosilica particles are covered with polar hydroxyl groups, while treated particles consist of methacrylic and carbonyl groups as well as nonpolar alkyl groups. Therefore, it can be expected that the stability of untreated particles in ethanol is higher than the treated ones. This can be explained by the higher polarity of the untreated particle. Furthermore, as shown in Fig. 8, the NTU values of the untreated particle change slightly with time, whereas these values decrease 43 units as the time elapses. It can be related to the polar characteristic of the pristine particle which leads to a better dispersion of this hydrophilic particle in ethanol. On the other hand, since the treated nanosilica particles are dispersed poorly in ethanol, they may precipitate with time, so NTU values decrease.

Moreover, quantified turbidity values of pure polyurethane acrylate and those of polyurethane acrylate samples loaded with untreated and treated nanosilica particles are shown in Fig. 9. As can be seen, the pure resin displays the lowest turbidity, as expected. However, in the presence of the untreated particles, particularly at high concentrations, the NTU values have increased significantly. It is known that pristine particles have a high surface area covered with hydroxyl groups, and when they are filled into UAc matrix, they can be dispersed poorly and tend to aggregate in the matrix. For this reason, the light transfer would not occur easily through the UAc matrix. On the other hand, in the presence of treated nanosilica particles the NTU values have decreased significantly in comparison with the untreated particle filled UAc matrix. This can be related to the better dispersion of treated particles into UAc matrix particularly at optimum concentration of 5%, indicating that MPTMS has a better compatibility with UAc matrix than the hydrophilic nanosilica particles.

Further evaluation of particles was performed by measuring the absorbance spectra of blank polyurethane acrylate in addition to the silica loaded samples as shown in Fig. 10. It can be observed that the absorbance of nanosilica filled matrix is higher than that of the blank UAc in all regions of the spectrum. This may increase the durability of the corresponding coatings in outdoor applications.26,27 Also, this figure demonstrates that the absorbance of the untreated filled UAc is higher than the treated silica filled matrix. It can be explained that the increased amount of hydrophilic nanosilica aggregates in the UAc matrix. This could increase the absorbance of the resulting coating, particularly in the ultraviolet portion of the spectrum.

Conclusion

An optimum modification condition was obtained for treatment of a hydrophilic nanosilica using an acrylic silane utilizing Taguchi DOE. Results revealed that the best condition for modification was acquired for silane: silica ratio much higher than the stoichiometric level and alkaline bath pH. On the other hand, hydrolysis ratio did not have any significant effect on the modification reaction between nanosilica particles and methacrylic silane molecules. The behavior of prepared films containing various types and contents of silica showed that the dispersibility of highly grafted nanosilica particles was significantly enhanced compared with the untreated particle.

References

Sepur, S, Kunze, N, Werner, B, Schmidt, H, “UV Curable Hard Coatings on Plastics.” Thin Solid Films, 351 216–219 (1999)

Bauer, F, Ernst, H, Decker, U, Findeisen, M, Gläsel, HJ, Langguth, H, Hartmann, E, Mehnert, R, Peuker, C, “Preparation of Scratch and Abrasion Resistant Polymeric Nanocomposites by Monomer Grafting onto Nanoparticles, 1 FTIR and Multi-nuclear NMR Spectroscopy to the Characterization of Methacryl Grafting.” Macromol. Chem. Phys., 201 2654–2659 (2000)

Zhang, MQ, Rong, MZ, Yu, SL, Wetzel, B, Friedrich, K, “Effect of Particle Surface Treatment on the Tribological Performance of Epoxy Based Nanocomposites.” Wear, 253 1086–1093 (2002)

Jesionowski, T, Krysztafkiewicz, A, “Preparation of the Hydrophilic/Hydrophobic Silica Particles.” Colloids Surf. A: Physicochem. Eng. Aspects, 207 49–58 (2002)

Zou, W, Peng, J, Yang, Y, Zhang, L, Liao, B, Xiao, F, “Effect of Nano-SiO2 on the Performance of Poly(MMA/BA/MAA)/EP.” Mater. Lett., 61 725–729 (2007)

Jalili, MM, Moradian, S, Dastmalchian, H, Karbasi, A, “Investigating the Variations in Properties of 2-pack Polyurethane Clear Coat Through Separate Incorporation of Hydrophilic and Hydrophobic Nano-silica.” Prog. Org. Coat., 59 81–87 (2007)

Bergna, HE, Roberts, WO, Colloidal Silica: Fundamentals and Applications, p. 131. CRC Press, Boca Raton, 2006

Sun, Y, Zhang, Z, Wong, C, “Study on Mono-dispersed Nano-size Silica by Surface Modification for Underfill Applications.” J. Colloid Interface Sci., 292 436–444 (2005)

Zhang, MQ, Rong, MZ, Yu, SL, Wetzel, B, Friedrich, K, “Effect of Particle Surface Treatment on the Tribological Performance of Epoxy Based Nanocomposites.” Wear, 253 1086–1093 (2002)

Plueddemann, EP, Silane Coupling Agents, p. 235. Plenum Press, London, 1982

Sun, S, Li, C, Zhang, L, Du, HL, Burnell-Gray, JS, “Effects of Surface Modification of Fumed Silica on Interfacial Structures and Mechanical Properties of Poly(vinyl chloride) Composites.” Eur. Polym. J., 42 1643–1652 (2006)

Iijima, M, Tsukada, M, Kamiya, H, “Effect of Particle Size on Surface Modification of Silica Nanoparticles by Using Silane Coupling Agents and Their Dispersion Stability in Methylethylketone.” J. Colloid Interface Sci., 307 418–424 (2007)

Rostami, M, Mohseni, M, Ranjbar, Z, “Investigating the Effect of pH on the Surface Chemistry of an Amino Silane Treated Nano Silica.” Pigment Resin Technol., 40 363–373 (2011)

Işın, D, Kayaman-Apohan, N, Güngör, A, “Preparation and Characterization of UV-Curable Epoxy/Silica Nanocomposite Coatings.” Prog. Org. Coat., 65 477–483 (2009)

Posthumus, W, UV-Curable Acrylate Metal Oxide Nanocomposite Coatings. Technische Universiteit Eindhoven, Eindhoven, 2004

Debnath, S, Wunder, SL, McCool, JI, Baran, JR, “Silane Treatment Effects on Glass/Resin Interfacial Shear Strengths.” Dental Mater., 19 441–448 (2003)

Gilberts, J, Tinnemans, AHA, Hogerheide, MP, Koster, TPM, “UV Curable Hard Transparent Hybrid Coating Materials on Polycarbonate Prepared by the Sol–Gel Method.” J Sol-Gel Sci. Technol., 11 153–159 (1998)

Xanthos, M, Functional Fillers for Plastics. Otto H. York Department of Chemical Engineering and Polymer Processing Institute, NJ Institute of Technology, 2005

Liu, X, Zhao, S, “Measurement of the Condensation Temperature of Nanosilica Powder Organically Modified by a Silane Coupling Agent and Its Effect Evaluation.” J. Appl. Polym. Sci., 108 3038–3045 (2008)

Yahyaei, H, Mohseni, M, Bastani, S, “Using Taguchi Experimental Design to Reveal the Impact of Parameters Affecting the Abrasion Resistance of Sol–Gel Based UV Curable Nanocomposite Films on Polycarbonate.” J. Sol-Gel Sci. Technol., 59 95–105 (2011)

Zhuravlev, LT, “The Surface Chemistry of Amorphous Silica. Zhuravlev Model.” Colloids Surf. A: Physicochem. Eng. Aspects, 173 (2000) 1–38 (2000)

Mrkoci, MI, “Influence of Silica Surface Characteristics on Elastomer Reinforcement.” M.Sc. Thesis, Queens University Kingston, Ontario, Canada, January 2001

Jesionowski, T, Krysztafkiewicz, A, “Influence of Silane Coupling Agents on the Surface Properties of Precipitated Silicas.” Appl. Surf. Sci., 172 18–32 (2001)

Rostami, M, Ranjbar, Z, Mohseni, M, “Investigating the Interfacial Interaction of Different Aminosilane Treated Nano Silicas with a Polyurethane Coating.” Appl. Surf. Sci., 257 899–904 (2010)

Dugas, V, Chevalier, Y, “Surface Hydroxylation and Silane Grafting on Fumed and Thermal Silica.” J. Colloid Interface Sci., 264 354–361 (2003)

Daniels, MW, Sefcik, J, Francis, LF, McCormick, AV, “Reactions of a Trifunctional Silane Coupling Agent in the Presence of Colloidal Silica Sols in Polar Media.” J. Colloid Interface Sci., 219 351–356 (1999)

Perera, DY, “Physical Ageing of Organic Coatings.” Prog. Org. Coat., 47 61–76 (2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lahijani, Y.Z.K., Mohseni, M. & Bastani, S. Utilizing Taguchi design of experiment to study the surface treatment of a nanosilica with an acrylic silane coupling agent and revealing the dispersibility of particles in a urethane acrylate resin. J Coat Technol Res 10, 537–547 (2013). https://doi.org/10.1007/s11998-013-9471-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-013-9471-9