Abstract

The UV protective coatings were developed by incorporating triazine derivative organic UV stabilizers into inorganic titania particles which were produced by sol–gel method. The objective of this study is to delay the color change of heat-treated wood subjected to outdoor conditions. The protective coatings were prepared in air at room temperature. The coatings were not further treated thermally after their application to heat-sensitive materials. Coatings were applied to heat-treated jack pine wood. Subsequently, accelerated aging tests were carried out using coated and uncoated jack pine samples. The color change of the wood samples was studied, and the results were compared. Also, the morphological analyses were done using XPS after having weathered the wood at different times.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wood is one of the major industries in North America, especially in Canada. Its physical properties and its warm appearance distinguish it in many areas from other competitive materials such as concrete, metals, and plastics.1 When exposed to solar irradiation, wood undergoes photochemical reactions which lead to significant changes in its appearance such as discoloration, loss of gloss and lightness, roughening and checking of surfaces, and destruction of mechanical and physical properties.2,3 UV portions of the solar radiation and moisture are the most important parameters contributing to wood aging4 but fungal colonization too plays an important role in wood degradation. The UV radiation has sufficient energy to chemically degrade the wood’s structural components (lignin and carbohydrates).5–7 The short wavelengths of visible portion of sunlight also cause surface changes in wood. These wavelengths do not directly initiate wood degradation; however, they enhance the photochemical reactions if they had already started.8 Among the wood components, lignin is the best UV absorber,2 and wood color degradation is mainly due to lignin photodegradation.4 Photooxidation of lignin refers to a process where this polymer undergoes chemical modifications such as bond cleavage and hydrogen abstraction resulting in formation of radical, formation of peroxides with oxygen, and finally decomposition with production of colored and hydrophilic by-products, the so-called chromophores.2,9,10 The rapid discoloration shields and protects the underneath surface.2

Motivated by growing environmental concerns and growing demand for sustainable use of natural resources, there are many studies on new technologies for enhancing durability and service life of wood due to its unique properties (e.g., wood is recyclable, renewable, and biodegradable) and its use in residential construction.2,11,12 Heat treatment of wood is a viable and environment-friendly wood preservation method, and it is one of the alternatives to chemical treatment which is harmful to the environment as well as to human health.13 The heat treatment improves the dimensional stability and the biological resistance of wood. It has a dark color which is important for decorative purposes. However, it loses this dark color when exposed to UV radiation from the sun. Aging of heat-treated wood differs from untreated wood due to the condensed structure of lignin and the presence of antioxidant compound consequent to the thermal modification.3,4

Since heat treatment does not protect wood from UV radiation, development of UV protective coating is of utmost important for this new product. Light stabilizers and UV absorbers are incorporated as additives in coating formulations to enhance the durability of protective coatings. UV absorbers are inorganic and organic materials which preferentially absorb the UV radiation to prevent the excitation state, thus, they protect the coating.14 Light stabilizers must be effective over a long period of time and must, therefore, not degrade, evaporate from the matrix, be leached out by solvents from the material.6,15 Furthermore, the additive must be uniformly distributed, which requires its compatibility with the base polymer. For UV protective coatings, both inorganic and organic UV absorbers can be used; however, no single UV absorber exhibits a complete UV absorption in the desired range (Fig. 1). Therefore, in order to achieve absorption in this range, organic and inorganic UV absorbers can be combined.16

The aim of this study is to develop a protective coating for heat-treated wood using combination of organic and inorganic UV absorbers and light stabilizers. In this study, sol–gel method was used for preparation of inorganic titania particles. Titania sol was combined with organic UV absorbers and light stabilizers at different weight percentages to develop different coatings. The UV absorption/transmission experiments were carried out to preselect the promising coatings. Furthermore, accelerated aging tests were performed to test the durability of chosen coatings by studying and comparing the color changes of coated and uncoated samples. To understand the mechanism of weathering XPS, analyses were carried out on weathered samples.

Experimental

Coating preparation

The organic UV absorber (Tinuvin5236, CIBA) and lignin stabilizer (Lignostab1198, CIBA) were used. The inorganic TiO2 sol was prepared by hydrolysis of equal volumes of titanium butoxide (Ti(OC3H7)4 obtained from Sigma Aldrich) and pure ethanol at room temperature by stirring for 15 min followed by 72 h of aging. Different concentrations of sol were prepared by diluting it with pure ethanol (for 5 mL concentrated sol 10–25 mL pure ethanol). The final coatings were prepared by dissolving Tinuvin5236 and Lignostab1198 in diluted sols (0.5–15 wt% Tinuvin5236 and 0.1–2 wt% Lignostab1198).

Optical investigation

Glass slides (75 mm × 25 mm × 1 mm) were coated with the prepared solutions using dip coating method. The absorbance and transmittance spectra of the prepared sols and coatings were evaluated by UV/VIS spectrophotometer (Agilent 8453 UV–VIS spectroscopy system).

Accelerated aging test

For this study, commercially available jack pine wood heat treated (210°C) by Thermowood technology was used. A total of 18 jack pine (Pinus banksiana) samples (20 cm × 8 cm × 1.9 cm) were prepared for aging tests. Two sets of the six samples were coated with titania sol embedded with Tinuvin5236 and titania sol embedded with Tinuvin5236 and Lignostab1198, respectively. The six uncoated samples were used as reference. The coatings were applied with brush along the grain direction.

The accelerated aging test was conducted in Atlas Xenon Weather-Ometer Ci65/Ci65A (outer filter soda and inner filter CIRA, irradiation 0.55 W m−2 at 340 nm, BPT 63 ± 3°C, RH 50 ± 5% and continuous light cycle without any specimen spray). The 18 samples were exposed to UV light for different time spans with maximum time of 1500 h. A sample from each set was taken out after exposures for 72, 168, 336, 672, 1008, and 1500 h.

Color measurement

The color of all the samples was measured before and after the aging test using Datacolor CHECK® spectrocolorimeter with diffuse illumination 8° viewing in conformation with CIE publication No. 15.2 (Colorimetry based on D65 light source by simulating day light). The CIE L*, a*, and b* coordinates are characterized by three parameters: L* axis represents the lightness, and it varies from 100 (white) to 0 (black); a* and b* are the chromaticity indices; +a* is the red direction; −a* is green; +b* is yellow; and −b* is blue. The CIE Lab values were used to evaluate the total color change, ΔE, as a function of aging time according to the following equation4:

XPS analysis

The XPS measurements of heat-treated and coated jack pine samples were performed by AXIS Ultra XPS spectrometer (Kratos Analytical) at the Alberta Centre for Surface Engineering and Science (ACSES), University of Alberta. The base pressure in the analytical chamber was lower than 2 × 10−8 Pa. Mono-chromate Al Kα (hν = 1486.6 eV) source was used at a power of 210 W. The resolution function of the instrument for the source in hybrid lens mode was 0.55 eV for Ag 3d and 0.70 eV for Au 4f peaks. The photoelectron exit was along the normal of the sample surface with an analysis spot of 400 × 700 μm2. Charge neutralizer was used to compensate sample charging during the analysis. The survey scans spanned from 1100 to 0 eV binding energy, which were collected with analyzer pass energy (PE) of 160 eV and a step of 0.35 eV. For the high-resolution spectra, the PE of 20 eV with a step of 0.1 eV was used. CASA software was applied in the data processing. A linear background was subtracted from each peak, and then the peak area was evaluated and scaled to the instrument’s sensitivity factors. The composition was calculated from the survey spectra with sum of all peaks after scaling equal to 100 %. The spectra fitting and component analysis was performed using the high-resolution spectra.

Results

Transmittance of inorganic UV absorbing nano-coatings

The inorganic oxide coatings were deposited on glass by dip coating method. As the concentration and the thickness of TiO2 coatings were increased, the wavelength (λ) limit of the region where the transmission of UV was less than 10% (T < 10%) was moved from 285 to 320 nm (Fig. 1). This is in good accordance with the result reported by Mahltig et al.16 Also, the interference effect was a good evidence of smoothness of the layers. The results show that titania coatings (Fig. 1) display a high transmission (T > 10%) in the UV range (320–400 nm). The organic UV absorber alone or with lignin stabilizer show better results but the upper limit was found at near UV region (T > 10% for λ > 390 nm). Therefore, these coatings cannot be used alone as a UV protective coating for wood.

Transmittance of organic UV absorber embedded in inorganic UV absorber

In order to reduce the transmission of UV radiation by the coatings over the whole UV range, organic UV absorbers were embedded into UV absorbing titania coating. The experiments show that the transmission of UV light decreases rapidly with increasing concentration of Tinuvin5236. Less than 10% of UV was transmitted below the wavelength of 440 nm when 15% Tinuvin was used (Fig. 2). Also, as the thickness of the coating (number of layers) was increased, the transmission curve was shifted toward red region. When two layers of coating were applied, less than 10% of UV was transmitted at wavelengths less than 470 nm (Fig. 2). Further increase in thickness results in fully opaque coatings which were undesirable. Addition of lignin stabilizer did not significantly affect the transmission in UV/VIS spectra. Interference effects were observed only for coatings with low concentration of UV absorber.

The decrease in transmission at a given wavelength and also red shift of the minimum can be explained by the formation of complex bonding between the embedded UV absorber and the titania as reported by Mahltig et al.16 The transmission tests indicate that the titania nanoparticles embedded Tinuvin5236 alone or together with Lignostab can be satisfactorily used as UV protective coatings. However, this has to be verified with aging tests.

Accelerated aging of wood samples and color measurements

The accelerated aging tests were carried out to study the effect of sun exposure on color. Xenon arc source simulates the sun radiation more closely than any other artificial light source. Both the spectral distribution of energy and irradiance control can be adjusted with this system (Atlas weathering device) through optical filtering and electrical power management, respectively.

The lightness values for coated and uncoated wood are presented in Fig. 3. The lightness value of uncoated wood was lower than those of the coated ones for the initial period of aging (up to 668 h). UV absorber (Tinuvin5236)- and lignin stabilizer (Lignostab1198)-embedded titania coatings have the lowest lightness value between 668 and 1000 h exposure. Although no effect of lignin stabilizer on UV protection can be detected with transmission tests when it was used with titania, its addition clearly improves the UV protection capacity of the titania-containing coatings resulting from artificial weathering. Subsequently, all the three curves approach each other. However, lignin stabilizer-containing coating always has the lowest lightness value.

Chromaticity coordinates a* and b* over the aging period are shown in Figs. 4 and 5 for the coated and uncoated wood samples. The variations of chromaticity coordinates over the aging period show similar trends for coated and uncoated woods except at initial times. Initially, the uncoated wood was redder than the coated wood. All the samples become greener after aging. Also, it can clearly be seen from Fig. 5 that the UV absorber- and lignin stabilizer-coated wood was initially more yellowish than the uncoated one and the wood coated with UV absorber-embedded titania. However, its color was distinctly different (becoming less yellowish) compared with the other two.

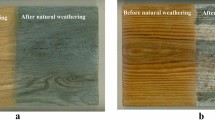

The total color change (Fig. 6) of the uncoated and coated wood samples increases with the exception of initial period of aging (168 h). The color change in the uncoated wood was lower than that of the coated wood for initial 600 h, but the wood coated with UV absorber- and lignin stabilizer-embedded titania seems to be better protected at longer times. Titania coating without lignin stabilizer has no UV protecting effect on wood. Further increase in lignin stabilizer (over 2%) did not affect the UV protection capacity of this coating. The visual assessment of these two coated jack pine surfaces after different weathering times is shown in Fig. 7. The wood surfaces become white after weathering due to degradation of lignin. From the visual assessment, it also was clear that better protection was observed for the titania sol containing Tinuvin5236 and Lignostab-coated heat-treated jack pine surfaces. However, even after this, the coating was not good enough to protect the heat-treated jack pine for a much longer period. Since wood is a porous material, coating applied on it tends to penetrate through the pores, and sometimes not enough protection is left on the surface. This can be a reason for poor coating performance.

XPS analysis of the weathered wood samples

The changes in surface chemical compositions were investigated by XPS analyses of Tinuvin5236 and Lignostab1198 in TiO2 sol-coated wood surfaces after weathering for 72 and 1500 h (Fig. 7a). The surveyed spectra of 72-h-aged coated-wood surfaces show prominent peaks of C 1s, O 1s, and Ti 2p, and small peaks of N 1s, Ti 3s, Ti 3p, OKLL, O 2s, Na 1s, and NaKLL implying the presence of titania coating. After 1500 h of weathering, Ti peaks disappeared indicating depletion of titania coating, and C 1s and O 1s peak intensities increased slightly whereas OKLL peak intensity decreased. Also, the spectra intensities over the entire binding energy ranges decrease significantly (Fig. 8a). The high-resolution spectra of C 1s were deconvoluted into four components: C1, C2, C3, and C4. The C1 peak is ascribable to hydrophobic bonds such as carbon-linked carbon or hydrogen present in lignin and aromatic low molecular weight extractives and fatty acids. The C2 peak corresponds to carbon-oxygen bonds present in hydroxyl or ether group of lignin and polysaccharides of wood. The C3 peak is mainly due to hemiacetal carbon of cellulose and hemicelluloses and, to a lower extent, to carbonyl groups. The C4 peak corresponds to carbonyl of carboxylic acid or ester functions present in wood.17,18 The deconvoluted spectra after 72 h of aging (Fig. 8b) reveal the highest contribution from the C1 component followed by C2, C3, and C4, although the C2 component contribution was also quite high which is mainly from cellulose. After 1500 h of aging, C2 component contribution becomes the highest (Fig. 8c) as cellulose becomes the most available component at the wood surface because of weathering, while C1 component contribution decreases significantly as a result of lignin degradation and depletion of degraded product from the surface due to the presence of moisture. The contribution of different types of oxygen atoms is more difficult to analyze. According to the literature, the O2 component represents all the oxygen elements in cellulose whereas the oxygen elements in benzyl aryl ether and diaryl ether were ascribed to O1, the oxygen elements in phenolic OH, aliphatic aromatic ether, and thioglycolic acid to O3.19–21 The O 1s spectrum was decomposed into three components after 72 h of aging and four components after 1500 h of aging. After 72 h of aging, O1% was almost 43%, and the contributions of O2 and O3 components were almost equal (Fig. 8d). However, after 1500 h of aging, a new component forms, and O2% increases to 83%, while O1% and O3% decrease significantly (Fig. 8e). The significant increase in percentage of O2 component clearly shows that after 1500 h of aging, the wood surface becomes rich in cellulose. In addition, decrease in contribution of O1 and O3 components illustrates that lignin was degraded and depleted with weathering from the wood surface. The formation of a new component O4 demonstrated that oxygenated products were formed due to aging of the coatings with weathering. As illustrated in Table 1, the O/C ratio increased from 0.4 (before weathering) to 0.55 after 72 h of weathering and after 1500 h of weathering to 0.56. The increase in O/C ratio was mainly due to the lignin degradation and production of oxygenated products during weathering.

It is well known that all polymers, except saturated hydrocarbons such as polypropylene or polyethylene, have acidic or basic functional sites. In general, most polymers have either an acidic or basic character or both to some extent. Some of the XPS peak shifts may, in principle, be related to the acid–base interactions. Particularly, the high resolution XPS spectrum of the basic oxygen of the surface sites is the most helpful in identifying the extent of base interaction. According to Fowke’s theory,22 the total acidity of any surface can be calculated by the contribution of C2 and C4 components, and the basicity depends on the contribution of C1 and C3 components. It is clear from Table 1 given above that the acidity of the surface increases whereas the basicity decreases with weathering. Therefore, it can be concluded that the products formed during weathering were acidic in nature.

Conclusions

The inorganic UV-absorbing titania coatings and organic UV absorbers do not provide sufficient UV protection for wood surfaces when used separately. The UV/VIS spectroscopy results for titania particles embedded with UV absorber indicate very promising UV protective characteristics. However, the accelerated aging test results do not lead to the same conclusion. The color change diagrams demonstrate that the titania embedded with UV absorber coating does not have a significant influence on wood color but addition of lignin stabilizer plays an important role in protection of wood against UV exposure as they mainly act as a radical scavenger. The coatings do not work effectively if they are not thick enough since wood is a porous material. There is not enough protection left at the surface when the coating fills the pores after the application of a thin layer. The XPS analyses reveal that, with weathering, the lignin degrades which results in the formation of oxygenated products, leaving behind a cellulose-enriched surface. Further study is needed to investigate the performance of UV protective coatings incorporated in wood clearcoats.

References

Hayoz, P, Peter, W, Rogez, D, “A New Innovative Stabilization Method for the Protection of Natural Wood.” Prog. Org. Coat., 48 297–309 (2003)

Hon, DNS, Shiraishi, N, Wood and Cellulosic Chemistry. Marcel Dekker Inc., New York, 2001

Nuopponen, M, Wikberg, H, Vuorinen, T, Maunu, SL, Jämsä, S, Viitaniemi, P, “Heat-Treated Softwood Exposed to Weathering.” J. Appl. Polym. Sci., 91 (4) 2128–2134 (2003)

Ayadi, N, Lejeune, F, Charrier, F, Charrier, B, Marlin, A, “Color Stability of Heat-Treated Wood During Artificial Weathering.” Holz als Roh-und Wrekstoff, 61 221–226 (2003)

Nzokou, P, Kamdem, DP, “Influence of Wood Extractives on the Photo-Discoloration of Wood Surfaces Exposed to Artificial Weathering.” Color Res. Appl., 31 (5) 425–434 (2006)

Pandey, KK, “A Note on the Influence of Extractives on the Photo Discoloration and Photo Degradation of Wood.” Polym. Deg. Stab., 87 375–379 (2005)

Zahri, S, Belloncle, C, Charrier, F, Pardon, P, Quideau, S, Charrier, B, “UV Light Impact on Illagitannins and Wood Surface Color of European Oak.” Appl. Surf. Sci., 253 4985–4989 (2007)

Georgea, B, Suttieb, E, Merlina, A, Deglise, X, “Photodegradation and Photostabilisation of Wood: The State of the Art.” Polym. Deg. Stab., 88 268–274 (2005)

Evans, PD, Michell, AJ, Schmalzl, KJ, “Studies of the Degradation and Protection of Wood Surfaces.” Wood Sci. Technol., 26 (2) 151–163 (1992)

Hon, DNS, Fiest, W, “Hydroperoxidation in Photoirradiated Wood Surfaces.” Wood Fiber Sci., 24 (4) 448–455 (1992)

Schaller, C, Rogez, D, “New Approaches in Wood Coating Stabilization.” J. Coat. Technol. Res., 4 (4) 401–409 (2007)

Tshabalala, MA, Gangstad, JE, “Accelerated Weathering of Wood Surfaces Coated With Multifunctional Alkoxysilanes by Sol-Gel Deposition.” J. Coating Technol., 75 37–43 (2003)

Kocaefe, D, Younsi, R, Poncsak, S, Poncsak, S, Kocaefe, Y, “Comparison of Different Models for High-Temperature Heat Treatment of Wood.” Int. J. Therm. Sci., 46 707–716 (2007)

McCusker, M, “A UVA/HALS Primer: Everything You’ve Ever Wanted to Know About Light Stabilizers. I.” Met. Finish., 97 (5) 51–53 (1999)

Schaller, C, Rogez, D, Braig, A. “Hydroxyphenyl-s-Triazines: Advanced Multipurpose UV-Absorbers for Coatings.” J. Coat. Technol. Res. (2007)

Mahltig, B, Bȍttcher, H, Rauch, K, Dieckmann, U, Fritz, T, “Optimized UV Protecting Coatings by Combination of Organic and Inorganic UV Absorber.” Thin Solid Films, 485 108–114 (2005)

Gérardin, P, Petric, M, Petrissans, M, Lambert, J, Ehrhrardt, JJ, “Evolution of Wood Surface Free Energy After Heat Treatment.” Polym. Deg. Stab., 92 653–657 (2007)

Evans, PD, Kiguchi, M, “Photostabilisation of Wood Surfaces Using a Grafted Benzophenone UV Absorber.” Polym. Deg. Stab., 61 33–45 (1998)

Nzokou, P, Pascal Kamdem, D, “X-Ray Photoelectron Spectroscopy Study of Red Oak- (Quercus rubra), Black Cherry- (Prunus serotina) and Red Pine- (Pinus resinosa) Extracted Wood Surfaces.” Surf. Interface Anal., 37 689–694 (2005)

Hua, X, Kaliaguine, S, Kokta, BV, Adnot, A, “Surface Analysis of Explosion Pulps by ESCA Part 2. Oxygen (1s) and Sulfur (2p) Spectra.” Wood Sci. Technol., 28 1–8 (1993)

Gérardin, P, Nguila Inari, G, Petrissans, M, Lambert, J, Ehrhardt, JJ, “XPS Characterization of Wood Chemical Composition After Heat-Treatment.” Surf. Interface Anal., 38 1336–1342 (2006)

Shen, Q, Mikkola, P, Rosenholm, JB, “Quantitative Characterization of the Subsurface Acid–Base Properties of Wood by XPS and Fowkes Theory.” Colloids Surfaces A: Physicochem. Eng. Aspect., 145 235–241 (1998)

Acknowledgments

The authors would like to thank the Développement Économique Canada (DEC), Ministère du Développement Économique, de l’Innovation et de l’Exportation (MDEIE), Conférence Régionale des Élus du Saguenay-Lac-St-Jean (CRÉ), Université du Québec à Chicoutimi (UQAC), Fondation de l’Université du Québec à Chicoutimi (FUQAC), Forintek, Alberta Research Council, and our industrial partners (PCI Ind., Ohlin Thermotech, Kisis Technology, and Industries ISA) for their technical and financial contributions, and Shihong (University of Alberta, ACSES) for XPS analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saha, S., Kocaefe, D., Sarkar, D.K. et al. Effect of TiO2-containing nano-coatings on the color protection of heat-treated jack pine. J Coat Technol Res 8, 183–190 (2011). https://doi.org/10.1007/s11998-010-9294-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-010-9294-x