Abstract

The concept of tethering quaternary ammonium salts (QASs) to a crosslinked polysiloxane matrix to produce a hybrid antifouling/fouling-release coating was investigated. A statistical experimental design was used to determine the effect of QAS concentration on biocidal activity toward a marine bacterium, Cellulophaga lytica (C. lytica). In addition to measuring biocidal activity, coating film quality as well as stability upon water immersion were evaluated. The results of the study showed that biocidal activity was strongly dependent on QAS concentration. For addition-curable coatings, the presence of 4 wt% QAS moieties resulted in approximately 50% reduction in C. lytica biofilm retention without any leachate toxicity. Attempts to increase the level of QAS moieties to increase biocidal activity resulted in coating delamination from the substrate and unacceptable film quality upon artificial seawater immersion due to excessive swelling. As a result, a moisture-curable system based on tethered QASs was investigated since moisture curing allows for higher crosslink densities to be achieved which would be expected to minimize swelling upon artificial seawater immersion. The moisture-curable coating developed showed enhanced stability upon artificial seawater immersion, greater than 80% reduction in C. lytica biofilm retention, and greater than 90% reduction in biofilm growth for the marine algae, Navicula incerta.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Marine biological fouling is defined as the undesirable accumulation of microorganisms, plants, and animals on artificial surfaces immersed in seawater.1 This biological settlement on ship hulls produces high frictional resistance and increased weight which ultimately results in a major increase in fuel consumption (up to 40%). In addition to an increase in fuel consumption, biofouling increases the frequency of dry-docking, initiates corrosion, and may result in the introduction of invasive species to a marine environment.2–4

There are more than 4000 species of marine organisms responsible for biofouling and many of these organisms can adapt to environmental changes, making the task of creating a fouling-free surface very challenging. In the first stage of biological fouling, organic molecules, such as polysaccharides and proteins, rapidly accumulate over the surface to form a “conditioning film.” Bacteria and single-cell diatoms settle on this modified surface to form a microbial biofilm. Microbial biofilm formation is believed to be necessary to initiate fouling by larger more complex organisms, referred to as macrofoulers, such as barnacles and tubeworms.5,6 Hence, prevention of the settlement of marine bacteria and diatoms over the surface could be a potential approach to preventing biofouling.

Quaternary ammonium salts (QASs) have been used as disinfectants for many years. Surfaces coated with QAS-containing polymers have been shown to kill a wide range of microorganisms including gram-positive and gram-negative bacteria, yeasts, and moulds.7–10 QAS-functionalized surfaces have a high positive charge density which exert a strong electrostatic interaction with negatively charged bacteria. After adsorption onto the bacterial cell, QASs diffuse through the cell wall and disrupt the cytoplasmic membrane to release potassium and other constituents that cause cell death.11–15

For QASs, alkyl chain lengths play an important role in biological activity.11 For example, Nakawaga et al. showed that alkyl chains longer than C8 exhibited high antibacterial activity.15,16 Tiller et al. reported that propylated, butylated, hexylated, and octylated immobilized poly (4-vinyl-N-alkylpyridinium bromide) (PVP) chains were effective in markedly reducing the number of viable bacterial cells (Staphylococcus aureus), whereas no activity was found for immobilized PVP possessing C8–C16 alkyl chains.17

A crosslinked polysiloxane matrix with pendant QAS groups was thought to be a potential candidate for an antifouling/fouling-release coating since the hydrophobicity and high flexibility of the polysiloxane matrix may allow for partial segregation of QAS groups to the coating-water interface. In addition, the high compliance and low surface energy of polysiloxanes imparts fouling-release character which may be required to obtain extended coating service life.18–21

It was thought that development of a QAS-containing polysiloxane antifouling/fouling-release coating would be very challenging since multiple variables such as QAS alkyl chain length, QAS concentration, and polysiloxane molecular weight may all affect biocidal activity and mechanical properties through complex, multi-variable interactions. To facilitate analysis of complex material systems, statistically based design of experiments (DOEs) are often employed.22–24 For the research presented in this article, a statistical experimental design was utilized to identify optimum coating compositions and develop structure–property relationships.

Experimental

Reagents

Allyldimethylamine and allyltrimethoxysilane were purchased from TCI America. Platinum oxide, Karstedt’s catalyst (platinum (0)-1,3-divinyl-1,1,3,3-tetramethyl disiloxane complex), 1-iodooctane, CDCl3, dimethyl sulfoxide, Sigma sea salt, and 1.0 M tetrabutylammoniumfluoride (TBAF) in tetrahydrofuran (THF) were obtained from Aldrich Chemical. Methylhydrosiloxane-dimethylsiloxane (PMHS-PDMS) copolymers possessing hydride equivalent weights of 135 and 245 g/mol, divinyl-terminated polydimethylsiloxanes (vinyl-PDMS) possessing molecular weights of 186 g/mol (DMS-V00), 500 g/mol (DMS-V03), 800 g/mol (DMS-V05), 6000 g/mol (DMS-V21), 9400 g/mol (DMS-V22), and 17,200 g/mol (DMS-V25) were obtained from Gelest. Crystal violet, glacial acetic acid, and toluene were purchased from VWR International. The reference coating material, DC 3140, was obtained from Dow Corning. Intergard 264 epoxy primer was obtained from International Marine Coating. A 50 mmol solution of TBAF in 4-methyl-2-pentanone (catalyst solution) was prepared for moisture-cured coating formulations. Artificial seawater for biological characterization was prepared by adding 38.50 g of Sigma sea salt in 1 L of deionized water. All other reagents were used as received.

Hydrosilylation reactions

A representative procedure for conducting hydrosilylation between PMHS-PDMS and allyldimethylamine (PMHS-PDMS-1) was as follows: to a 100 mL round-bottom flask equipped with a nitrogen inlet, condenser, and temperature controller, 20.00 g of PMHS-PDMS possessing a hydride equivalent weight of 135 g/mol (0.148 mol of hydride) and 8.83 g of allyldimethylamine (0.104 mol) were dissolved in 28.80 g of toluene. Once dissolved, approximately 2.00 g of platinum oxide was added to the reaction mixture and the reaction mixture vigorously stirred for 16 h at 60°C.

Completion of the reaction was confirmed by the disappearance of 1H-NMR (in CDCl3) peaks at 5.72 ppm (–N–CH2–CH=), 5.01 ppm (–N–CH 2 –CH=CH 2), and by the appearance of peaks at 0.56 ppm (Si–CH 2 –CH2–CH2–N), 1.57 ppm (Si–CH2–CH 2 –CH2–N), and at 2.22 ppm (Si–CH2–CH2–CH 2 –N–). After completion of the reaction, platinum oxide was removed by filtration.

For moisture-curable systems, two hydrosilylation steps were conducted to attach pendant trimethoxysilane groups and tertiary amino groups to a PMHS-PDMS polymer. A representative procedure for the synthesis of a PDMS copolymer containing pendant trimethoxysilane groups and tertiary amino groups (PMHS-PDMS-7) was as follows: to a 100 mL round-bottom flask equipped with a nitrogen inlet, condenser, and temperature controller, 20.00 g of a PMHS-PDMS copolymer possessing a hydride equivalent weight 245 g/mol (0.082 mol of hydride) and 3.37 g of allyldimethylamine (0.041 mol) were dissolved in 30.00 g of toluene. Approximately 2.00 g of platinum oxide was added to the reaction mixture and the reaction mixture vigorously stirred for 16 h at 60°C. 1H-NMR (in CDCl3) peaks were assigned at 0.56 ppm (Si–CH 2 –CH2–CH2–N), 1.57 ppm (Si–CH2–CH 2 –CH2–N), and 2.22 ppm (Si–CH2–CH2–CH 2 –N–). In the next step, 6.60 g of allyltrimethoxysilane (0.041 mol) was added along with some fresh platinum oxide catalyst. The reaction was continued for another 16 h at 60°C. Completion of the reaction was confirmed by the disappearance of 1H-NMR (in CDCl3) peaks at 5.65 ppm (–Si–CH2–CH=), 4.85 ppm (–Si–CH2–CH=CH 2 ), and a new peak appeared at 3.8 ppm [–Si–O–(CH 3 )3]. After completion of the reaction, platinum oxide was removed by filtration. Details of the syntheses involving hydrosilylation are provided in Table 1.

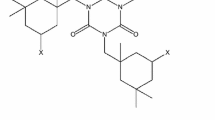

Quaternization procedure

Dimethylamine-functional PMHS-PDMS copolymers were quaternized using 1-iodooctane as the quaternizing agent. A representive quaternization procedure was as follows: to a 20 mL vial 2.74 g of PMHS-PDMS-1 (0.01 mol of dimethylamine in 2.74 g of copolymer) was mixed with 2.37 g of 1-iodooctane (0.01 mol). The quaternization reaction was carried out at room temperature for 48 h. A substantial increase in viscosity was observed. Using 1H-NMR (in CDCl3) new peaks appeared at 3.5 ppm (–N+–CH 2 –), 3.3 ppm [(–N+–(CH 3 )2] and a relative decrease of the dimethylamino protons at 2.2 ppm was observed. The details of each of the quaternization reactions are provided in Table 2.

Coating preparation

For addition-curable coatings, PMHS-PDMS copolymers with tethered QASs were mixed with the required combination of vinyl-PDMS crosslinkers in order to maintain a particular hydride to vinyl ratio and overall concentration of QAS groups as defined by the DOE. Approximately 0.01 wt% of Karstedt’s catalyst was added to the mixture to initiate crosslinking. Draw downs over aluminum panels were made at room temperature. About 0.25 mL of each coating formulation was deposited into one column of a 24-well polystyrene plate modified with epoxy primed aluminum discs for measurements using biological assays.25 Each array plate also contained a silicone reference coating (35% by weight solution of DC 3140 in 4-methyl-2-pentanone) which was used to compare coating performance among the plates. Coatings were allowed to cure for 24 h at room temperature, followed by an additional 24 h in an oven at 50°C. Detailed coating formulations for addition-cured coatings are provided in Appendices 1–4.

For moisture curable coatings, catalyst solution (50 mmol solution of TBAF in THF) was mixed with the copolymer solution at a concentration of 10 wt% based on copolymer solids. After thorough mixing, depositions were made over bare aluminum discs and also over primed aluminum discs for bioassays. Coatings were cured for 24 h at room temperature, followed by an additional 24 h in an oven at 50°C.

Instrumentation

1H-NMR spectra were recorded on a JEOL 400 MHz spectrometer at 25°C. CDCl3 was used as a solvent. A sweep width of 7503 Hz was used with 16K data points, resulting in an acquisition time of 2.184 s. Sixteen scans were obtained with a relaxation delay of 4 s. TMS was used as internal standard. Crystal violet absorbance and chlorophyll fluorescence measurements were made using a Biotek Synergy™ HT multi-well plate spectrophotometer.

Biological characterization

The total amount of marine bacterial biofilm retained on coatings cast in multi-well plates was determined using a crystal violet colorimetric assay as previously described in detail by Stafslien et al.25,26 Coating array plates that were preleached in a recirculating water tank for 30 days, were inoculated with an artificial seawater suspension of the marine bacterium, Cellulophaga lytica, and incubated at 28°C for 18 h. Plates were then rinsed with deionized water, dried for 1 h at ambient conditions, and stained with a biomass indicator dye, crystal violet. The crystal violet dye was extracted from the retained biofilms by the addition of 33% glacial acetic acid and the resulting eluate was measured for absorbance (600 nm) using a multi-well plate reader.

Algal biofilm growth was determined using the method reported previously by Casse et al.27 Coating array plates were inoculated with an artificial seawater suspension of the marine diatom, Navicula incerta, and placed in an 18°C illuminated growth chamber for 48 h. Plates were then removed from the growth chamber and dimethyl sulfoxide was added to extract the chlorophyll from the algal biofilm attached to the coating surfaces. The chlorophyll extract was then measured for fluorescence (excitation: 360 nm; emission: 670 nm) using a multi-well plate reader.

Prior to the bacterial biofilm retention and algal biofilm growth assays, each coating was evaluated for its potential to leach out or release toxic components when immersed in artificial seawater.26 Coatings were incubated in an artificial seawater nutrient medium for 24 h at ambient conditions on an orbital shaker. The resulting coating leachates were collected for toxicity analysis. C. lytica and N. incerta were introduced into separate 1 mL aliquots of each coating leachate (i.e., the two microorganisms were not added to the same 1 mL aliquot), transferred in triplicate (200 μL) to a noncoated 96-well polystyrene plate, and incubated at the conditions indicated above for each organism. C. lytica biofilm retention on the noncoated polystyrene well bottoms was determined by using the crystal violet colorimetric assay detailed above. N. incerta biofilm growth was determined by directly measuring the fluorescence of chlorophyll of the algal biofilm attached to the noncoated polystyrene well bottoms. A significant reduction in C. lytica biofilm retention or N. incerta biofilm growth, when compared to an artificial seawater nutrient medium control, was determined to be a consequence of toxicity of the coating leachate.

Software

Design-Expert Version 7.0.3 was used for statistically based DOEs and ANOVA. Contingency Analysis was done using JMP IN® Version 5.1.

Results and discussion

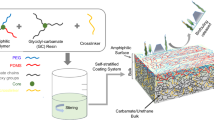

The reaction scheme for the formation of QAS-tethered polysiloxane coatings using addition-cure is shown in Fig. 1. QAS-functional polysiloxanes for addition-cure coatings were produced using a two-step process in which pendant tertiary amino groups were tethered to the polysiloxane backbone using hydrosilylation chemistry and the tertiary amino groups subsequently quaternized using 1-iodooctane.

Since the incorporation of QAS moieties in a hydrophobic polysiloxane matrix may cause large-scale phase separation leading to poor cure and film properties, an initial screening experiment was conducted to identify the appropriate formulation variables required to obtain adequate crosslinking and good film uniformity and integrity. The compositional variables utilized for the experiment were: (1) QAS moiety concentration, (2) hydride-to-vinyl ratio for crosslinking, and (3) hydride equivalent weight of the PMHS-PDMS starting polymer. These variables were separated as numerical and categorical variables as shown in Table 3. QAS moiety concentration was expressed as the mole fraction of hydride groups consumed by the QAS tethering process and was varied from 0.15 to 0.70. The hydride-to-vinyl ratio used for curing was varied on a molar basis from 2 to 3.

A summary of the three-level factorial design for the experiment is shown in Table 3 and the experimental details and results are shown in Table 4 (formulation details for each data point are shown in Appendix 1). Four additional center points were included for each categorical variable. Relative film uniformity/integrity was rated as 0, 1, and 2 by three individual observers. Films that were tacky or grossly nonuniform in appearance, due to macroscale phase separation prior to crosslinking, were considered “poor” and given a rating of “0,” while homogeneous, tack-free films were considered “good” and given a rating of “2.” The overall rating used for data analysis for a given composition was equal to the rating with the highest frequency. For example, the overall rating used for data analysis for standard order number 14 in Table 4 was “0” since two out of the three observers rated it a “0.”

A contingency analysis was performed in order to understand the effect of PMHS-PDMS hydride equivalent weight of the starting copolymer on coating film uniformity/integrity. Table 5 shows the frequency distribution of the categorical response, coating film uniformity/integrity (rating of 0, 1, and 2), for the categorical factor, PMHS-PDMS hydride equivalent weight, which was varied at two different levels (135 and 245 g/mol). Table 5 also depicts the results of two Chi-square statistical tests, the Likelihood ratio Chi-square test and the Pearson Chi-square test. Values of “Prob>Chisq” less than 0.05 were obtained from both test statistics, which indicated that hydride equivalent weight of the PMHS-PDMS starting copolymer affects the quality of film uniformity/integrity.

The effect of a categorical variable on a categorical response can be presented using a Mosaic plot.28–30 The Mosaic plot generated for this data set is shown in Fig, 2. Each column of rectangles in Fig. 2 represents the categorical variable, PMHS-PDMS hydride equivalent weight, along the horizontal axis and the size of each rectangle within a column represents the probability of obtaining a coating with a given relative degree of coating film uniformity/integrity. According to the Mosaic plot shown in Fig. 2, the chance of obtaining a coating having a rating of 2 for the relative degree of film uniformity/integrity is higher when the PMHS-PDMS copolymer possessing a hydride equivalent weight of 135 is used.

Use of the PMHS-PDMS copolymer with the lower hydride equivalent weight results in a higher concentration of hydride groups being present along the polymer backbone at the time of coating application, which according to the statistical analysis resulted in better film uniformity/integrity. With regard to the effects of QAS concentration and hydride-to-vinyl ratio on film uniformity/integrity, the statistical analysis indicated that these variables had no significant effect. The “Prob>Chisq” values were higher than 0.05 for both of these factors.

Since the use of the PMHS-PDMS copolymer possessing a hydride equivalent weight of 135 provided the best crosslinking and film uniformity and integrity, this copolymer was used as the starting material for producing QAS-functional PDMS polymers for experiments focused on optimizing biocidal activity. Three QAS-functional PDMS polymers were prepared that possessed variations in QAS moiety concentration. For convenience with respect to the experimental design, the concentration of QAS moieties was expressed as the mole fraction of hydride groups present in the PMHS-PDMS copolymer consumed by the QAS functionalization process. These three QAS-functional PDMS copolymers correspond to polymers PMHS-PDMS-Q1, PMHS-PDMS-Q2, and PMHS-PDMS-Q3 in Table 2.

For each QAS-functional PDMS synthesized, 13 coatings were prepared which possessed variations in QAS concentration and the molar ratio of hydride-to-vinyl functionality used for crosslinking. A description of the three-level factorial design with four additional center points used for the experiment is shown in Table 6 (formulation details are shown in Appendices 2–4). Initial screening simply involved characterization of the stability of the coatings after immersion in artificial seawater for 15 days. It was expected that the amphiphilic nature of the coatings would cause variations in the degree of water uptake which would ultimately affect film integrity and adhesion to the substrate. Those coatings which showed adequate stability in artificial seawater were carried forward to measurements of biocidal activity. The results of the artificial seawater immersion testing are shown in Table 6.

As shown in Table 6, all of the coatings produced from the QAS-functional PDMS copolymer possessing the highest concentration of QAS moieties (PMHS-PDMS-Q1) delaminated or displayed poor film integrity after 15 days of artificial seawater immersion and, as a result, were not characterized for biocidal activity. All of the coatings derived from the QAS-functional PDMS copolymer possessing the lowest concentration of QAS moieties (PMHS-PDMS-Q3) showed excellent stability upon artificial seawater immersion and, thus, were analyzed for biocidal activity. Coatings prepared from PMHS-PDMS-Q2 showed adequate stability after artificial seawater immersion (10 of the 13 coatings were stable) and were tested for biocidal activity.

Biocidal activity was measured using a biofilm retention assay based on the marine bacterium, C. lytica. Biocidal activity was expressed as a relative reduction in biofilm retention as compared to a nonbiocidal siloxane coating obtained from DC3140. Thus, coatings that showed no statistical reduction in biofilm retention relative to DC3140 were considered nonbiocidal or to have no biocidal activity.

The results of biocidal activity testing showed that none of the coatings prepared from the QAS-functional PDMS copolymer possessing the lowest concentration of QAS moieties (PMHS-PDMS-Q3) possessed biocidal activity. For the coatings based on QAS-functional PDMS copolymer possessing the intermediate concentration of QAS moieties that had adequate artificial seawater stability, a considerable variation in biocidal activity was observed. As a result, an ANOVA analysis was conducted on the biofilm retention data for these coatings.

Table 7 provides the variables and factors involved in the ANOVA, while Fig. 3 displays the results obtained from the biofilm retention assay (formulation details are shown in Appendix 3). Although coatings 7–9 showed very high biocidal activity, they also showed leachate toxicity using the leachate toxicity assay. This result suggests that some of the QAS-functional PDMS were not adequately crosslinked into the coating matrix. However, some coatings (coatings 1, 2, 4, 6, and 13) showed a 40–60% reduction in biofilm retention without any leachate toxicity. The ANOVA results of the reduction of biofilm retention of C. lytica are shown in Table 8.

Reduction of biofilm retention of C. lytica with respect to DC 3140 for the coatings described in Table 7

With regard to the ANOVA analysis used to model biofilm retention, the F-value of 10.09 implies that the model was significant. An F-value of this magnitude indicated that there was only a 0.87% chance that the responses could have been due to noise. The only model term that was found to be significant was the square of the concentration of QAS groups. The response surface obtained from the model is shown in Fig. 4 and indicates that approximately 50% reduction in biofilm retention of C. lytica can be achieved with as little as 4 wt% QAS moieties in the coating. With 18 wt% QAS moieties in a coating, the model indicates that a greater than 90% reduction in biofilm retention could be achieved.

Overall, the results obtained illustrate a “trade-off” in properties between biocidal activity and film stability upon seawater immersion. To obtain greater than 90% reduction in biofilm retention, approximately 18 wt% QAS moieties is required; however, this level of QAS moieties will result in poor film stability due to water absorption. As a result, moisture-cured systems were considered since moisture curing enables the possibility of obtaining a higher crosslink density which was thought to reduce swelling resulting from water absorption. In addition, unlike the addition-cured systems which require an oligomeric, divinyl crosslinking agent, moisture-curable PDMS copolymers can be prepared that contain both QAS moieties and trialkoxysilane groups eliminating the need for an oligomeric crosslinking agent. This aspect of a moisture-curable system provides a more homogeneous distribution of QAS moieties throughout the crosslinked polymer matrix and eliminates the possibility of obtaining large-scale phase separation during solvent evaporation and curing.

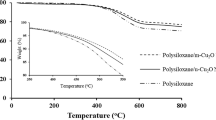

Figure 5 provides a schematic of the chemisty used for polymer precursor synthesis and coating cure. Since each pendant trimethoxy silane group on the PDMS can theoretically form a tetrafunctional crosslink, the overall crosslink density achieved with a moisture-cure mechanism can be designed to be much higher than with the previously investigated addition-cure mechanism. Initial screening experiments were conducted using the same PMHS-PDMS copolymer starting material used for the addition-cured systems described in Table 6 which possessed a hydride equivalent weight of 135 g/mol. The coatings produced from moisture-curable, QAS-functional polymers derived from this PMHS-PDMS starting polymer resulted in the formation of cracks in the crosslinked films. This result indicated that the crosslink density was too high. Thus, further experimentation was conducted using the PMHS-PDMS starting copolymer that had a hydride equivalent weight of 245 g/mol which, at a given QAS moiety concentration, produces PDMS copolymers possessing a lower concentration of pendant trimethoxysilane groups.

To determine the potential of utilizing a moisture-curable system to obtain both high biocidal activity and good coating stability upon immersion in seawater, a single polymer and coating composition was prepared and tested (see PMHS-PDMS-Q7 in Table 2). Coatings that possessed a QAS concentration of 29 wt% were cast and cured on both bare aluminum and primed aluminum substrates. Seawater stability was characterized after 36 days of immersion and bioactivity was characterized using both C. lytica and a marine algal species, N. incerta. Coatings over both bare aluminum and primed aluminum showed no delamination from the substrate or excessive swelling as a result of the artificial seawater immersion. In addition, as shown in Fig. 6, both coatings showed excellent biocidal activity without leachate toxicity for both C. lytica and N. incerta. A reduction of more than 80% biofilm retention was obtained for C. lytica and a reduction of more than 90% biofilm growth was obtained for N. incerta. These results clearly indicate that the use of a moisture-curing mechanism can be utilized to create QAS-functional, polysiloxane antifouling/fouling-release coatings that possess both high biocidal activity and good cured film stability during artificial seawater immersion. Follow-up optimization experiments are in progress.

Conclusions

Statistical experimental designs were used to investigate addition-curable polysiloxane coatings containing tethered QAS moieties for use as environmentally friendly antifouling/fouling-release coatings. The results obtained showed the existence of a “trade-off” in properties between biocidal activity and film stability upon seawater immersion. The QAS concentration required to obtain greater than 90% reduction in biofilm retention resulted in poor film stability upon seawater immersion. As a result, moisture-cured systems were considered since moisture curing enables the possibility of obtaining a higher crosslink density which was thought to reduce swelling resulting from water absorption.

Initial results involving the synthesis and characterization of a moisture-curable polysiloxane coating containing 29 wt% QAS moieties showed that moisture-curable systems allow for both very high biocidal activity without leachate toxicity and excellent film stability upon seawater immersion. A reduction of more than 80% biofilm retention was obtained for C. lytica and a reduction of more than 90% biofilm growth was obtained for N. incerta. These results suggest that the concept of tethering QASs to a crosslinked polysiloxane matrix could be effective in producing new, environmentally friendly hybrid antifouling/fouling-release coatings for marine applications.

References

Yebra, DM, Kiil, S, Dam-Johansen, K (2004) Antifouling Technology-Past, Present and Future Steps Towards Efficient and Environmentally Friendly Antifouling Coatings. Prog. Org. Coat., 50, 75–104

Rascio, VJD (2000) Antifouling Coatings: Where Do We Go From Here. Corrosion Reviews, 18, 133–154

Cooney, JJ, Tang, RJ (1999) Quantifying Effects of Antifouling Paints on Microbial Biofilm Formation. Meth. Enzymol., 310, 637–645

Majumdar, P, Ekin, A, Webster, DC (2007) Thermoset Siloxane-Urethane Fouling Release Coatings. ACS Symposium Series (Smart Coatings), 957, 61–75

Callow, ME, Fletcher, RL (1994) The Influence of Low Surface Energy Materials on Bioadhesion - a Review. Int. Biodeter. Biodegr., 34, 333–348

Abarzua, S, Jakubowsky, S (1995) Biotechnological Investigation for the Prevention of Biofouling. I. Biological and Biochemical Principles for the Prevention of Biofouling. Mar. Ecol. Prog. Ser., 123, 301–312

Sauvet, G, Fortuniak, W, Kazmierski, K, Chojnowski, J (2003) Amphiphilic Block and Statistical Siloxane Copolymers with Antimicrobial Activity. J. Polym. Sci., Part A: Polym. Chem., 41(19), 2939–2948

Gottenbos, B, Busscher, HJ, van der Mei, HC, Nieuwenhuis, P (2002) Pathogenesis and Prevention of Biomaterial Centered Infections. J. Mater. Sci.: Mater. Med., 13(8), 717–722

Gottenbos, B, van der Mei, HC, Klatter, F, Nieuwenhuis, P, Busscher, HJ (2002) In vitro and in vivo Antimicrobial Activity of Covalently Coupled Quaternary Ammonium Silane Coatings on Silicone Rubber. Biomaterials, 23(6), 1417–1423

Lenoir, S, Pagnoulle, C, Detrembleur, C, Galleni, M, Jerome, R, “Antimicrobial Activity of Polystyrene Particles Coated by Photo-Crosslinked Block Copolymers Containing a Biocidal Polymethacrylate Block.” e-Polymers, 074 (2005)

Sauvet, G, Dupond, S, Kazmierski, K, Chojnowski, J (2000) Biocidal Polymers Active by Contact. II. Biological Evaluation of Polyurethane Coatings with Pendant Quaternary Ammonium Salts. J. Appl. Polym. Sci., 75(8), 1005–1012

Nurdin, N, Helary, G, Sauvet, G (1993) Biocidal Polymers Active by Contact. II. Biological Evaluation of Polyurethane Coatings with Pendant Quaternary Ammonium Salts. J. Appl. Polym. Sci., 50, 663–670

Hazziza-Laskar, J, Nurdin, N, Helary, G, Sauvet, G (1993) Biocidal Polymers Active by Contact. I. Synthesis of Polybutadiene with Pendant Quaternary Ammonium Groups. J. Appl. Polym. Sci., 50, 651–662

Hazziza-Laskar, J, Helary, G, Sauvet, G (1995) Biocidal Polymers Active by Contact. IV. Polyurethanes Based on Polysiloxanes with Pendant Primary Alcohols and Quaternary Ammonium Groups. J. Appl. Polym. Sci., 58, 77–84

Tashiro, T (2001) Antibacterial and Bacterium Adsorbing Macromolecules. Macromol. Mater. Eng., 286, 63–87

Nakagawa, Y, Hayashi, H, Tawaratani, T, Kourai, H, Horie, T, Shibasaki, I (1984) Disinfection of Water with Quaternary Ammonium Salts Insolubilized on a Porous Glass Surface. Appl. Environ. Microbiol., 47, 513–518

Tiller, JC, Liao, C-J, Lewis, K, Klibanov, AM (2001) Designing Surfaces That Kill Bacteria on Contact. Proc. Natl. Acad. Sci. U.S.A., 98(11), 5981–5985

Brady, RF Jr (1999) Properties Which Influence Marine Fouling Resistance in Polymers Containing Silicon and Fluorine. Prog. Org. Coat., 35, 31–35

Zhang Newby, BM, Chaudhury, MK (1997) Effect of Interfacial Slippage on Viscoelastic Adhesion. Langmuir, 13, 1805–1809

Zhang Newby, BM, Chaudhury, MK, Brown, HR (1995) Macroscopic Evidence of The Effect of Interfacial Slippage on Adhesion. Science, 269(5529), 1407–1409

Kohl, JG, Singer, IL (1999) Pull-off Behavior of Epoxy Bonded to Silicone Duplex Coatings. Prog. Org. Coat., 36, 15–20

Anderson, MJ, Whitcomb, PJ (1996) Optimization of Paint Formulations Made Easy with Computer-Aided Design of Experiments for Mixtures. JCT Coatings Tech., 68(856), 71–75

Anderson, MJ, Whitcomb, PJ (1998) Find the Most Favorable Formulations. Chem. Eng. Prog., 94(4), 63–67

Anderson, MJ, Whitcomb, PJ (2000) Design Experiments That Combine Mixture Components with Process Factors. Chem. Eng. Prog., 96(12), 27–31

Stafslien, SJ, Bahr, JA, Feser, JM, Weisz, JC, Chisholm, BJ, Ready, TE, Boudjouk, P (2006) Combinatorial Materials Research Applied to the Development of New Surface Coatings I: A Multiwell Plate Screening Method for the High-Throughput Assessment of Bacterial Biofilm Retention on Surfaces. J. Comb. Chem., 8(2), 156–162

Stafslien, S, Daniels, J, Chisholm, B, Christianson, D (2007) Combinatorial Materials Research Applied to the Development of New Surface Coatings III. Utilization of a High-Throughput Multiwell Plate Screening Method to Rapidly Assess Bacterial Biofilm Retention on Antifouling Surfaces. Biofouling, 23(1), 37–44

Casse, F, Stafslien, S, Bahr, J, Daniels, J, Finlay, J, Callow, J, Callow, M (2007) Combinatorial Materials Research Applied to the Development of New Surface Coatings V. Application of a Spinning Water-Jet for the Semi-High Throughput Assessment of the Attachment Strength of Marine Fouling Algae. Biofouling, 23(2), 121–130

Majumdar, P, Christianson, DA, Roesler, RR, Webster, DC (2006) Optimization of Coating Film Deposition When Using an Automated High Throughput Coating Application Unit. Prog. Org. Coat., 56, 169–177

Friendly, M (1994) Mosaic Displays for Multi-Way Contingency Tables. J. Am. Stat. Assoc., 89, 190–200

Hofmann, H (2000) Exploring Categorical Data: Interactive Mosaic Plots. Metrika, 51, 11–26

Author information

Authors and Affiliations

Corresponding author

Additional information

Presented at 2007 FutureCoat! Conference, sponsored by Federation of Societies for Coatings Technology, October 3–5, 2007, in Toronto, Ont., Canada.

Appendices

Appendices

Rights and permissions

About this article

Cite this article

Majumdar, P., Lee, E., Patel, N. et al. Development of environmentally friendly, antifouling coatings based on tethered quaternary ammonium salts in a crosslinked polydimethylsiloxane matrix. J Coat Technol Res 5, 405–417 (2008). https://doi.org/10.1007/s11998-008-9098-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-008-9098-4