Abstract

This study aims to unveil the impact of high-pressure processing (HPP) on the structure and sensory properties of the mixture of egg white and whey protein at acidified conditions. Under HPP treatment, we hypothesized that egg white protein can form gel structures and encapsulate or crosslink with the whey protein, thus masking the interaction sites of whey protein with salivary protein and reduce its astringency at pH 3.5. Various characterization techniques, including turbidity measurements, zeta size, optical and scanning microscopy, native and sodium dodecyl sulfate polyacrylamide gel electrophoresis, and Fourier transform infrared spectroscopy, were used to illustrate the structural changes of the proteins and the interactions between the egg white and whey proteins. The results show that HPP treatment at 450 MPa and 600 MPa can induce significant changes to the egg white-whey protein mixture in terms of size, microstructure, secondary structure, and crosslinking. We also confirmed by electrophoresis that the egg white and whey protein form complexes through covalent bonding that feature a molecular weight of ~ 90 kDa under HPP treatment at a pH value of 3.5. Although the egg white forms microgel and may partially encapsulate the whey protein, sensory studies showed such complexation does not reduce the astringency of whey protein at acidified conditions (control astringency score = 9.0). On the contrary, the HPP-treated samples showed a higher astringency (astringency score = 11.1–11.3), possibly due to the exposure of more hydrophobic sites on the proteins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Astringency is a drying sensation in the mouth that is typically associated with beverages rich in polyphenols, such as tea and wine (Russell et al. 2006; Llaudy et al. 2004; McRae and Kennedy 2011; Carvalho et al. 2006). However, it is well known that whey protein beverages, especially in acidified conditions, also pose significant astringent taste (Beecher et al. 2008; Sano et al. 2005; Ye et al. 2012; Whetstine et al. 2005; Zhang et al. 2014a). The astringency of whey protein reduces consumer acceptance of acidified high-protein beverages, which has become a barrier for the promotion of these products by the food industry (Childs and Drake 2010; Prindiville et al. 2000).

The astringent sensation of acidified whey protein beverages is thought to be caused by the binding of positively charged whey protein with negatively charged salivary protein in acidic conditions, causing both proteins to precipitate on the tongue surface (Childs and Drake 2010; Kelly et al. 2010; Gibbins and Carpenter 2013; Ye et al. 2012; Vardhanabhuti et al. 2011). Research has also shown that whey protein beverages at around pH 3.5 are more astringent than those at other pH conditions (Beecher et al. 2008; Sano et al. 2005). Various methods have been used to reduce the astringency, such as adding polysaccharides and high-intensity sweeteners or changing the pH (Carvalho et al. 2006; Beecher et al. 2008; Gruen 2014; Zhang et al. 2014b).

As the astringency is caused by the precipitation of the salivary protein due to its complexation with whey protein (Fig. 1), methods reducing such interactions may be helpful to reduce its astringency. High-pressure processing (HPP) has been reported to inactivate microbes and induce structural changes of proteins (Galazka et al. 2000; Cadesky et al. 2017; He et al. 2016; Yuan et al. 2013; Pega et al. 2018; Rodríguez-Garayar et al. 2017; Laaksonen et al. 2014). Therefore, we may be able to reduce the astringency of acidified whey protein beverages by encapsulating the whey protein with egg white protein gels formed under ultra-high hydraulic conditions generated by the HPP equipment (Wang et al. 2019). Egg white protein could potentially form a complex with the whey protein or form gels to entrap it due to the conformational change under HPP, thus potentially blocking the sites of interaction between whey proteins and salivary proteins (Fig. 2). Meanwhile, the egg white protein is a relatively clean-tasting protein and does not pose any astringent taste under acidified conditions. Theoretically, if the active site of whey protein is blocked by the egg white, the astringency of the whey protein may be reduced due to the decreased chance of interaction with salivary protein.

Schematic illustration of the interaction of whey protein, salivary protein, and egg white protein. a Whey protein and salivary protein bind together at pH 3.5 and precipitate on the tongue surface. b Whey protein, which formed a complex with egg white protein under HPP, may not interact with salivary protein

This study aims to understand if the whey protein and egg white protein will interact with each other at pH 3.5 under high-pressure conditions and if there are any structural changes for both proteins (Kuropatwa et al. 2009). We also intend to use sensory evaluation techniques to determine the astringency and perceived acidity of the HPP-treated egg white-whey protein mixture and, specifically, whether the structural change of these materials can increase or decrease the astringency of whey protein as pH 3.5.

Materials and Methods

Materials and Chemicals

Whey protein (Thermax 690) was obtained from Glanbia Nutritionals, Inc. (Chicago, IL, USA). Pasteurized liquid egg white was purchased from a local Wegmans Food Market. Sodium hydroxide, sodium phosphate dibasic, sodium phosphate monobasic, phosphoric acid, methanol, and acetic acid were purchased from Sigma-Aldrich (St. Louis, MO, USA) and used without further purification. The chemicals for electrophoresis were obtained from Bio-Rad Laboratories (Hercules, CA, USA). Food-grade phosphoric acid (LD Carlson, USA) and citric acid (Milliard, USA) were purchased from Amazon.com. Deionized water (18.2 MΩ/cm) was used and prepared from a Milli-Q water purification system.

Preparation of Whey and Egg White Protein Mixtures at pH 3.5 and Different Concentration Ratios

The stock solution of whey protein (10%, w/w) was prepared by dissolving 100 g of whey protein isolate into 900 g of deionized water and blending by a high-shear mixer at a speed of 12,000 rpm for 5 min. Liquid egg white and deionized water were added into the whey protein solution to achieve a whey protein concentration of 5% and various concentrations of egg white protein (0–5%). The concentration of whey protein in all the mixtures was 5%. The pH of the mixtures was adjusted to 3.5 using citric acid (~ 20%, w/v).

Treatment of the Whey and Egg White Protein Mixture by High-Pressure Processing

The mixtures of whey and egg white protein were treated using a 55-L HPP machine from Hiperbaric USA (Hiperbaric 55, Burgos, Spain). The mixtures of egg white-whey protein were first filled in flexible polyethylene terephthalate bottles (8 oz), which were then sealed in plastic bags before being placed into the HPP chamber. The samples were treated at a pressure of 450 MPa or 600 MPa with a holding time of 3.5 min (Fig. S1) and a temperature of 5–10 °C, conditions used in the food industry for HPP (Rastogi et al. 2007; Rojo et al. 2019; Chien et al. 2019; Carreño-Olejua et al. 2010).

Turbidity Measurement of the Protein Mixture

The turbidity of the mixtures was measured by a plate reader at a wavelength of 610 nm (Zhang et al. 2012). The protein mixtures were first mixed well and diluted 15 times into citrate buffer (pH 3.5). For each sample, 0.1 mL of the mixture was transferred into the wells on the 96-well plate and measured by the plate reader. The protein mixtures that formed solid gels were not measured for turbidity.

Measurement of the Average Size of the Protein Complex in the Mixtures

The average size of the protein complex in the mixtures was measured using a Malvern zeta sizer (Nano ZS; Malvern Panalytical Ltd., UK). For each sample, 1.0 mL of the mixture was placed into the cuvette for measurement of the average particle size. The samples in the cuvettes were equilibrated at 25.0 °C for 60 s and subjected to 12–16 runs for three times. The average sizes were calculated based on the scattering intensities generated from the diffraction of the protein particles. The protein mixtures that formed solid gels were not measured.

Scanning Electron Microscopy Measurements

The egg white-whey protein samples were diluted 10 times by deionized water and deposited on the surface of the conductive carbon tape on the scanning electron microscopy (SEM) stub. The SEM stubs were air-dried at ambient temperature for 48 h. Then, a thin layer of gold was sputter-coated on the surface of the samples under vacuum. The gold-coated samples on SEM stub were placed into the chamber of Zeiss LEO 1550 FESEM (Germany). The SEM images of the egg white-whey protein samples were acquired under vacuum and with a distance of 5 mm and a voltage of 3 kV.

Electrophoresis of the Protein Mixtures

The protein mixtures were also analyzed using native and sodium dodecyl sulfate (SDS) polyacrylamide gel electrophoresis (PAGE) (Mulcahy et al. 2017). The gels were prepared from a premixed TGX FastCast Acrylamide starter kit, with a concentration of 12% (no. 1610175; Bio-Rad). The native PAGE buffer consists of 2.5 mM Tris and 19.2 mM glycine. For native PAGE, samples were diluted with native sample buffer (62.5 mM Tris HCl of pH 6.8, 40% (w/v) glycerol, and 0.01% (w/v) bromophenol blue). After that, 20 μL of the sample was loaded into the PAGE gels. The SDS-PAGE buffer was composed of 2.5 mM Tris and 19.2 mM glycine with 0.1% SDS. Similar to native PAGE, the SDS-PAGE samples were diluted 20-fold with SDS sample buffer (62.5 mM Tris HCl of pH 6.8, 2% SDS, 25% (w/v) glycerol, and 0.01% (w/v) bromophenol blue) and were loaded onto the PAGE gels. The electrophoresis was performed under 200 V for ~ 45 min. After electrophoresis, staining solution (50% methanol, 10% acetic acid, 0.15% Coomassie Brilliant R-250) was used to stain the gels for 30 min, and then the gel was placed into the de-staining solution (20% methanol, 10% acetic acid) to de-stain overnight.

Fourier Transform Infrared Spectroscopic Analysis of the Protein Mixtures

The mixtures of whey and egg white protein treated with/without HPP were freeze-dried for the Fourier transform infrared (FT-IR) (IRAffinity-1S; Shimadzu) measurements. The freeze-dried samples were placed in the diamond sample holder and pressed tightly by the metal pin. The FT-IR spectra were collected with a resolution of 2 cm−1, at 64 runs. Three replicates were performed for each sample. The secondary derivatives and the average of the spectra were calculated using Delight software (DSquared Development, OR, USA) (Zhang et al. 2015).

Sensory Evaluation of the Protein Mixtures

The samples selected for the sensory studies contained 3.5% of egg white protein and 5.0% of whey protein, as this combination forms gels that can be suspended in solution after HPP treatment. The sensory test was approved by the Institutional Review Board of Cornell University. The astringency of the protein samples was evaluated by an untrained panel with 17 panelists on a scale of 1–18. The egg white-whey protein sample without any HPP treatment was used as a control with a pre-set astringency and acidity score of 9.0. The samples treated at 450 MPa and 600 MPa were evaluated and compared to the control by the panelists. The significance of the differences was calculated using analysis of variance (ANOVA) (SPSS software; IBM, USA) with post hoc Duncan corrections (P < 0.05).

Results and Discussion

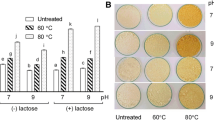

Appearance and Turbidity of the Protein Mixtures Treated With/Without HPP

Figure 3 shows optical images of the egg white-whey protein solutions (pH 3.5) treated without HPP treatment, with HPP at 450 MPa and 600 MPa for 3.5 min. The whey protein we selected for this study is a thermally denatured protein (Thermax 690), which displays a very strong astringent taste at acidified conditions. This whey protein forms a turbid solution (sample 1) after the pH was adjusted to 3.5 by citric acid before HPP treatment, possibly indicating the assembly of the whey protein molecules into small particles. The whey protein stays suspended in the solution when 1.5% and 2.0% of egg white protein is added into the mixture (pH 3.5, samples 2 and 3). However, the egg white-whey protein solutions start to precipitate when the concentration of egg white reaches 2.5% (samples 4–8). The isoelectric point (pI) for whey protein is between 4.2 and 5.3 (Pelegrine and Gasparetto 2005; Bouaouina et al. 2006). The egg white protein pI is between 4.6 (ovalbumin) and 10.7 (lysozyme) (Awadé and Efstathiou 1999; Hegg 1979). Therefore, both proteins should be positively charged at pH 3.5. The precipitation might be induced by the hydrophobic interactions between the egg white and whey protein. The worst phase separation was observed when the concentration of whey protein and egg white protein was 5.0% and 2.5%, respectively, which agrees with previous reports that 10:5 whey/egg albumen showed strong protein-protein interactions (Ngarize et al. 2004).

After HPP treatment at 450 MPa and 600 MPa for 3.5 min, sample 1 (whey protein only) did not show significant change in color. However, samples 2–6 (with different concentrations of egg white protein added, ranging from 1.5 to 3.5%) turned into a creamy white color. Samples 7 and 8 formed solid gels after the HPP treatments at 450 MPa and 600 MPa. It has been previously reported that 10% of whey protein isolate solution is needed to form gels at a pressure of 600 MPa (Kanno et al. 1998). Therefore, the creamy appearance was due to the formation of egg white protein microgels under HPP treatments.

We measured the turbidity of the protein samples using a UV-vis plate reader, as indicated by their absorbance at 610 nm (Fig. 4). The turbidity of a protein sample is usually correlated with the protein particle size, which can be used to predict the formation or dissolution of protein gels. As shown in Fig. 4, the turbidity of the samples without HPP treatment slightly increases with an increasing concentration of egg white protein (samples 1–8, 0–5%, absorbance = 0.123–0.303). After treatment at 450 MPa, the turbidity of the samples drastically and linearly increases with the concentration of egg white protein (samples 1–6, 450 MPa, absorbance = 0.119–0.728). This trend was also observed for the samples treated at 600 MPa (samples 1–6, 600 MPa, absorbance = 0.120–0.752). Samples 7 and 8 treated at 450 MPa and 600 MPa were not tested due to the formation of solid gels. In addition, the samples (2–6) treated at 600 MPa showed slightly higher turbidity than those treated at 450 MPa. The samples (3–6) treated by HPP showed much higher turbidity than all the samples without HPP treatment. The turbidity of sample 1 (whey protein only) did not change after HPP treatment at both pressures, which indicates that 5% whey protein at pH 3.5 cannot form gels under HPP treatment at 600 MPa for 3.5 min.

Turbidity of the mixture of whey protein and egg white protein with/without HPP treatment as measured by a UV-vis spectrophotometer. (Sample 1, 5.0% WPI + 0% EW; samples 2, 5.0% WPI + 1.0% EW; sample 3, 5.0% WPI + 2.0% EW; sample 4, 5.0% WPI + 2.5% EW; sample 5, 5.0% WPI + 3.0% EW; sample 6, 5.0% WPI + 3.5% EW; sample 7, 5.0% WPI + 4.0% EW; sample 8, 5.0% WPI + 5.0% EW) (0.1 MPa, standard atmosphere pressure)

Average Size of the Egg White-Whey Protein Samples

Figure 5 shows the average sizes of the egg white-whey protein samples without/with HPP treatments. Samples 1–3 demonstrated a very small particle size of less than 1000 nm without the HPP treatment (Fig. 5a). However, the average size of samples 4–8 increased significantly due to the higher concentration of egg white protein in the samples (> 2.5%) and the coacervation caused by the interactions between the egg white and whey proteins, which generated large and unpacked particles in the solution.

Size of the mixture of whey protein and egg white protein treated with/without HPP. a Control without HPP treatment. b HPP treatment, 450 MPa, 3.5 min. c HPP treatment, 600 MPa, 3.5 min. (Sample 1, 5.0% WPI + 0% EW; sample 2, 5.0% WPI + 1.0% EW; sample 3, 5.0% WPI + 2.0% EW; sample 4, 5.0% WPI + 2.5% EW; sample 5, 5.0% WPI + 3.0% EW; sample 6, 5.0% WPI + 3.5% EW; sample 7, 5.0% WPI + 4.0% EW; sample 8, 5.0% WPI + 5.0% EW)

After HPP treatment at 450 MPa for 3.5 min, we noticed that the size of the protein samples (samples 1–6) increased gradually with the concentration of egg white protein (Fig. 5b, 328 nm to 5994 nm). This trend correlates well with the turbidity of the samples (Fig. 4) and indicates that the egg white protein is responsible for the size changes during HPP treatment. The egg white protein, even at very low concentrations such as 1%, can form microgels under 450 MPa of HPP treatment, as indicated by the increased sizes (Fig. 5b). The size of the samples treated at a pressure of 600 MPa also showed the same trend (samples 1–6, 330 nm to 5917 nm, Fig. 5c). However, the size of sample 1 did not change significantly before and after HPP treatment (352 nm, 328 nm, 330 nm). The size data, in addition to the turbidity results, indicate that 450 MPa and 600 MPa of pressure both can turn the egg white protein into gel, but not the whey protein.

Optical and Scanning Electron Microscopy Images of the Protein Samples

Figure 6 shows the optical microscopy images of the egg white-whey protein samples without/with the HPP treatment. As shown in Fig. 6a, sample 1 at pH 3.5 (whey protein only) forms small spherical particles, most of which are less than 1.0 μm in size. The average size of those spherical particles is about 330 nm, as tested by the zeta sizer. The whey proteins used in this study have self-assembled into particles due to the crosslinking initiated by the citric acid. Previous reports have shown that citric acid, due to its three carboxyl groups, acts as spacer arms to modulate the hydrophilicity of the whey proteins and interact with whey protein through hydrogen bonding (Farjami et al. 2015; Zand-Rajabi and Madadlou 2016; Hashemi et al. 2017). Such crosslinking was also used to enhance the strength of whey protein microgels (Farjami et al. 2015). Samples 2 and 3 also show similar size particles, but with irregular shapes. Samples 4–8 coacervated and thus present much larger particle sizes, which correlate with the average size measured by the zeta sizer in Fig. 5.

Microscopic image of the egg white-whey protein mixture treated with/without HPP. a Control without HPP treatment. b HPP treatment, 450 MPa, 3.5 min. c HPP treatment, 600 MPa, 3.5 min. (Sample 1, 5.0% WPI + 0% EW; sample 2, 5.0% WPI + 1.0% EW; sample 3, 5.0% WPI + 2.0% EW; sample 4, 5.0% WPI + 2.5% EW; sample 5, 5.0% WPI + 3.0% EW; sample 6, 5.0% WPI + 3.5% EW; sample 7, 5.0% WPI + 4.0% EW; sample 8, 5.0% WPI + 5.0% EW)

After HPP treatment at 450 MPa and 600 MPa, the same trends can be observed. Samples 1–3 feature smaller particles, while samples 4–8 demonstrate much larger particle sizes (Fig. 6b, c). However, the particles in samples 4–8 are much more compact compared to those in the untreated samples, as evidenced by the higher contrast in the images. The particles in Fig. 6a and b/c feature different densities and are formed due to different mechanisms.

We also took SEM images of samples 1 and 6 before and after HPP treatment (Fig. 7). The samples were first diluted into citrate buffer (pH 3.5) and transferred onto a conductive tape on top of the SEM stub. Once the samples were dried, they formed a film on the conductive tape. The samples were coated with a layer of gold for SEM. As shown in Fig. 7a, c, and e, sample 1 (whey protein only) forms a relatively smooth film, which indicated that the whey protein does not form any gel even after 600 MPa of HPP treatment. However, when mixed with egg white protein, the whey protein (sample 6) coacervates with the egg white and forms rough structures, as evidenced in Fig. 7b. Furthermore, sample 6 forms gels after HPP treatments at 450 MPa and 600 MPa (Fig. 7d, f). The SEM images also indicated that the gel structures, similar to heat-set gels, were supported by various small gels of micrometer size (Handa et al. 1998; Woodward and Cotterill 1985).

SDS-PAGE and Native PAGE of the Protein Samples

To further illustrate what type of interactions occurred between the egg white and whey proteins before and after HPP treatment, we used SDS-PAGE and native PAGE to analyze the protein samples (Fig. 8). Both the SDS-PAGE and native PAGE show that HPP does not induce any changes to the whey protein-only sample (sample 1). However, HPP can induce structural changes in the egg white protein and also trigger crosslinking of the egg white and whey proteins. Both samples 5 and 8, without HPP treatment, showed nothing at the ~ 90 kDa region in the SDS-PAGE image (Fig. 8a). In comparison, a band with a molecular weight of ~ 88–92 kDa was formed for the HPP-treated samples (450 MPa, 600 MPa). The formation of this new band in the SDS-PAGE gel provides evidence that the egg white-whey proteins crosslinked, likely through the formation of disulfide bonds.

Native-PAGE and SDS-PAGE analysis of the whey protein-egg white protein mixtures treated by HPP. a SDS-PAGE for samples 1, 5, and 8. b Native PAGE for samples 1, 5, and 8. (Sample 1, 5.0% WPI + 0% EW; sample 5, 5.0% WPI + 3.0% EW; sample 8, 5.0% WPI + 5.0% EW) (BSA 66.5 kDa, β-lactoglobulin 18 kDa, α-lactalbumin 14 kDa; Conalbumin, 76 kDa, Ovalbumin, 44.5 kDa, Lysozyme 14.4 kDa)

Considering the molecular weight of this new band (~ 96 kDa), we suspect that it might be either a conjugate of conalbumin (76 kDa) from egg white and lactalbumin (14 kDa) or lactoglobulin (18 kDa) from whey protein. Previous reports state that β-lactoglobulin (2 disulfide bonds, 1 free sulfhydryl group) and ovalbumin (1 disulfide bond, 4 free sulfhydryl groups) might interact with each other through a sulfhydryl/disulfide reaction (Kuropatwa et al. 2009; Stadelman et al. 2017). The conalbumin contains 15 disulfide bonds but no free sulfhydryl group while the lactalbumin also contains 4 disulfide bonds but no free sulfhydryl group (Hirose et al. 1988; Iyer and Klee 1973). It is highly possible that the conjugated, new protein consists of conalbumin and β-lactoglobulin. The HPP treatment opens the protein and exposes the disulfide bond and sulfhydryl group, leading to the interaction and conjugation by the sulfhydryl/disulfide reaction (Patel et al. 2006; Funtenberger et al. 1997). The whey protein was not only entrapped in the egg white protein gels but also crosslinked with the egg white through covalent bonds. This structure, theoretically, should reduce the chance of interaction between the whey protein and salivary protein in the mouth, which may help mitigate the astringent taste of whey proteins at pH 3.5.

The native PAGE image also showed that HPP does not induce any significant structural changes for the whey protein only sample (sample 1; Fig. 8b). In contrast, the egg white-whey protein mixture can form a strong and large complex after the HPP treatment as evidenced by that fact that the marked bands of the control sample (no HPP treatment) disappeared after the HPP treatment at both 450 MPa and 600 MPa conditions. The large complex, possibly egg white-whey protein or egg white-egg white complex, is too big to enter the native PAGE gel.

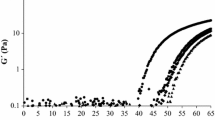

FT-IR Analysis of the Protein Mixtures Treated by HPP

FT-IR spectroscopy was used to further illustrate the HPP-induced structural changes and understand the formation of the egg white-whey protein complex/capsules (Zhu et al. 2018). The secondary derivatives of the spectrum were calculated by the Delight software to enhance the resolution between peaks. The region between 1600 and 1700 cm−1 is of particular interest to us as this region shows the secondary structure of the proteins (e.g., α-helix and β-sheet) (Kong and Yu 2007; Surewicz et al. 1993). The band at 1654 cm−1 is indicative of the α-helix structure of the protein samples (Wilder et al. 1992). As shown in Fig. 9a, α-helix is the dominant secondary structure of the whey protein-only sample (sample 1) and the egg white-whey protein samples (samples 2–8). After HPP treatment at 450 MPa and 600 MPa, the band intensity at 1654 cm−1 for all the samples (samples 1–8) significantly increased. This shows that even the whey protein-only sample (sample 1) did not form a gel after the HPP treatment, the secondary structures were altered under the pressure of 450 MPa and 600 MPa. The HPP treatments of samples 2–8 might unfold the proteins and expose more α-helix structures on the protein surface, as shown by the increased intensities at 1654 cm−1 (Considine et al. 2007, 2008), and β-sheet signals typically appear at 1625–1640 cm−1, giving confidence that the signal at 1636 cm−1 indicates the β-sheet of whey protein and egg white proteins. In addition, we also observed that HPP generated a new β-structure at 1618 cm−1 for samples 1–8 when compared to the untreated materials (Fig. 9). We suspect this β-structure, at 1618 cm−1, is the aggregated strand induced by the HPP treatment (Wilder et al. 1992).

Second derivatives of the FT-IR spectrum of the whey protein-egg white protein mixtures treated by HPP. a Samples 1 and 2. b Samples 3 and 4. c Samples 5 and 6. d Samples 7 and 8. (Sample 1, 5.0% WPI + 0% EW; sample 2, 5.0% WPI + 1.0% EW; sample 3, 5.0% WPI + 2.0% EW; sample 4, 5.0% WPI + 2.5% EW; sample 5, 5.0% WPI + 3.0% EW; sample 6, 5.0% WPI + 3.5% EW; sample 7, 5.0% WPI + 4.0% EW; sample 8, 5.0% WPI + 5.0% EW)

Sensory Evaluations of the Astringency of the Protein Mixtures Treated by HPP

Sample 6 formed microgels under HPP treatment and was selected for sensory evaluation to determine whether the interactions of the egg white (gel) and whey protein can reduce the astringency of the whey protein. The acidity attribute was introduced in the sensory test to help panelists differentiate from the astringency. As shown in Table 1, the precepted acidity for the control and HPP-treated samples (450 MPa and 600 MPa) showed no statistical differences (P > 0.05). This is reasonable since HPP does not change the structure for small molecules, e.g., citric acid. The results also indicated that citric acid might not participate in the crosslinking of proteins. However, the protein samples treated by HPP (450 MPa, 600 MPa) showed a much higher astringency score compared to the control sample without HPP treatment (P < 0.05). The astringency of the protein mixtures increased from 9.0 to 11.3 and 11.1 after the HPP treatment at 450 MPa and 600 MPa. Moreover, the astringency score of the samples treated at 450 MPa and 600 MPa showed no statistical difference.

The astringency of whey protein at pH 3.5 is caused by the electrostatic interaction between the negatively charged salivary protein and positively charged whey protein or by the hydrophobic interaction between the two proteins, regardless of the viscosity of the matrix (Gibbins and Carpenter 2013; Sano et al. 2005; Beecher et al. 2008). The sensory result indicated that even when egg white microgels were formed and whey protein was crosslinked/encapsulated with the egg white protein, the astringency of the whey protein was not improved. The HPP treatment exposed more secondary structures and promoted the formation of new secondary structures as evidenced by the FT-IR spectra in Fig. 9. The exposure of more secondary structures possibly makes the hydrophobic patches more accessible to the salivary proteins and lead to a more severe astringent taste. Similar to thermal treatment, the astringency increased with the heating time of whey protein, revealing that the denaturation of whey protein is a contributing factor for astringency (Bull et al. 2017). From the results, we can reasonably conclude that the astringent taste of whey protein at pH 3.5 is aggravated by the denaturation of whey protein under HPP treatments (Lopez-Fandino et al. 1996) and the egg white complexation does not compensate for the aggravated astringency.

Conclusion

This study investigated the impact of HPP on the structure and sensory properties of the mixture of egg white and whey protein at pH 3.5. We hypothesized that if egg white proteins form gels, they can encapsulate the whey protein and reduce its astringency at pH 3.5. However, the sensory results show that the astringency of the protein mixtures increased after the HPP treatments. The increased astringency may be caused by the exposure of the hydrophobic regions of the proteins, which would significantly increase the chances of interactions between the whey and salivary proteins. Interestingly, it was also found that the egg white and whey protein form complexes with a molecular weight of ~ 90.0 kDa through covalent bonding under HPP treatment.

References

Awadé, A. C., & Efstathiou, T. (1999). Comparison of three liquid chromatographic methods for egg-white protein analysis. Journal of Chromatography B: Biomedical Sciences and Applications, 723(1–2), 69–74.

Beecher, J., Drake, M., Luck, P., & Foegeding, E. (2008). Factors regulating astringency of whey protein beverages. Journal of Dairy Science, 91(7), 2553–2560.

Bouaouina, H., Desrumaux, A., Loisel, C., & Legrand, J. (2006). Functional properties of whey proteins as affected by dynamic high-pressure treatment. International Dairy Journal, 16(4), 275–284.

Bull, S. P., Hong, Y., Khutoryanskiy, V. V., Parker, J. K., Faka, M., & Methven, L. (2017). Whey protein mouth drying influenced by thermal denaturation. Food Quality and Preference, 56(Pt B), 233–240.

Cadesky, L., Walkling-Ribeiro, M., Kriner, K. T., Karwe, M. V., & Moraru, C. I. (2017). Structural changes induced by high-pressure processing in micellar casein and milk protein concentrates. Journal of Dairy Science, 100(9), 7055–7070.

Carreño-Olejua, R., Hofacker, W. C., & Hensel, O. (2010). High-pressure water-jet technology as a method of improving the quality of post-harvest processing. Food and Bioprocess Technology, 3(6), 853–860.

Carvalho, E., Mateus, N., Plet, B., Pianet, I., Dufourc, E., & De Freitas, V. (2006). Influence of wine pectic polysaccharides on the interactions between condensed tannins and salivary proteins. Journal of Agricultural and Food Chemistry, 54(23), 8936–8944.

Chien, S.-Y., Sheen, S., Sommers, C., & Sheen, L.-Y. (2019). Combination effect of high-pressure processing and essential oil (Melissa officinalis extracts) or their constituents for the inactivation of Escherichia coli in ground beef. Food and Bioprocess Technology, 12(3), 359–370.

Childs, J. L., & Drake, M. (2010). Consumer perception of astringency in clear acidic whey protein beverages. Journal of Food Science, 75(9), S513–S521.

Considine, T., Patel, H., Anema, S., Singh, H., & Creamer, L. (2007). Interactions of milk proteins during heat and high hydrostatic pressure treatments—a review. Innovative Food Science & Emerging Technologies, 8(1), 1–23.

Considine, K. M., Kelly, A. L., Fitzgerald, G. F., Hill, C., & Sleator, R. D. (2008). High-pressure processing—effects on microbial food safety and food quality. FEMS Microbiology Letters, 281(1), 1–9.

Farjami, T., Madadlou, A., & Labbafi, M. (2015). Characteristics of the bulk hydrogels made of the citric acid cross-linked whey protein microgels. Food Hydrocolloids, 50, 159–165.

Funtenberger, S., Dumay, E., & Cheftel, J. (1997). High pressure promotes β-lactoglobulin aggregation through SH/S–S interchange reactions. Journal of Agricultural and Food Chemistry, 45(3), 912–921.

Galazka, V. B., Dickinson, E., & Ledward, D. A. (2000). Influence of high pressure processing on protein solutions and emulsions. Current Opinion in Colloid & Interface Science, 5(3–4), 182–187.

Gibbins, H., & Carpenter, G. (2013). Alternative mechanisms of astringency—what is the role of saliva? Journal of Texture Studies, 44(5), 364–375.

Gruen, I. (2014). Application of natural, non-nutritive, high-potency sweeteners and sugar alcohols individually and in combination in an acidified protein beverage model. Columbia: University of Missouri.

Handa, A., Takahashi, K., Kuroda, N., & FRONING, G. W. (1998). Heat-induced egg white gels as affected by pH. Journal of Food Science, 63(3), 403–407.

Hashemi, B., Madadlou, A., & Salami, M. (2017). Functional and in vitro gastric digestibility of the whey protein hydrogel loaded with nanostructured lipid carriers and gelled via citric acid-mediated crosslinking. Food Chemistry, 237, 23–29.

He, X., Mao, L., Gao, Y., & Yuan, F. (2016). Effects of high pressure processing on the structural and functional properties of bovine lactoferrin. Innovative Food Science & Emerging Technologies, 38, 221–230.

Hegg, P.-O. (1979). Precipitation of egg white proteins below their isoelectric points by sodium dodecyl sulphate and temperature. Biochimica et Biophysica Acta (BBA)-Protein Structure, 579(1), 73–87.

Hirose, M., Takahashi, N., Oe, H., & Doi, E. (1988). Analyses of intramolecular disulfide bonds in proteins by polyacrylamide gel electrophoresis following two-step alkylation. Analytical Biochemistry, 168(1), 193–201.

Iyer, K. S., & Klee, W. A. (1973). Direct spectrophotometric measurement of the rate of reduction of disulfide bonds. The reactivity of the disulfide bonds of bovine α-lactalbumin. Journal of Biological Chemistry, 248(2), 707–710.

Kanno, C., Mu, T.-H., Hagiwara, T., Ametani, M., & Azuma, N. (1998). Gel formation from industrial milk whey proteins under hydrostatic pressure: effect of hydrostatic pressure and protein concentration. Journal of Agricultural and Food Chemistry, 46(2), 417–424.

Kelly, M., Vardhanabhuti, B., Luck, P., Drake, M., Osborne, J., & Foegeding, E. (2010). Role of protein concentration and protein–saliva interactions in the astringency of whey proteins at low pH. Journal of Dairy Science, 93(5), 1900–1909.

Kong, J., & Yu, S. (2007). Fourier transform infrared spectroscopic analysis of protein secondary structures. Acta Biochimica et Biophysica Sinica, 39(8), 549–559.

Kuropatwa, M., Tolkach, A., & Kulozik, U. (2009). Impact of pH on the interactions between whey and egg white proteins as assessed by the foamability of their mixtures. Food Hydrocolloids, 23(8), 2174–2181.

Laaksonen, O. A., Mäkilä, L., Sandell, M. A., Salminen, J.-P., Liu, P., Kallio, H. P., & Yang, B. (2014). Chemical-sensory characteristics and consumer responses of blackcurrant juices produced by different industrial processes. Food and Bioprocess Technology, 7(10), 2877–2888.

Llaudy, M. C., Canals, R., Canals, J.-M., Rozés, N., Arola, L., & Zamora, F. (2004). New method for evaluating astringency in red wine. Journal of Agricultural and Food Chemistry, 52(4), 742–746.

Lopez-Fandino, R., Carrascosa, A., & Olano, A. (1996). The effects of high pressure on whey protein denaturation and cheese-making properties of raw milk. Journal of Dairy Science, 79(6), 929–936.

McRae, J. M., & Kennedy, J. A. (2011). Wine and grape tannin interactions with salivary proteins and their impact on astringency: a review of current research. Molecules, 16(3), 2348–2364.

Mulcahy, E. M., Fargier-Lagrange, M., Mulvihill, D. M., & O’Mahony, J. A. (2017). Characterisation of heat-induced protein aggregation in whey protein isolate and the influence of aggregation on the availability of amino groups as measured by the ortho-phthaldialdehyde (OPA) and trinitrobenzenesulfonic acid (TNBS) methods. Food Chemistry, 229, 66–74.

Ngarize, S., Adams, A., & Howell, N. K. (2004). Studies on egg albumen and whey protein interactions by FT-Raman spectroscopy and rheology. Food Hydrocolloids, 18(1), 49–59.

Patel, H. A., Singh, H., Anema, S. G., & Creamer, L. K. (2006). Effects of heat and high hydrostatic pressure treatments on disulfide bonding interchanges among the proteins in skim milk. Journal of Agricultural and Food Chemistry, 54(9), 3409–3420.

Pega, J., Denoya, G. I., Castells, M., Sarquis, S., Aranibar, G., Vaudagna, S. R., & Nanni, M. (2018). Effect of high-pressure processing on quality and microbiological properties of a fermented beverage manufactured from sweet whey throughout refrigerated storage. Food and Bioprocess Technology, 11(6), 1101–1110.

Pelegrine, D., & Gasparetto, C. (2005). Whey proteins solubility as function of temperature and pH. LWT-Food Science and Technology, 38(1), 77–80.

Prindiville, E., Marshall, R., & Heymann, H. (2000). Effect of milk fat, cocoa butter, and whey protein fat replacers on the sensory properties of lowfat and nonfat chocolate ice cream. Journal of Dairy Science, 83(10), 2216–2223.

Rastogi, N., Raghavarao, K., Balasubramaniam, V., Niranjan, K., & Knorr, D. (2007). Opportunities and challenges in high pressure processing of foods. Critical Reviews in Food Science and Nutrition, 47(1), 69–112.

Rodríguez-Garayar, M., Martín-Cabrejas, M. A., & Esteban, R. M. (2017). High hydrostatic pressure in astringent and non-astringent persimmons to obtain fiber-enriched ingredients with improved functionality. Food and Bioprocess Technology, 10(5), 854–865.

Rojo, M. C., Cristiani, M., Szerman, N., Gonzalez, M., Lerena, M. C., Mercado, L. A., & Combina, M. (2019). Reduction of Zygosaccharomyces rouxii population in concentrated grape juices by thermal pasteurization and hydrostatic high pressure processing. Food and Bioprocess Technology, 12(5), 781–788.

Russell, T., Drake, M., & Gerard, P. (2006). Sensory properties of whey and soy proteins. Journal of Food Science, 71(6), S447–S455.

Sano, H., Egashira, T., Kinekawa, Y., & Kitabatake, N. (2005). Astringency of bovine milk whey protein. Journal of Dairy Science, 88(7), 2312–2317.

Stadelman, W. J., Newkirk, D., & Newby, L. (2017). Egg science and technology. CRC.

Surewicz, W. K., Mantsch, H. H., & Chapman, D. (1993). Determination of protein secondary structure by Fourier transform infrared spectroscopy: a critical assessment. Biochemistry, 32(2), 389–394.

Vardhanabhuti, B., Cox, P., Norton, I., & Foegeding, E. (2011). Lubricating properties of human whole saliva as affected by β-lactoglobulin. Food Hydrocolloids, 25(6), 1499–1506.

Wang, B., Liu, F., Luo, S., Li, P., Mu, D., Zhao, Y., Zhong, X., Jiang, S., & Zheng, Z. (2019). Effects of high hydrostatic pressure on the properties of heat-induced wheat gluten gels. Food and Bioprocess Technology, 12(2), 220–227.

Whetstine, M. C., Croissant, A., & Drake, M. (2005). Characterization of dried whey protein concentrate and isolate flavor. Journal of Dairy Science, 88(11), 3826–3839.

Wilder, C. L., Friedrich, A. D., Potts, R. O., Daumy, G. O., & Francoeur, M. L. (1992). Secondary structural analysis of two recombinant murine proteins, interleukins 1 alpha and 1 beta: is infrared spectroscopy sufficient to assign structure? Biochemistry, 31(1), 27–31.

Woodward, S., & Cotterill, O. (1985). Preparation of cooked egg white, egg yolk, and whole egg gels for scanning electron microscopy. Journal of Food Science, 50(6), 1624–1628.

Ye, A., Zheng, T., Jack, Z. Y., & Singh, H. (2012). Potential role of the binding of whey proteins to human buccal cells on the perception of astringency in whey protein beverages. Physiology & Behavior, 106(5), 645–650.

Yuan, F., Xu, D., Qi, X., Zhao, J., & Gao, Y. (2013). Impact of high hydrostatic pressure on the emulsifying properties of whey protein isolate–chitosan mixtures. Food and Bioprocess Technology, 6(4), 1024–1031.

Zand-Rajabi, H., & Madadlou, A. (2016). Citric acid cross-linking of heat-set whey protein hydrogel influences its textural attributes and caffeine uptake and release behaviour. International Dairy Journal, 61, 142–147.

Zhang, S., Zhang, Z., Lin, M., & Vardhanabhuti, B. (2012). Raman spectroscopic characterization of structural changes in heated whey protein isolate upon soluble complex formation with pectin at near neutral pH. Journal of Agricultural and Food Chemistry, 60(48), 12029–12035.

Zhang, S., Hsieh, F.-H., & Vardhanabhuti, B. (2014a). Acid-induced gelation properties of heated whey protein–pectin soluble complex (part I): effect of initial pH. Food Hydrocolloids, 36, 76–84.

Zhang, S., Zhang, Z., & Vardhanabhuti, B. (2014b). Effect of charge density of polysaccharides on self-assembled intragastric gelation of whey protein/polysaccharide under simulated gastric conditions. Food & Function, 5(8), 1829–1838.

Zhang, Z., Yu, Q., Li, H., Mustapha, A., & Lin, M. (2015). Standing gold nanorod arrays as reproducible SERS substrates for measurement of pesticides in apple juice and vegetables. Journal of Food Science, 80(2), N450–N458.

Zhu, Y., Vanga, S. K., Wang, J., & Raghavan, V. (2018). Effects of ultrasonic and microwave processing on avidin assay and secondary structures of egg white protein. Food and Bioprocess Technology, 11(11), 1974–1984.

Acknowledgments

We would like to thank John J. Churey at the HPP Validation Center in Geneva, NY, for his help in HPP treatment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 158 kb).

Rights and permissions

About this article

Cite this article

Zhang, Z., Li, Y., Lee, M.C. et al. The Impact of High-Pressure Processing on the Structure and Sensory Properties of Egg White-Whey Protein Mixture at Acidic Conditions. Food Bioprocess Technol 13, 379–389 (2020). https://doi.org/10.1007/s11947-019-02397-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-02397-6