Abstract

Microwave drying is usually combined with vacuum environment in conjunction with hot air flow to draw the moisture rapidly. The moisture content of the vegetables undergoing drying is hard to measure online. This research designed a microwave vacuum drying (MVD)-low-field nuclear magnetic resonance (NMR) smart device and investigated the feasibility of NMR method for online measurement of state of moisture during MVD. The relation between the signal amplitude (A 2) and the true moisture content (M 1) of six kinds of vegetables (mushroom, carrot, potato, lotus, edamame, vegetable corn) was fitted to estimate if NMR can measure the M 1 of vegetables directly. Results showed that A 2 and M 1 of different fresh vegetables had no single empirical mathematical model to fit. However, for each kind of these vegetables, the A 2 and corresponding M 1 in different MVD stages showed a significant linear relationship. The predicted moisture content (M 2) of mushroom: M 2 = 5.25351 × 10−4 A 2 − 0.34042, R = 0.996; carrot: M 2 = 5.78756 × 10−4 A 2 − 0.14108, R = 0.998; potato: M 2 = 3.10019 × 10−4 A 2 − 0.10612, R = 0.991; lotus: M 2 = 2.32415 × 10−4 A 2 − 0.01573, R = 0.998; edamame: M 2 = 3.13310 × 10−4 A 2 − 0.4198, R = 0.996; vegetable corn: M 2 = 1.69461 × 10−4 A 2 − 0.09063, R = 0.995. The linear models between M 2 and A 2 were able to estimate the end point (M 1 < 8%) of MVD with a high accuracy (P > 0.950).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fresh vegetables are always dried with different methods until the final moisture content is low enough for storage in a long time, and the product was called dehydrated vegetable. Dehydrated vegetable not only was widely used in the areas where it is hard to have fresh vegetable but also was consumed as snacks (Zhang et al. 2006; Zhang and Chen 2007). At present, hot airflow drying is the main method, which has a low drying efficiency and large energy consumption. Microwave drying about vegetables has the advantage of strong penetrability, high efficiency, low drying temperature, and easy to control for the microwave power. In microwave drying process, the moisture content measurement, especially in the last stage of drying is critical for improving the drying quality and stability (Zhang et al. 2006; Swain et al. 2014). Traditionally, the empirical drying models are based on the moisture ratios and the corresponding drying stages. At present, there are at least ten kinds of models of this type, such as Lewis model, Page model, and Henderson and Pabis model (Ruhanian and Movagharnejad 2016; Wang et al. 2007). However, these empirical models are sensitive to the drying parameters, and the fitting goodness shows strong difference in various drying stages (Jiang et al. 2017; Avhad and Marchetti 2016). Weighting directly by a balance is a simple method, which is efficient for the materials sampled from the drying process, but microwave drying always combines with vacuum environment or hot airflow (Ambros et al. 2016; Pu and Sun 2017; Giri and Prasad 2007). Both of these environments make the evaporated moisture drawn in time in high-efficiency microwave drying. However, these environments make it difficult to get the sample and obtain the accurate result by weighting directly. Askari et al. (2013) researched the mass variation in apple during microwave-hot-air combined drying, but for sample weighting purpose, the hot airflow was stopped in order to improve the accuracy. With the development of microwave drying process and equipment, the method of measuring the water status information online and in real time is needed to be developed for better predictability and quality control (Su et al. 2015).

Low-field nuclear magnetic resonance (NMR) technology has been widely applied in agricultural product process field (Tylewicz et al. 2016; Badea et al. 2016). If a pulse electromagnetic wave is radiated in the perpendicular direction of the magnetic field, the hydrogen protons in a certain energy level will jump to the higher energy state. When this pulse electromagnetic wave is stopped, the hydrogen protons come back to the original lower energy state (Yan et al. 2016). The time for two activated hydrogen protons with same frequency but different moving trends returning to the same state is called transverse relaxation time T 2, which provides the detailed information of water state in drying (Fundo et al. 2015; Sánchez-Alonso et al. 2014). The signal amplitude curve of T 2 provides the information on the activity of the hydrogen protons and reflects the state of water. If signal amplitudes (arbitrary unit, a.u.) of T 2 are large, the water molecules are much more active, which should come from the free water (Jiang et al. 2013; X. Wang et al. 2015). The total signal amplitude A 2 (arbitrary unit, a.u.) is the integral area of signal amplitudes of T 2 in a range (Lv et al. 2016; Xu et al. 2017; Zhou et al. 2016). Experiments have shown that the A 2 value has some relationship with the moisture content of the sample. Xu et al. (2013) researched the relationship between A 2 value and moisture content of carrots at different hot-airflow drying stages and established a linear model A 2 = 8.2337 + 0.9062M 2 (R = 0.995) to predict the moisture content efficiently(Xu et al. 2013). However, this NMR/MRI measuring system was not attached to the drying system online, and sampling process would affect the subsequent drying process and introduce some errors on measuring results (Zhang et al. 2012). In this research, a microwave vacuum drying (MVD)-NMR combined device was aimed to develop, and A 2 value can be measured online during drying process, and at the same time, the moisture content can be calculated through a formula fitting. Under this condition, the drying quality and stability of vegetables can be improved particularly in the last stage. In this work, the relation between the A 2 and moisture content between edamame and vegetable corn of the six kinds of fresh vegetables was fitted to determine if NMR method is capable of measuring the moisture content of vegetables directly. Thus, a MVD-NMR smart device was developed to estimate the relation model between the A 2 and corresponding M 1 in different drying stages for each kind of these vegetables.

Materials and Methods

Raw Materials

Mushroom (Pleurotus ostreatus), carrot (Daucus carota L. var. sativa Hoffm.), potato (Solanum tuberosum L.), lotus (Nelumbo nucifera Gaertn), edamame (Glycine max), and vegetable corn (Zea mays Linn.) of the six kinds of fresh vegetables were purchased in a local farmers market (Wuxi, China). In these materials, the vegetables with low moisture content are edamame (0.7019 ± 0.002, w/w), the vegetables with normal moisture content are potato (0.8321 ± 0.002, w/w), lotus (0.7908 ± 0.003, w/w), and vegetable corn (0.8270 ± 0.002, w/w), and the vegetables with high moisture content are mushroom (0.9171 ± 0.002, w/w) and carrot (0.9182 ± 0.003, w/w). These raw materials were not affected by pests and did not have any physical damage. Each kind of vegetable came from the same batch. Mushroom, carrot, potato, and lotus were cut into dices with 1 cm3 as a pretreatment, and edamame and vegetable corn were dried directly.

Main Equipment and Parameters

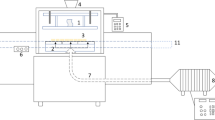

A MVD-NMR smart device capable of measuring water status information of vegetables online was designed (Fig. 1). As shown in the schematic diagram (Fig. 1a), it consists of 16 main components.

Schematic diagram of microwave vacuum dryer with water state measured using NMR. a Main structures. b Working process. 1 computer, 2 temperature sensor, 3 data line of microwave dryer, 4 date line of NMR, 5 moving pole, 6 vacuum chamber, 7 raw materials, 8 removable board, 9 NMR coil, 10 vacuum controller, 11 microwave controller, 12 temperature controller, 13 magnetron, 14 NMR box, 15 vacuum tube, 16 vacuum pump; (I) microwave drying, (II) board removing, (III) NMR measuring, (IV) returning, (V) microwave drying

In this device, a MVD unit was installed on the upper part of a NMR analyser (Suzhou Niumag Analytical Instrument Corporation, Suzhou, China). Microwave power of this system could be adjusted between 0 and 1200 W, consecutively. The drying chamber can be adjusted between the MVD unit and the NMR unit using a movable pole. The diameter of the vacuum chamber is almost 4 cm, and the height of the material in the chamber is no more than 3 cm, which is suitable for measuring in NMR. The online measuring process of water state in this device is shown in Fig. 1b. The drying of fresh vegetables was carried out in the MVD unit, and the entire drying chamber was transferred to the NMR unit in predetermined time periodically. The water state as signal amplitude curves of T 2 was detected quickly, and then the chamber was returned to the original position for further drying. During this measuring stage, the power on the drying unit was automatically stopped but the vacuum pressure was maintained within the controlled range. A temperature fibre sensor was attached to the drying chamber as well as to the computer to measure and control the temperature within the chamber during the entire drying process. During the drying process, the microwave power was 200 W and the temperature was no more than 70 °C, and if the temperature reached the set temperature, the microwave power stops. The end point of the moisture content was 8% (w/w, db) (Wang et al. 2009). Vacuum level within the chamber was maintained in no more than − 0.09 MPa.

Carr-Purcell-Meiboom-Gill (CPMG) pulse sequence was selected to collect the signal amplitude of T 2 of the vegetables in NMR measurement (Pereira et al. 2015; McDonald et al. 2016). Main parameters of NMR instrument were as follows: resonant frequency of 23.137 MHz, magnetic field intensity of 0.55 T, coil diameter of 30 mm, and magnet temperature of 32 °C. The drying chamber was placed in the center of the RF coil at the center of the permanent magnetic field. Main sequence parameters of CPMG were the following: sampling points TD = 350,014, sampling frequency SW = 100 kHz, repeat waiting time TW = 4S, and repeat accumulation number NS = 4. SIRT algorithm was applied in the 100,000 iterative fitting.

The signal amplitude curves about transversal relaxation time T 2 reflect the chemical environment about the protons of water molecules, especially the binding force and freedom in drying process. There is no uniform standard for the division of water states (Wang et al. 2012; Hills et al. 1990; Bertram et al. 2003; Fullerton et al. 1982). In this research, the water with relaxation time of T 21 (0.01–10 ms), T 22 (10–100 ms), and T 23 (100–10,000 ms) was defined as bond water, immobilised water, and free water, respectively. The total signal amplitude of different water states was integrated in the preset relaxation time ranges, A 21, A 22, and A 23 are the total signal amplitudes of bond water, immobilised water, and free water, and A 2 is the total signal amplitude of whole water in NMR.

Measurement of Moisture Content

The moisture content of each kind of these vegetables was measured using 105-°C hot air oven drying (Chandramohan and Talukdar 2017), and the values were average of three repetitions. In order to control the same mass in measuring basis of materials, wet basis is needed for calculating the moisture content of different kinds of fresh vegetables. The relationship between the total signal amplitudes of A 21, A 22, A 23, and A 2 (a.u.) and the wet basis moisture content M (g water/g fresh sample) of each kind of vegetable was analysed using Origin 9.0 software. If the relationship model between the moisture content and signal amplitude of different fresh vegetables was significant, the moisture content can be estimated using the NMR directly.

Determination of End Point of Drying

The most of the dehydrated vegetables can be stored with a maximum stability at low moisture content of around 0.08 (g water/g solid) (Roknul et al. 2014; R. Wang et al. 2009). The final moisture content calculated from the fitting models and the total signal amplitudes A 2 (or A 21, A 22, A 23) values should be decreased to this level.

The flow diagram of MVD with an aim of achieving the end point moisture content measurement using NMR is shown in Fig. 2. If the moisture content of the materials during MVD did not achieve the end point, the vacuum chamber with materials will return to the original position for drying. If the A 2 values of the materials in drying met the end point, drying is stopped, and the materials were considered as final dehydrated product. The values of A 2 and moisture content were average of three repetitions. In addition, the accuracy of the predicted moisture content as function of A 2 value was calculated as P

where M 1 is the true moisture content (g water/g solid) and M 2 is the predicted moisture content (g water/g solid).

Results and Discussion

The Relationship Between Signal Amplitudes and Moisture Content of Different Kinds of Fresh Vegetables

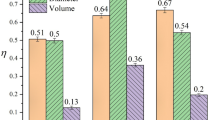

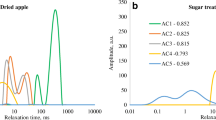

Signal amplitudes T 2 of six kinds of fresh vegetables were used to reflect the water state, to establish a relationship between T 2 and the states of moisture during drying. The signal amplitude curves T 2 measured using NMR are shown in Fig. 3a. It can be seen that the peaks and distribution of the six kinds of vegetables were different obviously. According to relaxation time of hydrogen protons, if the most of the signal amplitudes are located in the right, the water molecules are much freer (X. Zhang et al. 2012; Bauer et al. 2016). For example, the activity of hydrogen protons was strongest in fresh carrot but weakest in fresh edamame, which also meant that the most of the water molecules of fresh carrot were much freer than that of fresh edamame. The other vegetables also had different water states. On the basis of the preset relaxation time ranges of bond water T 21 (0.01–10 ms), immobilised water T 22 (10–100 ms), and free water T 23 (100–10,000 ms), the total signal amplitudes of A 21, A 22, A 23, and A 2 were calculated, which are shown in Fig. 3b. In order to discuss the water state in a same standard, the preset relaxation time ranges of T 21, T 22, and T 23 were the same among the six kinds of vegetables. With calculation, the total signal amplitudes of A 21, A 22, and A 23 were found different obviously. For example, fresh carrot had low bond water amplitudes A 21, and the fresh edamame had very weak free water signal A 23. At the same time, the total signal amplitudes A 2 were also different among vegetables. A simple empirical mathematical relationship model with the moisture content is useful to predict the moisture content using NMR measurements.

The initial moisture contents of six kinds of vegetable measured using 105-°C hot air oven drying were as follows: mushroom 0.9171 ± 0.002, carrot 0.9182 ± 0.003, potato 0.8321 ± 0.002, lotus 0.7908 ± 0.003, edamame 0.7019 ± 0.002, and vegetable corn 0.8270 ± 0.002 (w/w), which are generally the same with the front report (Srivastava et al. 2015; Aguiló-Aguayo et al. 2014; Li et al. 2017; Huang et al. 2014; Kumar et al. 2015). Fresh mushroom and carrot had the high moisture content of more than 90.0% (% w/w), and the moisture content of fresh edamame was the lowest as 70.2% (% w/w). The relationship between the between moisture content and the corresponding total signal amplitudes A 21, A 22, A 23, and A 2 of six kinds of fresh vegetables was fitted to establish a single mathematical model.

Figure 4 shows the scatter plots of A 21, A 22, A 23, and A 2 values of seven kinds of fresh vegetables and the corresponding moisture contents. Even though the moisture content was almost the same, the A 21, A 22, A 23, and A 2 values had obvious difference. For example, the fresh mushroom and carrot had an obvious difference in A 21, A 22, and A 23 values with almost the same moisture content of 0.9171–0.9182 g water/g fresh samples. The fresh potato and vegetable corn had an obvious difference in A 2 values (fresh potato: 17,695.26; vegetable corn: 20,161.50; arbitrary unit, a.u.) with the similar moisture contents (fresh potato: 0.8321 ± 0.002; vegetable corn: 0.8270 ± 0.002; g water/g fresh samples). Therefore, no single model will be suitable to describe the relation between the moisture content and the total NMR signal amplitudes of different fresh vegetables.

The Relation Between Signal Amplitudes and Moisture Content of Each Kind of Fresh Vegetables at Different MVD Stages

The signal amplitudes for each kind of vegetables at different MVD stages exhibited their own characteristics. The signal amplitudes T 2 of each kind of vegetables in different MVD stages were measured and shown in Fig. 5A–F. In order to explain the water state in a preset standard, the relaxation time T 21, T 22, and T 23 of six kinds of vegetables in MVD was defined as bond water when T 21 was 0.01–10 ms, immobilised water when T 22 was 10–100 ms, and free water when T 23 was 100–10,000 ms. For four vegetables (mushroom, potato, lotus, vegetable corn), the total signal amplitudes of immobilised water and free water decreased quickly, reflected by the shift of main peaks and main signal amplitudes to the left direction during as the drying progressed. During the drying process, the bond water became the main part of the moisture. The most of the signal amplitude of fresh carrot was from the free water, with little immobilised water and bond water. Therefore, it is clear that the free water is the main moisture loss during drying. In the MVD process of carrot, the main peaks and main signal amplitudes also had the tendency of moving to the left direction, which indicates that the remaining water molecules form a stronger adsorption with dry matter. Each kind of vegetable has its own water distribution, and the water state of edamame was divided as the same preset standard. If the immobilised water T 22 and free water T 23 ranges were redefined according to the proportion of water state of edamame, the immobilised water T 22 and free water T 23 of edamame at present may belong to the free water, and the added decreasing speed was much quicker than that in the ranges of bond water. In summary, the T 2 values of the main peaks and main signal amplitudes have the tendency of moving to the left direction and also confirm the fact that the residual water molecules always form a stronger adsorption with dry matter during MVD. This water state was not easy to dry.

The total signal amplitudes of A 21, A 22, A 23, and A 2 calculated respectively are shown in Fig. 5a–f. For the most of the vegetables, the total signal amplitudes of A 22, A 23, and A 2 have an obvious decreasing tendency, the total signal amplitudes of A 21 decreased slowly, and even in some middle stage, the A 21 values increased such as in edamame. Possibly caused by the stimulation of microwave, the water molecules always form a stronger adsorption with dry matter (Li et al. 2015; Zhao et al. 2017).

Total signal amplitudes A 21, A 22, A 23, and A 2 and dry basis moisture content of each kind of vegetables in different drying stages had obvious relation, especially for the A 2 and dry basis moisture content. Figure 6 shows the relation between signal amplitudes A 21, A 22, and A 23 and the corresponding moisture content. Among the total signal amplitudes, A 21 and A 22 had some linear relationships with the corresponding moisture content, but the fitting goodness was not good. The most of the A 23 and A 2 had good linear relation with the corresponding moisture content except A 23 of edamame. With calculation, the total amplitudes A 2 of whole moisture and the corresponding true moisture content M 1 (g water/g solid) had the best fitting goodness with some sample linear models, and for the predicted moisture content M 2, mushroom: M 2 = 5.25351 × 10−4 A 2 − 0.34042, R-squared R = 0.996; carrot: M 2 = 5.78756 × 10−4 A 2 − 0.14108, R = 0.998; potato: M 2 = 3.10019 × 10−4 A 2 − 0.10612, R = 0.991; lotus: M 2 = 2.32415 × 10−4 A 2 − 0.01573, R = 0.998; edamame: M 2 = 3.13310 × 10−4 A 2 − 0.4198, R = 0.996; and vegetable corn: M 2 = 1.69461 × 10−4 A 2 − 0.09063, R = 0.995. The mean square and F value in analysis of variance were shown in Table 1, respectively. Between edamame and vegetable corn of the six kinds of fresh vegetables, mean square was less than 0.05 and F value was more than 1000. Therefore, the fitting linear relation between the total signal amplitudes A 2 and the corresponding moisture content was significant. These fitting formulas were applied for predicting the moisture content and end point of the last drying stage.

End point determination of MVD

In general, the moisture contents of dehydrated vegetables is less than 0.08 (g water/g solid), which was selected as the end point of MVD. The relationship between the total signal amplitudes A 21, A 22, A 23, and A 2 and moisture content was analysed. Results showed that only whole signal amplitudes of A 2 of all six kinds of fresh vegetables have the best fitting model with their corresponding moisture content during drying. MVD has a high efficiency, and the moisture content measurement in the last stage of drying is critical for improving the drying quality and stability of dried products. Therefore, the A 2 was measured every 5 min in the last 15 min of drying. The measuring time was no more than 30 s, when the temperature and vacuum level can be controlled. Main parameters in last drying stage of different kinds of vegetables are shown in Table 1.

Fresh mushroom had the moisture content of 91.71% (wet basis), and in the pre-experiment of MVD with the same preset parameters, the drying time of edamame was more than 90 min. When drying for 90 min, the moisture was measured online and in real time. The signal amplitudes A 2 were 1413.189, 967.772, and 794.9352 at 90, 95, and 100 min of MVD, respectively. According to the fitting formula M 2 = 5.25351 × 10−4 A 2 − 0.34042, the predicted moisture content was calculated. If the values reached to the end point 0.08 g water/g solid, the drying process was stopped. If the moisture content did not reach to the end point, the residual moisture content still remained high, and the vacuum chamber would go back to the original position for further drying. For this experiment of mushroom, at 100 min of drying, the predicted moisture will be 0.075 g water/g solid (< 0.08 g water/g solid), which was considered as the end point. At this stage, the accuracy of the result was found to be 97.07%.

By the same method, the end point of MVD of other carrot, potato, lotus, edamame, and vegetable corn of the five kinds of fresh vegetables was measured through MVD-NMR device. Applying their own fitting formulas, the accuracy P was found to be 98.53, 96.15, 96.00, 97.65, and 98.61%, respectively. These results show that all of the accuracy values were more than 95%, when the measuring time used was 20–30 s and the measurement was performed in every 5 min at least. Therefore, the predicted mathematical models in Table 1 can be considered efficient to estimate the end point of the MVD process online and in real time. Because there was no single relationship model between the moisture content and the total signal amplitudes A 2 for all fresh vegetables, the mathematical model of one kind of vegetable in different MVD stages cannot be applied to other vegetables directly. Therefore, the empirical mathematical model and smart measuring system for moisture content during MVD should be developed independently for different kinds of fresh vegetables.

Conclusions

The distribution of NMR signal amplitudes T 2 between edamame and vegetable corn of the six kinds of fresh vegetables was found to be different obviously. The total integrated signal amplitude A 21, A 22, A 23, and A 2 and their corresponding moisture content of these fresh vegetables could not have a single mathematical model to fit. Thus, the measuring result from NMR could not predict the moisture content of all fresh vegetables directly. However, the moisture content vs total signal amplitudes (A 2) could be described by a linear fitting model (R ≥ 0.995) which can be applied to the last stage of drying to determine the end of drying with a high accuracy(P > 0.950). This work shows that the model should be developed for each vegetable. In addition, the improvement in online measuring efficiency (20–30 s) and the application in industry need further study.

References

Aguiló-Aguayo, I., Downey, G., Keenan, D. F., Lyng, J. G., Brunton, N., & Rai, D. K. (2014). Observations on the water distribution and extractable sugar content in carrot slices after pulsed electric field treatment. Food Research International, 64, 18–24.

Ambros, S., Bauer, S., Shylkina, L., Foerst, P., & Kulozik, U. (2016). Microwave-vacuum drying of lactic acid bacteria: influence of process parameters on survival and acidification activity. Food and Bioprocess Technology, 9(11), 1901–1911.

Askari, G., Emam-Djomeh, Z., & Mousavi, S. (2013). Heat and mass transfer in apple cubes in a microwave-assisted fluidized bed drier. Food and Bioproducts Processing, 91(3), 207–215.

Avhad, M. R., & Marchetti, J. M. (2016). Mathematical modelling of the drying kinetics of Hass avocado seeds. Industrial Crops and Products, 91, 76–87.

Badea, E., Şendrea, C., Carşote, C., Adams, A., Blümich, B., & Iovu, H. (2016). Unilateral NMR and thermal microscopy studies of vegetable tanned leather exposed to dehydrothermal treatment and light irradiation. Microchemical Journal, 129, 158–165.

Bauer, K., Kulenkampff, J., Henninges, J., & Spangenberg, E. (2016). Lithological controls on gas hydrate saturation: insights from signal classification of NMR downhole data. EGU General Assembly Conference Abstracts, 18, 13152.

Bertram, H. C., Karlsson, A. H., & Andersen, H. J. (2003). The significance of cooling rate on water dynamics in porcine muscle from heterozygote carriers and non-carriers of the halothane gene—a low-field NMR relaxation study. Meat Science, 65(4), 1281–1291.

Chandramohan, V., & Talukdar, P. (2017). Estimation of equilibrium moisture content and drying time of potato through hot air drying. In A. Saha, D. Das, R. Srivastava, P. Panigrahi, K. Muralidhar (Eds.), Fluid mechanics and fluid power–contemporary research. Lecture notes in mechanical engineering (pp. 205–213). New Delhi: Springer.

Fullerton, G. D., Potter, J. L., & Dornbluth, N. C. (1982). NMR relaxation of protons in tissues and other macromolecular water solutions. Magnetic Resonance Imaging, 1(4), 209–226.

Fundo, J. F., Amaro, A. L., Madureira, A. R., Carvalho, A., Feio, G., Silva, C. L., et al. (2015). Fresh-cut melon quality during storage: an NMR study of water transverse relaxation time. Journal of Food Engineering, 167, 71–76.

Giri, S., & Prasad, S. (2007). Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. Journal of Food Engineering, 78(2), 512–521.

Hills, B., Takacs, S., & Belton, P. (1990). A new interpretation of proton NMR relaxation time measurements of water in food. Food Chemistry, 37(2), 95–111.

Huang, M., Wang, Q., Zhang, M., & Zhu, Q. (2014). Prediction of color and moisture content for vegetable soybean during drying using hyperspectral imaging technology. Journal of Food Engineering, 128(1), 24–30.

Jiang, H., Zhang, M., Liu, Y., Mujumdar, A. S., & Liu, H. (2013). The energy consumption and color analysis of freeze/microwave freeze banana chips. Food and Bioproducts Processing, 91(4), 464–472.

Jiang, J., Dang, L., Yuensin, C., Tan, H., Pan, B., & Wei, H. (2017). Simulation of microwave thin layer drying process by a new theoretical model. Chemical Engineering Science, 162, 69–76.

Kumar, S., Gautam, S., & Sharma, A. (2015). Hurdle technology including chlorination, blanching, packaging and irradiation to ensure safety and extend shelf life of shelled sweet corn kernels. Journal of Food Processing & Preservation, 39(6), 2340–2347.

Li, B., Yin, Q., Yin, L., Zhang, K., Chen, H., & Han, Q. (2015). Studies on characteristics and mechanism of hot air-microwave fluidized drying of lentinusedodes. Journal of Chinese Institute of Food Science and Technology, 15(5), 134–139.

Li, S., Li, X., Lamikanra, O., Luo, Q., Liu, Z., & Yang, J. (2017). Effect of cooking on physicochemical properties and volatile compounds in lotus root (Nelumbo nucifera Gaertn). Food Chemistry, 216, 316.

Lv, W., Li, S., Han, Q., Zhao, Y., & Wu, H. (2016). Study of the drying process of ginger (Zingiber officinale Roscoe) slices in microwave fluidized bed dryer. Drying Technology, 34(14), 1690–1699.

McDonald, P., Gajewicz, A., & Morrell, R. (2016). 1H NMR characterisation of pore water in cement materials. In Proceedings of the 36th Cement and Concrete Science Conference, 2016.09.05–2016.09.06, Cardiff.

Pereira, F. M. V., Rebellato, A. P., Pallone, J. A. L., & Colnago, L. A. (2015). Through-package fat determination in commercial samples of mayonnaise and salad dressing using time-domain nuclear magnetic resonance spectroscopy and chemometrics. Food Control, 48, 62–66.

Pu, Y., & Sun, D. (2017). Combined hot-air and microwave-vacuum drying for improving drying uniformity of mango slices based on hyperspectral imaging visualisation of moisture content distribution. Biosystems Engineering, 156, 108–119.

Roknul, A. S. M., Zhang, M., Wang, A. S. M., & Yuchuan. (2014). A comparative study of four drying methods on drying time and quality characteristics of stem lettuce slices (Lactuca sativa L.) Drying Technology, 32(6), 657–666.

Ruhanian, S., & Movagharnejad, K. (2016). Mathematical modeling and experimental analysis of potato thin-layer drying in an infrared-convective dryer. Engineering in Agriculture, Environment and Food, 9(1), 84–91.

Sánchez-Alonso, I., Moreno, P., & Careche, M. (2014). Low field nuclear magnetic resonance (LF-NMR) relaxometry in hake (Merluccius merluccius L.) muscle after different freezing and storage conditions. Food Chemistry, 153, 250–257.

Srivastava, A. K., Singh, U. K., & Shukla, S. K. (2015). Modelling and evaluation of thermal diffusivity and activation energy of potato slices in forced convection multi tray solar dryer. Journal of Food Science, 55(1), 218–223.

Su, Y., Zhang, M., & Mujumdar, A. S. (2015). Recent developments in smart drying technology. Drying Technology, 33(3), 260–276.

Swain, S., Samuel, D., Kar, A., & Sahoo, L. (2014). Optimization of colour parameters and drying efficiency in osmotically pretreated microwave assisted drying of yellow sweet pepper (Capsicum annum L.) using response-surface methodology. Journal of Food Research and Technology, 2(2), 67–76.

Tylewicz, U., Aganovic, K., Vannini, M., Toepfl, S., Bortolotti, V., Dalla Rosa, M., et al. (2016). Effect of pulsed electric field treatment on water distribution of freeze-dried apple tissue evaluated with DSC and TD-NMR techniques. Innovative Food Science & Emerging Technologies, 37, 352–358.

Wang, R., Zhang, M., Mujumdar, A. S., & Sun, J.-C. (2009). Microwave freeze–drying characteristics and sensory quality of instant vegetable soup. Drying Technology, 27(9), 962–968.

Wang, X., Chen, Q., Bi, J., Gao, K., Zhou, L., Wu, X., et al. (2015). Effect of hot air-pulsed sudden decompression flashing drying on moisture and microstructure in apple slices. Transactions of the Chinese Society of Agricultural Engineering, 31(20), 287–293.

Wang, Y., Zhang, M., Mujumdar, A. S., Mothibe, K. J., & Azam, S. R. (2012). Effect of blanching on microwave freeze drying of stem lettuce cubes in a circular conduit drying chamber. Journal of Food Engineering, 113(2), 177–185.

Wang, Z., Sun, J., Chen, F., Liao, X., & Hu, X. (2007). Mathematical modelling on thin layer microwave drying of apple pomace with and without hot air pre-drying. Journal of Food Engineering, 80(2), 536–544.

Xu, F., Jin, X., Zhang, L., & Chen, X. D. (2017). Investigation on water status and distribution in broccoli and the effects of drying on water status using NMR and MRI methods. Food Research International, 96, 191–197.

Xu, J., Xu, G., Zhang, X., Gu, Z., Zhang, S., & Li, H. (2013). Moisture transport in carrot during hot air drying using magnetic resonance imaging. Transactions of the Chinese Society of Agricultural Engineering, 29(12), 271–276.

Yan, K., Chu, Y., Huang, J., Jiang, M., Li, W., Wang, Y., et al. (2016). Qualitative and quantitative analyses of compound Danshen extract based on 1H NMR method and its application for quality control. Journal of Pharmaceutical and Biomedical Analysis, 131, 183–187.

Zhang, M., & Chen, G. (2007). Research progress on the energy reduce of open-type air drying process of vegetables [J]. Drying Technology & Equipment, 6, 003.

Zhang, M., Tang, J., Mujumdar, A., & Wang, S. (2006). Trends in microwave-related drying of fruits and vegetables. Trends in Food Science & Technology, 17(10), 524–534.

Zhang, X., Zhu, S., Huang, J., Xu, G., Xu, J., & Li, H. (2012). Analysis on internal moisture changes of carrot slices during drying process using low-field NMR. Transactions of the Chinese Society of Agricultural Engineering, 28(22), 282–287.

Zhao, Y., Jiang, Y., Zheng, B., Zhuang, W., Zheng, Y., & Tian, Y. (2017). Influence of microwave vacuum drying on glass transition temperature, gelatinization temperature, physical and chemical qualities of lotus seeds. Food Chemistry, 228, 167–176.

Zhou, H., Ye, Z., Yu, Z., Su, M., & Du, J. (2016). Application of low-field nuclear magnetic resonance and proton magnetic resonance imaging in evaluation of ‘Jinxiu’ yellow peach’s storage suitability. Emirates Journal of Food ands, 28(9), 633.

Funding

We acknowledge the financial support provided to us by the China Key Research Program (Contract No. 2017YFD0400901), Jiangsu Province (China) “Collaborative Innovation Center for Food Safety and Quality Control” Industry Development Program, Jiangsu Province (China) Infrastructure Project (Contract No. BM2014051); all of which have enabled us to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, W., Zhang, M., Bhandari, B. et al. Smart NMR Method of Measurement of Moisture Content of Vegetables During Microwave Vacuum Drying. Food Bioprocess Technol 10, 2251–2260 (2017). https://doi.org/10.1007/s11947-017-1991-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-1991-3