Abstract

This paper studied the effects of different cooking conditions (methods, temperatures and time) on the retention rate of 4-(methylthio)-3-butenyl isothiocyanate (MTBITC) in Chinese white radish by using a method of ultrasound extraction coupled with gas chromatography—flame ionization detector (GC-FID). Results showed that the retention rate of MTBITC decreased with increasing cooking time and temperatures. The retention rate of MTBITC declined dramatically after holding for 1 min at 85 or 95 °C. The fitted equations demonstrated that the degradation of MTBITC followed an exponential decay pattern for non-microwave (water bath or steam stove) cooking, while for microwave cooking, the degradation of MTBITC followed approximately a linear decay.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

White radish (Raphanussativus L.) is one of the most commonly eaten root vegetables in China due to its important nutritional, improvement of digestibility and functional components. Myrosinase is a cytosolic plant enzyme present in radish and its known biological function is to catalyze the hydrolysis of a class of compounds called glucosinolates. Myrosinase is regarded as a defense-related enzyme and is capable of hydrolyzing glucosinolates into various compounds. The 4-(methylthio)-3-butenyl isothiocyanate (MTBITC) is released by the hydrolysis of 4-methylthio-3-butenyl glucosinolate (4-MTB-GSL) with the endogenous myrosinase by grating (Fig. 1). It is reported that MTBITC is the main flavoring substance of radish (Okano et al. 1990). MTBITC is good for human health due to its anti-bacterial and anti-inflammatory effects (Ji et al. 1996) and its anti-mutagenic activity (Yasushi et al. 2001). Yasushi et al. (2001) investigated the anti-mutagen of MTBITC in Japanese white radish using the UV-induced mutation assay of Escherichia coli B/r WP2 and found a correlation between the potency of anti-mutagenicity and the amount of MTBITC. The amount of total isothiocyanate in grated radish after 30 min of cooking was seven times higher than that in cut daikon, a Japanese mild-flavored winter radish (Raphanussativus). They also compared the glucosinolate-myrosinase systems among Japanese white radish varieties (Yasushi et al. 2008).

Heating or cooking is an effective way to enhance food flavor and taste, extend shelf life, and improve hygienic quality by inactivating pathogenic microorganisms. Traditional cooking involves heating the product by immersion in hot water or by the use of steam. Cooking can also be achieved by microwave (MW) heating. Microwave is a rapid and effective technology for food thermal processing (Cui et al. 2003, 2004a, b). In traditional cooking, the heat is predominantly transferred by conduction from the outside surface of the product to its interior whereas microwave cooking or heating is achieved by the generation of internal thermal energy. Although the inhomogeneity of microwave heating is often criticized by consumers, cooking using microwave is widely accepted and used due to its advantages of rapid heating and low-energy consumption. On the other hand, cooking at the medium temperatures below the boiling point of 100 °C is regarded as low temperature cooking. Low-temperature cooking can generally maintain high level of the nutritional value of the cooked product and is widely used in the food industry (Blahovec et al. 2015; Becker et al. 2016).

Several methods are available for measuring the 4- MTB-GSL in radish, including argentometry (Zhang 1990), iodometry and colorimetric methods, gas chromatography (GC) (Ji et al. 1996), gas chromatography–mass spectrometry (GC-MS), and liquid chromatography (LC) (Sang et al. 1984). Okano et al. (1990) used gas chromatography-flame ionization detector (GC-FID) to determine the pungent principle in roots of 14 Japanese radish and found that MTBITC contributed more than 95 % of peak area detected on the chromatographic tracing of radish volatiles. The same method was applied to the effect of drying and salting on the flavor compound of Asian white radish (Coogan and Wills 2002). The results indicated that the loss of MTBITC was about 50 % with heat pump drying at 50 °C or hot air drying at 40 °C. The loss of MTBITC reached 90 % with hot air drying at 70 °C while freeze-dried white radish showed a relatively low loss of 15 %. Recently, Li et al. (2015) extracted and determined MTBITC in Chinese radish (Raphanussativus L.) roots by GC. The effects of extraction conditions on the determination of MTBITC were also investigated. They concluded that the time for endogenous myrosinase hydrolysis was 10 min and the storage time after hydrolysis (held at 4 °C) was 1 h. On the other hand, Visentin et al. (1992) isolated the 4-MTB-GSL from radish roots by lyophilization, followed by extraction using 70 % methanol with 50 mM imidazole-formate, followed by ion-exchange chromatography on DEAE-Sephadex A-25, and finally by concentration and desalting. They also established a detection method based on the spectra of IR, UV, mass spectrometry, 1HNMR and 13CNMR for identifying 4-MTB-GSL. Results indicated that 4-MTB-GSL, usually described as a highly labile compound that is difficult to isolate and characterize directly in the presence of myrosinase, can be obtained to a high level of purity with appreciable yield using their method.

On the other hand, Zhang (2009) investigated radish fermentation with lactic acid bacteria as a starter culture and studied the volatile flavor components using simultaneous distillation-extraction (SDE) coupled with GC-MS. Wang et al. (2014) studied the influences of different fertilization treatments on flavor components in radish by GC-MS, revealing that the MTBITC contributed to 89.8–91.8 % of the detected volatiles in all the seven samples.

Despite the above studies, information on effects of low-temperature cooking on MTBITC from radish is limited. To the best of our knowledge, the reduction trend and degradation pattern of MTBITC in white radish as affected by different cooking conditions has not been investigated. Therefore, the current study aimed to assess the extraction efficiency and reduction trend of MTBITC in radish by different cooking treatments.

Materials and methods

Materials

The tested samples were bought from a local market in Guangzhou. The dichloromethane (analytical grade, CAS no.75-09-2, > 99.5 %) and the anhydrous sodium sulfate (analytical grade, CAS no. 7757-82-6, > 99.0 %) were obtained from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China), and Chinasun Specialty Products Co., Ltd. (Changshu, China), respectively. The organic needle membrane filter was purchased from Ameritech Technology (Tianjin) Co., Ltd. (Tianjin, China).

Experimental procedure for cooking

Each sample was processed by the three cooking methods, and the cooking temperatures were set at 65, 75, 85, and 95 °C to simulate low temperature cooking treatments. The cooking experiments were conducted in triplicate. For each treatment, the peeled radish was cut and about 64.00 ± 0.50 g was weighed. The sample was tempered to an initial temperature of 25 ± 2 °C and then placed in a cooking plate. Six temperature probes were inserted into the sample, and the time-temperature history of the sample was continuously recorded during cooking. The optic fiber thermometer and thermocouple thermometer were used to monitor the internal temperature of the samples heated by microwave and non-microwave (water bath or steam) ambient, respectively. After reaching the required temperature, the sample was held for 0, 1, 3, 5, 7, and 9 min (cooking holding time) before removing from the cooking process and cooled in the room temperature for analysis. The cooking conditions are shown in Table 1.

The cooked samples were grated for 2 min by a homogenizer (JYZ-C515, Joyoung Co., Ltd, Hangzhou, China). The homogenate was filtered through two layers of cotton gauze. Three milliliters of filtrate was poured into 5 mL of dichloromethane in a centrifuge tube and sealed. The mixtures were ultrasonically extracted for 10 min to dissolve the released MTBITC into dichloromethane. The mixtures were centrifuged at 3000 rpm for 10 min and the lower layer (dichloromethane) was recovered by a glass tube, which was then dehydrated with anhydrous sodium sulfate. The dichloromethane solution containing MTBITC was stored in the refrigerator at −18 °C until GC analysis.

Instruments and analytical methods

Low-temperature cooking experiments were conducted using a steam stove (X1-242A, Midea Group, Foshan, China), an inverter microwave oven (EV025LC7-NR, Midea Group, Foshan, China) and a water bath (AHYQ 501, Changzhou Aohua Instrument Co., Ltd., Changzhou, China). T-type thermocouples for both water bath and steam stove cooking and optic fiber thermocouples for microwave oven cooking were used to measure the temperature variations during the experiments. An optic fiber thermometer (FOTS-DINA-2060, Indigo Precision Co., Ltd., CA, USA) and a thermocouple thermometer (TC-08, Pico Technology Co., Ltd., Cambridgeshire, UK) were used to record the temperature data. The following equipments were also used: a high-speed refrigerated centrifuge (JW-3021HR, Anhui Jiaven Equipment Industry Co., Ltd., Hefei, China), an electronic balance (AL204, Mettler Toledo Co., Ltd., Shanghai, China), an ultrasonic extraction system (AS10200BT, Tianjin Autoscience Instrument Co., Ltd., Tianjin, China) and a refrigerator (BCD-539WT, Qingdao Haier Co., Ltd, Qingdao, China).

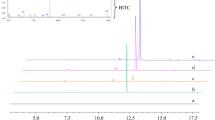

The analysis of MTBITC was performed on a gas chromatograph equipped with a flame ionization detector (GC-FID) (Agilent 7820 A, Agilent Technologies, Inc., CA, USA) and a recorder (EZchrom, Agilent Technologies, Inc., CA, USA). The analytical conditions were modified primarily based on the method of Okano et al. (1990). The gas chromatograph (GC) was equipped with a HP-5 capillary column (30 m × 0.25 mm × 0.25 μm) (Agilent Technologies, Inc., CA, USA). The injection mode was splitless and the injection volume was 5 μL. The flowrate of nitrogen gas (>99.999 %) was 1.0 mL min−1. The front inlet and detector temperature were controlled at 200 °C. The oven temperature was programmed as follows: started at 80 °C, a 5 °C min−1 ramp to 160 °C and then isotherm at 160 °C for 5 min with the total running time of 21 min.

The GC-MS (GC-MS-QP2010 Ultra) and AOC-5000 auto-sampler were all purchased from Shimadzu Co., Ltd. (Tokyo, Japan) for the identification of MTBITC. The temperatures of ion source and transfer line were set at 200 and 250 °C, respectively. The electron-impact (EI) ionization mode (70 eV) was used in the mass spectrometry. The quantification was performed in full scan and the monitoring range was 45–500 m/z.

Statistical and graphing analysis

Statistical analyses were carried out using SPSS version 19.0 (IBM SPSS Inc., NY, USA). P < 0.05 was identified as statistically significant at a 95 % confidence level.

Results

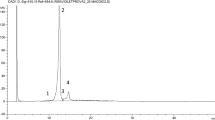

GC-MS

The GC-MS chromatogram of MTBITC released from glucosinolates in radish root is shown in Fig. 2. Only one peak could be detected in the chromatogram and the peak had the retention time of 15.042 min under the above-mentioned conditions. The identification of the peak was confirmed as MTBITC by the NIST mass spectral library and its characteristic ions were 159, 45, and 87 m/z. The CAS number of MTBITC is 51598-96-0. The quantification of MTBITC was performed by the comparison with a raw specimen to evaluate its variation due to cooking.

Content distribution of MTBITC from different part of white radish

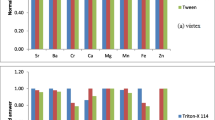

It is understood that the content of MTBITC varies in different parts of the radish. In order to ensure the reliability of the results, the content distribution of MTBITC in white radish was investigated. The analytical experiments were conducted in triplicate. Figure 3 shows the content distribution results of MTBITC of three representative samples with the sampling diagram from the head (1, 2), middle (3, 4, 5) to the root (6, 7) shown on the left. The analysis of variance and multiple comparison studies were performed with a 95 % confidence level, and the results indicated that (1) the content of MTBITC in the root of radish was the highest, in the head was the lowest, and (2) the content of MTBITC in the middle of radish had no significant difference (p > 0.05 in all cases). Therefore, it was suggested that selecting the middle part of the radish to perform the test was appropriate.

Effects of different cooking conditions on the retention rate of MTBITC

As MTBITC is the major flavor component of isothiocyanate in radish, it would be useful to determine MTBITC for the assessment of pungency of radish. As such, the effect of three cooking methods and four cooking temperatures were investigated and the retention rates of MTBITC are shown in Fig. 4. The retention rates of MTBITC were calculated by the following equation:

where ω is the retention rate of MTBITC, %; A is the peak area of MTBITC in GC chromatogram from cooked samples; A 0 is the peak area of MTBITC in GC chromatogram from raw samples. The minimum retention rates at cooking temperatures of 65, 75, 85, and 95 °C were 21.5 ± 3.3, 16.3 ± 2.3, 1.9 ± 1.0, and 0.7 ± 0.5 % for water bath cooking; 37.3 ± 9.5, 11.8 ± 0.5, 2.5 ± 0.1, and 2.2 ± 0.3 % for steam stove cooking; and 61.7 ± 7.5, 28.7 ± 3.6, 25.3 ± 3.0, and 19.1 ± 2.0 % for the inverter microwave oven, respectively.

Figure 4 reveals the following trends for the three cooking methods: (1) with the increase in cooking holding time, the retention rate of MTBITC was decreased gradually; and (2) with the increase in cooking temperature, the retention rate of MTBITC was reduced. The retention rate of MTBITC declined dramatically after holding for 1 min at 85 or 95 °C for both water bath and steam stove cooking methods. The extent of retention rate of MTBITC was different at 65 °C for the two cooking methods, while they were similar at 75, 85, and 95 °C. Nevertheless, for inverter microwave oven cooking method, the minimum retention rate of MTBITC was higher than that of the other two methods and its degradation pattern was different. This might be explained by the distinctiveness of the microwave heating principle. The reasons for the results are analyzed in the “Discussion” section.

Stability of MTBITC in the dichloromethane

The instability of the studied compound may lead to significant deviation of the results. The extracted MTBITC solution from the same experiment was stored at −18, 4, and 25 °C and its stability was determined for 7 consecutive days as shown in Fig. 4. The MTBITC in the dichloromethane was stable for about 7 days at 4 and −18 °C, while only stable for 4 days at 25 °C. Figure 5 demonstrates that under some conditions MTBITC was not stable. The increase in MTBITC loss was found in all cooking methods with cooking holding time from 0 to 9 min at 65, 75, 85, and 95 °C. For the same cooking time and temperature, MTBITC loss decreased in the following order: inverter microwave oven > steam stove > water bath.

Effect of ultrasound on the extraction efficiency of MTBITC

Ultrasound was used to assist extracting MTBITC in the current study. Figure 6 shows the difference of the extraction efficiency with and without ultrasound. Concerning the peak area of MTBITC at the 95 % confidence level, the paired t test (p < 0.0035 in all cases) indicated that the extraction efficiency was higher with ultrasound. As such, ultrasonic assisted extraction was used for sample preparation.

Dynamic degradation of MTBITC and their predicted values

The degradation trends of MTBITC were simulated in the form of an exponential equation using OriginLab 8.0 software (OriginLab Co. Ltd, Northampton, USA). Table 2 and Fig. 7 show the fitted equations and decay process, respectively, indicating that the degradation of MTBITC followed an exponential decay for both water bath and steam stove cooking methods. The fitted equation was in the following form:

where y is the retention rate of MTBITC, %; x is the cooking holding time, min; a, b, c are the fitted coefficients. The retention rate of MTBITC was markedly reduced in these two cooking methods after holding for 1 min at 85 or 95 °C.

However, the retention rate of MTBITC in radish after cooking by inverter microwave oven was higher than those of the other two cooking methods and the degradation of MTBITC followed approximately a linear decay. The fitted equation was as follows:

where y is the retention rate of MTBITC, %; x is the cooking holding time, min; a, b are the fitted coefficients (Table 2).

Discussion

It is generally accepted that MTBITC is released by the hydrolysis of 4-MTB-GSL by the endogenous myrosinase by grating. It will be pungent when people eat radish because the MTBITC is generated from 4-MTB-GSL by chewing (Fig. 1). Hence, the content of MTBITC is an important indicator to evaluate the flavor in white radish. MTBITC is good for human health due to its anti-bacterial and anti-inflammatory effects (Ji et al. 1996) and its anti-mutagenic activity (Yasushi et al. 2001). It was reported that MTBITC could be used to ameliorate the severity of a high fat diet inducted nonalcoholic fatty liver disease in rats (You et al. 2015). Therefore, it was necessary to study the retention rate in white radish after cooking. Different parameters, such as raw samples, cooking methods, cooking time and temperature, affect the loss of MTBITC. Because the MTBITC standard is expensive and hard to obtain, the retention rate is designed to assess the loss of MTBITC during cooking. On the basis of Eq. (1), a similar content of MTBITC in raw radish samples is essential in each experiment. In the current study, the content of MTBITC in the radish was studied from head to root and it was found that its content in the root of radish was the highest (Fig. 3) and the lowest in the head. This is consistent with reports from Ji et al. (1996). The content of MTBITC in the middle of radish had no significant difference, and thus, the middle part of the radish was selected as the raw samples to perform the experiment.

As shown previously, with the increase in cooking temperature and holding time, the retention rate of MTBITC was decreased gradually for the three cooking methods (Fig. 4). Coogan and Wills (2002) dried Asian white radish to <10 % moisture content using a hot air drier, a heat pump drier, and a freeze-drier and found that MTBITC was substantially decreased, which conformed to the current study. The current study suggested that heating or cooking might destroy 4-MTB-GSL, leading to the loss of MTBITC, which was supported by Song et al. (2013), who found that MTBITC could convert rapidly into a water-soluble degradation product in the hydrolytic process. For better understanding the degradation mechanism of MTBITC in radish by heating, further studies should be conducted.

As presented in Fig. 4c, the retention rate of MTBITC of white radish cooked by microwave oven has a more significant standard deviation (a notable error bar) than that of the other two cooking methods. This might be caused by the inhomogeneity of microwave heating, thus providing poor repeatability. However, the minimum retention rate of MTBITC cooked by the inverter microwave oven was higher than that of other two methods under the same temperatures. This might be explained by the rapid heating of microwave. Compared to the water bath and steam stove, microwave heating can reach the set temperature of the experiment quickly, thus saving the heating time of the samples. For heating samples to the required temperatures, both water bath and steam stove required about 10 min, while microwave oven only needed 40–60 s. As analyzed previously, MTBITC could convert rapidly into a water-soluble degradation product in the hydrolytic process. In other words, MTBITC loss would be increased with the increasing loss of moisture in cooked radish. With the increase in cooking holding time, the moisture loss was increased gradually, thus MTBITC was reduced. Therefore, in order to retain the MTBITC in radish as far as possible, microwave heating is recommended for cooking radish. Table 2 and Fig. 7 show the different degradation trends between the non-microwave (water bath or steam stove) and microwave ambient. Because of the long heating time for non-microwave cooking, the content of MTBITC was markedly reduced by following an exponential decay when samples were heated to the required temperature and then held at that temperature. However, for the microwave oven, due to the short heating time of only 40–60 s, the content of MTBITC was higher and was mainly affected by the holding time; thus, the degradation pattern tended to be linear with the holding time. For achieving “nutritional cooking”, the microwave oven should be a better cooking solution.

Conclusions

MTBITC in Chinese white radish was determined using the GC-FID method, as affected under different cooking condition methods and cooking temperatures. Ultrasound was used to enhance the extraction efficiency of MTBITC in radish. Results indicated that the retention rate of MTBITC was decreased with increasing cooking temperature and time, the retention rate of MTBITC was significantly reduced after holding for 1 min at 85 or 95 °C for both water bath and steam stove cooking methods, and the degradation of MTBITC in radish followed an exponential decay. For microwave oven cooking, the retention rate of MTBITC was much higher, which followed a linear decay with the holding time due to the short heating time to reach the required cooking temperature. In order to retain MTBITC in radish as far as possible, microwave heating method is recommended for cooking radish. The current results can be of importance to guide a more scientific “nutritional cooking” and reduce the overheating of traditional cooking methods.

References

Becker, A., Boulaaba, A., Pingen, S., Krischek, C., & Klein, G. (2016). Low temperature cooking of pork meat—physicochemical and sensory aspects. Meat Science, 118, 82–88.

Blahovec, J., Kouřím, P., & Kindl, M. (2015). Low-temperature carrot cooking supported by pulsed electric field—DMA and DETA thermal analysis. Food and Bioprocess Technology, 8(10), 2027–2035.

Coogan, R. C., & Wills, R. B. H. (2002). Effect of drying and salting on the flavour compound of Asian white radish. Food Chemistry, 77, 305–307.

Cui, Z.-W., Xu, S.-Y. and Sun, D.-W. (2003). Dehydration of garlic slices by combined microwave-vacuum and air drying. Drying Technology, 21(7), 1173–1184.

Cui, Z.-W., Xu, S.-Y. and Sun, D.-W. (2004a). Effect of microwave-vacuum drying on the carotenoids retention of carrot slices and chlorophyll retention of Chinese chive leaves. Drying Technology, 22(3), 563–575.

Cui, Z.-W., Xu, S.-Y. and Sun, D.-W. (2004b). Microwave–vacuum drying kinetics of carrot slices. Journal of Food Engineering, 65(2), 157–164.

Ji, Y. L., Shen, Q., Lin, G. Q., Wang, L. Z., & Wang, S. T. (1996). Determination of MTB-GSL in radish by gas chromatography. Journal of Nanjing Agricultural University, 19(4), 92–94.

Li, J., Xie, B. J., Yan, S. L., Li, H., & Wang, Q. Z. (2015). Extraction and determination of 4-methylthio-3-butenyl isothiocyanate in Chinese radish (Raphanussativus L.) roots. LWT–Food Science and Technology, 60(22), 1080–1087.

Okano, K., Asano, J., & Ishii, G. (1990). A rapid method for determining the pungent principle in Japanese radish (Raphanussativus L.). Journal of the Japanese Society for Horticultural Science, 59(3), 545–550.

Sang, J. P., Minchinton, I. R., Johnstone, P. K., & Truscott, R. J. W. (1984). Glucosinolate profiles in the seed, root, and leaf tissue of cabbage, mustard, radish and swede. Canadian Journal of Plant Science, 64, 77–93.

Song, D., Liang, H., Kuang, P. Q., Tang, P. W., Hu, G. F., & Yuan, Q. P. (2013). Instability and structural change of 4-methylsulfinyl-3-butenyl isothiocyanate in the hydrolytic process. Journal of Agricultural and Food Chemistry, 61(21), 5097–5102.

Visentin, M., Tava, A., & Iori, R. (1992). Isolation and identification of trans-4-(methylthio)-3-butenylglucosinolate from radish roots (Raphanussativus L.). Journal Agricultural and Food Chemistry, 40, 1687–1691.

Wang, P., Wei, M., Liu, X. X., Xu, W. L., Fu, W. M., Wang, C., & Wang, S. F. (2014). Study on influences of different fertilization treatments on flavor components in radish by GC-MS. Shandong Agricultural Sciences, 46(9), 74–77.

Yasushi, N., Takako, I., Atsuo, T., Jun, K., & Tomoaki, M. (2001). 4-(methylthio)-3-butenyl isothiocyanate, a principal antimutagen in daikon (raphanussativus; Japanese white radish). Journal Agricultural and Food Chemistry, 49, 5755–5760.

Yasushi, N., Kei, N., Yumi, A., Toyoaki, W., Kiwamu, T., Tomoaki, M., Shigehisa, O., Johan, M., Yasuki, K., Akiyoshi, N., Eun, Y. P., Kenji, S., & Kozo, O. (2008). Comparison of the glucosinolate-myrosinase systems among daikon (Raphanussativus, Japanese white radish) varieties. Journal Agricultural and Food Chemistry, 56, 2702–2707.

You, H., Hao, R., Li, R., Zhang, L., Zhu, Y., & Luo, Y. B. (2015). The effect of radish sourced 4-(methylthio)-3-butenyl isothiocyanate on ameliorating the severity of high fat diet inducted nonalcoholic fatty liver disease in rats. International Journal of Clinical and Experimental Medicine, 8(9), 15910–15919.

Zhang, W. Q. (1990). Determination of raphanin. Shandong Agricultural Science, 2, 10–13.

Zhang D. M. (2009) Radish fermentation with lactic acid bacteria as starter culture and volatile flavor components. MSc Thesis, Huazhong Agricultural University, Wuhan, China.

Acknowledgments

This research was funded by the Key Projects of Administration of Ocean and Fisheries of Guangdong Province (A201401C04), the Collaborative Innovation Major Special Projects of Guangzhou City (201508020097), the Natural Science Foundation of Guangdong Province (2014A030313244), the International S&T Cooperation Program of China (2015DFA71150), the International S&T Cooperation Program of Guangdong Province (2013B051000010) and the Fundamental Research Funds for the Central Universities, China (2015ZM159). The authors also gratefully acknowledge the financial support of Guangdong Province Government (China) through the program “Leading Talent of Guangdong Province (Da-Wen Sun)” and the support of the collaborative research program between the Midea Group and South China University of Technology. In addition, the authors wish to acknowledge the contribution of Paul B McNulty, Emeritus Professor of Biosystems Engineering, University College Dublin, Ireland, who assisted in editing this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Zhong Han and He Li contributed equally to this work.

Rights and permissions

About this article

Cite this article

Han, Z., Li, H., Yu, XC. et al. Effects of Low Temperature Cooking on the Retention of 4-(Methylthio)-3-Butenyl Isothiocyanate (MTBITC) of Chinese White Radish (Raphanussativus L.). Food Bioprocess Technol 9, 1640–1647 (2016). https://doi.org/10.1007/s11947-016-1787-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1787-x