Abstract

The aim of this study was to reduce the sodium chloride (NaCl) level in surimi-based products by adding lysine or cystine in combination with high hydrostatic pressure (HHP). For experiments, Alaska pollock surimi was used to prepare gels in a factorial design (3 × 3 × 2) using three additive levels (no additive, lysine, and cystine), three NaCl levels (0, 0.3, and 3 %), and two HHP levels (0 and 300 MPa/10 min/10 °C). After blending, the pastes, consisting of surimi, additives, and different levels of salt, were stuffed into casings, high pressure treated, and stored at 5 °C for 24 h (suwari gel). Subsequently, samples were heated at 90 °C for 30 min (kamaboko-type gel). To assess the degree of protein denaturation prior to gelation at 90 °C, suwari gels were analyzed by differential scanning calorimetry to determine myosin denaturation enthalpy. Kamaboko-type gels were characterized by lightness properties, water binding capacity, and mechanical properties (by puncture test). Results showed that the pressure treatment at 300 MPa and/or the addition of lysine or cystine (0 and 0.1 %) to low-sodium-chloride samples (0 and 0.3 %) resulted in gels with similar quality characteristics to those with the regular 3 % sodium chloride addition, most likely due to the protein unfolding induced by both HHP treatment and the additives used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Textural properties of surimi-based gels depend on the functionality of its proteins, as well as processing conditions, such as pH, temperature, pressure, and addition of certain ingredients (Park 2005). Sodium chloride (NaCl) in concentrations from 1 to 3 % is usually used to facilitate an acceptable protein solubilization which, as a result, renders good gels (Kim and Park 2008). Recent international recommendations (NAOS Strategy 2005; EFSA 2005) advise a reduction in NaCl content in order to obtain more healthy products. However, salt is required for the solubilization of myofibrillar proteins, mainly myosin in a step prior to gelation (Lanier et al. 2014). The substitution of sodium chloride by other salts could be an alternative but has been found to result in some undesirable flavors (Desmond 2006). The addition of low concentrations of some amino acids has been shown to be effective for improving surimi gelation. Cando et al. (2016) observed that the use of lysine and cystine did improve the water binding capacity and mechanical properties of surimi gels with low NaCl concentrations. This can be explained by that cystine is a weak oxidant that maximizes the formation of cross-linkages (Chen et al. 1999). Furthermore, lysine homopolymer ε-polylysine has been used to enhance texture in kamaboko gels (Ting et al. 1999). Although the mechanism of action of lysine has not yet been clarified, it is anticipated that free amino acids in the ε-polylysine molecule are able to interact with proteins and serve as substrate for endogenous transglutaminases, suggesting that lysine may have a similar effect as gelation improver.

Moreover, several studies have shown that the textural properties of surimi gels can be improved by applying high hydrostatic pressure (HHP) processing (Asghar et al. 1985; Ashie and Lanier 1999; Cando et al. 2014; Carlez et al. 1995; Chung et al. 1994). Pressurizing above 100–150 MPa at low temperature induces protein denaturation, thus favoring solubilization and unfolding (Macfarlane and Mckenzie 1976). HPP induces an aggregation characterized by side-to-side interactions of proteins with a low degree of denaturation and not by aggregation of proteins. Moreover, conformational changes in proteins result in an increase in cross-linking ability such as protein-protein and protein-solvent interaction that could result in a better network and thus improved water binding capacity and mechanical properties (Farkas and Mohácsi-Farkas 1996). These factors may contribute to HHP processing inducing protein unfolding. As a consequence, the addition of the studied additives would result in more efficient gelation. Hence, it could be considered as an interesting alternative in the production of surimi-based products with low salt content.

The aim of this work was to investigate the effect of the combination of hydrostatic high pressure (0 and 300 MPa/10 °C/10 min) and the addition of cystine and lysine (0.1 %) on surimi protein gelation with normal reduced and no NaCl content (0, 0.3, and 3 %).

Materials and Methods

Raw Material

Alaska pollock surimi (Theragra chalcogramma) KA grade supplied by Angulas Aguinaga (Guipuzcoa, Spain) in frozen blocks of 20 kg was used to prepare the gels.

The additives used were sodium chloride (Merck KGaA), l-lysine (CAS: 56-89-3, Sigma-Aldrich), and l-cystine (CAS: 56-87-1, Sigma-Aldrich).

Proximate Analysis

The ash, fat, crude protein, and moisture contents of Alaska pollock surimi were determined (AOAC 2000) in quadruplicate. Crude protein content was measured using a LECO FP-2000 nitrogen determinator (Leco Corporation, St. Joseph, MI, USA).

Experimental Design

A full factorial design of experiments (3 × 3 × 2) with three additive levels (no additive, lysine, and cystine −0.1 %), three sodium chloride levels (0, 0.3, and 3 %), and two pressure levels (0 and 300 MPa/10 min) was used. The pressure level was chosen considering the previous work by Cando et al. (2014, 2015).

Sample Preparation

Samples were prepared as shown in Fig. 1. Samples (500 g) of Alaska Pollock surimi with NaCl added at 0, 0.3, and 3 % were homogenized under refrigerated conditions using a hand blender (Braun MR 740 cc, Braun GmbH, Germany). After homogenization, the mixture was subjected to vacuum to remove entrapped air. Different samples were prepared by adding 0.1 % cystine (C) and 0.1 % l-lysine (L), both previously reported to yield elastic and strong surimi gels (Cando et al. 2016). Gel moisture was adjusted to 76 %, and each surimi paste was stuffed into a 35-mm Krehalon casing (Amcor group Flexibles Hispania S.L., Barcelona, Spain) and subjected to HHP processing (0 and 300 MPa/10 °C/10 min) in a high hydrostatic machine QFP 2L-700 (Avure Technologies Inc., Columbus, USA). After processing, the samples were kept at 5 °C for 24 h and then heated at 90 °C for 30 min.

Differential Scanning Calorimetry

Unheated samples were studied by differential scanning calorimetry to determine the thermal stability of the protein as an indirect way to determine the initial state of the protein. Samples ∼10 mg) were placed in hermetically sealed aluminum pans and scanned twice at 10 °C/min from 5 to 95 °C in the differential scanning calorimetry (DSC) equipment (Mettler Toledo DSC1/200 Star System, Schwerzenbach, Switzerland). Temperature T peak (°C) and enthalpy of transition ∆H (J/g dm) were determined for each sample. Each sample was analyzed in triplicate.

Lightness (L*)

Lightness of the gels was measured by image analysis Digi eye™ (VeriVide Ltd., Leicester, UK). Each sample was placed in an illumination cabinet that ensures a uniform lighting, standard daylight (6400 K) and photographed (Nikon D80 with a 35-mm Nikkor lens, Nikon Corp., Japan). The color of the total gel surface was measured using DigiPix (VeriVide Ltd.) color measurement software.

Water Binding Capacity

Approximately 1.5 g of kamaboko-type gel samples (C and L) was cut into small pieces and placed in a centrifuge tube (Ø = 10 mm) with two filter papers (Weiβband n°5892, 7cmØ, 30 μg) as absorber. The samples were centrifuged (10 min at 3000×g at room temperature) (Sorvall® RC5C, Kendro Laboratory Products, Connecticut, USA). Water binding capacity (WBC) was expressed as percent of water retained per 100 g water present in the sample prior to centrifuging (Moreno et al. 2009). All determinations were carried out in triplicate.

Mechanical Properties

The mechanical properties of the kamaboko-type gels were assessed by performing a puncture test. The test was carried out at room temperature (25 °C) on sample gels (diameter 35.0 mm; height 30.0 mm) which were penetrated up to breaking point using a 5-mm-diameter cylindrical stainless steel plunger attached to a 50 N cell connected to the crosshead on a TA-XT2®-Pro Texture Analyser (Stable Micro Systems, Surrey, UK). The measurements were carried out in quadruplicate. Breaking force (BF) and breaking deformation (BD) were determined from force-deformation curves derived at 1.0 mm s−1 crosshead speed.

Statistical Analysis

One-way ANOVA analysis was carried out with the SPSS® computer program (SPSS Inc., Chicago, IL, USA), and average differences were evaluated by the Tukey test using a 95 % confidence interval.

Principal component analysis (PCA) was carried out using The Unscrambler® X 10.3. (CAMO Software, Norway).

Results and Discussion

Proximate Analysis

The analyses showed the following composition of raw surimi: ash (0.52 ± 0.12 %), fat (0.30 ± 0.01 %), crude protein (15.33 ± 0.53 %), and moisture content (75.99 ± 0.11 %) (AOAC 2000). The rest, approximately 7.85 ± 0.15 % and determined by difference, was cryoprotectant (a mixture of sucrose and sorbitol), and polyphosphates were added to surimi to protect protein from freeze denaturation.

Differential Scanning Calorimetry

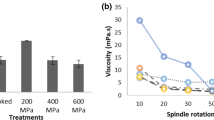

Table 1 shows the enthalpy values of the suwari gels. Addition of NaCl (N-0, N-03, N-3, Fig. 2a) caused a significant decrease in enthalpy (p < 0.05), and a reduction in the enthalpy observed in line with the increase in NaCl concentration can be observed. Salt causes protein solubilization (unfolding) (Liu et al. 2007) and reduces the energy required to reach the denaturation temperature. On the other hand, HHP processing induced protein denaturation which can be observed by the lower enthalpy values of N-0-300, N-03-300, and N-3-300 as compared to N-0, N-03, and N-3 (Table 1 and Fig. 2b). High-pressure processing has been reported to induce changes in the protein structure, disturbing the balance of non-covalent interactions which stabilize the native conformation of proteins, particularly myosin and actin (Okamoto et al. 1990). So, myosin and actin undergo protein depolymerization, thus resulting in myofibrillar protein solubilization (Montero and Gómez-Guillén 2005).

The addition of cystine (Table 1 and Fig. 2c) (N-0, C-0, C-03, and C-3) caused a significant reduction in the enthalpy (p < 0.05) relative to their corresponding control (N-0, N-03, and N-3) with the only exception of C-3 which showed an enthalpy similar to that of N-3. Moreover, when lysine was added (L-0, L-03, L-3), a similar trend was observed. As shown in Table 1, samples with lysine without NaCl (L-0) show significantly higher (p < 0.05) myosin denaturation and unfolding, due to their lower enthalpy as compared to the samples with cystine (C-0). The lower enthalpy can result in a better network formation.

With respect to the combination of the additives and NaCl, the addition of a higher NaCl level (3 %) resulted in a significant reduction (p < 0.05) in the enthalpy regardless of the additive, although the effect was more evident with cystine (Table 1). That would imply a higher protein denaturation with increasing NaCl content, as previously reported.

The combination of additives and HHP processing tends to induce protein solubilization as indicated by a significant reduction (p < 0.05) in the enthalpy value (Table 1).

In heated samples (kamaboko type), myosin is completely denatured and there is no observable thermal effect during the DSC analysis (Cando et al. 2014; Fernandez-Martín et al. 1997).

Lightness (L*)

Table 1 shows the results of L* value of surimi gels. Regarding the effect of NaCl (N-0, N-03, N-3), it is observed that lightness significantly increased (p < 0.05) when salt is added although there was not a linear effect of salt upon L*. The increase in L* value has been mainly related to the formation of bonds (Uresti et al. 2004), and it is directly related to previous gelation and protein unfolding related to the exposure of reactive groups (Park 2005). DSC analysis showed that protein denaturation increased with NaCl addition (N-03 and N-3) which would induce a higher formation of bonds during further gelation and hence would explain the significant increase (p < 0.05) in L* values. Moreover, it has to be taken into consideration that NaCl can induce protein oxidation which would cause an increase in bonds and, hence, in L* value (Lund et al. 2011).

HHP did not affect L* values regardless of the NaCl concentration. The same effect was observed with the addition of cystine and lysine (Table 1). The DSC analysis indicates that both additives induced protein unfolding, particularly evident with cystine addition, which could cause the higher bond formation during heat treatment. The combination of the addition of cystine and HPP processing resulted in significantly higher L* values (p < 0.05), regardless of the NaCl concentration (Table 1). This is most likely due to the abovementioned formation of bonds which lead to increasing the lightness of surimi samples (Uresti et al. 2004). In samples with lysine, the effect of HHP processing is only observed in L-3-300, which may be due to the ability of HHP to induce protein denaturation (DSC analysis) that would result in further bond formation.

Water Binding Capacity

The WBC of the control samples (N-0, N-03, N-3) shows differences that can be related to the NaCl concentration (Table 1). When NaCl was increased to 3 %, WBC also increased significantly (p < 0.05) because the solubilization/denaturation of muscle proteins is higher and the active sites that form bonds are more exposed, thus increasing the ability of binding water (Hamm 1960). This is desirable in surimi gels because the higher WBC reflects a good protein-water interaction which has a positive influence on texture (Lakshmanan et al. 2007; Romero et al. 2014).

When pressure was applied, WBC increased significantly (p < 0.05) in all samples regardless of the NaCl and additives. The effect of HHP is based on the induction of protein unfolding, which exposes hydrophobic domains. That results in increased hydrophobic interactions which stabilize the water/protein system (Park 2005), and in addition, the unfolded protein exposes reactive groups that links water molecules and creates new sites where water is entrapped (Cheftel and Culioli 1997).

Addition of cystine and lysine significantly (p < 0.05) increased WBC (Table 1). This increase could be caused by the formation of covalent bonds and cross-linkages forming a network which traps water inside (Kamath et al. 1992; Sato et al. 2001). Regarding the combination of additives and pressure processing, without NaCl (C-0-300 and L-0-300), WBC was not significantly different from the corresponding control sample (N-0-300). When 0.3 % NaCl was added, however, significant differences (p < 0.05) were observed between lysine (L-03-300) and control samples (N-03-300). The sample with cystine and 0.3 % NaCl, processed at 300-MPa pressure (C-03-300), however, did not show significant differences (p < 0.05) when compared to the control (N-03-300), which indicates that there is no synergistic effect of cystine and pressure processing (C-03-300). The combination of lysine and pressure processing (L-03-300), at the same level of salt, resulted in a significant increase (p < 0.05) of WBC compared to the control (N-03-300). This could be due to lysine prompting endogenous transglutaminase to act which results in the formation of non-disulphide covalent bonds. These bonds induce protein net enhancement, and water molecules are more easily hold in the network (Han et al. 2006). Regarding samples containing 3 % NaCl, there was no observed significant increase (p < 0.05) in WBC (Table 1). Hence, it can be concluded that WBC was mainly affected by the NaCl concentration, especially 3 %, followed by pressure processing and lysine addition.

Mechanical Properties

Table 2 shows the results of breaking force (BF) and breaking deformation (BD).

No significant differences on BF were observed with increasing NaCl concentration. BD significantly increased (p < 0.05), however, indicating that the addition of NaCl resulted in more elastic, cohesive, and stable gels.

High-pressure processing resulted in a significant increase (p < 0.05) of BF in samples without additives (N-0-300, N-03-300, and N-3-300) as compared to their corresponding controls (N-0, N-03, and N-3). HHP treatment induces protein denaturation followed by further protein aggregation due to the heating, which can result in improved mechanical properties (Uresti et al. 2006). BD increased significantly (p < 0.05) in both sample with 3 % NaCl (control, N-3-300) and sample with cystine added (C-3-300), meaning that the network formed is more elastic than the one without HHP processing.

Cystine and lysine addition resulted in a significant increase (p < 0.05) of BF and BD regardless of the NaCl concentration. On the other hand, the combination of pressure processing and additives (C-0-300 and L-0-300) resulted in a significant increase (p < 0.05) of BF and BD compared to their counterparts without pressure (C-0 and L-0).

These results showed that not only BF in particular, but also BD, is mainly affected by the addition of NaCl (3 %) and the high-pressure processing (300 MPa).

The effect of NaCl and pressure on mechanical properties is strongly related to the protein unfolding, so better gel textures are achieved from pastes with the most denatured proteins, prior to gelation. Our results indicate a direct correlation between the addition of salt and pressure and reduction of the enthalpy required to reach the denaturation temperature.

Multivariate Analysis Principal Component Analysis

Figure 3 shows the score and loading plot (bi-plot) of the first and second principal components, based on 18 different samples studied. PC-1 explained 54 % of the variance dominated by the enthalpy in the positive part and by the WBC, deformation (BD) and force (BF) on the opposite side. PC-2, explaining 20 % of the variance, is dominated by the L* value. Together, PC-1 and PC-2 explain the 74 % of variance of the gels.

PC-1 is mainly related to the pressure processing and sodium chloride addition, as suggested by the uniform distribution of the variables along this axis, being located the samples treated at 300 MPa and with 3 % of NaCl on the left hand of PC-1 axis. This indicates a positive correlation of those variables with force (BF), deformation (BD) and WBC and a negative correlation with the enthalpy. Samples without pressure processing and low amounts of NaCl (0–0.3 % NaCl) were located rightmost, which is in agreement with the higher enthalpy (Fig. 2a), meaning a lower protein denaturation prior to gelation. That fact resulted in lower BF, BD, and WBC since protein denaturation is mostly induced by NaCl and pressure processing which can be observed in Tables 1 and 2. According to that, it can be inferred that denaturation prior to the gelation process is of great importance to obtain gels with adequate physical properties.

PC-2 shows that the samples’ position is related to the additives. Samples with cystine are located on the upper side of the axis corresponding to the positive values of the PC-2, which are the ones with a positive correlation with L* value. Samples with lysine are, on the other hand, located on the lower side, indicating a negative correlation with L*.

Conclusion

The BF, BD, and water binding capacity of the gels with low NaCl amount (0.3 %) and without NaCl were improved by the addition cystine and lysine and/or pressure processing (300 MPa).

Our results suggest the feasibility to obtain gels with low NaCl content (0.3 % NaCl) with appropriate mechanical and functional properties, similar to those gels with regular amount of NaCl (3.0 %), by applying HHP processing and/or by adding lysine or cystine. However, no synergetic effect between HHP processing and additives was observed. Gels without added NaCl also exhibited improved mechanical and functional properties, as a result of the HHP processing and the addition of lysine and cystine. This effect is particularly evident in the gels with added lysine or processed by HHP.

In conclusion, these results suggest the possibility to produce healthier surimi-based products with reduced NaCl content and with similar or even improved characteristics to those produced with regular NaCl content (3.0 %).

References

AOAC. (2000). Official methods of analysis (17th ed.). Maryland: Association of Official. Analytical Chemistry.

Asghar, A., Samejima, K., & Vasui, T. (1985). Functionality of muscle proteins in gelation mechanisms of structured meat products. Critical Reviews in Food Science and Nutrition, 22, 27–106.

Ashie, I. N. A., & Lanier, T. C. (1999). High pressure effects on gelation of surimi and turkey breast muscle enhanced by microbial transglutaminase. Journal of Food Science, 64, 704–708.

Cando, D., Moreno, H. M., Tovar, C. A., Herranz, B., & Borderías, A. J. (2014). Effect of high pressure and/or temperature over gelation of isolated hake myofibrils. Food and Bioprocess Technology, 7, 3197–3207.

Cando, D., Herranz, B., Borderías, A. J., & Moreno, H. M. (2015). Effect of high pressure on reduced sodium chloride surimi gels. Food Hydrocolloids, 51, 176–187.

Cando, D., Herranz, B., Borderías, A. J., & Moreno, H. M. (2016). Different additives to enhance the gelation of surimi gel with reduced sodium content. Food Chemistry, 196, 791–799.

Carlez, A., Borderías, J., Dumay, E., & Cheftel, J. C. (1995). High pressure gelation of fish myofibrillar proteins. In E. Dickinson & D. Lorient (Eds.), Food macromolecules and colloids (pp. 400–409). Cambridge: Royal society of Chemistry.

Cheftel, J. C., & Culioli, J. (1997). Effects of high pressure on meat: a review. Meat Science, 46(3), 211–236.

Chen, W. L., Chow, C. J., & Ochiai, Y. (1999). Effects of some food additives on the gel-forming ability and color of milkfish meat paste. Fisheries Science, 65(5), 777–783.

Chung, Y. C., Gebrehiwot, A., Farkas, D. F., & Morrisey, M. T. (1994). Gelation of surimi by high hydrostatic pressure. Journal of Food Science, 59, 523–524.

Desmond, E. (2006). Reducing salt: a challenge for the meat industry. Meat Science, 74, 188–196.

European Food Safety Authority. (2005). EFSA provides advice on adverse effects of sodium. New and Events

Farkas, J., & Mohácsi-Farkas, C. (1996). Application of differential scanning calorimetry in food research and food quality assurance. Journal of Thermal Analysis, 47(6), 1787–1803.

Fernandez-Martín, F., Fernandez, P., Carballo, J., & Jimenez-Colmenero, F. (1997). High pressure-cooking of chicken meat batters protein behavior and product rheological properties. Journal of Agricultural and Food Chemistry, 45, 4440–4445.

Hamm, R. (1960). Biochemistry of meat hydration. Advances in Food Research, 10, 355–463.

Han, M. Y., Zhang, Y. J., Fei, Y., Xu, X. L., & Zhou, G. H. (2006). Effect of microbial transglutaminase on NMR relaxometry and microstructure of pork myofibrillar protein gel. European Food Research and Technology, 228, 665–670.

Kamath, G. G., Lanier, T. C., Foegeding, E. A., & Hamann, D. D. (1992). Non disulfide covalent cross-linking of myosin heavy chain in “setting” of Alaska Pollock and Atlantic croaker surimi. Journal of Food Biochemistry, 16, 151–172.

Kim, Y. S., & Park, J. W. (2008). Negative roles of salt in gelation properties of fish protein isolate. Food Chemistry, 73, C585–C588.

Lakshmanan, R., Parkinson, J. A., & Puggot, J. R. (2007). High-pressure processing and water-holding capacity of fresh and cold-smoked salmon (Salmo salar). Food Science and Technology, 40, 544–551.

Lanier, T. C., Yongsawatdigul, J., & Carvajal-Rondanelli, P. (2014). Surimi gelation chemistry. In J. W. Park (Ed.), Surimi and surimi seafood (pp. 101–140). Boca Ratón: CRC Press. Taylor and Francis Group.

Liu, R., Zhao, S. M., Xiong, S. B., Xie, B. J., & Liu, H. M. (2007). Studies on fish and pork paste gelation by dynamic rheology and circular dichroism. Journal of Food Science, 72(7), E399–E403.

Lund, M. N., Heinonen, M., Baron, C. P., & Estévez, M. (2011). Protein oxidation in muscle foods: a review. Molecular Nutrition and Food Research, 55, 83–95.

Macfarlane, J. J., & Mckenzie, I. J. (1976). Pressure-induced solubilization of myofibrillar proteins. Journal of Food Science, 41, 1442–1446.

Montero, P., & Gómez-Guillén, C. (2005). High-pressure applications on myosystems. In M. P. Cano, M. S. Tapia, & G. V. Barbosa-Canovas (Eds.), Novel food processing technologies (pp. 311–342). New York: CRC Press.

Moreno, H. M., Cardoso, C., Solas, M. T., & Borderías, A. J. (2009). Improvement of cold and thermally induced gelation of giant squid (Dosidicus gigas) surimi. Journal of Aquatic Food Product Technology, 18(4), 312–330.

NAOS Strategy. (2005). Spanish strategy for nutrition, physical activity and prevention of obesity. Spain: Minister of Health and Consumer Affairs.

Okamoto, M., Kawamura, Y., & Hayashi, R. (1990). Application of high pressure to food processing: textural comparison of pressure and heat induced gels of food proteins. Agricultural and Biological Chemistry, 54, 183–189.

Park, J. W. (2005). Surimi and surimi seafood (2nd ed.). Boca Raton: CRC Press.

Romero, A., Cordobés, F., Guerrero, A., & Puppo, M. C. (2014). Influence of protein concentration on the properties of crayfish protein isolated gels. International Journal of Food Properties, 17(2), 249–260.

Sato, K., Tanaka, C., Kotaru, M., Yoshikawa, H., Kawabata, M., Ikeuchi, T., Sato, K., Nakamura, Y., & Ohtsuki, K. (2001). Different arrangement of epsilon (gamma-glutamyl) lysine cross-linking in Alaska pollock (Theragra chalcogramma) surimi proteins by Streptoverticillium and endogenous transglutaminases during suwari process. Journal of Food Biochemistry, 25, 397–409.

Ting, H.Y., Ishizaki, S., & Tanaka, M. (1999). Epsilon-polylysine improves the quality of surimi products. Journal of muscle foods, 279–294.

Uresti, R. M., Velazquez, G., Ramírez, J. A., Vázquez, M., & Torres, J. A. (2004). Effect of high-pressure treatments on mechanical and functional properties of restructured products from arrowtooth flounder (Atheresthes stomias). Journal of the Science of Food and Agriculture, 84, 1741–1749.

Uresti, R. M., Velazquez, G., Vázquez, M., Ramírez, J. A., & Torres, J. A. (2006). Effects of combining microbial transglutaminase and high pressure processing treatments on the mechanical properties of heat-induced gels prepared from arrowtooth flounder (Atheresthes stomias). Food Chemistry, 94, 202–209.

Acknowledgments

This research was supported by the Spanish Ministry of Economy and Competitiveness and the Spanish National Research Council (CSIC) under the project AGL2011-24693 and the PhD student training program FPI 2012 (BES-2012-053420, Author Cando, D.). The authors would like to thank Dagbjørn Skipnes, Karin Tranøy, Laila Budal, Sigurd Øines, Lene Kramer, and Bjørn Tore Rotabakk for their excellent laboratory assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cando, D., Moreno, H.M., Borderías, A.J. et al. Combined Effect of High Hydrostatic Pressure and Lysine or Cystine Addition in Low-Grade Surimi Gelation with Low Salt Content. Food Bioprocess Technol 9, 1391–1398 (2016). https://doi.org/10.1007/s11947-016-1728-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1728-8