Abstract

The objective of the work was to investigate the potential of low-field nuclear magnetic resonance of protons (1H LF NMR) relaxometry to produce indicators useful in the estimation of the quality and shelf life of frozen hake (Merluccius merluccius L.) muscle as affected by storage temperature and time. 1H low-field NMR T 2 transverse relaxation measurements were performed from fillets of a total of 145 hakes that had been stored at −10, −20, −30, or −80 °C for up to 150 weeks. The principal component (PC) scores from the 1H LF NMR distribution of T 2 relaxation times were adjusted to zero-order kinetics and the reaction rates followed an Arrhenius-type pattern. Kinetic modeling using the PC scores of the 12–400-ms range resulted in the best model corresponding to both T 21 and T 22 regions. The temperature dependency of the rate of reactions, measured by B values, was similar to that previously found for shear resistance and for the hydrolysis of phospholipids, well-known markers related to the sensory quality in this species. Thus, our results suggest that this methodology has a great potential to evaluate the frozen storage time and temperature in hake as well as to provide an indication of the expected quality of the fillet.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The quality of fish muscle is related to some measurable attributes and properties that can be determined by standard methods which provide indicators that, in turn, can be used to evaluate the product or to set specifications (Bremner 2000) and which may be of different relative importance to the various parts of the supply chain in the fish sector (Jørgensen et al. 2003).

Fish muscle contains proteins, lipids (most notably the omega-3 fatty acids, DHA, and EPA), and a wide variety of vitamins and minerals, including vitamins A and D, phosphorus, magnesium, selenium, and iodine, making it a very good source of high-value nutrients. Fish also have special eating features largely due to the specific nature of the constituent muscle proteins and their structural configurations, as well as the high water holding capacity, that make it so acceptable as a food (Mackie 1997).

Unfortunately, one of the characteristics of fish muscle is its high perishability. Therefore, and in order to minimize spoilage processes, fish is usually stored at low temperatures, either above freezing, if the fish is to be consumed in a short time, or well below freezing for long-term storage. The latter is one of the most effective methods to prolong shelf life since it decreases the rate of many physical and chemical reactions. However, several factors including species, season, fishing, and/or slaughtering methods, post mortem handling, freezing, and frozen storage conditions, as well as their interactions, may affect the fish flesh structure, composition, and functionality, all of which can lead to the loss of acceptability by the consumer (Haard 1992).

Currently, there is a need to identify methodologies to provide new and objective indicators related to the loss of quality attributes caused by prolonged times and/or high temperatures of frozen storage applicable to estimate the quality and shelf life of frozen fish products and to verify the compliance of European Regulations on the provision of food information to consumers [(EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011] and on the common organization of the markets in fishery and aquaculture products [Regulation (EU)No 1379/2013 of the European Parliament and of the Council of 11 December 2013].

Kinetic models have been successfully used to monitor changes occurring due to both storage time and temperature. The Arrhenius equation, for example, has been applied in many food systems and has been used to estimate shelf life (e.g., Labuza 1984; Fu and Labuza 1993; Taoukis et al. 1997). Few reports in the literature use this approach for frozen seafood products (Tsironi et al. 2009; Careche et al. 2014; Sánchez-Valencia et al. 2014), as opposed to their extended use in chilled storage (i.e., Zhang et al. 2011) or during thermal processing (i.e., Kong et al. 2007).

On the other hand, spectroscopic techniques are preferred for fish quality and safety evaluation and the analysis of data is usually performed by chemometrics (Cheng et al. 2013). Spectroscopic markers for kinetic modeling of frozen hake muscle (Merluccius merluccius L.) have been found by using principal components (PCs) of Fourier transform infrared (FTIR) spectra of the lipid fraction (Careche et al. 2014). Principal component analysis (PCA) is a technique that reduces a data set into a small number of new, non-correlated variables, on each of which, a score for each sample is calculated (Afifi and Clark 1984), and these scores can reveal patterns within a data set.

Low-field nuclear magnetic resonance of protons (1H LF NMR) has been used in myosystems mainly in the study of meat and meat products (Bertram and Andersen 2004; Pearce et al. 2011) although their application to fish products has increased recently (Erikson et al. 2004, 2012; Aursand et al. 2008, 2009; Gudjónsdóttir et al. 2011, 2013). In model systems with proteins and other biopolymers, as well as in muscle, it has been shown that the transverse relaxation times (T 2) can provide information about the physical-chemical nature and spatial organization of muscle components (Belton 2011; Erikson et al. 2012). We previously had analyzed hake muscle stored at a fixed temperature (i.e., −10 °C), and T 2 relaxation times provided information related to deterioration due to frozen storage time (Sánchez-Alonso et al. 2012) which suggested that these indicators might be useful for kinetic modeling.

The objective of the present work was to explore the potential of 1H LF NMR relaxometry to provide indicators useful in the estimation of quality and shelf life of frozen hake (M. merluccius) muscle as affected by temperature and time, which could be associated to quality standards or could be used to establishing the remaining shelf life of hake products, either alone or in combination with other existing methods.

Material and Methods

Fish Samples

Hakes (M. merluccius) were captured in the Northeast Atlantic (FAO area 27, division VIa) in November 2009. They were gutted and iced on board and landed on Puerto de Celeiro (Galicia, Spain) 24 h after capture. Immediately after landing, they were weighted (average 1.81 ± 0.19 kg) and visually inspected, and the scales were removed. The fish in post-rigor condition were beheaded, washed with iced water to remove blood and rests of viscera, and allowed to drain in stainless steel racks. Then, they were manually filleted (skin left on) and visually inspected to make sure of the complete removal of any rests of bones, scales, or viscera and individually packed in Ariex-3 plastic bags (polyamide 20/polyethylene 70, thickness 90 μm, Industrias Plásticas Arias S.L., Lugo, Spain), labeled, and sealed with no vacuum in a packaging and sealing equipment (model VP-800, Ramón, Vilassar de Dalt, Barcelona, Spain). The temperature during handling was always kept under 7 °C. Fillets of five hakes were stored refrigerated until they were analyzed and the rest were frozen in a blast freezer (RF 201 AB, Fagor, Mondragón, Spain) for 1 h until the fish reached a core temperature of −20 °C, placed in polystyrene boxes with dry ice, and immediately transported from Puerto de Celeiro to the ICTAN Laboratory in Madrid. They were stored at −10 °C (Liebherr model GGPV 5520, Liebherr GmbH Korneuburg, Austria), −20 °C (walk in freezer, DWM Copeland model DLL-401), −30 °C (Radiber model CVED-310-30, Radiber S.A. Barcelona, Spain), and −80 °C (Nuaire model Glacier −86, Nuaire, Inc., USA).

Those stored at −10 °C were sampled up to 23 weeks and the ones at −20 and −30 °C, for up to 104 and 147 weeks, respectively. Fillets from ten frozen fish were kept at −80 °C and analyzed after 106 and 150 weeks of storage. For each storage period, fillets from five individuals were subjected to analyses as described below.

Low-Field NMR Analysis

A 1H LF NMR analyzer minispec mq20 (Bruker Optik GmbH, Germany) with a magnetic field strength of 0.47 T corresponding to a proton resonance frequency of 20 MHz was used for the NMR measurements. Frozen fillets were cut in two, and the dorsal part was allowed to semi-thaw on a cutting board placed on top of a container filled with ice and cut in 1 × 1 × 2-cm parallelepipeds of about 2 g. The samples were placed in NMR tubes (1.8-cm diameter and 18-cm height) in an ice bath, let to thaw, and transferred to a thermostated water bath until they reached 4 °C. During the measurements, the samples were kept at ∼4 °C by using a variable temperature probe head (model PA225) coupled to a thermo Haake® refrigerated circulator C/DC class DC10-K10 (Fisher Scientific S.L., Madrid, Spain). Transverse relaxation data (T 2) were measured using the Carr-Purcell-Meiboom-Gill (CPMG) pulse sequence with a τ value of 150 μs. For each sample, 16 scans were acquired at a 2-s interval with a total of 3000 echoes. At least three parallels per fish were performed.

NMR T 2 transverse relaxation data were analyzed by the measurement of biexponentials and the distribution of relaxation times (Sánchez-Alonso et al. 2012). By the first method, the transverse relaxation data were fitted to a biexponential model using the software Bruker the minispec v 1.2.

where T 21 and T 22 were, respectively, the shorter and longer transversal relaxation components, A 21 and A 22 were the corresponding amplitudes, and t is the acquisition time.

In the second method, the relaxation data were treated using the CONTIN regularization algorithm (Provencher 1982a, 1982b) resulting in the corresponding distributions of the relaxation times from the decay curve; this is also part of the software provided with the equipment (CONTIN the minispec v 1.2). Data were analyzed using SPSS software (IBM SPSS statistics version 20, IBM Corporation 2011).

Data Analysis

The number of individuals per storage time and temperature (replicates) was N = 5. Data from (a) biexponential fitting to the T 2 transverse relaxation decay curves (A 21, A 22, T 21, and T 22), (b) principal component (PC) scores from the decay curves, (c) PC scores from the biexponential parameters, and (d) PC scores from the CONTIN distribution function were taken as the response variables for the analyses described below.

For a first estimation of the kinetic reaction parameters for each temperature, the data obtained per storage time were averaged and fitted to zero-order kinetics. The equation can be expressed as

where A 0 is the value of the response variable at time 0, A is the value of this response variable at time t, and k is the rate constant.

The temperature dependence of the response variables can be analyzed with an Arrhenius-type equation (van Boekel 2008):

where k is the rate constant, T is the absolute temperature in Kelvin, k A is the pre-exponential factor, and B is a constant. Time and temperature can be modeled in one step by using non-linear regression instead of using a two-step approach in which the kinetic parameters for each temperature are calculated first and then applied to estimate the temperature dependence. The one-step approach increases the degrees of freedom and results in a more accurate estimation of k at each temperature, giving narrower confidence intervals (Taoukis et al. 1997; van Boekel 2008).

Secondly, in agreement with previous works (Taoukis et al. 1997; van Boekel 2008), the standard error of k A can be lowered by applying the model to the relevant temperature range (although the model itself may be applicable to a wider range). The reference rate constant (k ref), usually corresponding to an average of the temperature range characteristic of the process, has, in this way, a more relevant meaning and the applicability of the equation is maximal within the range of temperatures of interest. The non-linear regression by using the T ref approach for zero-order kinetics is written as follows:

where T ref is the reference temperature and k ref is the rate constant at this temperature. In this case, the chosen T ref was 253 K (−20 °C), close to the maximum recommended storage temperature of −18 °C. Starting values for the non-linear regression were calculated using the parameters calculated by applying Eqs. 1 and 2. For the final model, A 0, k ref, and B parameters were estimated with all data from −10, −20, and −30 °C (N = 135 fish) using the Non-Linear Regression program (Levenberg-Marquardt algorithm) with the SPSS software (IBM SPSS statistics version 20, IBM Corporation 2011).

Certification UNE-EN ISO 9001

The Instituto de Ciencia y Tecnología de Alimentos y Nutrición (ICTAN-CSIC) is certified since 2008 under the UNE-EN ISO 9001 with scope “Management and execution of research projects and contracts in the area of Food Science and Technology and Nutrition” (certificate number ER-0366/2008).

Results and Discussion

Proximate analyses and pH of hake muscle from this experiment have been published by Sánchez-Valencia et al. (2014) and were within the values previously reported for this species (Careche and Tejada 1990; Sánchez-Alonso et al. 2012).

Influence of Storage Time and Temperature

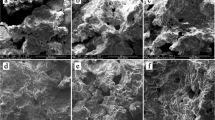

Figure 1 shows initial distribution of relaxation times of hake muscle frozen stored at the different temperatures, as well as unfrozen muscle. In the latter case, a major band was observed at relaxation times corresponding to T 21 and the band corresponding to T 22 was not present, as it was previously observed for this species (Sánchez-Alonso et al. 2014). In muscle stored at −80 °C, T 21 band widened and its maximum height decreased as compared to the unfrozen muscle, and no T 22 band was observed, as in unfrozen muscle. At increasing frozen storage temperatures, a progressive widening and decreasing intensity of the T 21 band was observed concomitantly with the appearance of the T 22 population. Intensity peak of the T 21 band appeared at values corresponding to protons with more restricted mobility as the storage temperature was higher. The differences between frozen/thawed and unfrozen fish were previously observed in an experiment where various freezing rates were studied (Sánchez-Alonso et al. 2014). Following the interpretation given by Belton (Belton et al. 1988; Belton 2011) based in model systems of biopolymers and water, it was suggested that the appearance of T 22 in a thawed product could mirror the morphological changes resulting from freezing and thawing (Sánchez-Alonso et al. 2014). The absence of this band in −80 °C frozen samples can be explained if we assume that morphological changes due to the formation of small ice crystals are small at this temperature. Belton et al. (1988) did not find either any extra band in thawed agarose gels that had been frozen with liquid nitrogen when the size of the ice crystals was smaller than 3–4 μm.

The modifications of the T 2 relaxation time distribution at increasing storage times were more evident with increasing storage temperature (Fig. 2). These changes affected the relative abundances of protons with intermediate (T 21) and high (T 22) mobility. Relaxation times in the range of 1–4 ms (T 2b) were also observed. The relative abundance of T 21 decreased with storage time, and a simultaneous increase of T 22 was observed. Likewise, at higher temperatures and longer storage times, a progressive shift of T 21 band toward lower relaxation times was found. No clear trend was identified for T 2b. The data obtained at −10 °C were in accordance with previously reported results in hake (Sánchez-Alonso et al. 2012, 2014) and cod (Steen & Lambelet 1997) although, in none of these cases, the storage times covered the range of storage temperatures and times of the present work.

The progressive decrease of T 21 relaxation time may be explained by a chemical exchange between water and myofibrillar proteins protons affected by denaturation and aggregation (Sánchez-Alonso et al. 2014). This process was explained by Hills et al. (1989), based in relaxometry experiments with bovine serum albumin (BSA): the authors observed lower T 2 transverse relaxation of protons from aggregated BSA than from unfrozen BSA solutions. The increase of T 22 and decrease of T 21 abundances along storage time have been suggested to be associated to a migration of intramyofibrillar water to extracellular crystals (Sánchez-Alonso et al. 2014).

T 2 transverse relaxation time parameters extracted by biexponential fitting (Fig. 3) showed, for all four parameters (T 21, T 22, A 21, A 22), changes along storage. At −10 and −20 °C, the intermediate relaxation time (T 21) and its corresponding amplitude (A 21) decreased gradually whereas the relaxation time corresponding to more mobile protons (T 22) and its amplitude (A 22) increased in these conditions. However, at −30 °C, the variations were less pronounced, and at −80 °C, no changes were observed except for T 22.

Thus, large changes were observed in the 1H LF NMR relaxometry measured values which kept a direct relationship with the storage temperature and time, i.e., the higher the temperature and the longer the time, the larger the change. This suggests the value of these measurements as indicators for frozen storage quality loss.

Kinetic Models

Several kinetic models were calculated using the parameters: a) from exponential fitting to the T 2 transverse relaxation decay curves (A 21, A 22, T 21 and T 22), b) PC scores from the decay curves, c) PC scores from the biexponential parameters, and d) PC scores from the CONTIN distribution function. Only the later will be described since it gave the best results.

Factor analysis was performed with T 2 relaxation time distribution mean data values averaged by week in the range of 12 and 700 ms. Nine PCs explained the 99.7 % of the variance; PC1 and PC2, which explained 61 and 15 % of the variance, respectively, showed a clear relation with storage temperature (Fig. 4).

The intermediate and long relaxation components might keep a different relation with storage time. In order to check this, we used PCAs from different ranges (12–112; 12–400; 12–700; 112–400; 112–700 ms) of the T 2 relaxation time distribution, thus covering protons with intermediate and long relaxation times separately or in combination. A similar approach was performed for FTIR of the lipid fraction (Sánchez-Alonso et al. 2014) and showed distinct features depending on the region of the spectra. The first PC of each of the analyzed ranges explained between 60 and 85 % of the variance, and since all these PCs kept a relationship with temperature and time, they were used for kinetic modeling. In all cases, the best R 2 values were found for zero-order kinetics (Table 1). The Arrhenius parameters by non-linear regression analysis (Table 2) showed that the best models were obtained when using ranges where both intermediate and high-mobility protons were included (12–400 and 12–700 ms), in terms of lower-standard errors and higher R 2. Although differences between both ranges were small, the best one was between 12 and 400 ms. For this range, the final kinetic model was performed with all data values (Table 3, Fig. 5) and as expected, lower-standard-error values were obtained. The residuals were independent and normally distributed, and they had constant variance and zero mean. The model had a good agreement between predicted and observed values at −10 and −20 °C being worse at −30 °C.

Several other methods have been proposed to predict the frozen storage time of hake products at a fixed temperature, including the quality index method (QIM) based on sensory inspection (Herrero et al. 2003), stress relaxation test (Herrero and Careche 2005), visible spectroscopy (Heia et al. 2003), or a combination of methods such as apparent viscosity of muscle homogenates, puncture test, and Kramer shear resistance (Herrero and Careche 2006).

One of the main advantages of 1H LF NMR, as an indicator of the quality of frozen fish muscle, is to obtain relevant information at the ultrastructural level (heterogeneity in muscle spaces by the presence of ice crystals) and molecular level (e.g., protein aggregation). This information is consistent with the results obtained by other physicochemical techniques that measure the quality in frozen fish, which in turn are already known to correlate well with other spectroscopic parameters (Sánchez-Alonso et al. 2012). Thus, standardization of the method proposed here could raise the possibility of replacing the physical-chemical techniques for the faster relaxometry 1H LF NMR methods.

Other indicators such as Kramer shear resistance, water holding capacity, and the FTIR spectra of the lipid fraction of hake muscle have shown to follow an Arrhenius-type equation and could therefore be used to predict time at a given temperature and vice versa (Sánchez-Valencia et al. 2014; Careche et al. 2014). The functions that integrate time and temperature in order to measure quality for processes occurring during storage of fish muscle usually follow a similar pattern (Bremner et al. 1987). The results obtained for parameter B (i.e., temperature dependence of a given reaction rate) with 1H LF NMR showed similar values to those found using shear resistance (Sánchez-Valencia et al. 2014) and hydrolytic changes in the phospholipid fraction as measured by FTIR spectra of fish lipids (Careche et al. 2014).

The estimation of storage times showed a good fitting at relatively high temperatures (e.g., −10 and −20 °C) (Fig. 5), but at lower ones (e.g., −30 °C), there was a lack of fit between observed and predicted values. This may be, in part, a consequence of the experimental error, but also to a biological zero temperature at which all reactions stop (Bremner et al. 1987). For many reactions in frozen stored hake, this temperature could be close to −30 °C. This would involve a lack of linearity of the activation energies as a function of temperature which could only be achieved in a certain range. In fact, when data at −80 °C were included, the kinetic models worsened (not shown), thus supporting the halting of biological reactions. Models other than Arrhenius have been proposed (e.g., Peleg et al. 2002) for ranges including temperatures where the system may be practically inert, together with temperatures where the activity of the system is accelerated. Nevertheless, and given that the temperatures of interest for most fish products are between −10 and −30 °C, we considered that the used Arrhenius in this range would be suitable to estimate the product’s quality.

As discussed previously (Sánchez-Valencia et al. 2014; Careche et al. 2014), information provided by kinetic modeling can be applied for inspection or authentication purposes; it could also help in finding time-temperature indicators with close correlations with muscle quality changes. Another advantage would be their usefulness to ensure homogenous or premium quality products in the processing industry. In any case, the usefulness of 1H LF NMR models for estimation of time and temperature or as quality indicators should be validated with new batches of fish. A similar experimental approach should be used for other species and/or conditions so that a product-specific time temperature relationship could be identified and used for quality monitoring.

Conclusion

Kinetic modeling was successfully applied to 1H LF NMR data from frozen stored hake muscle. The best model was obtained with PC1 from the spectral data of the 12–400-ms range, corresponding to both T 21 and T 22 relaxation times. The temperature dependency of the rate of reactions, measured by B values, was similar to that previously found for shear resistance and changes in the lipid fraction, mainly phospholipid hydrolysis, that are well documented to be related to sensory quality for this species. Accordingly, we suggest that this methodology has a great potential to estimate frozen storage time and temperature which, in turn, could be related to the quality of lean fish flesh under commercially relevant conditions.

References

Afifi, A. A., & Clark, V. (1984). Computer-aided multivariate analysis. Belmont: Lifetime Learning Publications.

Aursand, I. G., Gallart-Jornet, L., Erikson, U., Axelson, D. E., & Rustad, T. (2008). Water distribution in brine salted cod (Gadus morhua) and Salmon (Salmo salar): a low-field 1H NMR study. Journal of Agricultural and Food Chemistry, 56(15), 6252–6260.

Aursand, I. G., Veliyulin, E., Bocker, U., Ofstad, R., Rustad, T., & Erikson, U. (2009). Water and salt distribution in Atlantic salmon (Salmo salar) studied by low-field 1H NMR, 1H and 23Na MRI and light microscopy: effects of raw material quality and brine salting. Journal of Agricultural and Food Chemistry, 57(1), 46–54.

Belton, P. S. (2011). Spectroscopic approaches to the understanding of water in foods. Food Reviews International, 27(2), 170–191.

Belton, P. S., Hills, B. P., & Raimbaud, E. R. (1988). The effects of morphology and exchange on proton N.M.R. relaxation in agarose gels. Molecular Physics, 63(5), 825–842.

Bertram, H. C., & Andersen, H. J. (2004). Applications of NMR in meat science. In G. A. Webb (Ed.), Annual reports on NMR spectroscopy (pp. 157–202). San Diego: Elsevier Academic Press Inc.

Bremner, H. A. (2000). Toward practical definitions of quality for food science. Critical Reviews in Food Science and Nutrition, 40(1), 83–90.

Bremner, H. A., Olley, J., & Vail, A. M. A. (1987). Estimating time-temperature effects by a rapid systematic sensory method. In D. E. Kramer & J. Liston (Eds.), Seafood quality determination, Proceedings of an International Symposium Coordinated by the University Of Alaska Sea Grant College Program, Anchorage, Alaska, U.S.A. 10–14 November 1986 (pp. 413–435). Amsterdam: Elsevier Science Publishers B.V.

Careche, M., Carmona, P., & Sánchez-Alonso, I. (2014). Monitoring the time and temperature history of frozen hake (Merluccius merluccius, L.) muscle by FTIR spectroscopy of the lipid fraction. Food and Bioprocess Technology. doi:10.1007/s11947-014-1386-7.

Careche, M., & Tejada, M. (1990). The effect of neutral and oxidized lipids on functionality in hake (Merluccius merluccius L.): a dimethylamine and formaldehyde forming species during frozen storage. Food Chemistry, 36(2), 113–128.

Cheng, J.-H., Dai, Q., Sun, D.-W., Zeng, X.-A., Liu, D., & Pu, H.-B. (2013). Applications of non-destructive spectroscopic techniques for fish quality and safety evaluation and inspection. Trends in Food Science and Technology, 34, 18–31.

Erikson, U., Standal, I. B., Aursand, I. G., Veliyulin, E., & Aursand, M. (2012). Use of NMR in fish processing optimization: a review of recent progress. Magnetic Resonance in Chemistry, 50(7), 471–480.

Erikson, U., Veliyulin, E., Singstad, T. E., & Aursand, M. (2004). Salting and desalting of fresh and frozen-thawed cod (Gadus morhua) fillets: a comparative study using 23Na NMR, 23Na MRI, low-field 1H NMR, and physicochemical analytical methods. Journal of Food Science, 69(3), 107–114.

Fu, B., & Labuza, T. P. (1993). Shelf-life prediction: theory and application. Food Control, 4(3), 125–133.

Gudjónsdóttir, M., Arason, S., & Rustad, T. (2011). The effects of pre-salting methods on water distribution and protein denaturation of dry salted and rehydrated cod—a low-field NMR study. Journal of Food Engineering, 104, 23–29.

Gudjónsdóttir, M., Karlsdóttir, M. G., Arason, S., & Rustad, T. (2013). Injection of fish protein solutions of fresh saithe (Pollachius virens) fillets studied by low field nuclear magnetic resonance and physicochemical measurements. Journal of Food Science & Technology, 50(2), 228–238.

Haard, N. F. (1992). Biochemical reactions in fish muscle during frozen storage. In E. G. Bligh (Ed.), Seafood science and technology (pp. 176–209). Canada: Fishing News Books, Blackwell Scientific Publications.

Heia, K., Esaiassen, M., Nilsen, H., & Sigernes, F. (2003). Visible spectroscopy—evaluation of storage time of ice stored cod and frozen hake. In J. B. Luten, J. Oehlenschläger, & G. Ólafsdóttir (Eds.), Quality of fish from catch to consumer: labelling, monitoring and traceability (pp. 201–209). The Netherlands: Wageningen Academic Publishers.

Herrero, A. M., & Careche, M. (2005). Stress-relaxation test to evaluate textural quality of frozen stored Cape hake (M. capensis and M. paradoxus). Food Research International, 38(1), 69–76.

Herrero, A. M., & Careche, M. (2006). Prediction of frozen storage time of Cape hake (Merluccius capensis and Merluccius paradoxus) by instrumental methods. Journal of the Science of Food and Agriculture, 86(13), 2128–2133.

Herrero, A. M., Huidobro, A., & Careche, M. (2003). Development of a quality index method for frozen hake (M. capensis and M. paradoxus). Journal of Food Science, 68(3), 1086–1092.

Hills, B. P., Takacs, S. F., & Belton, P. S. (1989). The effects of proteins on the proton N.M.R. transverse relaxation time of water. II. Protein aggregation. Molecular Physics, 67(4), 919–937.

Jorgensen, B. M., Oehlenschläger, J., Olafsdóttir, G., Tryggvadóttir, S. V., Careche, M., Heia, K., Nesvadba, P., Nunes, M. L., Poli, B. M., Natale, C. D., Pérez-Villarreal, B., Ballo, H., Luten, J. B., Smelt, A. J., Denton, W., Bossier, P., Hattula, T., & Akesson, G. (2003). A study of the attitudes of the European fish sector towards quality monitoring and labelling. In B. Luten, J. Oehlenschläger, & G. Olafsdóttir (Eds.), Quality of fish from catch to consumer: labelling, monitoring and traceability (pp. 57–74). The Netherlands: Wageningen Academic Publishers.

Kong, F., Tang, J., Rasco, B., & Crapo, C. (2007). Kinetics of salmon quality changes during thermal processing. Journal of Food Engineering, 83(4), 510–520.

Labuza, T. P. (1984). Application of chemical-kinetics to deterioration of foods. Journal of Chemical Education, 61(4), 348–358.

Mackie, I. M. (1997). The effects of post-mortem storage on fish muscle proteins. In G. Olafsdóttir, J. Luten, P. Dalgaard, M. Careche, V. Verrez-Bagniz, E. Martinsdóttir, & K. Heia (Eds.), Methods to determine de freshness of fish in research and industry. Proceedings of the final meeting of the Concerted Action “Evaluation of Fish Freshness” AOR3CT94 2283, Nantes, November 12-14, 1997 (pp. 185–189). Paris: International Institute of Refrigeration.

Pearce, K. L., Rosenvold, K., Andersen, H. J., & Hopkins, D. L. (2011). Water distribution and mobility in meat during the conversion of muscle to meat and ageing and the impacts on fresh meat quality attributes—a review. Meat Science, 89, 111–124.

Peleg, M., Engel, R., Gonzalez-Martinez, C., & Corradini, M. G. (2002). Non-Arrhenius and non-WLF kinetics in food systems. Journal of the Science of Food and Agriculture, 82, 1346–1355.

Provencher, S. W. (1982a). A constrained regularization method for inverting data represented by linear algebraic or integral-equations. Computer Physics Communications, 27(3), 213–227.

Provencher, S. W. (1982b). CONTIN: a general-purpose constrained regularization program for inverting noisy linear algebraic and integral-equations. Computer Physics Communications, 27(3), 229–242.

Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers.

Regulation (EU) No 1379/2013 of the European Parliament and of the Council of 11 December 2013 on the common organisation of the markets in fishery and aquaculture products.

Sánchez-Alonso, I., Martínez, I., Sánchez-Valencia, J., & Careche, M. (2012). Estimation of freezing storage time and quality changes in hake (Merluccius merluccius, L.) by low field NMR. Food Chemistry, 135(3), 1626–1634.

Sánchez-Alonso, I., Moreno, P., & Careche, M. (2014). Low field NMR relaxometry in hake (Merluccius merluccius, L.) muscle after different freezing and storage conditions. Food Chemistry, 153, 250–257.

Sánchez-Valencia, J., Sánchez-Alonso, I., Martínez, I., & Careche, M. (2014). Estimation of frozen storage time or temperature by kinetic modeling of the Kramer shear resistance and water holding capacity (WHC) of hake (Merluccius merluccius, L.) muscle. Journal of Food Engineering, 120, 37–43.

Steen, C., & Lambelet, P. (1997). Texture changes in frozen cod mince measured by low-field nuclear magnetic resonance spectroscopy. Journal of the Science of Food and Agriculture, 75(2), 268–272.

Taoukis, P. S., Labuza, T. P., & Saguy, I. S. (1997). Kinetics of food deterioration and shelf-life prediction. In K. J. Valentas, E. Rotstein, & R. D. Singh (Eds.), The handbook of food engineering practice (pp. 2–75). New York: CRC Press.

Tsironi, T., Dermesonlouoglou, E., Giannakourou, M., & Taoukis, P. (2009). Shelf life modelling of frozen shrimp at variable temperature conditions. LWT - Food Science and Technology, 42(2), 664–671.

Van Boekel, M. A. J. S. (2008). Kinetic modeling of food quality: a critical review. Comprehensive Reviews in Food Science and Food Safety, 7(1), 144–158.

Zhang, L., Li, X., Lu, W., Shen, H., & Luo, Y. (2011). Quality predictive models of grass carp (Ctenopharyngodon idellus) at different temperatures during storage. Food Control, 22(8), 1197–1202.

Acknowledgments

This work was financed by the Spanish Ministry of Economy and Competitiveness (AGL2007-65661 and AGL2009-12485-C03-01). Isabel Sánchez-Alonso was funded by a Juan de la Cierva postdoctoral contract and Javier Sánchez-Valencia by a FPI predoctoral fellowship from the same Ministry. Thanks are due to Ms. Pilar Moreno for her excellent technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sánchez-Valencia, J., Sánchez-Alonso, I., Martinez, I. et al. Low-Field Nuclear Magnetic Resonance of Proton (1H LF NMR) Relaxometry for Monitoring the Time and Temperature History of Frozen Hake (Merluccius merluccius L.) Muscle. Food Bioprocess Technol 8, 2137–2145 (2015). https://doi.org/10.1007/s11947-015-1569-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1569-x