Abstract

In general, vinification of sound grapes is an essential requirement for the production of high-quality wines. Grape rot, mainly caused by filamentous fungi, commonly impairs perceptual quality of wine; food safety may be affected due to the formation of biogenic amines and mycotoxins. Grape rot assessment by visual examination, taste or smell remains subjective. Other methods for grape rot quantification frequently lack specify, sensitivity or reproducibility. In contrast, ergosterol represents an objective and specific marker for filamentous fungal grape rot. In our study, we approved the suitability of ergosterol as a marker for grape rot of commercially harvested grapes, delivered to wineries under normal operating conditions. A total of 177 grape samples from five grape varieties was analysed by HPLC-UV for ergosterol content. Pinot Meunier showed the highest ergosterol contents up to 11.4 mg/kg. Mean ergosterol content for all varieties amounted to 2.3 mg/kg. About 20 % of the samples exceeded the limit of 3.0 mg/kg for sound grapes, and about 3.4 % were above the limit of 6.2 mg/kg indicating rotten grapes. Moreover, near-infrared/visible (NIR/VIS) spectroscopy has been applied as a rapid tool for online determination of ergosterol under industrial conditions. Calibration models were established and validated. Validation statistics for a dependent test set were coefficient of determination of the validation (R 2 val) of 0.726, root mean square error of prediction (RMSEP) of 0.84 mg/kg and ratio of prediction to deviation (RPD) of 2.0. At least semi-quantitative measurements of ergosterol in grape mashes upon delivery at wineries appeared feasible, thus enabling the objective detection of grape rot. Thereby, fair and incentive quality-based payment may be enabled; quality management and food safety may be improved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Grape rot impairs perceptual quality due to the formation of e.g. musty, earthy and fresh mushroom-like off-flavours (Rousseaux et al. 2014; Steel et al. 2013). Grape rot may also cause bitter taste (Ribéreau-Gayon et al. 2006; Walter 2012), and desirable varietal aroma may be degraded (Scott et al. 2010). Additionally, browning in all and colour loss in red varieties is elicited (Scott et al. 2010). The microbial formation of mycotoxins and biogenic amines is a major food safety concern due to their health-affecting human toxicity (Flamini and Larcher 2008). Mycotoxins, including ochratoxin A (OTA), which is one of the most potent mycotoxins toxic to humans, are formed by grape-associated moulds (Rousseaux et al. 2014; Somma et al. 2012). Furthermore, fungal grape rot has also been reported to produce elevated levels of biogenic amines (Kiss et al. 2006).

Visual assessment and tasting are commonly applied in industrial practice for grape quality determination but suffer from being subjective. Visual assessment is particularly challenging for machine-harvested grapes (Dewey and Meyer 2004; Gishen et al. 2010; Stummer et al. 2006). Besides metabolites of microorganisms commonly applied for indicating grape bunch rot, several alternative parameters have been proposed. Laccase is secreted by various grape rotting fungi; however, the relationship between grape rot and laccase activity may be ambiguous (Dewey et al. 2008; Lorenzini et al. 2013). Indication of fungal contaminations by chitin lacks specify, sensitivity and reproducibility (Gourama and Bullerman 1995; Pitt and Hocking 2009). Adenosine triphosphate (ATP) content indicates metabolic activity but occurs ubiquitously in all living cells (Gourama and Bullerman 1995). Quantitative polymerase chain reaction (qPCR) is generally highly sensitive and specific for the detection and quantification of specific organisms (Saito et al. 2013; Sanzani et al. 2012; Stummer et al. 2006), however, inapplicable for the detection of universal fungal spoilage. Commonly used conventional plate count techniques are time-consuming and restricted to the detection of viable fungi (Gourama and Bullerman 1995). Howard mould count (HMC) is a microscopic method developed for the detection of fungal rot, especially in tomato products, but remains subjective (Jay et al. 2005; Kadakal and Artık 2004).

Ascomycetes, to which the relevant grape rot fungi entirely belong, exhibit ergosta-5,7,22-trien-3β-ol (ergosterol) (Fig. 1) as the major sterol. Ergosterol is essential for growth of fungi and yeasts that synthesise it, while it is completely or virtually absent in plants, animals and bacteria (Weete et al. 2010; Weete and Gandhi 1996; Czub and Baginski 2006). However, the occurrence of ergosterol cannot be directly related to an infection of vine powdery mildew (Erysiphe necator Schw.), accumulating ergosta-5,24(28)-dien-3β-ol (24-methylene cholesterol) instead of ergosterol (Debieu et al. 1995; Loeffler et al. 1992). Downy mildew (Plasmopara viticola Berk. & M.A. Curtis) does not synthesise any of the mentioned steroids but rather appears to be fully dependent on sterol biosynthesis of its host (Nes 1987; Mikes et al. 1997). Thus, the detection of downy mildew via sterol determination might be impractical.

Ergosterol has been suggested for the determination of fungal contamination in matrices similar to grapes such as tomato products (Battilani et al. 1996; Kadakal et al. 2004; de Sio et al. 2000; Porretta 1995) and apple juice (Kadakal et al. 2005). Recently, ergosterol has been proven to be a suitable and objective phytosanitary marker for fungal grape rot (Porep et al. 2014b).

Additionally, ergosterol has often been suggested as a readily measurable indicator of mycotoxins in agricultural commodities like grains (Abramson et al. 2005; Moretzsohn de Castro et al. 2002; Olsson et al. 2002; Pietri et al. 2004; Saxena et al. 2001), dried figs (Karaca and Nas 2006), apple juice (Kadakal et al. 2005) and hazelnuts (Ekinci et al. 2014).

Near-infrared (NIR) spectroscopy represents an advantageous technique because of low running costs and the needlessness of sample preparation. Due to the latter, it allows non-destructive, environmentally friendly and rapid measurements. Ultimately, it is capable for online applications (Nicolaï et al. 2007; Woodcock et al. 2008; Williams 2008). Thus, NIR spectroscopic online applications meet the requirements of modern viticultural industry for highly desired rapid quality assessment of grapes delivered to the winery (Bauer et al. 2008; Cozzolino et al. 2011a).

The NIR region covers wavelengths from 780 to 2500 nm. The most predominant absorption bands in NIR spectra of biological samples originate from overtones and combinations of fundamental vibrations of C–H, N–H, O–H and S–H bonds in organic molecules (Sandorfy et al. 2007; Blanco and Villarroya 2002). Unfortunately, NIR bands are usually broad and severely overlapped. Therefore, assignment of NIR bands is mostly difficult (Ozaki et al. 2007), although representing a ‘fingerprint’ of the chemical composition and comprising information of the physical properties of the investigated sample (Siesler 2008). Multivariate calibration is therefore applied in order to extract analytical information from the spectra and find quantitative relationships between the recorded spectra and the results determined by conventional techniques. The calibration model obtained may be applied to accurately predict the desired parameters in unknown samples using the rapid NIR method, therefore replacing the conventional method (Heise and Winzen 2002; Næs et al. 2002; Herold et al. 2009).

The successful application of NIR spectroscopy for ergosterol detection has previously been reported for red pepper (Kim et al. 2003), barley (Börjesson et al. 2007), maize (Berardo et al. 2005), soil (Rinnan and Rinnan 2007; Terhoeven-Urselmans et al. 2008) and leaf litter (Mancinelli et al. 2014). Particularly, NIR spectroscopy has previously been proven to be applicable for the prediction of ergosterol contents of grape mashes, i.e. crushed grapes (Porep et al. 2014a). Moreover, promising results for online applications under industrial conditions for holistic grape quality assessments were reported (Porep et al. 2015). However, the online prediction of ergosterol in grapes has not been investigated so far.

In the present study, we aimed at confirming the validity of ergosterol as a grape rot indicator for commercially harvested grapes delivered to wineries under normal operating conditions. Additionally, calibration experiments for the prediction of the ergosterol content of the corresponding grape mashes by online NIR spectroscopy under industrial conditions at wineries should be conducted.

Materials and Methods

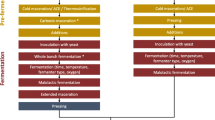

Measurements by Near-Infrared/Visible Spectroscopy

Industrial near-infrared/visible (NIR/VIS) spectrometers, Process Analyser X-Three (NIR-Online, Walldorf, Germany), were used for online spectra collection. They were integrated into the grape reception line at the wineries in a bypass pipe of the mash-collecting tank after passing the de-stemmer/crusher and the weighing container. Grape mash was pumped in a loop through the bypass pipe back into the collecting tank (see also Porep et al. (2015)). Crushed and blended grapes represented a homogeneous sample material at this stage. Spectra acquisition was performed in reflectance mode with a scanning range of 400–1800 nm in 10 nm intervals using a photodiode array detector (PAD) comprising a Si detector for the VIS and an InGaAs detector for the NIR range, respectively. Spectra were stored as the average of a 15 s measurement period with an exposure of 30 ms per single spectrum. Instrument internal black and white references were used for automatic balancing. Data acquisition was performed using the software SX-Center Version 2.9.0.53 (NIR-Online).

Samples

Samples were commercially harvested grapes, delivered to wineries under normal operating conditions. No classification or preselection of the samples according to the severity or type of rot before sampling was performed in order to obtain samples typical for authentic industrial practice. Representative grape mash samples (approximately 1 kg) for reference analyses were taken from the grape reception line right after the mash passed the NIR/VIS spectrometer (see section “Measurements by Near-Infrared/Visible Spectroscopy”) by drawing them from the bypass pipe prior to pumping the mash back into the collecting tank. Subsequently, they were preserved by the addition of 200 mg sodium azide (NaN3) and immediately stored at −20 °C until further analyses. Samples and corresponding spectra were unambiguously labelled with a time stamp. Recording of the NIR/VIS spectra was performed at the two winemaking cooperatives, Genossenschaftskellerei Heilbronn-Erlenbach-Weinsberg (Heilbronn, Germany) and Winzergenossenschaft Weinbiet (Neustadt-Mußbach, Germany), located in two distinct wine-growing regions, namely Württemberg and Pfalz (Palatinate), respectively. In total, spectra of 177 grape mash samples of vintage 2013 were collected online, and the corresponding reference analysis of ergosterol was carried out using HPLC-UV. Total samples can be subdivided by colour, comprising white (n = 76) and red varieties (n = 101); by growing area/winery, namely Heilbronn (n = 163) and Neustadt-Mußbach (n = 14) and by varieties, consisting of Müller-Thurgau (n = 45), Dornfelder (n = 34), Riesling (n = 31), Pinot Meunier (Schwarzriesling) (n = 31), Trollinger (n = 23) and Lemberger (n = 13). For the samples and spectra of the vintage 2010–2012 collected offline, used for some calibration models considered, see Porep et al. (2014a).

Reagents

Reagents and solvents purchased from Merck (Darmstadt, Germany) were at least of analytical or HPLC grade unless otherwise specified. Ultrapure water, generated by an ultrapure water system (Millipore Milli-Q, Billerica, MA, USA), was used throughout.

Reference Analyses of Ergosterol

Samples for the reference analyses were prepared as described by Porep et al. (2014b). The HPLC method for ergosterol determination as described by Seitz et al. (1977) and Seitz et al. (1979) was adopted according to Schwadorf and Müller (1989) and Ghiretti et al. (1995) with slight modifications. Briefly, for ergosterol extraction, 20 g of homogenised grape mash were weighed into a 250 mL round-bottom flask. For saponification, 75 mL methanol, 50 mL ethanol 96 % (v/v) denatured with methyl ethyl ketone (MEK; Brüggemann Alcohol, Heilbronn, Germany) and 10 g potassium hydroxide (KOH) were added. The mixture was heated in a heating mantle (G2 250, Heraeus Wittmann, Heidelberg, Germany) and refluxed with a Dimroth condenser for 30 min under continuous stirring with a magnetic stirrer (RCO 23403, IKA-Werke, Staufen, Germany). After cooling, the suspension was filtered (No. 1, Whatman, Little Chalfont, UK), rinsing the flask and washing the filter once with 25 mL methanol. The resulting filtrate was transferred to a 250 mL separation funnel, and 25 mL ultrapure water was added to rinse the Büchner flask. Ergosterol was twice extracted from the alcoholic phase with 50 mL n-hexane. The upper organic layers were combined and filtered over anhydrous sodium sulphate (Na2SO4) through a pleated filter (MN 615 ¼, Macherey-Nagel, Düren, Germany), rinsing once with 5 mL hexane. Hexane was evaporated to dryness under reduced pressure, and the residue was dissolved in 5 mL methanol assisted by ultrasonication. The solution was membrane-filtered (0.45 μm, Chromafil RC-45/15MS, Macherey-Nagel, Düren, Germany) into a vial. Subsequent HPLC analysis was performed on a Dionex UltiMate 3000 HPLC System (Dionex, Idstein, Germany) equipped with a diode array detector and the Chromeleon software (Version 6.80). The column (Luna 5 μ C18, 100 A, 250 × 4.6 mm, 5 μm, Phenomenex, Aschaffenburg, Germany) was maintained at 25 °C. The injection volume was 25 μL. The mobile phase consisted of acetonitrile/water 80:20 (v/v), isocratically applied at a flow rate of 0.8 mL/min. Ergosterol was monitored at 282 nm. Retention time of ergosterol was about 20.1 min. Total run time was 40 min for equilibration and purging of the column. External calibration was conducted with an authentic ergosterol standard (>95 % (HPLC), Sigma-Aldrich, Steinheim, Germany). Stock solution was prepared by dissolving 500 mg/L of ergosterol in methanol assisted by ultrasonication and gentle warming. Working standard solutions for calibration were prepared therefrom by diluting in methanol resulting in concentrations of 0.5, 1.0, 2.0, 4.0, 7.5, 15.0, 30.0, 62.5, 125.0 and 250.0 mg/L.

Limit of detection (LOD) and limit of quantification (LOQ) were calculated from the signal-to-noise ratio of 3 and 9 determined from the baseline noise in a blank run and amounted to 0.006 and 0.019 mg/kg, respectively. The standard error of the laboratory (SEL) (Workman 2008) amounted to 0.08 mg/kg.

Both extractions and HPLC analyses were carried out in duplicate. Statistical evaluation of the ergosterol reference analysis of the grape mash samples for defined vintages used for NIR spectroscopic calibration and validation is shown in Table 1.

Chemometrics and Data Analysis

Statistical analysis of the HPLC data was performed using XLStat (Version 2011.1.05, Addinsoft, Paris, France). Tukey’s honestly significant difference at 0.05 level (HSD0.05) test was used to identify groups showing significant differences among the samples.

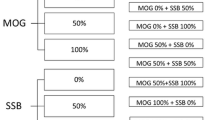

Processing of the spectral data and building of the calibration models were carried out with the software SX-Plus Version 2.10 (NIR-Online, Walldorf, Germany). Noisy edge regions were avoided by narrowing the VIS and NIR region to 450–850 and 1050–1650 nm, respectively. Partial least squares (PLS) regression was applied as regression method being commonly used (Næs et al. 2002). For the validation with a separate dependent test set, the entire sample set was divided into two thirds for calibration and one third solely used for validation. In general, the first sample was selected for validation and the remaining two for calibration per group of three samples in the chronological order of spectra collection. Moreover, the data structure of the entire dataset was divided into one sub-dataset per vintage and growing area/winery, respectively, resulting in eight sub-datasets. If the selection procedure led to minimal or maximal values of a sub-dataset contained in the validation set, these samples were relocated from the validation to the calibration set. Thus, extreme values were avoided to be contained in the validation. Calibration and the predictive ability of the model were assessed based on the coefficient of determination (R 2), the root mean square error of calibration (RMSEC), the root mean square error of cross-validation (RMSECV), the root mean square error of prediction (RMSEP) (Næs et al. 2002) and the ratio of prediction to deviation (RPD) being the standard deviation (SD) of the reference values of the entire sample set of the respective calibration and validation divided by the standard error of cross-validation or prediction (SD/RMSECV or RMSEP) (Cozzolino et al. 2011b; Herold et al. 2009). The limit of PLS factors was set to 20. The criterion used for the final factor selection was to find the first lower number of factors where the RMSECV or RMSEP is less than 5 % higher than its successor and less than 10 % higher than the minimum residual. Automatic outlier detection performed removed any samples from the calibration data with a standardised error greater than 2.5, any sample from the calibration and validation data with a Mahalanobis distance greater than 5 and any samples from the validation data with a standardised residual exceeding 3.5. Deletion and recalibration processes were repeated until no further samples were deleted.

Results and Discussion

Results of ergosterol analyses are shown in Fig. 2. The highest ergosterol contents (mean: 3.1 mg/kg, maximum: 11.4 mg/kg) were found in Pinot Meunier, a variety being prone to microbial infection (Kast et al. 2004). In addition, Riesling and Müller-Thurgau exhibited relatively high ergosterol contents. This is most probably due to their characteristic density of grape clusters, which also favour infections (Molitor and Evers 2012). The lowest contents on average were found in Dornfelder and Lemberger, with Dornfelder showing significantly (p < 0.05) lower values than Pinot Meunier. Dornfelder is rich in polyphenols, namely anthocyanins, which may prevent its grapes from mould infections (Liu et al. 2010; Ky et al. 2012). According to ANOVA (Tukey’s HSD0.05 test), all other varieties did not show any significant differences regarding their ergosterol content.

Tentative thresholds of below 3.0 mg/kg and above 6.2 mg/kg ergosterol for sound and rotten grapes, respectively, have been derived from glycerol values suggested by Sturm (2009) due to the high correlation of the ergosterol and glycerol content (Porep et al. 2014b). In our study, 36 samples (20.3 %) showed ergosterol contents between 3.0 and 6.2 mg/kg. In total, six samples (3.4 %) had ergosterol contents above 6.2 mg/kg. Thus, from a phytosanitary point of view, nearly a quarter of the grape samples under investigation may be considered as conspicuous or definitely rotten by moulds. This observation is in agreement with the anecdotal report of the infection rate of vintage 2013, which was purely visually determined (A. Maier, Genossenschaftskellerei Heilbronn, pers. communication).

Statistical analysis revealed good correlation of ergosterol with both glycerol (R 2 = 0.876) and gluconic acid (R 2 = 0.708) (data not shown). The correlation for glycerol confirmed earlier findings (R 2 = 0.911), while the correlation with gluconic acid was much higher than previously determined (Porep et al. 2014b). These metabolites are also indicators of mould infestations; thus, their correlation with ergosterol is not surprising (Zanardi et al. 2013; Cetó et al. 2011).

Spectral Properties

The mean spectrum and the SD spectrum of all samples are shown in Fig. 3. In the VIS range, spectra are essentially influenced by pigments contained in grape berries, namely chlorophyll a and b, carotenoids and anthocyanins. The highest SD observed at around 550 nm may be ascribed to the latter (Agati et al. 2007), which was to be expected because both white and red varieties were included in the sample set. High SD near 740 nm can be ascribed to water combination bands, but C–H and other O–H groups influence this area as well. In the NIR range considered, absorption bands referring to O–H bonds of water, aliphatic alcohols and phenols; C–H bonds of aliphatic and aromatic hydrocarbons and N–H bonds of (aromatic) amines and amides are generally predominant (Workman and Weyer 2008). As expected for the highly water containing grape mashes, the spectra were dominated by the water band at 1440 nm (first overtone of the O–H stretch) (Bokobza 2002). Moreover, further O–H bands, e.g. of sugars, N–H bands, e.g. of proteins, and C–H bands are also related to this area. The adjoining part of the broad peak up to 1600 nm is generally attributed to the first overtone of the hydroxyl group of hydrogen-bonded alcohols but as well as to various other O–H, C–H and N–H groups. Further marked local maxima were observed at around 1100 nm (possibly the second overtone of the terminal methylene C–H stretch) and 1200 nm (possibly second overtones of C–H stretching and O–H combination bands of water) (Workman and Weyer 2008). Additionally, spectral variation could be observed at similar bands in the PLS loading plots of the PLS factors of the NIR/VIS model comprising the vintage 2013 with a dependent test set (Fig. 4). Comparable spectral properties were reported by other authors for intact grape berries (Ferrer-Gallego et al. 2011; González-Caballero et al. 2010) and grape homogenates (Janik et al. 2007).

Mean spectrum (solid line) (calculated from the arithmetic mean of each wavelength) and standard deviation spectrum (dashed line) (calculated from the standard deviation of each wavelength, upscaled by factor 10) of the online recorded near-infrared/visible (NIR/VIS) spectra of vintage 2013 (n = 177)

Calibration Experiments

The results of different calibration models tested are shown in Table 2. The models relying on online recorded spectra of the combined NIR and VIS range were used as reference for the vintage 2013, like in our previous study (Porep et al. 2014a). Model performance was evaluated from the coefficient of determination of the calibration (R 2 cal), the RMSEC, the coefficient of determination of the cross-validation (R 2 CV), the RMSECV, the coefficient of determination of the validation (R 2 val), the RMSEP and RPD, respectively. The number of factors (latent variables) used for the model should minimise RMSECV or RMSEP. In case of insufficient number of factors, not all relevant information are covered, leading to underfitted, suboptimal calibration models. Contrarily, using too many factors goes along with redundancies and noise of the spectral variability within the calibration equation. Hence, the model becomes overfitted, thus being strongly data dependent with poor prediction results. Therefore, smaller numbers of factors together with approximately the same prediction error are favourable (Næs et al. 2002; Blanco Romía and Alcalà Bernàrdez 2009).

The NIR/VIS calibration for the vintage 2013 with a separate dependent test set resulted in an R 2 val of 0.726, an RMSEP of 0.84 and an RPD of 2.0. Predictive performance with R 2 val values between 0.7 und 0.8 and a RPD value of about 2 are considered to be suitable for semi-quantitative predictions or rough estimations (Nicolaï et al. 2007). Further details about the data distribution of the calibration und validation are shown in Fig. 5. A leave-one-out full cross-validation of the same dataset showed a similar performance (Table 2). According to the number of PLS factors of the calibration models, the usage of the NIR region alone, in contrast to the addition of the VIS region as well, resulted in simpler models exhibiting similar performance (Table 2). Such models may be more robust on one hand; but on the other hand, valuable information may get lost. This has to be taken into consideration for future calibration models.

Combination of the dataset of the offline measurements and the online measurements of the vintages 2010–2013 showed similar or even better results (Table 2), with, e.g. R 2 val = 0.735 and RPD = 2.1 for the NIR/VIS model with the dependent test set, but showed a higher RMSEP of 3.66 mg/kg. These findings are in accordance with the wider distribution and higher variance of the ergosterol levels of the respective samples. Moreover, compared to the offline calibration (2010–2012), with R 2 val = 0.851, RMSEP = 3.61 mg/kg and RPD = 2.72 (Porep et al. 2014a), the RMSEP reached was almost the same, and R 2 val and RPD indicated a lower performance, which, again, was in accordance with the data distribution with more samples of lower ergosterol values.

Prediction of the online measured values (2013) as an independent test set with the offline data (2010–2012) used for calibration did not perform satisfactory (data not shown). Hence, the calibration with the offline data appeared not to cover the necessary variance for a robust calibration reliably predicting these samples.

Deleting 10 and 11 % of the samples as outliers for NIR/VIS models of the vintage 2013 with dependent test set and full cross-validation, respectively, did not lead to significant model improvement (Table 2). Although the errors were lowered (RMSEP = 0.60 mg/kg and RMSECV = 0.52 mg/kg), the R 2 and RPD were just slightly improved with R 2 val = 0.850 and RPD = 2.0 for the dependent test set and R 2 CV = 0.844 and RPD = 2.2 for the full cross-validation, respectively. However, elimination of outliers may omit valuable information for a robust calibration model necessary for reliable sample prediction.

Some other studies about the determination of ergosterol in plant foodstuffs have been reported. The best predictive ability observed in a model for predicting the ergosterol content in maize meal showed an R 2 cal of 0.81 and a standard error of prediction (SEP) of 1.74 mg/kg (Berardo et al. 2005). For barley samples, the best performance reported was R 2 CV = 0.83 and RMSECV = 4.5 mg/kg (Börjesson et al. 2007). In red pepper powders, SEP = 7.7 mg/kg and R 2 val = 0.63 has been reported (Kim et al. 2003).

Conclusion

The suitability of ergosterol as an objective indicator of grape rot in commercial grape mashes has been verified. Moreover, the feasibility of ergosterol prediction under normal industrial operating conditions at wineries by online NIR/VIS spectroscopy has been confirmed. The performance achieved has been demonstrated to be appropriate for at least semi-quantitative ergosterol determinations, thus allowing the detection of conspicuous grape deliveries and a holistic quality assessment when considering further parameters. Objective detection of grape rot may be used for objective quality control and management in viticulture. Therefore, it may serve as a basis for improving the perceptive quality and food safety of wines. Based on the proposed methodology, fair and incentive pricing as well as the definition of threshold values for the rejection of rotten grape lots prior to their processing may be established.

References

Abramson, D., Hulasare, R., York, R. K., White, N., & Jayas, D. S. (2005). Mycotoxins, ergosterol, and odor volatiles in durum wheat during granary storage at 16 % and 20 % moisture content. Journal of Stored Products Research. doi:10.1016/j.jspr.2003.11.002.

Agati, G., Meyer, S., Matteini, P., & Cerovic, Z. G. (2007). Assessment of anthocyanins in grape (Vitis vinifera L.) berries using a noninvasive chlorophyll fluorescence method. Journal of Agricultural and Food Chemistry. doi:10.1021/jf062956k.

Battilani, P., Chiusa, G., Cervi, C., Trevisan, M., & Ghebbioni, C. (1996). Fungal growth and ergosterol content in tomato fruits infected by fungi. Italian Journal of Food Science, 8(4), 283–289.

Bauer, R., Nieuwoudt, H., Bauer, F. F., Kossman, J., Koch, K. R., & Esbensen, K. H. (2008). FTIR spectroscopy for grape and wine analysis. Analytical Chemistry, 80(5), 1371–1379.

Berardo, N., Pisacane, V., Battilani, P., Scandolara, A., Pietri, A., & Marocco, A. (2005). Rapid detection of kernel rots and mycotoxins in maize by near-infrared reflectance spectroscopy. Journal of Agricultural and Food Chemistry. doi:10.1021/jf0512297.

Blanco, M., & Villarroya, I. (2002). NIR spectroscopy: a rapid-response analytical tool. TrAC Trends in Analytical Chemistry. doi:10.1016/S0165-9936(02)00404-1.

Blanco Romía, M., & Alcalà Bernàrdez, M. (2009). Multivariate calibration for quantitative analysis. In D.-W. Sun (Ed.), Infrared spectroscopy for food quality analysis and control (pp. 51–82). Amsterdam: Elsevier/Academic Press.

Bokobza, L. (2002). Origin of near-infrared absorption bands. In H. W. Siesler, Y. Ozaki, S. Kawata, & H. M. Heise (Eds.), Near-infrared spectroscopy: Principles, instruments, applications (pp. 11–41). Weinheim: Wiley-VCH.

Börjesson, T., Stenberg, B., & Schnürer, J. (2007). Near-infrared spectroscopy for estimation of ergosterol content in barley: a comparison between reflectance and transmittance techniques. Cereal Chemistry. doi:10.1094/CCHEM-84-3-0231.

Cetó, X., Céspedes, F., Capdevila, J., & del Valle, M. (2011). A new amperometric bienzymatic biosensor based on biocomposites for the determination of gluconic acid in wines. Talanta. doi:10.1016/j.talanta.2011.05.047.

Cozzolino, D., Cynkar, W., Shah, N., & Smith, P. (2011a). Technical solutions for analysis of grape juice, must, and wine: the role of infrared spectroscopy and chemometrics. Analytical and Bioanalytical Chemistry. doi:10.1007/s00216-011-4946-y.

Cozzolino, D., Cynkar, W. U., Shah, N., & Smith, P. (2011b). Multivariate data analysis applied to spectroscopy: potential application to juice and fruit quality. Food Research International. doi:10.1016/j.foodres.2011.01.041.

Czub, J., & Baginski, M. (2006). Comparative molecular dynamics study of lipid membranes containing cholesterol and ergosterol. Biophysical Journal. doi:10.1529/biophysj.105.072801.

de Sio, F., Laratta, B., Giovane, A., Quagliuolo, L., Castaldo, D., & Servillo, L. (2000). Analysis of free and esterified ergosterol in tomato products. Journal of Agricultural and Food Chemistry. doi:10.1021/jf990475d.

Debieu, D., Corio-Costet, M.-F., Steva, H., Malosse, C., & Leroux, P. (1995). Sterol composition of the vine powdery mildew fungus, Uncinula necator: comparison of triadimenol-sensitive and resistant strains. Phytochemistry. doi:10.1016/0031-9422(95)00015-Y.

Dewey, F., & Meyer, U. (2004). Rapid, quantitative tube immunoassays for on-site detection of Botrytis, Aspergillus and Penicillium antigens in grape juice. Analytica Chimica Acta. doi:10.1016/j.aca.2003.11.088.

Dewey, F. M., Hill, M., & DeScenzo, R. (2008). Quantification of Botrytis and laccase in winegrapes. American Journal of Enology and Viticulture, 59(1), 47–54.

Ekinci, R., Otağ, M., & Kadakal, Ç. (2014). Patulin & ergosterol: new quality parameters together with aflatoxins in hazelnuts. Food Chemistry. doi:10.1016/j.foodchem.2013.10.120.

Ferrer-Gallego, R., Hernández-Hierro, J. M., Rivas-Gonzalo, J. C., & Escribano-Bailón, M. T. (2011). Determination of phenolic compounds of grape skins during ripening by NIR spectroscopy. LWT - Food Science and Technology. doi:10.1016/j.lwt.2010.12.001.

Flamini, R., & Larcher, R. (2008). Grape and wine contaminants: ochratoxin A, biogenic amines, trichloroanisole and ethylphenols. In R. Flamini (Ed.), Hyphenated techniques in grape and wine chemistry (pp. 129–172). Chichester: John Wiley & Sons.

Ghiretti, G. P., Spotti, E., Strina, F., Sandei, L., Mori, G., Attolini, G., et al. (1995). Ergosterol production by different types of moulds able to colonize tomatoes. Industria Conserve, 70, 3–12.

Gishen, M., Cozzolino, D., & Dambergs, R. G. (2010). The analysis of grapes, wine, and other alcoholic beverages by infrared spectroscopy. In E. C. Y. Li-Chan (Ed.), Applications of vibrational spectroscopy in food science (Vol. 2, pp. 539–556). Chichester: John Wiley & Sons.

González-Caballero, V., Sánchez, M.-T., López, M.-I., & Pérez-Marín, D. (2010). First steps towards the development of a non-destructive technique for the quality control of wine grapes during on-vine ripening and on arrival at the winery. Journal of Food Engineering. doi:10.1016/j.jfoodeng.2010.06.016.

Gourama, H., & Bullerman, L. B. (1995). Detection of molds in foods and feeds: potential rapid and selective methods. Journal of Food Protection, 58(12), 1389–1394.

Heise, H. M., & Winzen, R. (2002). Chemometrics in near-infrared spectroscopy. In H. W. Siesler, Y. Ozaki, S. Kawata, & H. M. Heise (Eds.), Near-infrared spectroscopy: Principles, instruments, applications (pp. 125–162). Weinheim: Wiley-VCH.

Herold, B., Kawano, S., Sumpf, B., Tillmann, P., & Walsh, K. B. (2009). VIS/NIR spectroscopy. In M. Zude (Ed.), Optical monitoring of fresh and processed agricultural crops (Contemporary food engineering, pp. 141–249). Boca Raton: CRC.

Janik, L. J., Cozzolino, D., Dambergs, R., Cynkar, W., & Gishen, M. (2007). The prediction of total anthocyanin concentration in red-grape homogenates using visible-near-infrared spectroscopy and artificial neural networks. Analytica Chimica Acta. doi:10.1016/j.aca.2007.05.019.

Jay, J. M., Loessner, M. J., & Golden, D. A. (2005). Modern food microbiology (7th edn, Food science text series). New York: Springer.

Kadakal, Ç., & Artık, N. (2004). A new quality parameter in tomato and tomato products: ergosterol. Critical Reviews in Food Science and Nutrition. doi:10.1080/10408690490489233.

Kadakal, Ç., Tağı, İ., & Artık, N. (2004). Effect of tomato decay proportion on ergosterol level and some tomato pulp properties. Journal of Food Quality. doi:10.1111/j.1745-4557.2004.00631.x.

Kadakal, Ç., Nas, S., & Ekıncı, R. (2005). Ergosterol as a new quality parameter together with patulin in raw apple juice produced from decayed apples. Food Chemistry. doi:10.1016/j.foodchem.2004.03.030.

Karaca, H., & Nas, S. (2006). Aflatoxins, patulin and ergosterol contents of dried figs in Turkey. Food Additives and Contaminants. doi:10.1080/02652030600550739.

Kast, W. K., Fox, R., Schiefer, H. C., Häußer, S., & Weis, M. (2004). Steigerung der Weinqualität bei Schwarzriesling. Rebe und Wein, 57, 22–57.

Kim, S., Park, J., Chun, J. H., & Lee, S. M. (2003). Determination of ergosterol used as a fungal marker of red pepper (Capsicum annuum L.) powders by near-infrared spectroscopy. Food Science and Biotechnology, 12(3), 257–261.

Kiss, J., Korbász, M., & Sass-Kiss, A. (2006). Study of amine composition of botrytized grape berries. Journal of Agricultural and Food Chemistry. doi:10.1021/jf061578g.

Ky, I., Lorrain, B., Jourdes, M., Pasquier, G., Fermaud, M., Gény, L., et al. (2012). Assessment of grey mould (Botrytis cinerea) impact on phenolic and sensory quality of Bordeaux grapes, musts and wines for two consecutive vintages. Australian Journal of Grape and Wine Research. doi:10.1111/j.1755-0238.2012.00191.x.

Liu, H. M., Guo, J. H., Cheng, Y. J., Liu, P., Long, C. A., & Deng, B. X. (2010). Inhibitory activity of tea polyphenol and Hanseniaspora uvarum against Botrytis cinerea infections. Letters in Applied Microbiology. doi:10.1111/j.1472-765X.2010.02888.x.

Loeffler, R. S. T., Butters, J. A., & Hollomon, D. W. (1992). The sterol composition of powdery mildews. Phytochemistry. doi:10.1016/0031-9422(92)83106-9.

Lorenzini, M., Azzolini, M., Tosi, E., & Zapparoli, G. (2013). Postharvest grape infection of Botrytis cinerea and its interactions with other moulds under withering conditions to produce noble-rotten grapes. Journal of Applied Microbiology. doi:10.1111/jam.12075.

Mancinelli, G., Costantini, M. L., & Rossi, L. (2014). Predicting ergosterol in leaf litter by near-infrared spectroradiometry: a preliminary assessment. European Journal of Soil Biology. doi:10.1016/j.ejsobi.2014.05.003.

Mikes, V., Milat, M.-L., Ponchet, M., Ricci, P., & Blein, J.-P. (1997). The fungal elicitor cryptogein is a sterol carrier protein. FEBS Letters. doi:10.1016/S0014-5793(97)01193-9.

Molitor, D., & Evers, D. (2012). Neues Verfahren: Entfernen der Verdichtungszone in kompakten Rieslingtrauben - "Trauben-Bruch". Das Deutsche Weinmagazin, 14, 16–18.

Moretzsohn de Castro, M. F. P., Bragagnolo, N., & de Toledo Valentini, S. R. (2002). The relationship between fungi growth and aflatoxin production with ergosterol content of corn grains. Brazilian Journal of Microbiology. doi:10.1590/S1517-83822002000100004.

Næs, T., Isaksson, T., Fearn, T., & Davies, T. (2002). A user-friendly guide to multivariate calibration and classification. Chichester: NIR Publications.

Nes, W. D. (1987). Biosynthesis and requirement for sterols in the growth and reproduction of oomycetes. In G. Fuller & W. D. Nes (Eds.), Ecology and metabolism of plant lipids (ACS Symposium Series, Vol. 325, pp. 304–328). Washington: American Chemical Society.

Nicolaï, B. M., Beullens, K., Bobelyn, E., Peirs, A., Saeys, W., Theron, K. I., et al. (2007). Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: a review. Postharvest Biology and Technology. doi:10.1016/j.postharvbio.2007.06.024.

Olsson, J., Börjesson, T., Lundstedt, T., & Schnürer, J. (2002). Detection and quantification of ochratoxin A and deoxynivalenol in barley grains by GC-MS and electronic nose. International Journal of Food Microbiology. doi:10.1016/S0168-1605(01)00685-7.

Ozaki, Y., Morita, S., & Du, Y. (2007). Spectral analysis. In Y. Ozaki, W. F. McClure, & A. A. Christy (Eds.), Near-infrared spectroscopy in food science and technology (pp. 47–72). Hoboken: John Wiley & Sons.

Pietri, A., Bertuzzi, T., Pallaroni, L., & Piva, G. (2004). Occurrence of mycotoxins and ergosterol in maize harvested over 5 years in Northern Italy. Food Additives and Contaminants. doi:10.1080/02652030410001662020.

Pitt, J. I., & Hocking, A. D. (2009). Methods for isolation, enumeration and identification. In Fungi and food spoilage (pp. 19–52). Dordrecht: Springer.

Porep, J. U., Erdmann, M. E., Körzendörfer, A., Kammerer, D. R., & Carle, R. (2014a). Rapid determination of ergosterol in grape mashes for grape rot indication and further quality assessment by means of an industrial near infrared/visible (NIR/VIS) spectrometer – a feasibility study. Food Control. doi:10.1016/j.foodcont.2014.03.008.

Porep, J. U., Walter, R., Kortekamp, A., & Carle, R. (2014b). Ergosterol as an objective indicator for grape rot and fungal biomass in grapes. Food Control. doi:10.1016/j.foodcont.2013.09.012.

Porep, J. U., Mattes, A., Pour Nikfardjam, M. S., Kammerer, D. R., & Carle, R. (2015). Implementation of an on-line near infrared/visible (NIR/VIS) spectrometer for rapid quality assessment of grapes upon receival at wineries. Australian Journal of Grape and Wine Research. doi:10.1111/ajgw.12120.

Porretta, S. (1995). Quality evaluation of canned whole tomatoes. Food Science and Technology International. doi:10.1177/108201329500100205.

Ribéreau-Gayon, P., Dubourdieu, D., Donèche, B., & Lonvaud, A. (2006). The grape and its maturation. In Handbook of Enology (The microbiology of wine and vinifications 2nd ed., Vol. 1, pp. 241–297). Chichester: John Wiley & Sons.

Rinnan, R., & Rinnan, Å. (2007). Application of near infrared reflectance (NIR) and fluorescence spectroscopy to analysis of microbiological and chemical properties of arctic soil. Soil Biology and Biochemistry. doi:10.1016/j.soilbio.2007.01.022.

Rousseaux, S., Diguta, C. F., Radoï-Matei, F., Alexandre, H., & Guilloux-Bénatier, M. (2014). Non-Botrytis grape-rotting fungi responsible for earthy and moldy off-flavors and mycotoxins. Food Microbiology. doi:10.1016/j.fm.2013.08.013.

Saito, S., Dunne, K. J., Evans, K. J., Barry, K., Cadle-Davidson, L., & Wilcox, W. F. (2013). Optimisation of techniques for quantification of Botrytis cinerea in grape berries and receptacles by quantitative polymerase chain reaction. Australian Journal of Grape and Wine Research. doi:10.1111/ajgw.12011.

Sandorfy, C., Buchet, R., & Lachenal, G. (2007). Principles of molecular vibrations for near-infrared spectroscopy. In Y. Ozaki, W. F. McClure, & A. A. Christy (Eds.), Near-infrared spectroscopy in food science and technology (pp. 11–46). Hoboken: John Wiley & Sons.

Sanzani, S. M., Schena, L., de Cicco, V., & Ippolito, A. (2012). Early detection of Botrytis cinerea latent infections as a tool to improve postharvest quality of table grapes. Postharvest Biology and Technology. doi:10.1016/j.postharvbio.2012.02.003.

Saxena, J., Munimbazi, C., & Bullerman, L. (2001). Relationship of mould count, ergosterol and ochratoxin A production. International Journal of Food Microbiology. doi:10.1016/S0168-1605(01)00584-0.

Schwadorf, K., & Müller, H.-M. (1989). Determination of ergosterol in cereals, mixed feed components, and mixed feeds by liquid chromatography. Journal - Association of Official Analytical Chemists, 72(3), 457–462.

Scott, E. S., Dambergs, R. G., & Stummer, B. E. (2010). Fungal contaminants in the vineyard and wine quality. In A. G. Reynolds (Ed.), Managing wine quality (Viticulture and wine quality, Vol. 1, pp. 481–514). Oxford: Woodhead/CRC.

Seitz, L. M., Mohr, H. E., Burroughs, R., & Sauer, D. B. (1977). Ergosterol as an indicator of fungal invasion in grains. Cereal Chemistry, 54(6), 1207–1217.

Seitz, L. M., Sauer, D. B., Burroughs, R., Mohr, H. E., & Hubbard, J. D. (1979). Ergosterol as a measure of fungal growth. Phytopathology. doi:10.1094/Phyto-69-1202.

Siesler, H. W. (2008). Basic principles of near-infrared spectroscopy. In D. A. Burns & E. W. Ciurczak (Eds.), Handbook of near-infrared analysis (3rd ed., pp. 7–19). Boca Raton: CRC.

Somma, S., Perrone, G., & Logrieco, A. F. (2012). Diversity of black Aspergilli and mycotoxin risks in grape, wine and dried vine fruits. Phytopathologia Mediterranea, 51(1), 131–147.

Steel, C. C., Blackman, J. W., & Schmidtke, L. M. (2013). Grapevine bunch rots: impacts on wine composition, quality, and potential procedures for the removal of wine faults. Journal of Agricultural and Food Chemistry. doi:10.1021/jf400641r.

Stummer, B. E., Zanker, T., Harvey, P. R., & Scott, E. S. (2006). Detection and quantification of Erysiphe necator DNA in wine grapes and resultant must and juice. Mycological Research. doi:10.1016/j.mycres.2006.07.008.

Sturm, J. (2009). Wertebereiche qualitätsrelevanter Parameter in Mosten der zehn in Deutschland am häufigsten angebauten Rebsorten (Vitis vinifera L.). Mitteilungen Klosterneuburg, 59(3), 152–158.

Terhoeven-Urselmans, T., Schmidt, H., Georg Joergensen, R., & Ludwig, B. (2008). Usefulness of near-infrared spectroscopy to determine biological and chemical soil properties: importance of sample pre-treatment. Soil Biology and Biochemistry. doi:10.1016/j.soilbio.2007.12.011.

Walter, R. (2012). Fäulnispilze an Weintrauben - Erregerkomplex, Mykotoxine und Bekämpfungsstrategien. Journal für Kulturpflanzen, 64(4), 378–383.

Weete, J. D., & Gandhi, S. R. (1996). Biochemistry and Molecular Biology of Fungal Sterols. In K. Esser, P. A. Lemke, R. Brambl, & G. A. Marzluf (Eds.), The Mycota: A comprehensive treatise on fungi as experimental systems for basic and applied research (Vol. III, pp. 421–438). Berlin: Springer-Verlag.

Weete, J. D., Abril, M., Blackwell, M., & Butler, G. (2010). Phylogenetic distribution of fungal sterols. PLoS ONE. doi:10.1371/journal.pone.0010899.

Williams, P. (2008). Sampling, sample preparation, and sample selection. In D. A. Burns & E. W. Ciurczak (Eds.), Handbook of near-infrared analysis (3rd ed., pp. 268–295). Boca Raton: CRC.

Woodcock, T., O'Donnell, C., & Downey, G. (2008). Better quality food and beverages: the role of near infrared spectroscopy. Journal of Near Infrared Spectroscopy. doi:10.1255/jnirs.758.

Workman, J. J., Jr. (2008). NIR spectroscopy calibration basics. In D. A. Burns & E. W. Ciurczak (Eds.), Handbook of near-infrared analysis (3rd ed., pp. 123–150). Boca Raton: CRC.

Workman, J., Jr., & Weyer, L. (2008). Practical guide to interpretive near-infrared spectroscopy. Boca Raton: CRC Press.

Zanardi, C., Ferrari, L., Zanfrognini, B., Pigani, L., Terzi, F., Cattini, S., et al. (2013). Development of a sensor system for the determination of sanitary quality of grapes. Sensors. doi:10.3390/s130404571.

Acknowledgment

This research project was supported by the Raiffeisen-Stiftung (Berlin, Germany), project number 2013-009-fw.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Porep, J.U., Mrugala, S., Pour Nikfardjam, M.S. et al. Online Determination of Ergosterol in Naturally Contaminated Grape Mashes Under Industrial Conditions at Wineries. Food Bioprocess Technol 8, 1455–1464 (2015). https://doi.org/10.1007/s11947-015-1509-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1509-9