Abstract

In order to explore novel processing for modifying the functional properties of pale, soft, exudative (PSE)-like chicken breast meat, we investigated the effects of high-intensity ultrasound on the functional and rheological properties, particle size distribution, microstructure, and protein secondary structures of PSE-like meat batter suspension. Normal and PSE-like chicken breast meat batter suspensions (7.5 % meat proteins, w/w) were prepared and treated by ultrasound for either 0, 3, or 6 min (frequency 20 kHz and amplitude 60 %). Ultrasound treatment significantly increased pH, gel strength, and water holding capacity of normal and PSE-like meat gels (P < 0.05). Ultrasound treatment altered the rheological behavior of normal and PSE-like batter samples, which was accompanied with the increase of the elastic (G′) and viscous (G″) modulus. After ultrasound treatment, the microstructure of heated normal and PSE-like batter samples enabled the formation of a compact and more dense gel network. Ultrasound treatment reduced the salt solubility of myosin as indicated by its intensity in SDS-PAGE. However, the particle size of ultrasound-treated normal and PSE-like batter samples was reduced and became more uniform. Moreover, ultrasound decreased the α-helical content and increased the formation β-sheet, β-turns, and unordered contents of normal and PSE-like meat proteins. These results suggest that high-intensity ultrasound may be used to modify the functionality of PSE-like meat with the potential to increase economical benefits for the poultry industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pale, soft, exudative-like (PSE-like) poultry meat continues to be a major quality defect which affects the poultry industry through the world, where the meat is characterized by a lighter color, lower water holding capacity, and poorer texture (Barbut 2009). Recent reports have estimated that the incidence of PSE-like chicken meat produced commercially in China and Brazil is approximately 24.0 and 10.2 %, respectively (Garcia et al. 2010; Zhu et al. 2012). Thus, it has continued to be a great challenge for poultry producers and processors, where reduced water holding capacity and gel strength of processed meat products lead to a great economic loss (Droval et al. 2012; Petracci et al. 2013). It is well known that alteration/denaturation of sarcoplasmic or myofibrillar proteins caused by a rapid postmortem pH decline, together with a high carcass temperature, is responsible for the formation of PSE-like poultry meat which has impaired protein functionality (Barbut et al. 2008; Pietrzak et al. 1997; Zhu et al. 2011). However, to date, there are no absolute solutions for eliminating the occurrence of PSE in poultry. Researchers and processors are now largely accepting the PSE meat quality defect, but are seeking ways to improve its functional properties through other processing techniques.

High-intensity ultrasound is a very effective innovative technology for the food processing industry and has been widely used in many processes such as inactivation of microorganisms and enzymes, extraction, and homogenization (Bevilacqua et al. 2013; Horžić et al. 2012; Rastogi 2011). Specifically, conventional applications of ultrasound to meat and meat products have been mainly used for the purpose of meat tenderization, curing, and changes in meat color and color stability (Cárcel et al. 2007; Jayasooriya et al. 2007; McDonnell et al. 2014; Stadnik and Dolatowski 2011). High-intensity ultrasound creates physical disruption of meat tissues, increases proteolytic activity, and accelerates mass transfer through cavitation. These result in significant improvements in fragmentation and extraction of myofibrillar proteins and they also cause disintegration of connective tissues in meat (Chang et al. 2012; Jayasooriya et al. 2004). Moreover, high-intensity ultrasound has the potential for functionality modification of different food proteins based on its mechanical, chemical, and/or biochemical effects through cavitation, dynamic agitation, and shear stresses (Awad et al. 2012; Chandrapala et al. 2012). Several studies have reported that ultrasound treatment affected the structural properties and improved the functional properties of food proteins, such as whey protein (Jambrak et al. 2008; Jambrak et al. 2014), soy protein isolate (Hu et al. 2013a), and egg white proteins (Arzeni et al. 2012a; Arzeni et al. 2012b). However, little information is available concerning the use of ultrasound to alter gel-forming properties of muscle protein systems as in gel-type products. Gelation is a multistep thermodynamic process that involves protein denaturation, aggregation, and formation of a three-dimensional network resulting in an elastic gel (Lesiów and Xiong 2001). Since cavitation within the muscle tissue can lead to physical damage and to chemical changes by formation of free radicals, the structure of proteins can be altered (Jayasooriya et al. 2004). High-intensity ultrasound is of much interest and expected to have the potential to alter thermal protein denaturation and aggregation patterns of muscle proteins which may be beneficial for the development of processed meat products having unique functionality. In particular, one of the great challenges in meat processing is how to improve or to restore the functionality of protein denatured PSE-like meat. The application of high-intensity ultrasound to modify the denatured meat proteins may enable structural modifications that result in improved aggregation and gelation.

Therefore, the objective of this study was to investigate the effects of high-intensity ultrasound technology on the functional (gelling and rheological properties, water holding capacity (WHC)), microstructure, and protein secondary structures of PSE-like chicken meat batter suspensions to explore a novel method to improve the protein functionality of PSE-like meat.

Materials and Methods

Chicken Breast Meat Selection

A total of 60 skinless, boneless broiler chicken breast muscles (musculus pectoralis major) were collected on three different occasions from the deboning line of a major Chinese commercial plant. The average Arbor Acre broilers’ age was 44.6 ± 2.1 days and the average live weight was 2.05 ± 0.38 kg. Normal and PSE-like chicken breast meat was selected based on color and pH. Broiler breasts from each color group, based on the L* value at 3 h postmortem, were labeled and placed in polyethylene bags, packed on ice, and transported to the laboratory. At 24 h postmortem, L* and pH values were measured again on all the muscles for further selection. The criteria values for normal (46 < L* < 53, 5.7 < pH24 h < 6.1) and PSE-like (L* > 53, pH24 h < 5.7) meat were based on L*3 h (Zhu et al. 2012), L*24 h, and pH24 h (Zhang and Barbut 2005). Drip loss of meat was also measured. These attributes demonstrated clearly that each of the color group samples was representative for either normal or PSE-like chicken breast meat quality (Table 1). After selection of chicken breast meat, all visible connective tissue, fat, and skin of meat samples were trimmed. The meat within each group was then cut into small cubes (approximately 1 × 1 × 1 cm3) and mixed, then labeled and packed in polyethylene bags, and frozen (−18 °C) and used within 2 weeks.

Color, pH, and Drip Loss of Chicken Breast Meat

The color of chicken breast meat was determined using a Minolta CR-400 (illuminate D and 65° standard observer) device (Minolta Camera Co., Osaka, Japan) on the bone side of broiler pectoralis major muscles. Three measurements were taken on the surface areas. The lightness (L*) value was expressed as an average of three measurements. The pH values of normal and PSE-like chicken breast meat were determined with a portable pH meter (Orion 3-star, USA) and a penetration electrode (Orion 9120 APWP, UK) at three different positions of broiler pectoralis muscles. Drip loss was performed using the Honikel bag method (Honikel 1998). At 24 h postmortem, 20 g of chicken breast meat sample was placed in a sealed polyethylene package at 4 °C for 24 h. On opening of the bags, the meat was removed and the exudate on the surface of samples was removed with filter paper. The weight of the samples was recorded again. Drip loss was expressed as a percentage of the weight loss in 24 h over the initial sample weight. It was calculated from the average of three replicates for each muscle.

Preparation of the Meat Batter Suspensions

The Kjeldahl protein values (AOAC 2000) were used to formulate meat batter suspensions to 7.5 % (w/w) protein. The meat was thawed overnight at 4 °C and chopped three times in a chilled cutter (Grindomix GM 200, Retsch, Germany) for 10 s at the speed of 3,000 rpm. The chopped meat was then adjusted by the addition of deionized water to a protein level of 7.5 and 2 % salt. Finally, the batter suspensions were prepared by mixing and dispersing well with a magnetic stirrer (C-MAG HS4, IKA, Germany) on medium speed for 30 min at 4 °C to be subjected to high-intensity ultrasound treatment. The temperature of the samples was measured before and after the ultrasound treatments. PSE batter suspensions (P) were defined as those prepared from PSE-like breast meat and normal batter suspensions (N) were those prepared from meat of normal pH and color.

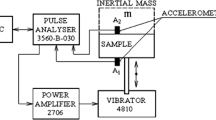

High-Intensity Ultrasound

Ultrasound treatment was performed using a Vibra-Cell TM Ultrasonic Processor (VC 750, Sonics & Materials, Inc., USA) with an ultrasonic horn with a maximum net power output of 750 W at a frequency of 20 kHz and an amplitude of 60 %. The samples (60 mL each) were sonicated in a glass double-walled beaker equipped with a cooling jacket for either 0, 3, or 6 min. During ultrasound treatment, the probe (13 mm diameter) was immersed in the liquid to a depth of 1.5 cm and ice water was circulated around the vessel. An ultrasound pulse mode of on-time 2 s and off-time 4 s was used. The ultrasonic intensity was 28–32 W/cm2, as measured by calorimetry according to the method of Jambrak et al. (2014). In order to ensure better homogeneity, the sample was gently stirred for 15 s every 1 min during application of ultrasound treatment. After ultrasound treatment, the samples were stored at 4 °C for analyses. All sample preparations and treatments were carried out in triplicate. Six treatments were labeled as follows: two nonultrasound treatments: N and P; two ultrasound treatments for 3 min: N3 and P3; and two ultrasound treatments for 6 min: N6 and P6.

Temperature and pH Measurements

Before and after each ultrasound treatment, the temperature of batter samples was measured using a HI 9063 thermocouple (Hanna Instruments Ltd., UK). The pH of meat samples was determined using a Hanna 211 pH meter (Hanna, Italy).

Particle Size Determination

The particle size was determined immediately after ultrasound treatment when the particles were still dispersed. The particle size distribution was performed using a Mastersizer laser light scattering analyzer (Mastersizer 2000, Malvern Instruments Ltd., Worcester shire, UK). A small quantity of each sample was dispersed in distilled water and the particle distribution was monitored during four successive readings. The particle size was expressed as D 50, D 90 (accumulated value to achieve volume percent of particle size of 50 and 90 %, respectively), D 3,2 (surface weighted mean), and D 4,3 (volume weighted mean).

Gel Strength

After ultrasound treatment, each sample was transferred to a glass breaker (40 mm diameter, 35 mm height), maintained in a water bath at 80 °C for 20 min, and then cooled to room temperature. Gel strength was measured according to the method of Hu et al. (2013b). The samples were tested using a Texture Analyser (TA.XT2i, Stable Micro Systems, Godalming, UK) equipped with a spherical plunger (5 mm diameter) at a speed of 1 mm/s to a compression strain of 50 %. Gel strength was defined as the maximum force required to compress the samples.

Water Holding Capacity

WHC of the batter samples was determined as described by Zhang and Barbut (2005) with a slight modification. Each sample (20 g) was transferred into a 50-mL polypropylene tube, heated in a water bath at 80 °C for 20 min, and then cooled to room temperature. The containers of gels were centrifuged at 10,000 × g (Avanti J-E, Beckman Coulter, CA, USA) for 10 min. The weight (g) after centrifugation and the weight (g) of the samples before centrifugation were determined. WHC is expressed as the amount of released water divided by the original weight (g) of the gel before centrifugation. A low value indicates that the samples have a superior WHC to gels with a high value.

Dynamic Rheological Measurements

Dynamic rheological measurements of untreated and ultrasound-treated batter samples were carried out using a rheometer (Anton Paar, Physica MCR 301, Austria) under the oscillatory mode and was equipped with a 25-mm parallel plate measuring geometry, as described by Omana et al. (2010) with slight modifications. Rheological measurements were conducted within the linear range at a strain of 0.5 % and a constant frequency of 0.1 Hz. The batter samples were heated between parallel plates with a programmable circulating water bath, and the probe was set with the gap of 1 mm. The edges of the samples were covered with silicone oil to prevent dehydration. Heating was performed from 25 to 80 °C at a scan rate of 2 °C/min using a temperature control unit. The storage modulus (G′) and loss modulus (G″) were collected during dynamic oscillatory measurements.

Scanning Electron Microscopy (SEM)

SEM of untreated and ultrasound-treated batter samples after heating was performed according to the method of Han et al. (2009). Samples for SEM were cut into cubes (3 × 3 × 2 mm3) and fixed with 2.5 % glutaraldehyde in 0.1 M phosphate buffer (pH 7.0) for 48 h at 4 °C. The post-fixed samples were then washed three times with 0.1 M phosphate buffer (pH 7.0) for 10 min, followed by dehydration in incremental concentrations of ethanol (30, 50, 70, 75, 80, 90, and 95 %, and three times with 100 %, respectively) for 15 min per solution, and finally dipped into isoamyl acetate for 10 min. The dehydrated samples were dried by the method of carbon dioxide supercritical drying. The dried samples were gold-coated (about 10-nm layer) using a high-vacuum ion sputter. Sample observation and photomicrography were performed using a scanning electron microscope (S-3000, Hitachi Science System Ltd., Hitachinaka, Japan) with an accelerating voltage of 7.0 kV.

SDS-PAGE

Each of the untreated and ultrasound-treated batter samples was combined with 50 mL of extraction buffer (50 mM sodium phosphate, 0.5 M NaCl, pH 6.5) and mixed with a magnetic stirrer at medium speed for 10 min at 4 °C. The mixture was centrifuged (Avanti J-E, Beckman Coulter, CA) at 15,800 × g for 10 min at 4 °C, and the supernatant was filtered through Whatman #1 filter paper. The salt-soluble protein concentration in the filtrate of each sample was determined by the biuret method at an absorbance of 540 nm (Gornall et al. 1949). SDS-PAGE was performed on the solubilized fraction. Protein concentration was determined and each sample was diluted to 3 mg/mL using treatment buffer (125 mM Tris, 4 % SDS, 20 % glycerol) containing 10 % β-mercaptoethanol and 0.001 % bromophenol blue. Samples were well mixed, heated at 95 °C for 5 min, and then stored at −80 °C for subsequent SDS-PAGE. The prepared protein samples were subjected to SDS-PAGE using a 10 % acrylamide resolving gel and a 4 % acrylamide stacking gel (Laemmli 1970). Gel was loaded with 15 μg of protein per well. After electrophoresis, the gel was scanned (GT-800 F, Epson, Japan) at a resolution of 600 dpi, and the densities of bands were analyzed by Quantity One software (Bio-Rad, Laboratories Inc., Benicia, CA, USA).

Raman Spectroscopy

Raman experiments were determined using a modified procedure of Shao et al. (2011). The spectra were obtained in the range of 400 to 3,600 cm−1. Each spectrum of the untreated and ultrasound-treated batter samples was obtained under the following conditions: three scans, 30 s exposure time, 2 cm−1 resolution, sampling speed 120 cm−1/min, and data collection every 1 cm−1. The spectra were smoothed, baseline-corrected, and normalized against the phenylalanine band at 1,003 cm−1 (Herrero 2008) using Labspec version 3.01c (Horiba/Jobin Yvon, Longjumeau, France). The secondary structures of each sample were determined as percentages of α-helix, β-sheet, β-turn, and unordered conformations (Alix et al. 1988).

Statistical Analysis

The data were expressed as mean value ± SD. An independent sample t test was used to determine the level of significance between normal and PSE-like chicken breast meat. The data obtained for the temperature, pH, particle size, functional properties, and protein secondary structures of batter suspensions were submitted to analysis of variance (ANOVA) using the general linear model procedure of Statistical Analysis System (SAS 8. 2, SAS Inst. Inc., Cary, NC, USA, 2000). The means of variable among different treatments were compared using the Duncan’s multiple comparisons. Statistical significance was set at P < 0.05.

Results and Discussion

Temperature and pH

As shown in Table 2, the temperature of normal and PSE-like batter samples increased significantly from 2.5 to 25 °C after high-intensity ultrasound treatments (N6 and P6) (P < 0.05). This was attributed to the collapse of cavitation bubbles (Chandrapala et al. 2011) and the input of mechanical vibration energy by ultrasound, which resulted in an increase of temperature. As expected, there was no significant difference (P > 0.05) at the same ultrasound time between the temperature of normal and PSE-like batter samples (N3 and P3 and N6 and P6, respectively).

Ultrasound treatment also had a significant effect (P < 0.05) on the pH of normal and PSE-like batter samples (Table 2). The pH of normal batter sample (N) increased about 0.10 units from 5.92 up to 6.02 after ultrasound treatment for 6 min, while pH of PSE-like batter sample (P) increased 0.15 units from 5.66 to 5.83. The increase in pH was probably associated with protein denaturation. High-intensity ultrasound can generate highly reactive free radicals and hydrogen peroxide which interact with proteins (Soria and Villamiel 2010), resulting in a decrease in the acidic groups of muscle proteins (Poulter et al. 1985). In addition, the increase in local temperature and pressure in the surrounding area of the collapsing bubble created by ultrasound can also induce the protein denaturation.

Particle Size Distribution

The changes in particle size distribution of normal and PSE-like batter samples after ultrasound treatments are shown in Fig. 1 and Table 3. Figure 1 shows that ultrasound treatment had significant effects on the particle size distributions of batter samples. Both untreated normal and PSE-like batter samples had two peaks (the first peak range 10–100 μm, the second peak range 100–1,000 μm). There were significant differences (P < 0.05) in particle size distributions between untreated normal and PSE-like batter samples (Fig. 1 and Table 3). Untreated PSE-like batter samples had lower particle size than that of untreated normal batter samples, due to the different integrity of muscle fiber structure between PSE and normal meat, as was observed by Wilhelm et al. (2010). After high-intensity ultrasound treatment, the distribution became more uniform and narrowed, with a greater number of particles in the smaller size range. The second peak intensity (size range 100–1,000 μm) of both normal and PSE-like batter samples was decreased by ultrasound treatment, indicating that the myofibrillar integrity had been further disrupted.

Compared to the untreated batter samples, ultrasound treatment for 3 and 6 min significantly decreased the values of D 50, D 90, D 3,2, and D 4,3 in the normal and PSE-like batter samples (P < 0.05) (Table 3). Jambrak et al. (2014) reported that high-intensity ultrasound (20 kHz for 15 or 30 min with a probe) caused a decrease in particle size of both whey protein isolate and whey protein concentrate suspensions. Sun et al. (2014) determined the D 50 of milk protein concentrate as being the average particle size and found that D 50 was decreased from 28.45 to 0.13 μm after ultrasound treatment. The decrease in particle size can be attributed to the shear effects generated by acoustic cavitation of high-intensity ultrasound.

Gel Strength and Water Holding Capacity

Gel strength and WHC are two important parameters of gel-type composite food systems. Table 4 shows the gel strength and WHC of untreated and ultrasound-treated normal and PSE-like batter samples. Ultrasound treatment had a significant positive effect on gel strength (P < 0.05). For normal batter samples, ultrasound treatment for 3 min significantly increased the gel strength, while the gel strength of the samples treated with ultrasound for 6 min was not significantly different from the untreated normal batter samples (P > 0.05). Untreated PSE-like meat gels had the lowest gel strength; however, the value of the gel strength increased significantly (P < 0.05) after ultrasound treatment for 6 min (P6) and was not different (P > 0.05) from the untreated normal batter samples (N), showing that high-intensity ultrasound can improve the gel strength of PSE-like batter samples. There was also a significant effect of high-intensity ultrasound on WHC (Table 4). Untreated ultrasound PSE-like batter samples had significantly lower WHC than the normal batter samples (P < 0.05). However, after high-intensity ultrasound for both 3 and 6 min, the PSE-like and normal samples had higher WHC compared to that of untreated batter samples (P < 0.05), where a significant difference was observed for WHC between ultrasound-treated PSE-like batter samples and untreated normal batter samples (P < 0.05). The increase in pH of PSE-like batter samples can cause increased protein net charge, resulting in more sites of hydrogen bonding with the surrounding water. Moreover, the reduction of the particle size of batter samples led to a much more uniform size (Fig. 1) and this contributed to the improvement of WHC and gel strength. Similar findings were reported by Hu et al. (2013b), who compared the gel strength and WHC of untreated and ultrasound-treated CaSO4-induced soy protein isolate gels and found that high-intensity ultrasound improved both the gel strength and WHC. Further, Madadlou et al. (2010) reported that sonication of casein solutions prior to acidification increased the final firmness of gels.

Dynamic Viscoelastic Measurement

Changes in elastic modulus (G′) and the viscous modulus (G″) of untreated and ultrasound-treated normal and PSE-like batter samples during heating from 25 to 80 °C are presented in Fig. 2. The G′ of normal batter sample (N) slightly increased up to approximately 37 °C (Fig. 2a). Then, it decreased sharply to a minimum at 55 °C. On subsequent heating to 80 °C, the G′ rose steadily. The G′ of normal batter sample had a peak at 37 °C. The G′ of PSE-like batter sample (P) remained relatively unchanged up to 35 °C and then reduced sharply to a minimum at 54 °C (Fig. 2a). Subsequently, G′ increased steadily on further heating, reaching a plateau at 80 °C, indicating that a gel-forming network structure had formed completely. The PSE-like batter sample had no peak during heating from 25 to 55 °C. Thus, two meats having different qualities demonstrated different dynamic rheological behaviors, which clearly was due to the different extents of protein denaturation and their pH. These rheological transitions were also observed in natural actomyosin from PSE and normal pork (Wang et al. 2009). High-intensity ultrasound created different patterns of G′ for the thermal gelation of normal and PSE-like batter samples. For the normal batter samples, ultrasound treatment for 3 min had the highest peak value at 45 °C and improved the protein unfolding and aggregation, while ultrasound treatment for 6 min decreased the peak value of G′. Compared with the PSE-like batter samples, the G′ of ultrasound-treated PSE-like batter samples for 3 and 6 min slightly increased up to approximately 42 and 48 °C, respectively (Fig. 2a). Then, they decreased sharply to a minimum at 55 °C. On subsequent heating to 80 °C, the G′ rose steadily. The initial increase of G′ indicated that the preliminary protein network structure formed through hydrogen bonding and association of myosin heads as a result of unfolding and denaturation of the S1 subfragment (Egelandsdal et al. 1986; Jiang and Xiong 2013). Then, denaturation of the myosin tails caused G′ to decease sharply and disrupted the temporary protein network (Xiong 1997). On further heating, the increase of G′ was attributed to an increase in the number of cross-links between protein aggregates or strands, such as hydrophobic and sulfhydryl-disulfide where irreversible interactions in myosin and actomyosin occurred transforming the viscous sol into a highly elastic gel network (Ferris et al. 2009). Ultrasound treatment for 6 min had the highest peak value of G′ at 48 °C and increased the cross-linked interaction, resulting in forming an elastic gel network based on the ordered aggregations of the partially unfolded proteins. The results clearly indicated that ultrasound-treated PSE-like batter samples improved the gel network and protein matrix formation. This was likely attributed to factors such as pH, different particle sizes, and native protein interactions (Hu et al. 2013a; Xiong 1994). Ultrasound treatment induced some structural changes which resulted in particles being uniform in size enabling a more ordered and homogeneous gel structure to be produced after heating. Further, the formed gel proteins were stabilized by molecular forces such as hydrogen bonds and hydrophobic and electrostatic interactions. Ultrasound treatment created a chemical effect which exposed the hidden reactive groups and modified the protein structure or hydrophobic interactions (Hu et al. 2013a; Madadlou et al. 2010). Furthermore, due to the different extents of protein denaturation of PSE-like and normal meat, high-intensity ultrasound, at the same treatment time, created different gelation processes.

Figure 2b shows the changes of G″ in untreated and ultrasound-treated normal and PSE-like batter samples. The changes in G″ for both were similar to those observed for G′, despite the differences in magnitude (Liu et al. 2007; Zhou et al. 2014). This demonstrated that PSE-like batter samples had lower viscosity than normal samples. However, ultrasound treatment was able to also increase the final viscosity of PSE-like and normal batter samples.

Microstructure

The microstructures of untreated and ultrasound-treated normal and PSE-like meat gels are presented in Fig. 3. SEM revealed significant variations in the appearances of untreated and ultrasound-treated meat gels. The microstructure of normal meat gels showed a compact gel network, displaying many protein filaments and fine strands (Fig. 3a). Those treated with ultrasound treatment for 3 min showed disrupted fiber filaments which formed more compact structures having an increased number of small cavities between protein strands (Fig. 3b). After high-intensity ultrasound for 6 min, the meat matrix exhibited irregular cavities and many large protein aggregates (Fig. 3c). Unlike the normal meat gels, PSE-like meat gels (Fig. 3d) showed many short myofibrils which formed a disordered and loose gel network. With ultrasound treatment of PSE-like batter samples, the myofibrils appeared to be broken down and disrupted (Fig. 3e, f). Those that had been treated with ultrasound treatment for 3 min had a more compact structure together with a great number of small protein aggregates (Fig. 3b). Ultrasound treatment for 6 min generated a porous network structure containing reticular structures and fine strands (Fig. 3f). The difference in the microstructure between untreated PSE-like and normal meat gels was attributed to the differences in salt-soluble protein contents and pH (Barbut 1997; Somboonpanyakul et al. 2007). For the PSE-like meat gels, ultrasound treatment for 3 and 6 min decreased the length of the myofibrils and created small open spaces, which contributed to the improvement of the structure development of gel forming. For the normal meat gels, ultrasound treatment for 6 min created more protein aggregates as a result of excessive power delivery when the salt-soluble protein had been already extracted. Therefore, ultrasound treatment had superior effects on the microstructure of PSE-like batter samples compared with normal batter samples. In addition, high-intensity ultrasound can create rupturing and mechanical damage and the generation of free radicals from water molecules which decreases the particle size and modifies the aggregates through acoustic cavitation (Jambrak et al. 2010). Thus, it improved protein association during thermal gelling and generated a more compact and tighter protein interaction to form firmer gels and retain more water compared with untreated batter samples. Zisu et al. (2010) showed that the improvement in the gel strength of sonicated whey proteins was attributed to the reduction in particle size and the formation of a dense and compact protein network. Hu et al. (2013b) also reported that high-intensity ultrasound improved the water holding capacity of soybean protein isolate gel induced by calcium sulfate, which resulted from the stable and denser gel network created by high-intensity ultrasound.

Scanning electron microscopy of untreated and ultrasound-treated normal and PSE-like meat gels. a N (normal batter sample); b N3 (ultrasound treatment for 3 min); c N6 (ultrasound treatment for 6 min); d P (PSE-like batter sample); e P3 (ultrasound treatment for 3 min); f P6 (ultrasound treatment for 6 min)

SDS-PAGE

Figure 4 shows the SDS-PAGE patterns of the salt-extracted soluble proteins from the untreated and ultrasound-treated normal and PSE-like batter samples. There were no significant differences in the protein profiles between untreated normal and PSE-like batter samples (lanes 2 and 5). However, the use of ultrasound treatment for 3 and 6 min mainly decreased the intensity of the myosin heavy chains (lanes 3, 4, 6. and 7). High-intensity ultrasound (20 kHz) modified the protein profile of the salt-soluble proteins, indicating that treatment with a probe (20 kHz) caused the proteins to unfold which leads to the formation of protein aggregation, resulting in their lower salt solubility. The increase in local temperature and pressure in the surrounding area of the collapsing bubble created by ultrasound also promoted the protein denaturation and aggregation of suspensions. Furthermore, the formation of the aggregates likely resulted from the formation of intermolecular disulfide bridges between protein molecules (Gülseren et al. 2007). In general, the extraction of salt-soluble proteins, under conventional meat processing condition, is an important point to improve the gel texture of the final processed meat products. However, high-intensity ultrasound did not increase the solubility of salt-soluble proteins from PSE-like meat batter suspensions as shown in SDS-PAGE (Fig. 4). This infers that ultrasound affected other factors relating to measured improved gelling properties of PSE-like batter samples, such as pH, viscoelastic characteristics, protein-protein interactions (aggregation), and protein conformational changes induced by ultrasound (Arzeni et al. 2012a).

SDS-PAGE of salt-soluble proteins extracted from untreated and ultrasound-treated normal and PSE-like batter samples. Lane 1: standard marker; lanes 2–4: N, N3, and N6; lanes 5–7: P, P3, and P6. N and P: normal and PSE-like batter samples; N3 and P3: ultrasound treatments for 3 min; N6 and P6: ultrasound treatments for 6 min. MHC myosin heavy chains

Raman Spectroscopic Analysis

The secondary structural contents of proteins in normal and PSE-like batter samples, as affected by high-intensity ultrasound, are shown in Table 5. High-intensity ultrasound treatment had a significant effect on the secondary structures of both normal and PSE-like batter samples (P < 0.05). Ultrasound treatment significantly decreased α-helical contents and increased the β-sheet contents of normal batter samples compared to the untreated normal samples, with greater changes at higher ultrasound time (N6). Compared with untreated PSE-like batter samples, ultrasound treatment of PSE-like batter samples for 6 min also significantly decreased the α-helical contents and increased the β-sheet, β-turns, and unordered contents (P < 0.05). High-intensity ultrasound treatment appears to have induced changes in the spatial structure of myosin, leading to the unfolding of the α-helical region followed by the formation of β-sheet. The secondary structure of PSE-like batter samples treated for 6 min was not significantly different from the untreated normal samples (P > 0.05). The higher β-sheet and β-turn fractions contributed to protein aggregates and gel formation in the meat system, resulting in an improvement in gel texture (Herrero 2008; Liu et al. 2008; Liu et al. 2010). High-intensity ultrasound also increased the exposure of hydrophobic and sulfhydryl residues to the water molecules, which favored the aggregation and the gelling process (Arzeni et al. 2012a; Gülseren et al. 2007). Investigation of the secondary structural changes in proteins using Raman spectroscopy provides an explanation for the mechanisms for the improvement in functional properties based on protein unfolding and aggregation. In addition, the results in the present study regarding secondary structures for ultrasound-treated meat batter samples were similar to the finding of Li et al. (2014), who reported that peanut protein isolate-glucomannan conjugates, prepared by ultrasound treatment, increased the β-structure which was accompanied by a decrease of α-helical structures compared to native peanut protein isolate. On the other hand, Chandrapala et al. (2011) and Hu et al. (2013c) found that ultrasonic treatment increased in the α-helical component and decreased the β-sheet component of whey protein concentrate and soy protein isolate. These different findings for the effects of ultrasound on the secondary structures of proteins may result from their intrinsic native structures.

Conclusion

High-intensity ultrasound modified normal and PSE-like chicken breast batter suspensions and improved the protein functionality of PSE-like meat. High-intensity ultrasound (20 kHz, 450 W, and 6 min) significantly increased their gel strength, viscosity-elasticity, and WHC giving them properties similar to normal meat gels. Treatment also resulted in PSE-like meat gels having a more uniform and compact gel network. However, treatment was unable to induce an increase in the salt-soluble protein extraction as shown in gel electrophoresis. However, high-intensity ultrasound resulted in a significant increase of pH and a reduction in particle size with greater uniformity. Importantly, we found that PSE-like meat proteins treated by ultrasound had less α-helical and more β-sheet, β-turns, and unordered contents than those not treated. These physicochemical modifications may explain the improved gel texture and water retention of the treated PSE-like meat gels. The present study suggests that high-intensity ultrasound technology may successfully be employed for the modification of PSE-like chicken breast meat to develop new processed meat products having a unique functionality.

References

Alix, A. J. P., Pedanou, G., & Berjot, M. (1988). Fast determination of the quantitative secondary structure of proteins by using some parameters of the Raman amide I band. Journal of Molecular Structure, 174, 159–164.

AOAC, (2000). Official methods of analysis of AOAC international (17th ed.), AOAC International, Gaithersburg, MD, USA.

Arzeni, C., Martínez, K., Zema, P., Arias, A., Pérez, O. E., & Pilosof, A. M. R. (2012a). Comparative study of high intensity ultrasound effects on food proteins functionality. Journal of Food Engineering, 108, 463–472.

Arzeni, C., Pérez, O. E., & Pilosof, A. M. R. (2012b). Functionality of egg white proteins as affected by high intensity ultrasound. Food Hydrocolloids, 29, 308–316.

Awad, T. S., Moharram, H. A., Shaltout, O. E., Asker, D., & Youssef, M. M. (2012). Applications of ultrasound in analysis, processing and quality control of food: a review. Food Research International, 48, 410–427.

Barbut, S. (1997). Microstructure of white and dark turkey meat batters as affected by pH. British Poultry Science, 38(2), 175–182.

Barbut, S. (2009). Pale, soft, and exudative poultry meat—reviewing ways to manage at the processing plant. Poultry Science, 88, 1506–1512.

Barbut, S., Sosnicki, A. A., Lonergan, S. M., Knapp, T., Ciobanu, D. C., Gatcliffe, L. J., Huff-Lonergan, E., & Wilson, E. W. (2008). Progress in reducing the pale, soft and exudative (PSE) problem in pork and poultry meat. Meat Science, 79, 46–63.

Bevilacqua, A., Sinigaglia, M., & Corbo, M. R. (2013). Ultrasound and antimicrobial compounds: a suitable way to control Fusarium oxysporum in juices. Food and Bioprocess Technology, 6(5), 1153–1163.

Cárcel, J. A., Benedito, J., Bon, J., & Mulet, A. (2007). High intensity ultrasound effects on meat brining. Meat Science, 76, 611–619.

Chandrapala, J., Zisu, B., Palmer, M., Kentish, S., & Ashokkumar, M. (2011). Effects of ultrasound on the thermal and structural characteristics of proteins in reconstituted whey protein concentrate. Ultrasonics Sonochemistry, 18, 951–957.

Chandrapala, J., Oliver, C., Kentish, S., & Ashokkumar, M. (2012). Ultrasonics in food processing. Ultrasonics Sonochemistry, 19(5), 975–983.

Chang, H. J., Xu, X. L., Zhou, G. H., Li, C. B., & Huang, M. (2012). Effects of characteristics changes of collagen on meat physicochemical properties of beef semitendinosus muscle during ultrasonic processing. Food and Bioprocess Technology, 5, 285–297.

Droval, A. A., Benassi, V. T., Rossa, A., Prudencio, S. H., Paião, F. G., & Shimokomaki, M. (2012). Consumer attitudes and preferences regarding pale, soft, and exudative broiler breast meat. Journal of Applied Poultry Research, 21, 502–507.

Egelandsdal, B., Fretheim, K., & Samejima, K. (1986). Dynamic rheological measurements on heat-induced myosin gels: effect of ionic strength, protein concentration and addition of adenosine triphosphate or pyrophosphate. Journal of Science and Food Agriculture, 37, 915–926.

Ferris, J. J., Sandoval, A. J., Barreiro, J. A., Sánchez, J. J., & Müller, A. J. (2009). Gelation kinetics of an imitation-mortadella emulsion during heat treatment determined by oscillatory rheometry. Journal of Food Engineering, 95, 677–683.

Garcia, R. G., de Freitas, L. W., Schwingel, A. W., Farias, R. M., Caldara, F. R., Gabriel, A. M. A., Graciano, J. D., Komiyama, C. M., & Almeida Paz, I. C. L. (2010). Incidence and physical properties of PSE chicken meat in a commercial processing plant. Brazilian Journal of Poultry Science, 4, 233–237.

Gornall, A. G., Baradawill, C. J., & David, M. M. (1949). Determination of serum protein by means of the biuret reaction. Journal of Biological Chemistry, 177, 751–766.

Gülseren, I., Güzey, D., Bruce, B. D., & Weiss, J. (2007). Structural and functional changes in ultrasonicated bovine serum albumin solutions. Ultrasonics Sonochemistry, 14, 173–183.

Han, M., Zhang, Y., Fei, Y., Xu, X., & Zhou, G. (2009). Effect of microbial trans-glutaminase on NMR relaxometry and microstructure of pork myofibrillar protein gel. European Food Research and Technology, 228(4), 665–670.

Herrero, A. M. (2008). Raman spectroscopy a promising technique for quality assessment of meat and fish: a review. Food Chemistry, 107, 1642–1651.

Honikel, K. O. (1998). Reference methods for the assessment of physical characteristics of meat. Meat Science, 49, 447--457.

Horžić, D., Jambrak, A. R., Belščak-Cvitanović, A., Komes, D., & Lelas, V. (2012). Comparison of conventional and ultrasound assisted extraction techniques of yellow tea and bioactive composition of obtained extracts. Food and Bioprocess Technology, 5(7), 2858–2870.

Hu, H., Fan, X., Zhou, Z., Xu, X. Y., Fan, G., Wang, L. F., Huang, X. J., Pan, S. Y., & Zhu, L. (2013a). Acid-induced gelation behavior of soybean protein isolate with high intensity ultrasonic pretreatments. Ultrasonics Sonochemistry, 20(1), 187–195.

Hu, H., Li-Chan, E. C. Y., Wan, L., Tian, M., & Pan, S. Y. (2013b). The effect of high intensity ultrasonic pre-treatment on the properties of soybean protein isolate gel induced by calcium sulfate. Food Hydrocolloids, 32, 303–311.

Hu, H., Wu, J. H., Li-Chan, E. C. Y., Zhu, L., Zhang, F., Xu, X. Y., Fan, G., Wang, L. F., Xingjian Huang, X. J., & Pan, S. Y. (2013c). Effects of ultrasound on structural and physical properties of soy protein isolate (SPI) dispersions. Food Hydrocolloids, 30, 647–655.

Jambrak, A. R., Mason, T. J., Lelas, V., Herceg, Z., & Herceg, I. L. (2008). Effect of ultrasound treatment on solubility and foaming properties of whey protein suspensions. Journal of Food Engineering, 86, 281–287.

Jambrak, A. R., Herceg, Z., Šubarić, D., Babić, J., Brnčić, M., Brnčić, S. R., Bosiljkov, T., Čvek, D., Tripalo, B., & Gelo, J. (2010). Ultrasound effect on physical properties of corn starch. Carbohydrate Polymers, 79, 91–100.

Jambrak, A. R., Mason, T. J., Lelas, V., Paniwnyk, L., & Herceg, Z. (2014). Effect of ultrasound treatment on particle size and molecular weight of whey proteins. Journal of Food Engineering, 121, 15–23.

Jayasooriya, S. D., Bhandari, B. R., Torley, P., & D’Arcy, B. R. (2004). Effect of high power ultrasound waves on properties of meat: a review. International Journal of Food Properties, 7(2), 301–319.

Jayasooriya, S. D., Torley, P. J., D’Arcy, B. R., & Bhandari, B. R. (2007). Effect of high power ultrasound and ageing on the physical properties of bovine semitendinosus and longissimus muscles. Meat Science, 75, 628–639.

Jiang, J., & Xiong, Y. L. (2013). Extreme pH treatments enhance the structure-reinforcement role of soy protein isolate and its emulsions in pork myofibrillar protein gels in the presence of microbial transglutaminase. Meat Science, 93(3), 469–476.

Laemmli, V. K. (1970). Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature, 227, 680–685.

Lesiów, T., & Xiong, Y. L. (2001). Mechanism of rheological changes in poultry myofibrillar proteins during gelation. Avian & Poultry Biology Reviews, 12, 137–149.

Li, C., Huang, X., Peng, Q., Shan, Y., & Xue, F. (2014). Physicochemical properties of peanut protein isolate-glucomannan conjugates prepared by ultrasonic treatment. Ultrasonics Sonochemistry. doi:10.1016/j.ultsonch.2014.03.018.

Liu, R., Zhao, S. M., Xiong, S. B., Xie, B. J., & Liu, H. M. (2007). Studies on fish and pork paste gelation by dynamic rheology and circular dichroism. Journal of Food Science, 72(7), E399–E403.

Liu, R., Zhao, S. M., Xiong, S. B., Xie, B. J.,& Qin, L. H. (2008). Role of secondary structures in the gelation of porcine myosin at different pH values. Meat Science, 80, 632–639.

Liu, R., Zhao, S. M., Liu, Y. M., Yang, H., Xiong, S. B., Xie, B. J., & Qin, L. H. (2010). Effect of pH on the gel properties and secondary structure of fish myosin. Food Chemistry, 121, 196–202.

Madadlou, A., Emam-Djomeh, Z., Mousavi, M. E., Mohamadifar, M., & Ehsani, M. (2010). Acid-induced gelation behavior of sonicated casein solutions. Ultrasonics Sonochemistry, 17, 153–158.

McDonnell, C. K., Allen, P., Morin, C., & Lyng, J. G. (2014). The effect of ultrasonic salting on protein and water-protein interactions in meat. Food Chemistry, 147, 245–251.

Omana, D. A., Moayedi, V., Xu, Y., & Betti, M. (2010). Alkali-aided protein extraction from chicken dark meat: textural properties and color characteristics of recovered proteins. Poultry Science, 89, 1056–1064.

Petracci, M., Bianchi, M., Mudalala, S., & Cavani, C. (2013). Functional ingredients for poultry meat products. Trends in Food Science and Technology, 33, 27–39.

Pietrzak, M., Greaser, M. L., & Sosnicki, A. A. (1997). Effect of rapid rigor mortis processes on protein functionally in pectoralis major muscle of domestic turkeys. Journal of Animal Science, 75, 2106–2116.

Poulter, R. G., Ledward, D. A., Godber, S., Hall, G., & Rowlands, B. (1985). Heat stability of fish muscle proteins. Journal of Food Technology, 20, 203–217.

Rastogi, N. (2011). Opportunities and challenges in application of ultrasound in food processing. Critical Reviews in Food Science & Nutrition, 51, 705–722.

Shao, J. H., Zou, Y. F., Xu, X. L., Wu, J. Q., & Zhou, G. H. (2011). Evaluation of structural changes in raw and heated meat batters prepared with different lipids using Raman spectroscopy. Food Research International, 44, 2955–2961.

Somboonpanyakul, P., Barbut, S., Jantawat, P., & Chinprahast, N. (2007). Increasing the salt level resulted in an overall increase of cook yield, textural and sensory quality of poultry meat batter containing malva nut gum, salt and phosphate. LWT- Food Science and Technology, 40, 498–505.

Soria, A. C., & Villamiel, M. (2010). Effect of ultrasound on the technological properties and bioactivity of food: a review. Trends in Food Science and Technology, 21(7), 323–331.

Stadnik, J., & Dolatowski, Z. J. (2011). Influence of sonication on Warner-Bratzler shear force, colour and myoglobin of beef (M. semimembranosus). European Food Research Technology, 233, 553–559.

Sun, Y. J., Chen, J. H., Zhang, S. W., Li, H. J., Lu, J., Liu, L., Uluko, H., Su, Y. L., Cui, W. M., Ge, W. P., & Lv, J. P. (2014). Effect of power ultrasound pre-treatment on the physical and functional properties of reconstituted milk protein concentrate. Journal of Food Engineering, 124, 11–18.

Wang, H. L., Pato, M., Pietrasik, Z., & Shand, P. (2009). Biochemical and physicochemical properties of thermally treated natural actomyosin extracted from normal and PSE pork longissimus muscle. Food Chemistry, 113, 21–27.

Wilhelm, A. E., Maganhini, M. B., Hernandez-Blazquez, F. J., Ida, E. I., & Shimokomaki, M. (2010). Protease activity and the ultrastructure of broiler chicken PSE (pale, soft, exudative) meat. Food Chemistry, 119, 1201–1204.

Xiong, Y. L. (1994). Myofibrillar protein from different muscle fiber types: implications of biochemical and functional properties in meat processing. Critical Reviews in Food Science and Nutrition, 34(3), 293–320.

Xiong, Y. L. (1997). Structure-functionality relationships of muscle proteins. In S. Damodaran & A. Paraf (Eds.), Food protein and their application (pp. 341–392). New York: Marcel Dekker, Inc.

Zhang, L., & Barbut, S. (2005). Rheological characteristics of fresh and frozen PSE, normal and DFD chicken breast meat. British Poultry Science, 46, 687–693.

Zhou, F. B., Zhao, M. M., Zhao, H. F., Sun, W. Z., & Cui, C. (2014). Effects of oxidative modification on gel properties of isolated porcine myofibrillar protein by peroxyl radicals. Meat Science, 96(4), 1432–1439.

Zhu, X., Ruusunen, M., Gusella, M., Zhou, G., & Puolanne, E. (2011). High post-mortem temperature combined with rapid glycolysis induces phosphorylase denaturation and produces pale and exudative characteristics in broiler pectoralis major muscles. Meat Science, 89, 181–188.

Zhu, X. S., Xu, X. L., Min, H. H., & Zhou, G. H. (2012). Occurrence and characterization of pale, soft, exudative-like broiler muscle commercially produced in China. Journal of Integrative Agriculture, 11(8), 1384–1390.

Zisu, B., Bhaskaracharya, R., Kentish, S., & Ashokkumar, M. (2010). Ultrasonic processing of dairy systems in large scale reactors. Ultrasonics Sonochemistry, 17, 1075–1081.

Acknowledgments

The authors thank Dr Ron Tume from CSIRO, Animal, Food and Health Sciences for his helpful discussion and manuscript corrections. This study was supported by the National Natural Science Foundation of China (NSFC, Grant Nos. 31171707 and 31101308), the National Science and Technology Pillar Program during the Twelfth Five-year Plan Period of China (Grant No. 2012BAD28B01), and China Agriculture Research System (CARS-42) funded by the China Ministry of Agriculture.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, K., Kang, ZL., Zhao, YY. et al. Use of High-Intensity Ultrasound to Improve Functional Properties of Batter Suspensions Prepared from PSE-like Chicken Breast Meat. Food Bioprocess Technol 7, 3466–3477 (2014). https://doi.org/10.1007/s11947-014-1358-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1358-y