Abstract

Mildew growth on wheat kernels reduces grain quality due to gray discoloration of kernels that has negative impact on the resulting flour color. Higher levels of mildew damage equate to lower levels of quality. In this study, grain spectra in the 400–1,000 (visible-shortwave-near-infrared) and 1,000–2,500-nm (near-infrared) wavelength ranges were investigated for their ability to quantify mildew damage in Soft Red Winter (SRW) wheat grown in eastern Canada. For each wavelength range, partial least squares (PLS) regression models were developed for various commonly used data pre-treatments. Spectra in the 400–1,000-nm region with a mean-centering pre-treatment were optimal for quantification of mildew damage in SRW wheat. A PLS model using this approach predicted mildew damage in an independent test sample set accurately achieving a root-mean-squared-error of 0.69 and ratio-performance-deviation of 3.84 with the classification accuracy of 96 % for predictions within ±1 level against the trained inspectors’ visual assessment of mildew damage scored on a nine-level scale.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mildew is a surface fungal contamination of grain caused by various fungi such as Cladosporium spp. and Alternaria alternata that thrive under wet, humid conditions. Mildew damage in wheat has a negative impact on processing quality and commercial value of the grain (Dexter and Edwards 1998). The early stage of mildew contamination is often characterized by a gray discoloration of the brush end of the wheat kernel. As the severity of mildew damage increases, the infection spreads over the entire surface of the kernel (Dexter and Matsuo1982). Mildew is not known to have any toxicological effects in humans but has a negative impact on the aesthetic quality of the products made from mildewed wheat. While severely mildewed wheat lots, characterized by blackened kernels, do not make it to the milling grade, wheat with mild or moderate levels of damage are milled. Increasing levels of mildew damage in common wheat are inversely related to quality (color) of flour. Flour milled from mildewed common wheat (Triticum aestivum) has a darker color (Dexter and Edwards 1998; Dexter and Matsuo 1982). The impact of mildew damage on durum wheat (Triticum durum) products is more evident due to the glassy yellow color of the kernels. Mildew infection causes a reduction in yellow pigment, a duller appearance and a significant increase in the speckiness of the milled product, semolina, producing pasta of low visual appeal—a major consumer criterion for acceptance—although no impact on semolina yield was observed (Dexter and Matsuo 1982). Powdery mildew, a foliar disease, causes a reduction in milling yield with increasing levels of mildew (Everts et al. 2001).

The Canadian Grain Commission is the Canadian federal agency responsible for establishing tolerances for the various grades of wheat classes grown in Canada and has carried out extensive research to ensure that the level of mildewed kernels within each grade are appropriate and reflect the intrinsic value of the grain. The current grain grading system is based on a relatively slow and subjective human visual inspection by trained inspectors, whereby the degree of mildew damage is assessed by comparison to standard samples. In Canada, to enhance the accuracy of visual grading, reference is made to mildew-guides: reference grain samples where mildew is the predominant degrading factor. Even with these visual guides, it remains difficult to quickly quantify the amount of mildew damage through visual inspection, especially for samples with light to moderate degrees of damage. Fast and accurate objective methods for quantification of mildew damage are required to cope with high volume inspection demanded by the grain industry to meet the needs of national as well as international trade.

Luo et al. (1999) used conventional image analysis to detect mildew and five other types of damage factors (broken, grass-green/green-frosted, black-point/smudge, heated, and bin/fire-burnt) on Canadian western red spring wheat kernels. They were able to detect visually obvious severely damaged mildewed kernels highly accurately (97 %); however, detection of visually challenging slight or moderate levels of mildew damage was not reported. The identification of damaged regions of individual kernels by imaging appears to be a logical solution. However, variations in the discoloration of the damaged regions and the color of underlying kernels make this impossible to achieve using a traditional imaging platform.

The use of near-infrared spectroscopy (NIRS) has become commonplace for grain analyses in the agricultural sector over the last few decades. Grain moisture and protein are determined by NIRS methods for operational speed. These methods have been extensively researched and are some of the earliest grain components reported as being measured by diffuse reflectance NIRS (Williams et al. 1985; Williams 1991; Williams and Sobering 1993). Pojic and Mastilovic (2012) have presented a very comprehensive review of recent advances in the use of NIR spectroscopy for measuring end-use quality, safety, and functionality of wheat as applicable in wheat breading, trade, and processing. NIRS as a detection method has proven effective for grain components that have a relatively homogenous distribution both throughout the sample and throughout the individual kernels such as moisture, protein, and kernel texture or hardness (Williams et al. 1985; Williams 1991; Maghirang and Dowell 2003). While it has been demonstrated that NIRS methods can detect other grading factors such as vitreous kernels (Dowell 2000) or scab (Delwiche 2003), it has been found by experience in our laboratory to work effectively only within the calibration sets that were used to derive the prediction models. This is also evidenced by the simple fact that no NIRS instruments are being used commercially to estimate these parameters. The prediction of grading effects in unknown samples has proven to be of limited practical use for application to a grain grading system as practiced in Canada. This can be simply explained since factors such as sprouting, vitreous kernels or scab do not uniformly affect every kernel in the sample creating a heterogeneous distribution, compounded by the uneven damage to individual kernels. Damage may be regionalized to the germ or brush end, or change with degree of damage.

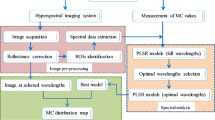

Hyperspectral imaging (HSI) has recently emerged as a research tool for food quality and safety control (Gowen et al. 2007). HSI is the combination of conventional imaging with spectroscopy providing information in both spatial and spectral domains. Each pixel in a hyperspectral image (hypercube) contains the entire spectrum that can be used as a fingerprint to characterize the composition of image regions. HSI systems have been used in a wide variety of fields including remote sensing, pharmaceutical, medical, and agricultural industries. In the agro-food industry, HSI applications have been reported for the quality assessment of fruits (Kim et al. 2002; Lu 2003), vegetables (Cheng et al. 2004), poultry (Park et al. 2002), beef steaks (Naganathan et al. 2008), and cereal grains (Cogdill et al. 2004; Lin et al. 2006; Goretta et al. 2006; Shahin and Symons 2008). Recent studies have shown that hyperspectral imaging can distinguish sprout damaged (Singh et al. 2009; Xing et al. 2009) as well as stained and fungal infected (Berman et al. 2007; Singh et al. 2007; Shahin and Symons 2011, 2012) wheat kernels from sound kernels. Shahin et al. (2012) summarized hyperspectral imaging research at the Canadian Grain commission for the quantification of grain damage due to various grading factors including fusarium damage, sprout damage and its effect on alpha-amylase activity in sprouted kernels, as well as mildew damage and its effect on the quality of flour milled from mildew damaged wheat. Spectral characteristics of mildewed wheat kernels are significantly different from those of sound undamaged kernels (Shahin and Symons 2007). Based on these spectral differences, Shahin et al. (2010) were able to measure varying degrees of mildew damage in commercial soft red wheat samples. Using PLS regression models, nine visually determined levels of mildew damage in wheat samples representing three grades were predicted using HSI with an accuracy approaching 91 % for within ±1 level of severity. The current objectives are (a) evaluating the performance of the PLS model for predicting the severity of mildew damage in SRW wheat on an independent sample set collected from a different crop year and (b) comparing the spectral measurements in the 400–1,000 and 1,000–2,500-nm wavelength ranges for predicting the severity of mildew damage by comparing commonly used data pre-processing techniques. The overall goal was to determine the most suitable instrument, wavelength range and pre-processing technique for detection and quantification of mildew damage in soft red winter wheat.

Materials and Methods

Samples

Two independent sets of Canada eastern soft red winter (CESRW) wheat samples, selected on the basis of mildew damage being the primary degrading factor, were used. Set A (calibration set) consisted of 68 samples collected from the 2008 crop year while set B (test set) consisted of 27 samples from the 2009 crop year. Each sample weighed approximately 1 kg. These samples consisted of several varieties of the CESRW class of wheat from multiple growers in different regions of eastern Canada reflecting variations in growing conditions and soil types. Each sample was visually graded and scored by a trained grain inspector from the Industry Services division of the Canadian Grain Commission based on mildew damage. Samples in each set were selected that covered a wide range of mildew damage over three grades (1, 2, and 3). Each grade category was further subdivided into three levels—high (H), medium (M), and low (L)—based on the severity of mildew damage. For example, a sample with a score of H1 represents top of grade 1 (highest quality grain) while a sample scored as L3 represents bottom of grade 3 (most severely damaged by mildew in the range of samples studied). Nine levels of mildew damage were created for experimental purposes, each assigned a numerical value from 1 (H1) to 9 (L3) where a bigger number meant a higher degree of mildew damage (Table 1).

Spectral Measurements

Each sample was hand mixed thoroughly and a representative sub-sample, consisting of approximately 100 g, was manually drawn for spectral measurements. Two instruments were used to collect spectra separately in the 400–1,000 and 1,000–2,500-nm wavelength ranges. For measurements in the 400–1,000-nm range, approximately 100 g of bulk grain per sample was imaged with a push-broom type hyperspectral imaging system (VNIR 100E; Lextel Intelligence Systems, Jackson, MS, USA) in reflectance mode. Two 250 w quartz-tungsten-halogen lamps were used for sample illumination. Power to each lamp was regulated through a radiometric power supply (M-69931; Newport Oriel, Stratford, CT, USA). Image size was 800 by 400 pixels by 218 wavebands within 400–1,000 nm range at a spectral resolution of approximately 2.75 nm. Each sample image was calibrated against a white reference tile with 99 % reflectance (Spectralon, Labsphere, USA) and an image-mean-spectrum was computed from the calibrated image. Details of the imaging system as well as the spectral data extraction were previously described in Shahin et al. (2010).

For measurements in the 1,000–2,500 nm range, a Fourier Transform (FT)-NIR Analyzer (Antaris II, Thermo Scientific, USA) was used to collect absorbance spectra for bulk wheat samples. Whole spectrum scanning was done over the wavelength range of 1,000–2,500 nm at a spectral resolution of approximately 1 nm. Approximately 50 g of bulk grain per sample was placed in a spinner cup centered over the integrating sphere of the instrument. Each spectrum obtained was an average of 32 scans collected over 1 revolution of the spinner cup. Background spectra were taken hourly. RESULT Integration v3.0 software (Thermo Electron Corp) saved the data as Nicolet spectra (.spa) files for subsequent analyses. SWIR HSI instruments operating in the 1,000–2,500 nm range do not provide the desired spatial and spectral resolution at this time for this analytical approach.

Data Analysis

The image mean spectra extracted from hyperspectral images of both calibration set (2008 crop samples) and test set (2009 crop samples) were analyzed using Unscrambler X (v10.1, CAMO Software, Oslo, Norway) using the corresponding visually assessed inspector scores of mildew damage as the reference. Partial least squares (PLS) regression models were developed and tested for predicting mildew damage. Using spectra within 450–950 nm as input variables (X) and inspector visual scores for mildew damage as the reference variable (Y), PLS models were developed for a number of commonly used transformation techniques as a pre-treatment of the X variables. Wavelengths outside of this range had a low signal-to-noise ratio and were not usable. Pre-treatments used included mean-centering (center) as well as mean-normalization (normalize), baseline-correction (baseline), standard-normal-variate (SNV), multiplicative-scatter-correction (MSC), 1st-order derivative (D1), and 2nd-order derivative (D2) with and without mean-centering. The calibration data set was used to develop the PLS models while the test set was used to evaluate the performance of the models. Performance of the PLS models was evaluated based on slope, offset (y intercept), coefficient of determination (R 2), and root mean squared error (RMSE) between predicted and target mildew scores. A single measure of relative performance of PLS models, ratio-performance-deviation (RPD), was computed as the ratio of the standard deviation of reference values (SDy) to the standard error of prediction (SEP) using Eq. 1 (Williams 2001).

Where, RMSE for the test set was used as a measure of SEP. PLS models with an RPD value greater than that for the reference model (no pre-treatment of the spectral data) on the test set were further analyzed for accuracy of mildew level classification compared with the inspector visual scores for mildew damage. For mildew level classification, output of PLS models was partitioned into nine equally spaced discrete classes using the following rule base:

-

if (output < 1.5) then class = H1

-

if (1.5 ≤ output < 2.5) then class = M1

-

if (2.5 ≤ output < 3.5) then class = L1

-

if (3.5 ≤ output < 4.5) then class = H2

-

if (4.5 ≤ output < 5.5) then class = M2

-

if (5.5 ≤ output < 6.5) then class = L2

-

if (6.5 ≤ output < 7.5) then class = H3

-

if (7.5 ≤ output < 8.5) then class = M3

-

if (output ≥ 8.5) then class = L3

Improvements in model performance were sought through fine-tuning/slope–offset correction. Estimates of slope (m) and offset (c) values were determined using PLS predictions of nine randomly selected samples (one for each mildew level) from the test set. Based on these estimates, test set predictions (yp) with the PLS model were corrected using Eq. (2) such that the resultant offset and slope for the least-squares line passing through the scatter of reference vs. corrected predictions (ypc) would approach the desired values of zero and one, respectively.

Similarly, PLS models to predict mildew damage were developed and evaluated using the spectral data measurements in the 1,000–2,500-nm range as the input variables with the same data pre-treatments as previously described. Performance of the PLS models using 1,000–2,500 nm were compared to those using 450–950 nm to determine which spectral range quantified mildew damage in CESRW wheat with most accuracy.

Results and Discussion

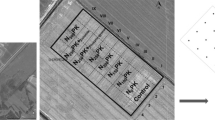

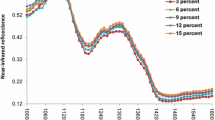

Hyperspectral images of two samples with different mildew levels from slight (ML1) to severe (ML7) show differences in overall color/appearance due to the severity of mildew damage (Fig. 1). Mean spectra from these two samples (Fig. 2) show differences in reflectance intensity due to mildew damage. Spectra collected using VNIR HSI system (Fig. 2a) showed no distinct absorption peaks except for a chlorophyll absorption band at around 475 nm and a water absorption band at around 900 nm. Mildew damage affected the intensity and slope changes in the 450–950 nm spectral range. The largest spectral differences due to mildew were above 700 nm. Spectra from the FT-NIR instrument (1,000–2,500 nm) had a number of peaks and valleys below 2,000 nm, while the spectra above 2,000 nm were virtually flat (Fig. 2b). Spectral differences due to mildew damage are intensity shifts within 1,000–2,000 nm range.

a Mean-spectra of samples in Fig. 1 as captured with a VNIR hyperspectral imaging system in the 400–1,000-nm range and b FT-NIR instrument in the 1,000–2,500-nm range

Data standardization through normalization or correction as a pre-treatment typically creates robust PLS models that generalize well to new samples unknown to the models. The performance of PLS models using the 450–950 nm range varied with pre-treatments for the quantification of mildew damage in CESRW wheat (Table 2). The reference model using the raw spectra with no pre-treatment applied had an RMSE of 1.37 with an RPD of 1.92 for the test samples. There were eight models using pre-treated spectra that had lower RMSE (1.19–1.30) and higher RPD (2.02–2.21) for the test samples, indicating that these pre-treatments improved the predictability of these models. These values of RPD suggest that these models have the potential for quantitative prediction, but remain below the desired RPD of greater than three for acceptable predictions (Williams 2001). The best model based on the 450–950 nm spectra used the mean-center pre-treatment and had the lowest RMSE (1.19) and the highest RPD (2.21) amongst all the pre-treatments investigated. The scores plot for the first two PLS factors (latent variables) of this model had near symmetrical sample distribution (Fig. 3a). Factor-1 and Factor-2 collectively explained 94 % of the X variance and 60 % of the Y variance of the calibration sample set. Samples were generally grouped into three grade levels based on scores of Factor-1 and Factor-2 (Fig. 3a). Groupings based on nine mildew levels (3 levels in each grade), required at least eight factors in the model to minimize the Y-residuals for the test samples (Fig. 3b). PLS loadings for the 8-factor model (Fig. 3c) were relatively larger at the lower and higher ends of the spectrum as expected based on the spectral differences in these regions (Fig. 2a). Mildew damage was not associated with any single wavelength. Instead, several wavebands correlated with the target variable (mildew) as indicated by strong PLS loadings (Fig. 3c). PLS loadings and/or regression coefficients can be used for selecting a reduced set of significant wavelengths for building simpler models without compromising the model performance (Shahin et al. 2010). Details of the process of wavelength selection, which are beyond the scope of this paper, can be found in the published literature (Shahin and Symons 2012; Shahin et al. 2012; Esquerre et al. 2011). The majority of the Y residuals were within ±1 for both the calibration and test samples (Fig. 3d); however, residuals larger than 1 for some samples lead to larger than desired prediction error for the 8-factor PLS model. Even the best RPD achieved in this case remained below the target of better than 3, a value for acceptable prediction. Seven of the other pre-treatments that generated prediction models better than the reference model were SNV, MSC, and mean-normalization with and without mean-centering, as well as the 1st-order derivative (D1). Six of these seven models also required 7–8 PLS factors with the scores, loadings and regression coefficients plots qualitatively similar to the mean centered model described. The model for the D1 plus mean-centering pre-treatments required four PLS factors capturing 97 % of the X variance and 77 % of the Y variance, with the first 2 factors explaining 58 % of the X variance and 60 % of the Y variance. Five models (based on baseline, baseline and mean-centering, D2, D2 and mean-centering, as well as D1 pre-treatments) had prediction levels below that of the reference model.

Model space information for the PLS model based on mean-centered 450–950 nm spectra. a Scatter plot of scores for PLS Factor-1 and Factor-2 showing sample grouping based on grade, b Residual variance of the target variable (mildew) as affected by the number of factors in the PLS model, c X-loadings for the 8-factor PLS model showing peaks indicative of important wavebands, and d residuals scatter plot for the calibration (cesrw2008) and the test (cesrw2009) sample sets for the 8-factor model

The prediction model based on the raw 1,000–2,500 nm spectra with no pre-treatment was a poor predictor with an RPD below 1.50 and an RMSE of 1.76 for the test samples (Table 3). The performance of this model was lower than the reference model based on 450–950 nm spectra. Similarly, PLS prediction models with pre-treatments in the 1,000–2,500-nm range had lower RPD values than similar models in the 450–950-nm range. The best of these models had RPD values close to 2.0 indicating models were unsuitable for quantitative prediction. This indicates that spectra of bulk grains measured at 450–950 nm with a hyperspectral imaging system were a better predictor of mildew levels in the CESRW wheat class than the 1,000–2,500-nm spectra measured with an FT-NIR instrument. Mean-centering was the most appropriate pre-treatment for this application. Performance of the best PLS model, based on the mean-centered 450–950 nm spectra (RPD = 2.21, RMSE = 1.19) was less than desirable for mildew quantification. For this application, an RMSE close to 0.5 and an RPD greater than 3 (preferably close to 5) would be ideal.

Performance of these models (450–950 nm) for sample classification based on mildew levels was below acceptable levels for direct application to grain classification. The best accuracy of classification, 37 %, when comparing model predictions to the inspector visual scores was achieved using the PLS model for the D1 pre-treatment followed by mean-center transformation. Classification accuracy in all other models was 15 % to 26 %. A logical reason for this poor prediction performance was low slope values for the best fit least squares models for the test set predictions. The slope values for the test set predictions were smaller than the calibration set slopes for the equivalent models and less than the desired slope of 1.0 while the offset values are larger than calibration data set and the desired offset value of 0 (Table 2). These slope and offset deviations from the “ideal” values is a cause for higher RMSE for model predictions. Corrections to slope and offset are common steps in the development of prediction models in spectroscopy (Candolfi and Massart 2000; Myles et al. 2006). Slope and offset corrections were applied to the 450–950-nm PLS models to test their effect on mildew predictions. A set of randomly selected nine samples (one for each mildew level) from the test sample set was used to determine the amount of corrections needed. Following slope and offset correction, prediction models improved with RPD values in excess of 3.3 for 4 of the 450–950-nm models, indicating the potential for good quantitative prediction (Table 4). Maximum improvement was observed for the mean-center pre-treatment with the RPD increasing to 3.84 and RMSE decreasing to 0.69. Models with mean-normalization, with and without mean-centering, had similar improvements in performance (RPD = 3.36, RMSE = 0.79). Similarly SNV plus mean-centering also produced a prediction model that should prove satisfactory (RPD = 3.42, RMSE = 0.78).

Classification results for these models improved, as would be expected from the higher RPD values following slope and offset correction (Table 5). The model based on mean-centered data showed the highest accuracy (67 %) for classification into nine mildew levels as determined by inspector visual scores. Mean-normalized spectra gave 63 % accuracy followed by SNV transformed mean-centered spectra at 56 %. Class by class accuracy of prediction after slope and bias correction was 100 % (3 out of 3) for three mildew levels (1, 7, and 8), 67 % (2/3) for four mildew levels (3, 4, 6, and 9), 33 % (1/3) for mildew level 2, and 0 % for the level 5 where 3/3 samples were misclassified into adjacent levels. When classification within one adjacent level of mildew was considered as an acceptable prediction, which is a reasonable assumption given that mildew damage is a continuous, not a discrete characteristic, the accuracy of classification improved to over 90 % for 2 models (Table 5). The increase in classification accuracy shows that most misclassifications were within one adjacent level of mildew damage, e.g., mildew level of 5 was misclassified as either level 4 or 6 (Fig. 4). A small proportion of sample predictions (11 %) crossed the grade line, which might be debatable as the shift in grade is undesirable. Considering the subjective nature of the visual scores and the continuous nature of mildew damage, variations among inspectors in assigning visual scores are not uncommon especially for the borderline samples (unpublished experimental data). Sampling errors may also cause disagreements between inspectors or between an inspector and an instrument. Hence, classification within ±1 level of mildew can be acceptable for practical purposes. Given that in this study, each grade, which is the real world segregation of quality, was split into three divisions of high, medium and low, this approach to mildew classification shows practical potential for grain grading in Canada.

Inspector assessed (actual) mildew levels for CESRW wheat test samples vs. mildew predictions with the PLS model based on mean-centered 450–950 nm spectra after slope–offset correction. Smaller dotted squares represent mildew levels and larger solid squares represent grades. Arrows point to the samples for which the model predictions crossed the grade line

As the proposed method determines the extent of mildew damage based on the spectral characteristics of bulk samples, no sample preparations are required for sample analysis. This makes it an easy to use and practical method in contrast to the previously suggested methods of fungal detection based on single kernels analyses (Berman et al. 2007; Singh et al. 2007; Shahin and Symons 2011, 2012). Kernel singulation is laborious and time-consuming and has been one of the liming factors to the acceptance of imaging in grain grading. In comparison with the current industry standard, the method of human visual inspection, the proposed instrumental approach offers a relatively faster and more repeatable alternative approach. Instrumental analysis has the possibility of analyzing multiple sub-samples drawn from a particular lot of wheat and assessing mildew damage in a larger proportion of the grain lot. This approach with a larger sampling capacity has the potential to reduce the measurement error due to non-representative sampling, leading to improvements in the accuracy of assessment of grain damage due to mildew.

The results obtained in this research indicated that spectra in the 450–950-nm range are better suited for the quantification of mildew damage in CESRW wheat as well as for the classification of samples based on the extent of mildew damage. Spectra in the 1,000–2,500 nm range were less effective at mildew detection and hence prediction models were less accurate. This is explained because kernel discoloration due to mildew damage is more readily detectable in the visible range of the electromagnetic spectrum. Mean-centering proved to be the best pre-treatment for this application followed by the mean-normalization. Slope and offset corrections based on nine samples randomly selected from the test set improved the model predictions and classification accuracy to acceptable levels. Corrections based on 18 samples (two sample for each mildew level) selected from the test set further improved the 9-level mildew classification from 67 % to 70 % for the best model. Classification within ±1 level was at 96 % as compared to 91 % for the previously reported model (Shahin et al. 2010) which dealt with samples from one crop year. The fact that only a small number of samples were required for the slope and offset correction has demonstrated that the proposed models can easily be adapted to new samples. However, the need for a larger sample set from multiple crop years cannot be overemphasized if creating a model that is generalized and of practical use over many growing seasons. Prediction models based on large data sets account for more inherent variations in the samples. Only when large multi-year data sets are available can true general models become established using multi-layer neural networks. A model draws its intelligence from between-class variances in the sample base used to develop calibrations. Slope and bias corrections as well as model fine-tuning are often required, especially during earlier stages of developments, to cope with year-to-year variability. Near-infrared spectroscopy models for wheat moisture and protein have evolved to their current level of accuracy with tens of thousands of samples collected over multiple crop years. Despite their huge (and ever expanding) sample bases, these models still need periodic maintenance (slope and/or bias correction; fine-tuning). Continuous improvements of the proposed models through retraining and validation with additional samples accounting for year-to-year environmental as well as geographical variations remains the focus of the ongoing development of objective grain grading methods at the Canadian Grain Commission.

Conclusions

Based on the results obtained in this study, it can be concluded that the grain spectra in the 450–950-nm wavelength range are more effective for quantification of mildew damage in the Soft Red Winter wheat than the spectra in the 1,000–2,500-nm range. Mean-centering is the best pre-treatment for this application. A PLS model based on mean-centered 450–950 nm spectra gave an RMSE of less than 0.70 for the test samples with an RPD approaching 3.85 leading to a classification accuracy of 96 % (±1 level) as compared to visually assessed nine mildew levels. Mean-normalization as well as a combination of SNV and mean-centering pre-treatments can produce PLS prediction models with satisfactory performance.

References

Berman, M., Connor, P. M., Whitbourn, L. B., Coward, D. A., Osborne, B. G., & Southan, M. D. (2007). Classification of sound and stained wheat grains using visible and near infrared hyperspectral image analysis. Journal of Near Infrared Spectroscopy, 15, 351–358.

Candolfi, A., & Massart, D. L. (2000). Model updating for the identification of NIR spectra from a pharmaceutical excipient. Applied Spectroscopy, 54, 48–53.

Cheng, X., Chen, Y. R., Tao, Y., Wang, C. Y., Kim, M. S., & Lefcourt, A. M. (2004). A novel integrated PCA and FLD method on hyperspectral image feature extraction for cucumber chilling inspection. Transactions of the American Society of Agricultural and Biological Engineering, 47, 1313–1320.

Cogdill, R. P., Hurdburgh, C. R., & Rippke, G. R. (2004). Single kernel maize analysis by near-infrared hyperspectral imaging. Transactions of the American Society of Agricultural and Biological Engineering, 47, 311–320.

Delwiche, S. R. (2003). Classification of scab- and other mold-damaged wheat kernels by near-infrared reflectance spectroscopy. Transactions of the American Society of Agricultural and Biological Engineering, 46, 731–738.

Dexter, J. E., & Edwards, N. M. (1998) The implications of frequently encountered grading factors on the processing quality of common wheat. Association of Operative Millers – Bulletin, 7115.

Dexter, J. E., & Matsuo, R. R. (1982). Effect of smudge and blackpoint, mildewed kernels, and ergot on durum wheat quality. Cereal Chemistry, 59, 63–69.

Dowell, F. E. (2000). Differentiating vitreous and nonvitreous durum wheat kernels by using near-infrared spectroscopy. Cereal Chemistry, 77, 155–158.

Esquerre, C., Gowen, A. A., Downey, G., & O’Donnell, C. P. (2011). Selection of variables based on most stable normalized partial least squares regression coefficients in an ensemble Monte Carlo procedure. Journal of Near Infrared Spectroscopy, 19, 343–350.

Everts, K. L., Leath, S., & Finney, P. L. (2001). Impact of powdery mildew and leaf rust on milling and baking quality of soft red winter wheat. Plant Disease, 85, 423–429.

Goretta, N., Roger, J. M., Aubert, M., Bellon-Maurel, V., Campan, F., & Roumet, P. (2006). Determining vitreouness of durum wheat kernels using near infrared hyperspectral imaging. Journal of Near Infrared Spectroscopy, 14, 231–239.

Gowen, A. A., O’Donnell, C. P., Cullen, P. J., Downy, G., & Frias, J. M. (2007). Hyperspectral imaging—an emerging process analytical tool for food quality and safety. Trends in Food Science & Technology, 18, 590–598.

Kim, M. S., Lefcourt, A. M., Chao, K., Chen, Y. R., Kim, I., & Chan, D. E. (2002). Multispectral detection of fecal contamination on apples based on hyperspectral imagery. Transactions of the American Society of Agricultural and Biological Engineering, 45, 2027–2037.

Lin, L. H., Lu, F. M., & Chang, Y. C. (2006). Development of a near-infrared imaging system for determination of rice moisture. Cereal Chemistry, 83, 498–504.

Lu, R. (2003). Detection of bruise on apples using near-infrared hyperspectral imaging. Transactions of the American Society of Agricultural and Biological Engineering, 46, 523–530.

Luo, X., Jayas, D. S., & Symons, S. J. (1999). Comparison of statistical and neural network methods for classifying cereal grains using machine vision. Transactions of the American Society of Agricultural and Biological Engineering, 42, 413–419.

Maghirang, E. B., & Dowell, F. E. (2003). Hardness measurement of bulk wheat by single-kernel visible and near-infrared reflectance spectroscopy. Cereal Chemistry, 80, 316–322.

Myles, A. J., Zimmerman, T. A., & Brown, S. D. (2006). Transfer of multivariate classification models between laboratory and process near-infrared spectrometers for the discrimination of green Arabica and Robusta coffee beans. Applied Spectroscopy, 60, 1198–1203.

Naganathan, G. K., Grimes, L. M., Subbiah, J., Calkins, C. R., Samal, A., & Meyer, G. E. (2008). Partial least squares analysis of near-infrared hyperspectral images for beef tenderness prediction. Sensing and Instrumentation for Food Quality and Safety, 2, 178–188.

Park, B., Lawrence, K. C., Windham, W. R., & Buhr, R. J. (2002). Hyperspectral imaging for detecting fecal and ingesta contaminants on poultry carcasses. Transactions of the American Society of Agricultural and Biological Engineering, 45, 2017–2026.

Pojic, M. M., & Mastilovic, J. S. (2012). Near-infrared spectroscopy—advanced analytical tool in wheat breading, trade and processing. Food and Bioprocess Technologies. doi:10.1007/s11947-012-0917-3.

Shahin, M. A., & Symons, S. J. (2007) The use of hyperspectral imaging to characterize wheat grading factors. In: Prococeedings of the 13th International Conference on NIR, Umea, Sweden.

Shahin, M. A., & Symons, S. J. (2008). Detection of hard vitreous and starchy kernels in amber durum wheat samples using hyperspectral imaging. NIR News, 19, 16–18.

Shahin, M. A., & Symons, S. J. (2011). Detection of Fusarium damage in Canada Western Red Spring wheat using visible/near-infrared hyperspectral imaging and principal component analysis. Computers and Electronics in Agriculture, 75, 107–112.

Shahin, M. A., & Symons, S. J. (2012). Detection of Fusarium damage in Canadian wheat using visible/near-infrared hyperspectral imaging. Food Measurement & Characterization, 6, 3–11. doi:10.1007/s11694-012-9126-z.

Shahin, M. A., Hatcher, D. W., & Symons, S. J. (2010). Assessment of mildew levels in wheat samples based on spectral characteristics of bulk grains. Quality Assurance and Safety of Crops & Foods, 2, 133–140.

Shahin, M. A., Hatcher, D. W., & Symons, S. J. (2012). Developing multispectral imaging systems for quality evaluation of cereal grains and grain products. In D.-W. Sun (Ed.), Computer vision technology in the food and beverage industries (pp. 451–482). Cambridge, UK: Woodhead Publishing Limited.

Singh, C. B., Jayas, D. S., Paliwal, J., & White, N. D. G. (2007). Fungal detection in wheat using near-infrared hyperspectral imaging. Transactions of the American Society of Agricultural and Biological Engineering, 50, 2171–2176.

Singh, C. B., Jayas, D. S., Paliwal, J., & White, N. D. G. (2009). Detection of sprouted and midge-damaged wheat kernels using near-infrared hyperspectral imaging. Cereal Chemistry, 86, 256–260.

Williams, P. C. (1991). Prediction of wheat kernel texture in whole grains by near-infrared transmittance. Cereal Chemistry, 68, 112–114.

Williams, P. C. (2001). Near-infrared technology in the agricultural and food industries. In N. Williams (Ed.), Implementation of near-infrared technology (2nd ed., pp. 145–169). St Paul, USA: American Association of Cereal Chemists.

Williams, P. C., & Sobering, D. C. (1993). Comparison of commercial near infrared transmittance and reflectance instruments for analysis of whole grains and seeds. Journal of Near Infrared Spectroscopy, 1, 25–32.

Williams, P. C., Norris, K. H., & Sobering, D. C. (1985). Determination of protein and moisture in wheat and barley by near-infrared transmission. Journal of Agricultural and Food Chemistry, 33, 239–244.

Xing, J., Hung, P., Symons, S., Shahin, M., & Hatcher, D. (2009). Using a SWIR hyperspectral imaging system to predict alpha amylase activity in individual Canadian Western wheat kernels. Sensing and Instrumentation for Food Quality and Safety, 3, 211–218.

Acknowledgments

The authors would like to thank the Industry Services Division of the Canadian Grain Commission (CGC) for providing inspected samples for this research. They would also like to appreciate the assistance of Loni Powell of the Image Analysis & Spectroscopy Program (CGC) in sample collection, preparation, and scanning.

Author information

Authors and Affiliations

Corresponding author

Additional information

GRL # 1056

Rights and permissions

About this article

Cite this article

Shahin, M.A., Symons, S.J. & Hatcher, D.W. Quantification of Mildew Damage in Soft Red Winter Wheat Based on Spectral Characteristics of Bulk Samples: A Comparison of Visible-Near-Infrared Imaging and Near-Infrared Spectroscopy. Food Bioprocess Technol 7, 224–234 (2014). https://doi.org/10.1007/s11947-012-1046-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1046-8