Abstract

The quality of stored minced pork meat was monitored using a rapid multispectral imaging device to quantify the degree of spoilage. Bacterial counts of a total of 155 meat samples stored for up to 580 h have been measured using conventional laboratory methods. Meat samples were maintained under two different storage conditions: aerobic and modified atmosphere packages as well as under different temperatures. Besides bacterial counts, a sensory panel has judged the spoilage degree of all meat samples into one of three classes. Results showed that the multispectral imaging device was able to classify 76.13 % of the meat samples correctly according to the defined sensory scale. Furthermore, the multispectral camera device was able to predict total viable counts with a standard error of prediction of 7.47 %. It is concluded that there is a good possibility that a setup like the one investigated will be successful for the detection of spoilage degree in minced pork meat.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

So far, more than 50 chemical, physical and microbiological methods have been proposed for the detection and measurement of bacterial safety or spoilage in meat (Ellis and Goodacre 2001; Byun et al. 2003; Nychas et al. 2008). However, most of these methods are time-consuming and provide retrospective information, so they cannot be used on- or at-line (Ellis et al. 2002, 2004; Nychas et al. 1998, 2008). Additionally, the development in food processing and preservation technologies [e.g., vacuum packaging (VP), modified atmosphere packaging (MAP), active packaging, etc] as well as the storage temperature either misused or even abused in the meat chain (Koutsoumanis and Taoukis 2006) make it evident that the important and urgent task of identifying safety and spoilage indicators is a complicated proposition. On the other hand, the meat industry needs rapid analytical methods or tools for quantification of these indicators in order to determine and select suitable processing procedures for their raw material and to predict the remaining shelf life of their products. The use of microbial metabolites as well as the quantification of fingerprinting e.g. with vibrational spectroscopy instruments in meat has been continuously recognized as a potential means for assessing meat quality (Dainty 1996; Nychas et al. 2008).

Recently the potential of using image analysis of digital colour pictures has been applied for assessing the quantitative distribution of different tissues in the surface of hams prior to salting (Sánchez et al. 2008) and for the quantification of fat content in salmon fillets (Stien et al. 2007). It is, however, still difficult with most vision technologies to reliably distinguish small differences in the appearance of food products, because the visual variation is typically within shades of red, shades of green, shades of yellow, or in the case of fried meat within shades of greyish-brown. A way to combine the strengths of vision technology and spectroscopy is to use multispectral imaging in the visual and near infrared range of wavelengths. This is the case with a videometer, an instrument able to record spectral reflection properties in narrow bands, thereby making it possible to assess the surface chemistry maps or hypecubes of the object of interest (Carstensen et al. 2006; Chevallier et al. 2006). In short, multispectral images can provide not only spatial information, such as regular imaging systems, but also spectral information for each pixel in an image. Thus, using hyperspectral images, it is possible to assess physical and geometric characteristics such as colour, size, shape and texture. Several publications have been written on the subject of using multispectral imaging for food control (Gowen et al. 2007; Daugaard et al. 2010; Taghizadeh et al. 2010). Multispectral images are a natural source of massive, high dimensional datasets, which may be analyzed using specific techniques. A discipline, which is gaining ground in the area of chemical and biological analysis, is the discipline of machine learning that covers advanced statistical and numerical methods such as support vector machines, cluster analysis, neural networks, partial least squares and logistic regression. Both supervised as well as unsupervised statistical methods are considered, and may be used in conjunction with multispectral image analysis to relate multispectral images to chemical reference measurement values or sensory labels. Clustering algorithms based on data from multispectral images have been thoroughly investigated to assess food quality (Tran et al. 2005). In this study, the potential of multispectral imaging techniques was exploited for the assessment of spoilage degree in pork meat. The specific objective was to evaluate pork meat quality based on spectral as well as spatial information using various chemometric techniques, namely regression and clustering. The aim was to find a method that would be able to evaluate meat spoilage regardless of storage temperature (0, 5, 10, 15 and 20 °C) as well as different package types (aerobic and modified atmosphere). The evaluation was based on predicting microbial growth as well as on classifying between different quality classes as evaluated by a sensory panel.

Materials and Methods

Experimental Design and Sample Preparation

Fresh minced pork (Sus scrofa domesticus, pH 5.6–5.8) obtained from different carcasses was purchased immediately after grinding from the central meat market in Athens and transported under refrigeration to the laboratory within 30 min. Minced pork was divided in portions of 50 g, packed individually and stored under controlled isothermal conditions at 0, 5, 10, 15 and 20 °C in high precision (± 0.5 °C) incubators (MIR-153, Sanyo Electric Co., Osaka, Japan) for up to 580 h, depending on storage temperature, until spoilage was pronounced (intense discolouration and presence of off-odours) either aerobically (AIR) or modified atmosphere packaging (MAP). For aerobic storage, meat samples were placed on Styrofoam trays which were subsequently wrapped manually with air-permeable polyethylene plastic film. The underlying objective of the treatment was to simulate the pre-packaged meat available in retail outlets. Samples packaged in MAP were also enclosed in plastic pouches with oxygen permeability of 6 cm3 m−2 24 h−1 at 20 °C and 50 % RH, flushed with a gas mixture of 60 % CO2/20 % O2/20 % N2 and heat-sealed with a HencoVac machine (Howden Food Equipment BV, The Netherlands). This mixture is a typical gas mixture used in the meat industry. Oxygen was used in the packages to maintain the desirable red colour of the meat while carbon dioxide was used for antimicrobial purposes and nitrogen to get a rigid pack. For every time point two samples were withdrawn for further analysis. The first sample was divided into two portions; one portion was used for microbiological analysis and the other for image analysis. The second sample was also divided into to two portions; one portion was used for microbiological analysis and the other portion for sensory analysis. It was assumed that the microbial population in the first portion of the meat would be representative of the microbial population in the other portion of the meat subjected to image analysis or sensory analysis. Samples stored at AIR packaging at 5 and 0 °C were analyzed approximately every 12 and 24 h, respectively, whereas samples stored at 10 and 15 °C were analyzed every 6–7 h. Finally, samples stored at 20 °C were analyzed every 4 h. For samples stored at MAP at 0 and 5 °C, analysis was undertaken approximately every 24 h, whereas samples stored at 10 °C were analyzed every 8 h. Samples stored at 15 and 20 °C were analyzed every 5 h. In total, 310 meat samples (160 samples stored in AIR and 150 samples stored in MAP) underwent microbiological analysis (results are shown as mean values) for all temperatures and packaging conditions tested. Specifically, 32 and 30 meat samples were analyzed from each storage temperature at aerobic and MAP conditions, respectively.

Microbial Analyses

Duplicate packages from each storage temperature and packaging condition were analyzed at appropriate time intervals to allow for efficient kinetic analysis of different microbial groups. In this study only total viable counts (TVC) were used for the development of models, although Enterobacteriaceae, lactic acid bacteria, pseudomonads, Brochothrix thermosphacta and yeasts were also analyzed (Papadopoulou et al. 2011). In particular, in order to estimate the number of viable cells, minced meat samples (25 g) were weighed aseptically, added to sterile quarter strength Ringer's solution and homogenized in a stomacher (Lab Blender 400, Seward Medical, London, UK) for 60 s at room temperature. Serial dilutions were prepared with the same Ringer’s solution, and duplicate 0.1- or 1-ml samples of the appropriate dilutions were spread or mixed on the following media: plate count agar (PCA, Biolife 4021452, Milano, Italy) for total viable counts, incubated at 30 °C for 48–72 h; Pseudomonas agar base selective supplement (PAB, Biolife 401961, Milano, Italy) for Pseudomonas spp., incubated at 25 °C for 48–72 h; streptomycin thallous acetate actidione agar (STAA, Biolife 402079, Milano, Italy) for B. thermosphacta, incubated at 25 °C for 72 h; violet red bile glucose agar (VRBGA, Biolife, 402185, Milano Italy) for Enterobacteriaceae counts, overlaid with the same medium and incubated at 37 °C for 18–24 h; and de Man–Rogosa–Sharp medium with pH adjusted at 5.7 (MRS, Biolife, 4017282, Milano, Italy) for lactic acid bacteria, overlaid with the same medium and incubated at 30 °C for 48–72 h. Growth data from plate counts were log-transformed and fitted to the primary model of Baranyi and Roberts (1994) using the DMFitprogram (available at www.combase.cc) to determine the kinetic parameters of microbial growth (maximum specific growth rate and lag phase duration). In parallel with microbiological analyses, the pH value of minced pork meat was recorded with a digital pH-meter (Metrohm pH Lab, Switzerland), the glass electrode of which was immersed in the homogenised meat sample after the end of microbiological analysis.

Sensory Analysis

Sensory evaluation of pork samples was performed during storage by a sensory panel composed of five members (in-house trained staff from the laboratory) at the same time intervals as for microbiological analyses as described elsewhere (Argyri et al. 2010). The same trained persons were used in each evaluation, and all were blinded to the meat sample tested. The sensory evaluation was carried out in artificial light, and the temperature of the packed product was close to ambient. The descriptors selected were based on the perception of colour, smell and taste. The first two descriptors were assessed before and after cooking for 20 min at 180 °C in a preheated oven, while the last descriptor was evaluated only after cooking. Each sensory attribute was scored on a three-point hedonic scale corresponding to fresh, semi-fresh and spoiled. The first vague indication of meat spoilage occurred at the point labelled semi-fresh. Odour characteristics of minced pork, as determined by special samples kept frozen and thawed prior to each sensory evaluation, were considered as fresh. Putrid, sweet, sour or cheesy odours were regarded as indicative of microbial spoilage and classified the samples as spoiled. Bright colours typical of fresh oxygenated meat were considered fresh, whereas a persistent dull or unusual colour rendered the sample spoiled (Skandamis and Nychas 2002; Ammor et al. 2009; Argyri et al. 2010). Overall, 155 minced pork meat samples were scored by the taste panel and discriminated into the pre-defined groups as fresh (18), semi-fresh (64) and spoiled (73).

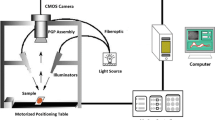

Multispectral Imaging System

The data acquisition was done using VideometerLab (Carstensen and Hansen 2003; Videometer 2009), which acquires multi-spectral images in 18 different wavelengths ranging from 405 to 970 nm. The spectral radiation of the 18 bands is not uniformly distributed over the sampling area, but rather at wavelengths 405, 435, 450, 470, 505, 525, 570, 590, 630, 645, 660, 700, 850, 870, 890, 910, 940 and 970 nm. The acquisition system records surface reflections with a standard monochrome charge coupled device chip, nested in a Point Grey Scorpion camera. The object of interest is placed inside an integrating or Ulbricht sphere in which the camera is top-mounted. The sphere has its interior coated with a matt coating. The coating together with the curvature of the sphere ensures a uniform reflection of the cast light, and thereby a uniform light in the entire sphere. At the rim of the sphere, light emitting diodes (LEDs) with narrow-band spectral radiation distribution are positioned side by side. The LEDs are placed in a pattern which distributes them uniformly around the entire rim. When an image is obtained, the LEDs are turned on successively, and the reflection from that specific wavelength is recorded by the top-mounted camera. The result is a monochrome image with 32-bit floating point precision for each LED type, giving in the end a hyperspectral cube of dimensionality 1280 × 960 × 19. The system is first calibrated radiometrically and geometrically using well-defined standard targets, followed by a light setup based on the type of object to be recorded (Folm-Hansen 1999). The homogeneous diffuse light, together with the calibration steps, ensures an optimal dynamic range and minimizes shadows and shading effects as well as specular reflection and gloss-related effects. The system has been developed to guarantee the reproducibility of images collected, which means it can be used in comparative studies of time series or across a large variety of different samples (Hansen et al. 2005; Clemmensen et al. 2007; Gomez et al. 2007; Dissing et al. 2009).

Image Processing and Statistical Analysis

An example of a recorded multispectral image is seen in Fig. 1a, where the channels are listed according to wavelengths mentioned in the previous section. Moreover, Fig. 1b, c illustrates the mean reflectance spectrum, with error bars indicating one standard deviation for three different locations in the same piece of meat. The mean spectra are calculated as mean values of all the pixels within each of the three squares indicated in Fig. 1b. The diversity of spectra contained within each image may be appreciated when looking at the difference between these mean spectra. The largest difference between the spectra is a scaling, which basically indicates how much light is reflected in general in a point or in other words the luminosity. Scaling differences has many causes, but two essential causes are shadow effects as well as light-scattering effects due to the topology of the surface. In order to compensate for such influences, a simple pre-processing step, commonly known as autoscaling or simple standardization of data (Hastie et al. 2009), which centers all spectra and ensures unit variance, has been used on the images. Such a pre-processing step will help enhance the true differences in the spectra, and thereby improve the later signal processing. Figure 2 shows an overview of the entire data processing pipeline which has been performed in order to quantify the spoilage degree. The images are initially segmented or divided into regions of interest. This means dividing the images into foreground and background, meaning only the meat area, except fat areas, is to be considered in the further statistical analysis. It is common to use orthogonal transformations such as principal component analysis to find similar tissues in the multispectral image space. However, PCA creates orthogonal projection vectors based on a variance maximizing criterion and does not take spatial information into account. The maximum noise fraction (MNF) (Green et al. 1988) is a related method, also belonging to the orthogonal transformation function family, which seeks to maximize the signal to noise ratio (SNR) instead of the variation. This is done by estimating the covariance matrix of the spectra, Σ, as well as the covariance matrix of the noise Σ ∆ (Nielsen 1999) and finding vectors, b, that maximize the ratio of these (the Rayleigh quotient).

When the noise covariance structure is estimated as the covariance of the difference of neighbouring pixels, the MNF reduces to the maximum autocorrelation factor (MAF). A maximization of the signal to noise ratio is then achieved by minimizing the autocorrelation between neighbouring pixels. This optimally finds projection directions of similar neighbouring reflection properties. Two components are used to cut away background as well as fat tissue, where an adaptive thresholding technique (Otsu 1979) is used to transform components into masks which indicate pure meat. Before clustering the spectra, a standardization of the spectra as previously described is performed. All pixels are finally mapped to identify clusters to indicate areas of spoilage in order to improve predictability of the entire sample image. The model used was not aware of any conditions the meat was treated under. An unsupervised K-means algorithm was used to find a set of clusters based on the recorded spectral images. These clusters merely describe a spectral grouping, thus completely disregarding packaging conditions and temperature. The number of pixels in the images belonging to the various clusters was counted which showed correlation with spoilage degree. The size of these areas was then used in a regression model with output being spoilage degree. In this sense, when a new spectral image is acquired, all pixels in the new image must be mapped to one of the analysed clusters and counted, and finally the spectral image may be predicted to a spoilage degree.

Results and Discussion

Development of Microbial Association

The microbial association during storage of minced pork meat under aerobic and MAP condition is described elsewhere (Papadopoulou et al. 2011). In brief, the initial microbiota of minced pork consisted of Pseudomonas spp., B. thermosphacta, lactic acid bacteria and Enterobacteriaceae. In general, aerobic storage of minced pork at all temperatures allowed the members of microbial association to reach higher population levels in comparison with samples stored at MAP conditions. At air packaging, Pseudomonas spp. were the dominant microorganisms followed by B. thermosphacta, whereas lactic acid bacteria and Enterobacteriaceae remained at lower levels. On samples stored under modified conditions, lactic acid bacteria became the dominant bacteria throughout storage, together with B. thermosphacta (data not shown). This is in line with the existing data from previous studies dealing with the meat spoilage and the contribution of the ESO (Ercolini et al. 2006; Nychas et al. 2008; Doulgeraki et al. 2010). The kinetic parameters estimated by the Baranyi model fitted the experimental data well, as can be inferred by the low values of the standard error of fit and the high values of R 2 (Table 1). In more detail, pronounced lag phase was evident at 0 °C, the duration of which was greatly reduced or not observed at all at higher temperatures. A progressive increase of maximum specific growth rate (μ max) was observed with increasing storage temperature (Table 1).

The sensory panel judged a meat sample as semi-fresh or spoiled on different time points for each temperature and packaging condition. Specifically, the sensory panel judged a sample as semi-fresh after 108, 48, 21.5 and 16 and 12 h at 0, 5, 10, 15 and 20 °C, respectively, for samples stored under aerobic conditions, while for samples stored under modified atmospheres the corresponding time was 118.5, 97, 65, 36 and 16 h, respectively. In addition, at the time of sensory rejection (meat characterized as spoiled), the mean value of total viable counts was ca. 8 log cfu/g at all storage temperatures. This observation is in agreement with those by previous researchers who concluded that bacterial counts of 7–8 log cfu/g can cause noticeable off-odours and slime (Koutsoumanis et al. 2006, 2008), whereas others have reported that proteolytic changes do not occur until bacterial counts reach approximately 9 log cfu/cm2 (Brooks et al. 2008).

Imaging Analysis

Based on pre-processed spectra originating from the pure meat area, a large variation in the pixels is still found; however, it is more subtle. By empirically looking at spectra as well as colour-transformed images, it was found that five different types of meat was the optimal subdivision of meat types existing across the meat samples. These types of meat were basically very bright areas with high fat content, more pure meat, which had been oxidized, areas which appeared very spoiled with abnormal meat colours and two intermediate types. A K-means algorithm (Hastie et al. 2009) was used to identify the cluster centers shown in Fig. 3 as normalized spectra. A specific cluster center is shown as a dashed line, which indicates areas of meat with a spoiled appearance. Carefully inspecting the characteristics of this spectrum reveals a higher response in the area of shorter wavelengths corresponding to blue and a lower response from 600 to 800 nm resembling the reddish colours. Furthermore, it then seems to shift in the high, near infrared area, indicating a higher response here compared to the remaining four cluster centers. These characteristics resemble quite well an intuitive understanding of the appearance of spoiled meat as being less red and more green/blue.

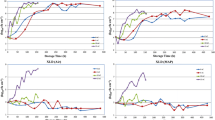

Having normalized images as well as identified cluster centers, a mapping of each recorded spectrum in each picture may be done by calculating either true or approximated Euclidean distances and assigning each pixel to its closest cluster. This process creates a further segmented image, where it is possible to estimate the distribution of different types of meat surface in each image. This distribution may then directly or indirectly be used to classify the image as being fresh, semi-fresh or spoiled, for example, or to quantify the amount of bacterial growth on the meat by predicting the total viable counts, which are both shown as the two output boxes in Fig. 2. The actual classification of images, and prediction of total viable counts, was done using a logistic regression model (Hastie et al. 2009) and a partial least squares model (Hastie et al. 2009), respectively. Figure 4a shows a binary mask of the meat sample in Fig. 4b. The mask indicates the areas which represent only meat, i.e. no background or fat. This mask was created using a maximum autocorrelation transformation, which decomposes a multispectral image into similar tissue types, the first step in the spectral process line (Fig. 2). This specific piece of meat is very spoiled, having a total viable count of 9.8 log cfu/g. A graphical representation of the image after each pixel has been assigned to a cluster center is shown in Fig. 4c. The image contains five levels of greytone, each corresponding to a cluster center. The very dark area represents spoiled meat, while the very bright area represents less spoiled meat. For comparison a fresh piece of meat is seen in Fig. 4d, with TVC measured to 5.6 log cfu/g. A clear difference is seen as the meat area generally appears much brighter in the fresh sample (Fig. 4d) compared to the spoiled image in Fig. 4b. Thus, the majority of pixels in the two images have been assigned to different clusters. The dark edges of the fresh piece of meat might be due to an initial spoilage, but may also be due to scattering effects as well as shadow effects caused by the change in topology in these regions. Being able to spatially determine areas of spoilage enables spatial inference on the images. This means e.g. that it is possible to count how many pixel occurrences of each meat type there exist in the image, and estimate the total area percentage covered by a specific meat type. Doing this for all types of area on all images, and plotting it as a function of total viable count, is seen in Fig. 5. In Fig. 5 the meat area for cluster 1 shows an increase in area as TVC increases, while the area for cluster 5 shows a linear decrease as TVC increases. The area size for the intermediate clusters shows little or no development as TVC increases. The trends of clusters 1 and 5 are interpreted as a spoiled meat cluster and a fresh meat cluster. In order to extract the best features for a prediction model of TVC, as well as for a classification model of sensory labels, the mean spectrum of the area of spoiled meat in all images is used as a feature space. A logistic regression model using the extracted features as covariates was used to classify the pork samples into three sensorial categories (fresh, semi-fresh and spoiled). For comparison, a logistic regression was similarly used to classify the same samples into the same categories using the four microbial measurements as independent variables. Due to the small number of samples, both classification models were assessed using leave-one-out cross-validation in order to obtain realistic and generalizable results. The classification accuracy of the models is seen as confusion matrices together with their sensitivity and specificity, and each meat sample analyzed was determined by the bias and accuracy factors (Ross 1996), the mean relative percentage residual, the mean absolute percentage residual (Palanichamy et al. 2008) and finally the root mean squared error of prediction and the standard error of prediction. A classification rate of 73.6 % for overall correct classification as seen in Table 2 was obtained. The sensitivity of the model was found to be 55.5 %, 71.8 % and 84.9 % for fresh, semi-fresh and spoiled meat samples, respectively. This indicates fairly high uncertainty for the fresh samples, which are frequently identified as semi-fresh and vice versa. The sensory labels were based on other organoleptic senses than visual appearance, such as taste and odour, which are very subjective factors. The number of fresh samples compared to the number of semi-fresh and spoiled is very small, which gives a high probability that even a small subset of semi-fresh samples, which overlaps fresh samples in feature space, will affect the fresh class sensitivity significantly.

a Binary mask for a piece of spoiled meat having TVC of 9.83 log cfu/g. A greyscale image of this same piece of meat is seen in (b) where the recording at 590 nm is shown. The binary mask indicates where in the image meat is located, which is used in further analysis. c Spatial distribution of how pixels have been mapped to identified clusters. There is a total of five clusters. Dark areas indicate spoiled meat, while lighter areas represent more fresh meat. d Spatial distribution of clusters in a fresh portion of pork meat. The clusters are colour coded in the same order as in (c), i.e. light clusters indicate fresh meat. The difference in cluster colours in the two images is very clear

It needs to be stressed that the developed model [a partial least square regression (PLS-R) model] was not aware of any conditions that the meat was treated. An unsupervised K-means algorithm was used to find a set of clusters based on the recorded spectral images. These clusters merely describe a spectral grouping, thus completely disregarding packaging conditions and temperature. The number of pixels in the images belonging to the various clusters was counted which showed correlation with spoilage degree. The size of these areas was then used in a regression model with output being spoilage degree. In this sense, when a new spectral image is acquired, all pixels in the new image must be mapped to one of the analysed clusters and counted, and finally the spectral image may be predicted to a spoilage degree.

Microbial vs Colour Measurements vs Sensory Labels

For comparison, the actual microbial counts were likewise used to classify the sensory labels, as seen in Table 3. Slightly better results are seen for this set of predictors with sensitivity of 66.6 %, 71.8 % and 90.4 %. Thus, the same problem of differentiating between fresh and semi-fresh classes exists for these predictors. Cohens kappa value (Cohen 1960) was calculated to be 0.59 and 0.66, meaning that both values lie in the region of substantial agreement between predicted and observed classes. The prediction of total viable counts as seen in Fig. 6a shows very small errors around the line of equality, y = ax + b, a = 1, b = 0, all within ± 1 log unit area shown with dashed lines. However, three samples did fall outside the area of 1 log unit. A partial least squares model was used for TVC prediction, which requires a separate training and test set to select model parameters and to evaluate the model. The selection of parameters was done using leave-one-out cross-validation on 2/3 of randomly selected data from the entire set of 155 samples. The remaining 52 samples were used for validating the model. It is crucial that the data used for selecting model parameters is not used for validating the model, as this will clearly give a biased and over-fitted model. The PLS regression equation between total viable counts (TVC) and image data is given by the following equation:

where Y is the total viable counts (log cfu/g) of the meat samples and X 1…X 5 are the five clusters of pixels derived from K-means clustering. The parameters in the above equation represent the beta coefficients of the PLS regression equation and express the relative importance of each cluster with regard to microbial counts.

a Regression results for total viable counts using a partial least square. Model trained using cross-validation on a training set and validated on an unknown test set. The plotted values are predicted versus total viable counts. The lines show the line of equality, i.e. a perfect fit, while the dashed lines represent ± 1 log cfu unit. b Relative errors in % between observed and predicted total viable counts (TVC) during storage of pork meat at different temperatures, atmospheres and time spans. F fresh, SF semi-fresh, S spoiled meat samples

The predictive performance of the TVC model is furthermore presented in Fig. 6b, where the relative error in per cent is plotted as a function of the observed microbial population. The errors are seen to be distributed equally around 0, with 83 % of the predicted microbial counts included within the ± 10 % zone of relative errors. Further statistical values for the TVC prediction model are presented in Table 4. Ross (1996) introduced bias factor and accuracy factor as interpretable indices for average deviation or the spread of the results about the prediction. Perfect agreement between the predicted and observed values will lead to bias factors of 1. The bias factor shows values slightly below 1, indicating a very small tendency of underestimation for all types of meat, including the overall bias factor. The accuracy factor furthermore shows that on average the predictions were ≈ 11.3 %, ≈ 20.8 % and ≈ 10.3 % above the observed values for fresh, semi-fresh, and spoiled meat samples, respectively, while in total ≈ 15 %. This is also confirmed by the mean absolute percentage error, representing the average deviation between observed and predicted counts. The mean relative percentage residual index confirmed the under-prediction for all classes, since they are all below 0. The standard error of prediction index is a relatively typical deviation of the mean prediction values and expresses the expected average error associated with future predictions. The model shows good predictive performance, i.e. below 10 % standard error of prediction for all three classes, although especially for spoiled and fresh samples with only a percentage standard error of 5.4 % and 5.8 %.

The multispectral imaging device recorded spectra in the visible and the start of the near-infrared area, and these images can be analysed in conjunction with various machine learning and vision techniques. Features were extracted to evaluate the spoilage process of the meat by predicting total viable counts as well as classifying meat pieces into one of three classes, namely fresh, semi-fresh or spoiled, with ground truth being set by a sensory panel. For the multispectral images, an overall classification performance of 76.1 % was achieved. For the microbial counts an overall classification performance of 80.0 % was achieved. Thus, considering the fact that the electromagnetic area was sampled in only 18 distinct areas, mainly in the visible region, a classification error of 76.1 % is a relatively good performance. A very good discrimination between spoiled and fresh pieces of meat was achieved, while semi-fresh meat caused some misclassification, an issue that can be limited if a significantly larger amount of samples could be introduced for analysis. In conclusion, in contrast with the retrospective and laborious microbiological analysis, the rapid non-invasive equipment that has been used, requiring no sample preparation and in which additional parameters have been included in this work such as time, temperature and atmosphere, provided a rather promising tool for assessing pork spoilage. As indicated in Fig. 6a, b and Table 4, the prediction performance on an unknown test set yielded good results, especially for fresh and spoiled samples (standard error of prediction under 6 %). The values of the bias factor were close to unity, indicating good agreement between predictions and observations. Thus, a setup as the one presented in this paper could in the future be used to satisfactorily predict microbial counts as well as sensory labels of pork meat.

The version of the videometer technology used in this work requires sampling of the product for at-line inspection; however, adaption of the instrument to on-line measurements is possible. An example which comes close to the challenges in food processing is the use of the videometer technology for automatic sorting of mink skins according to length and colour.

References

Ammor, S. A., Argyri, A., & Nychas, G.-J. E. (2009). Rapid monitoring of the spoilage of minced beef stored under conventionally and active packaging conditions using Fourier transform infrared spectroscopy in tandem with chemometrics. Meat Science, 81, 507–514.

Argyri, A. A., Panagou, E. Z., Tarantilis, P. A., Polysiou, M., & Nychas, G.-J. E. (2010). Rapid qualitative and quantitative detection of beef fillets spoilage based on Fourier transform infrared spectroscopy data and artificial neural networks. Sensors an Actuators B: Chemical, 145, 146–154.

Baranyi, J., & Roberts, T. A. (1994). A dynamic approach to predicting bacterial growth in food. International Journal of Food Microbiology, 23, 277–294.

Brooks, J. C., Alvarado, M., Stephens, T. P., Kellermeier, J. D., Tittor, A. W., & Miller, M. F. (2008). Spoilage and safety characteristics of ground beef packaged in traditional and modified atmosphere packages. Journal of Food Protection, 71, 293–301.

Byun, J. S., Min, J. S., Kim, I. S., Kim, J. W., Chung, M. S., & Lee, M. (2003). Comparison of indicators of microbial quality of meat during aerobic cold storage. Journal of Food Protection, 66, 1733–1737.

Carstensen, J. M., & Hansen, J. F. (2003). An apparatus and a method of recording an image of an object. Patent family EP1051660, Issued in 2003.

Carstensen, J. M., Hansen, M. E., Lassen, N. K., & Hansen, P. W. (2006). Creating surface chemistry maps using multispectral vision technology. In B. Ersbøll, T. M. Jørgensen (Eds.), 9th medical image computing and computer assisted intervention (MICCAI)—workshop on biophotonics imaging for diagnostics and treatment, Institute of Mathematical Modelling. Technical Report-2006-17. Kgs. Lyngby: IMM.

Chevallier, S., Bertrand, D., Kohler, A., & Courcoux, P. (2006). Application of PLS-DA in multivariate image analysis. Journal of Chemometrics, 20, 221–229.

Clemmensen, L. H., Hansen, M. E., Ersbøll, B. K., & Frisvad, J. C. (2007). A method for comparison of growth media in objective identification of Penicillium based on multi-spectral imaging. Journal of Microbiological Methods, 69, 249–255.

Cohen, J. (1960). A coefficient of agreement for nominal scales. Educational and Psychological Measurement, 20, 37.

Dainty, R. H. (1996). Chemical/biochemical detection of spoilage. International Journal of Food Microbiology, 33, 19–34.

Daugaard, S. B., Adler-Nissen, J., & Carstensen, J. M. (2010). New vision technology for multidimensional quality monitoring of continuous frying of meat. Food Control, 21, 626–632.

Dissing, B. S., Clemmesen, L. H., Løje, H., Ersbøll, B. K., &Adler-Nissen, J. (2009). Temporal reflectance changes in vegetables. Proceedings of Institute of Electrical and Electronics Engineers (IEEE) color and reflectance in imaging and computer vision workshop, Kyoto, Japan.

Doulgeraki, A. I., Paramithiotis, S., Kagkli, D. M., & Nychas, G.-J. E. (2010). Lactic acid bacteria population dynamics during minced beef storage under aerobic or modified atmosphere packaging conditions. Food Microbiology, 27, 1028–1034.

Ellis, D. I., & Goodacre, R. (2001). Rapid and quantitative detection of the microbial spoilage of muscle foods: current status and future trends. Trends in Food Science and Technology, 12, 414–424.

Ellis, D. I., Broadhurst, D., Kell, D. B., Rowland, J. J., & Goodacre, R. (2002). Rapid and quantitative detection of the microbial spoilage of meat by Fourier transform infrared spectroscopy and machine learning. Applied and Environmental Microbiology, 68, 2822–2828.

Ellis, D. I., Broadhurst, D., & Goodacre, R. (2004). Rapid and quantitative detection of the microbialspoilage of beef by Fourier transforminfraredspectroscopy and machine learning. Analytica Chimica Acta, 514, 193–201.

Ercolini, D., Russo, F., Torrieri, E., Masi, P., & Villani, F. (2006). Changes in the spoilage related microbiota of beef during refrigerated storage under different packaging conditions. Applied and Environmental Microbiology, 72, 4663–4671.

Folm- Hansen, J. (1999). On chromatic and geometrical calibration. Ph.D. thesis, Technical University of Denmark, Kgs. Lyngby.

Gomez, D. D., Clemmensen, L. H., Ersbøll, B. K., & Carstensen, J. M. (2007). Precise acquisition and unsupervised segmentation of multi-spectral images. Computer Vision and Image Understanding, 106, 183–193.

Gowen, A., O’Donnell, C., Cullen, P., Downey, G., & Frias, J. (2007). Hyperspectral imaging—an emerging process analytical tool for food quality and safety control. Trends in Food Science and Technology, 18, 590–598.

Green, A. A., Berman, M., Switzer, P., & Craig, M. D. (1988). A transformation for ordering multispectral data in terms of image quality with implications for noise removal. IEEE Transactions on Geoscience and Remote Sensing, 26, 65–74.

Hansen, M. E., Ersbøll, B. K., Carstensen, J. M., & Nielsen, A. A. (2005). Estimation of critical parameters in concrete production using multispectral vision technology. In: Lecture notes in Computer Science, LNCS3540. Kgs. Lyngby: Informatics and Mathematical Modelling, Technical University of Denmark, DTU. pp. 1228–1237.

Hastie, T., Tibshirani, R., & Friedman, J. (2009). Elements of statistical learning: data mining, inference and prediction (2nd ed.). New York: Springer.

Koutsoumanis, K., & Taoukis, P. (2006). Meat safety, refrigerated storage and transport: modelling and management. In J. Sofos (Ed.), Improving the safety of fresh meat (pp. 503–561). Cambridge: Woodhead.

Koutsoumanis, K. A., Stamatiou, A. P., Skandamis, P., & Nychas, G. J. E. (2006). Development of a microbial model for the combined effect of temperature and pH on spoilage of ground meat and validation of the model under dynamic temperature conditions. Applied and Environmental Microbiology, 71, 124–134.

Koutsoumanis, K. A., Stamatiou, A. P., Drosinos, E. H., & Nychas, G. J. E. (2008). Control of spoilage microorganisms in minced pork by a self-developed modified atmosphere induced by the respiratory activity of meat microflora. Food Microbiology, 25, 915–921.

Nielsen, A. A. (1999). An extension to a filter implementation of a local quadratic surface for image noise estimation. In: 10th international conference on image analysis and processing, ICIAP’99, 119–124.

Nychas, G. J. E., Drosinos, E. H., & Board, R. G. (1998). Chemical changes in stored meat. In R. G. Board & A. R. Davies (Eds.), The microbiology of meat and poultry (pp. 288–326). London: Blackie.

Nychas, G. J. E., Skandamis, P. N., Tassou, C. C., & Koutsoumanis, K. P. (2008). Meat spoilage during distribution. Meat Science, 78, 77–89.

Otsu, N. (1979). A threshold selection method from gray-level histograms. IEEE Transactions on Systems, Man, and Cybernetics, 9, 62–66.

Palanichamy, A., Jayas, D., & Holley, R. (2008). Predicting survival of Escherichia coli O157:H7 in dry fermented sausage using artificial neural networks. Journal of Food Protection, 71, 6–12.

Papadopoulou, O., Panagou, E. Z., Tassou, C. C., & Nychas, G.-J. E. (2011). Contribution of Fourier transform infrared (FTIR) spectroscopy data on the quantitative determination of minced pork meat spoilage. Food Research International, 44, 3264–3271.

Ross, T. (1996). Indices for performance evaluation of predictive models in food microbiology. Letters in Applied Bacteriology, 81, 501–508.

Sánchez, A. J., Albarracin, W., Grau, R., Ricolfe, C., & Barat, J. M. (2008). Control of ham salting by using image segmentation. Food Control, 19, 135–142.

Skandamis, P. N., & Nychas, G.-J. E. (2002). Preservation of fresh meat with active and modified atmosphere packaging conditions. International Journal of Food Microbiology, 79, 35–45.

Stien, L. H., Kiessling, A., & Manne, F. (2007). Rapid estimation of fat content in salmon fillets by colour image analysis. Journal of Food Composition and Analysis, 20, 73–79.

Taghizadeh, M., Gowen, A., Ward, P., & O’Donnell, C. P. (2010). Use of hyperspectral imaging for evaluation of the shelf-life of fresh white button mushrooms (Agaricusbisporus) stored in different packaging films. Innovative Food Science & Emerging Technologies, 11, 423–431.

Tran, T. N., Wehrens, R., & Buydens, L. M. (2005). Clustering multispectral images: a tutorial. Chemometrics and Intelligent Laboratory Systems, 77, 3–17.

Videometer (2009). Testimonial: Kopenhagen Fur, April 19, 2007. <http:// www.videometer.com/news/artikler2007/Testimonial_Kopenhagen_Fur.html> Accessed 01.09.09.

Acknowledgments

The authors acknowledge the Symbiosis-EU (www.symbiosis-eu.net) project (no. 211638) financed by the European Commission under the 7th Framework Programme for RTD. The information in this document reflects only the authors’ views, and the Community is not liable for any use that may be made of the information contained therein.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dissing, B.S., Papadopoulou, O.S., Tassou, C. et al. Using Multispectral Imaging for Spoilage Detection of Pork Meat. Food Bioprocess Technol 6, 2268–2279 (2013). https://doi.org/10.1007/s11947-012-0886-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0886-6