Abstract

Folates are a group of vitamins vital for the growth and development of the central nervous system. Most of these natural derivatives of folic acid are prone to oxidation and are very sensitive towards heat, temperature, oxygen, and light. Encapsulation of folic acid within inert matrices of a polymer can improve its stability and stop its degradation by light and oxygen. Electrohydrodynamic (EHD) technology is capable of generating fine droplets ranging from micrometers to nanometers in diameter from the breakup of a jet depending on the flow rate and applied electrical potential difference. The aims of this study were to generate nano-sized particles of folic acid encapsulated in sodium alginate (Na alginate) using EHD technology and to study the effect of voltage and flow rate on particle size as well as the structure of the prepared particles. It was established that 40 mg/ml (Na alginate) concentration can be used in single jet EHD technology. However, only 10 mg/ml concentration furnished stable jetting at any applied voltage and flow rate. So, this concentration was utilized and used to encapsulate higher dosages of folic acid. It was observed that the optimum flow rate for obtaining spherical particles of uniform diameter (4.2 ± 1.2 μm) was 10 μl/min at a voltage of 12 kV. Upon drying, these particles acquired a diameter in the range of 50–200 nm and became less spherical in shape. As the folic acid concentration is increased from 1 to 10 mg/ml, the percentage yield of particles at a constant Na alginate concentration increased by over 10 % and the corresponding encapsulation efficiency doubled. FTIR spectroscopic studies revealed the presence of folic acid within Na alginate matrices and also no characteristic chemical interaction between them. It can be concluded from the above research findings that, at 10 mg/ml Na alginate concentration, 10 μl/min flow rate, and 12 kV voltage, a high amount of folic acid (5 mg/ml) can be encapsulated within Na alginate matrices, with high percentage yield (70 %) and loading capacity (96 %), generating non-spherical dried beads/particles of 90–150 nm in diameter.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Folates are a broad group of compounds, having recognized vitamin functionality, that include the synthetic form of the vitamin folic acid (FA; also known as pteroyl glutamic acid or PGA) (Department of Health 2000). These compounds exist in low concentrations naturally because they are normally present in biological substances together with enzymes capable of modifying or degrading them and thus making them highly unstable (Baugh and Krumdieck 2006). Folic acid is a water-soluble vitamin which is vital for maintaining and producing new cells (Yoo and Park 2004). It is very important for rapid cell growth especially in pregnancy and infancy where rapid cell division is required and its deficiency in mothers is known to cause neural defects in newborns (Kafrissen and Oakley 2001). Further, its deficiency can cause megaloblastic anemia due to hindered DNA synthesis and cell division. It is also known to prevent changes in DNA causing cancerous tissue buildup (Kanthamneni and Prabhu 2006). Folic acid is also beneficial in the reduction of risk of cardiovascular disease by lowering of homocysteine concentration (Edirisinghe 2004).

Various derivatives of folic acid present in the human body and in plants as well as animal-derived foods are reduced folates (Scholl and Johnson 2000). Folic acid is a synthetic form of folate which is used for food fortification and has about twice the bioavailability of naturally present food folates (Daly et al. 1997) but is highly unstable (Herbert 1999). Naturally occurring folate derivatives, even in foods, are highly susceptible to degradation by environmental factors such as the presence of oxygen, high temperature, pH, and light. Thus, the stability of folates during food processing and storage is uncertain (Witthoft et al. 1999; Williams et al. 1995; Wigertz et al. 1997; Vahteristo et al. 1998; Scott et al. 2000). However, its presence in diet for normal bodily function is essential, but at the same time its stability in food and the natural environment is dubious. Therefore, in some parts of the world, mandatory fortification of grain foods with folic acid has been implemented for the reduction of occurrence of neural tube defects in the newborn (Honein et al. 2001).

The food and bioprocessing industry is facing enormous challenges for developing and implementing systems that can produce high-quality, safe foods while also being efficient, environmentally acceptable, and sustainable (Manufuture 2006). Considering the importance of folic acid in bodily functions, its instability, and government strategies to fortify food with folic acid, encapsulated formulations of folic acid can serve as a solution to stabilize folic acid. Enveloping the unstable ingredient in polymeric matrices to furnish stability and controlled release is a well-known technology (Gonnet et al. 2010). In this regard, electrohydrodynamic (EHD) processing, which involves the application of high voltage to a needle through which a liquid is flowing to generate a fine jet, is beneficial for generating small-diameter particles/beads entrapping the active ingredient (Enayati et al. 2011). The size of the particles generated using EHD technology is usually on the micrometer scale but this can be reduced further. Particles in the micro–nano range can be more easily absorbed by the body (Kanwar et al. 2011). It is well known that the physical, chemical, and biological properties of structures and systems at the nanoscale are substantially different from their macro-scale counterparts due to the interactions of individual atoms and molecules and this offers unique and novel functional applications. As the size of the particles gets reduced to the nanoscale range, there is an immense increase in the surface-to-volume ratio which increases reactivity and changes the properties of the particles (Neethirajan and Jayas 2011). In this regard, nano-size particles of folic acid may be easily absorbed by the body in its encapsulated stable formulation.

The aim of this study is to apply single-jet EHD technology to encapsulate folic acid in Na alginate matrices and to optimize the voltage, flow rate, and Na alginate concentration for generating uniform nano-sized folic-acid-containing particles. The use of EHD technology to process food materials is very appropriate as the structural features of the products can be easily varied in terms of both scale and morphology (Luo et al. 2012).

Materials and Methods

Reagents and Materials

Sodium alginate is a well-known food-grade polymer widely used for encapsulating active ingredients in gel matrices. Sodium alginate, calcium chloride, and folic acid (all in powder form) were procured from Sigma Aldrich, UK. Double-distilled water was used in all experiments which were repeated three times.

EHD Studies

Sodium alginate was dissolved in the double-distilled water heated to 55 °C in a vial, using a magnetic stirrer, at different concentrations (10–40 mg/ml). To this was added pre-weighed different folic acid dosages and the solution was stirred again to give a homogeneous slurry. This vial containing the slurry of sodium alginate and folic acid was immediately covered in aluminum foil to prevent photo-degradation of folic acid. Appropriate quantities of this slurry were than subjected to EHD jetting as shown in Fig. 1.

The experimental setup for EHD jetting consisted of a stainless steel needle (450 μm inner diameter and 840 μm outer diameter) set in an epoxy resin holder and charged by a high-voltage power supply (range of 0–30 kV). A 10-ml plastic syringe was filled with the slurry and connected to a high-precision syringe pump (Harvard Apparatus Ltd., Edenbridge, UK) for controlling the flow rate of slurry to the needle. The slurry was then subjected to EHD jetting at different voltages to obtain a stable cone jet. Also, the flow rate of polymeric slurry of Na alginate and folic acid was varied between 10 and 50 μl/min. The resultant jet spray of slurry was collected in 0.45 M CaCl2, which is a cross-linking agent. The distance between the needle tip and the CaCl2 bath was 120–150 mm (Fig. 1). A metallic sheet (540 × 54 × 30 mm) was placed 100 mm below the CaCl2 bath as shown in Fig. 1. Optimization of flow rate and voltage was conducted with a view of obtaining a stable cone jet. For the observation of the slurry during EHD jetting, a high-speed camera (Weinberger AG, Dietikon, Switzerland) was connected to a computer and a fiber optic light source was used for illumination. Data were recorded at 138 frame/s and shutter control was 1/140 s.

The concentration of folic acid (FA) was varied from 1 to 10 mg/ml, keeping the Na alginate concentration constant at 10 mg/ml. The higher concentrations of folic acid were not soluble in water, so each time the solution was sonicated for 300 s using a Sonifier (Branson, Sonifier-250, UK), prior to EHD jetting. The EHD product was dried at ambient temperature (27 ± 2 °C) and was weighed, and the yield was calculated as:

Morphology of Product

The size and shape of the prepared particles after curing in a CaCl2 bath for 1,800 s, in the wet condition, were studied using an optical microscope (Nikon Eclipse model ME600). The average diameter of the prepared particles (300 in number) was determined using a 16-bit Image Processing and Analysis tool (Image Pro Express, USA).

Scanning Electron Microscopy

A JEOL JSM 3600 scanning electron microscope (SEM) was used to investigate in detail the size, shape, and topography of microencapsulated products. The encapsulated particles were air-dried for 48 h prior to sample preparation for the SEM study. The dried encapsulated particles were fixed to SEM stubs using double-sided adhesive tape (Nisshin EM Co. Ltd., Tokyo, Japan). In all cases, the specimens were subsequently coated with a thin layer of gold (<100 nm) for 60 s using a model MSP-1 S magnetron sputter coater (Vacuum Device Inc., Tokyo, Japan). The coated samples were then analyzed using the SEM operating at 2 kV.

Infra-red Studies

Fourier-transform infra-red (FTIR) spectra of pure folic acid, folic-acid-encapsulated Na alginate particles, and sodium alginate particles were recorded on a Perkin Elmer 2000 FTIR spectrometer (UK) using 30 scans with a resolution of 4 cm−1 in the 4,000–500 cm−1 region. The samples were studied using the standard preparation of potassium bromide (KBr)-containing pellets. These samples, i.e., folic acid, sodium alginate beads, and sodium-alginate-beads-encapsulating folic acid, were prepared by mixing and milling each ingredient separately with KBr to form a very fine powder. This powder was then compressed into a thin pellet for analysis.

UV Spectroscopy

The UV measurements were performed using a Perkin Elmer Lambda 35 UV–vis spectrophotometer (UK) in the frequency interval of 200–500 nm. For determining the amount of encapsulated FA in particles, a known mass of particles in CaCl2 was subjected to UV spectrophotometry. As folic acid absorbs light at the wavelength of 259 and 362 nm, the concentration (amount of FA) in particles was calculated using a calibration curve which was prepared to include the concentration range of 0.0125–0.1875 mg/ml of folic acid reported by Stevanovic et al. (2008), valid for the folic acid encapsulated poly(dl-lactide-co-glycolide) nanospheres.

Encapsulated Amount and Encapsulation Efficiency

Folic acid is known to absorb light at wavelengths of 259 and 362 nm. Figure 2a shows absorbance at various wavelengths for different folic acid concentrations. A calibration curve based on known concentrations of folic acid was plotted at 362 nm (Stevanovic et al. 2008) as shown in Fig. 2b. Folic acid concentration was varied in order to maximize the folic acid concentration in encapsulated particles prepared by EHD. However, sedimentation of folic acid was observed at higher concentrations. So, a simple procedure to quantify folic acid used for EHD jetting was adopted as:

It is probable that some of the folic acid soluble in water leaked into the calcium chloride bath, decreasing the encapsulated amount of folic acid in particles. Encapsulation efficiency, i.e., percentage of folic acid encapsulated in the particles prepared after curing in calcium chloride, was calculated as:

Results and Discussion

Process Optimization

It is well established that EHD can be used to generate and control the size of liquid droplets. The shear stress generated by the electric field as well as the gravitational force exerted on the liquid generates elongated/thin ligaments of liquid which finally separate into drops below the needle. The optimization studies were conducted with the aim of investigating the effect of applied voltage, flow rate, and sodium alginate concentration on encapsulation of folic acid within Na alginate matrices. Table 1 summarizes these results and Fig. 3 depicts the shape of the slurry spray under the influence of the electric field.

It is evident from these data that a low concentration of Na alginate (i.e., 10 mg/ml) at low flow rates, i.e., 10 μl/min, at a voltage of 9–12 kV results in stable jetting. In addition, under these conditions, uniformly sized particles were generated. Increasing the voltage plays a significant role in the type of spray generated which ultimately determines the size distribution of the particles obtained. It was observed that at 10 mg/ml concentration and 10 μl/min flow rate, as the voltage was increased from 0 to 3 kV, thinning/elongation of the drop at the end of the needle occurs (Fig. 3a, b) and this transformed to dripping and micro-dipping as the voltage increased from 3 to 6 kV. The formation of an unstable cone jet at 6–9 kV (Fig. 3c) followed and finally a stable cone jet was obtained in the range of 9–12 kV (Fig. 3d). Any further increase in voltage (13–25 kV) again led to an unstable cone jet resulting in different particle sizes (Fig. 3c). This variation in particle size is very significant as some particles were quite small (2.6 μm) and these are formed as a result of occasional stability in the cone jet and the rest were comparatively quite large (1,800 μm). At the same Na alginate concentration, upon increasing the flow rate, a stable jet could not be obtained at any applied voltage. However, some thinning, dripping, micro-dripping, and unstable cone jetting were observed in different applied voltage ranges as described in Table 1.

Size and Shape of Particles

The results from the shape and size measurements of the particles generated before drying are depicted in Table 2. It is apparent from Table 2 that these particles, after 1,800 s of curing, are in the micrometer size range and their shape is spherical. Also, the small standard deviation of particle size at 10 μl/min flow rate and 12 kV voltage clearly establishes that the particle size is not only small but uniform as well. This can be attributed to the fact that, at this concentration, applied voltage, and flow rate, a stable cone jet was attained. Figure 4 shows the optical micrographs of wet particles generated at 10 mg/ml Na alginate, 10 μl/min flow rate, and 12 kV applied voltage.

It is apparent from previous studies that the particle size depends on a number of parameters including solute concentration, curing agent concentration, curing time, nozzle diameter, voltage, flow rate and collection point (Jaworek 2008). Previous reports establish that increasing the curing time, calcium chloride, and Na alginate concentrations increases the particle size. The effect of curing time and calcium chloride concentration on particle size was not explored in this study and is published elsewhere (Madziva et al. 2005). Klokk and Melvik (2002) and Moghadam et al. (2009) reported that increasing the concentration of Na alginate results in increased viscosity and hence larger particles. They also investigated increasing the concentration of the curing agent, i.e., CaCl2, and found the same increased particle size. However, they found that lowering the flow rate decreased the particle diameter. Klokk and Melvik (2002) also found that needle diameter significantly affects the particle size. They reported that smaller particles (300 μm) are obtained using a needle of 180 μm inner diameter. The larger-diameter (296–1,760 μm) particles obtained by Moghadam et al. (2009) may be attributed to the larger size needle with an inner diameter of 1–2 mm.

The results of the present study also demonstrated that an increase in solute concentration increases viscosity and therefore the product particle size. It was found that the increase in viscosity due to an increase in Na alginate concentration from 10 to 40 mg/ml could be as high as 1,500 times and this would be expected to cause an appreciable increase in particle size generated (Jayasinghe and Edirisinghe 2002). Priority was given, however, in this study to producing similar-sized particles through developing a stable cone jet rather than varying the size itself.

Encapsulating Folic Acid

Based on the above preliminary experiments, Na alginate concentration, flow rate, and voltage were optimized to develop uniform-sized particles containing folic acid. The Na alginate concentration was kept at 10 mg/ml, the applied voltage at 12 kV, and the flow rate at 10 μl/min. The concentration of folic acid in the particles was varied to achieve maximum loading. Three concentrations of folic acid were chosen for encapsulation: 10, 5, and 1 mg/ml. As 1 mg/ml folic acid was completely soluble, it was assumed that at this level it is fully incorporated into the slurry for encapsulation without any precipitation in the syringe. Even for the dosage of 5 mg/ml, complete solubility was observed because of sonication. However, at 10 mg/ml dosage, even after sonication, a significant amount of folic acid precipitated and therefore not all the folic acid added to the slurry was encapsulated, thus affecting the percentage yield. The results of percentage yield determined for each dosage of folic acid at constant Na alginate concentration (i.e., 10 mg/ml) is given in Table 3. These results clearly indicate that a significant amount of folic acid is lost in 10 mg/ml concentration due to sedimentation, leading to a lower percentage yield.

Particles were prepared at a constant Na alginate concentration of 10 mg/ml and varying folic acid concentration. However, as folic acid has limited water solubility, a higher dosage of 10 mg/ml folic acid was found to be sedimenting in the needle. Therefore, the total amount encapsulated was calculated as mentioned previously, and it was found that at a starting concentration of 10 mg/ml folic acid, only 49.9 (~50) % of folic acid was encapsulated and the rest was sedimented in the needle. However, on reducing the folic acid concentration to 5 and 1 mg/ml, caused no sedimentation and the encapsulation of folic acid in the particles was 26, 25, and 5 mg/5 ml for starting concentrations of 10, 5, and 1 mg/ml, respectively. It is therefore clear that increasing the concentration of folic acid beyond 5 mg/ml does not result in higher encapsulation as higher dosages are deposited in the form of sediments. So, 5 mg/ml dosage is most appropriate in terms of initial loading, but even after encapsulation of folic acid in particles, some amount of folic acid is lost in the curing agent (CaCl2) because of folic acid solubility in aqueous CaCl2. The UV spectra of starting concentrations of 10 and 5 mg/ml are shown in Fig. 5. The spectra indicate that some amount of folic acid leaked into CaCl2 during curing of the particles. However, no folic acid was detected in the CaCl2 bath for the 1 mg/ml concentration, indicating perhaps a 100 % loading. Using the calibration curve of Fig. 2b, leakage in CaCl2 was determined and is given in Table 4 along with the loading capacity at each folic acid concentration.

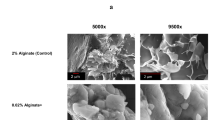

Dried Particles

The scanning electron microscope images of the dried particles of Na alginate (10 mg/ml) encapsulating folic acid at different flow rates and voltages are shown in Fig. 6a–d. These images revealed that, upon drying, nano-particles were obtained. It is notable that under wet conditions the particle size was in the micrometer range but after drying the particle size was in the range of 90–150 nm. Na alginate has the capacity to absorb 200–300 times its own weight in water (Rowe et al. 2009). So, most of the weight and volume acquired by the Na-alginate-particles-encapsulating folic acid is because water was absorbed from the calcium chloride bath, but as the particles are dried, this excess water is evaporated from the beads, resulting in the shrinkage of the particle, thus acquiring nanometer size from micrometer size. However, the shape of the particles is affected by drying as the particles lose their spherical characteristic and shrink to a more irregular, less spherical shape. This was consistently observed under different processing conditions (Fig. 6) and is therefore caused by drying naturally at ambient conditions (as described in the experimental details). Perhaps more controlled drying at a slower rate may avoid shape change.

Particle Chemistry

It is the primary requisite in encapsulation technology that inert ingredients or polymeric matrices (here Na alginate) should not chemically react with the active ingredient (here folic acid). To find out any possible chemical interaction between Na alginate and folic acid, FTIR spectroscopic analysis of pure folic acid, Na alginate particles, and Na-alginate-encapsulating folic acid particles was carried out. Figure 7 shows the FTIR spectra of folic acid (Fig. 7a), Na alginate particles (Fig. 7b), and Na-alginate-encapsulating folic acid particles (Fig. 7c).

It is evident from Fig. 7 that apart from the characteristic peaks for Na alginate, the spectra also show the characteristic peaks of folic acid. The characteristic band at 3,545 cm−1 corresponds to the O–H stretching of the hydroxyl group (Zhang et al. 2008). The presence of bands at 3,418 and 3,323 cm−1 indicates the N–H stretching vibrations. The bands at 2,925 cm−1 corresponds to the C–H stretching vibrations and carbonyl bond (i.e. C = O) stretching vibrations of the carboxyl group at 1,695 cm−1. Bending mode vibrations of the N–H group were characterized by the presence of a band at 1,606 cm−1. The band at 1,485 cm−1 can be ascribed to the absorption in the phenyl ring (Stevanovic et al. 2008). All these characteristic peaks signify the presence of folic acid entrapped within matrices of Na alginate and there is no interaction between the Na alginate and the folic acid.

It is quite likely that Na alginate matrices will stabilize folic acid against degradation from light, oxygen, and environment by providing excellent matrices for encapsulation as reported previously (Madziva et al. 2005). Furthermore, Na alginate, a food-grade polymer, is acceptable as a food additive. Owing to this, in wet form, folic acid–Na alginate particles may find application in the dairy industry and the nutrient-fortified beverage industry. In its dry form, they might be used to fortify flour, bread, and other dry commodities, especially in the countries where folic acid fortification in flour is mandatory, offering stability to a rather unstable but crucially important ingredient.

Conclusions

Encapsulation of folic acid in Na alginate matrices was achieved using single-jet electrohydrodynamic processing. The shape and type of flow generated at the tip of the EHD needle were affected by the flow rate of the liquid slurry and the applied voltage it was subjected to. These conditions were optimized with a view to generating a stable cone jet at the tip of the needle. Up to 40 mg/ml Na alginate solutions were processed using EHD to prepare micrometer-sized particles but uniformly sized particles were obtained only at 10 mg/ml. It was established that at 10 mg/ml Na alginate, 10 μl/min flow rate, and 12 kV applied voltage, a stable cone jet can be achieved, resulting in the generation of uniformly sized particles, which upon drying produced particles 90–150 nm in size. Under these optimized conditions, encapsulation of higher dosages of folic acid was attempted and successfully done. At increased folic acid concentrations, i.e., 10, 5, and 1 mg/ml, the percentage yield of prepared particles at constant Na alginate concentration (i.e., 1 %) were 64, 70, and 75 %, respectively. The loading capacity at similar folic acid dosages and Na alginate concentration were 50, 96, and 100 %, respectively. However, more investigations are needed to establish the release kinetics of folic acid in various mediums.

References

Baugh, C. M., & Krumdieck, C. L. (2006). Naturally occurring folates. Annals of the New York Academy of Sciences, 186, 7–28.

Daly, S., Mills, J. L., Molloy, A. M., Conley, M., Lee, Y. J., Kirke, P. N., et al. (1997). Minimum effective dose of folic acid for food fortification to prevent neural tube defects. Lancet, 350, 1666–1669.

Department of Health. (2000). Folic acid and the prevention of disease. TSO: Report of the Committee on Medical Aspects of Food and Nutrition Policy.

Edirisinghe, S. P. (2004). Homocysteine-induced thrombosis. British Journal of Biomedical Sciences, 61, 40–47.

Enayati, M., Chang, M. W., Bragman, F., Edirisinghe, M., & Stride, E. (2011). Electrohydrodynamic preparation of particles, capsules and bubbles for biomedical engineering applications. Colloids and Surfaces A. Physicochemical and Engineering Aspects, 382, 154–164.

Gonnet, M., Lethuaut, L., & Boury, F. (2010). New trends in encapsulation of liposoluble vitamins. Journal of Controlled Release, 146, 276–290.

Herbert, V. (1999). Folic acid. In M. E. Shils, J. A. Olson, M. Shike, & A. C. Ross (Eds.), Modern nutrition in health and disease (9th ed., pp. 433–446). Baltimore: Williams & Wilkins.

Honein, M. A., Paulozzi, L. J., Mathews, T. J., Erickson, J. D., & Wong, L.-Y. C. (2001). Impact of folic acid fortification of the US food supply on the occurrence of neural tube defects. Journal of the American Medical Association, 285, 2981–2986.

Jaworek, A. (2008). Electrostatic micro- and nanoencapsulation and electroemulsification: a brief review. Journal of Microencapsulation, 25, 443–468.

Jayasinghe, S. N., & Edirisinghe, M. J. (2002). Effect of viscosity on the size of relics produced by electrostatic atomization. Journal of Aerosol Science, 33, 1379–1388.

Kafrissen, M. E., & Oakley, G. (2001). Pharmaceutical methods of delivering folic acid. US Patent, 6190693.

Kanthamneni, N. & Prabhu, S. (2006) Formulation development of targeted nanoparticle-based drug delivery systems for the chemoprevention of colon cancer. AAPS Annual Meeting Exposition, 28th Oct to 2nd Nov, Texas, USA. http://www.aapsj.org/abstracts/AM_2006/AAPS2006-003413.pdf.

Kanwar, J. R., Long, B. M., & Kanwar, R. K. (2011). The use of cyclodextrins nanoparticles for oral delivery. Current Medicinal Chemistry, 18, 2079–2085.

Klokk, T. I., & Melvik, J. E. (2002). Controlling the size of alginate gel beads by use of a high electrostatic potential. Journal of Microencapsulation, 19, 415–424.

Luo, C. J., Loh, S., Stride, E., & Edirisinghe, M. (2012). Electrospraying and electrospinning of chocolate suspensions. Journal of Food and Bioprocess Technology. doi:10.1007/s11947-011-0534-6.

Madziva, H., Kailasapathy, K., & Phillips, M. (2005). Alginate–pectin microcapsules as a potential for folic acid delivery in foods. Journal of Microencapsulation, 22, 343–351.

Manufuture (2006) Vision 2020 and Strategic Research Agenda of the European Agricultural Machinery Industry and Research Community for the 7th Framework Programme for Research of the European Community, Brussels, Belgium.

Moghadam, H., Samimi, M., Samimi, A., & Khorram, M. (2009). Study of parameters affecting size distribution of beads produced from electro-spray of high viscous liquids. Iranian Journal of Chemical Engineering, 6, 88–98.

Neethirajan, S., & Jayas, D. S. (2011). Nanotechnology for the food and bioprocessing industries. Food and Bioprocess Technology, 4, 39–47.

Rowe RC, Sheley PT & Quinn ME (2009) Alginic acid. In: Handbook of pharmaceutical excipients, 6th edn. American Pharmacist Association, USA, page 20–22

Scholl, T. O., & Johnson, W. G. (2000). Folic acid: influence on the outcome of pregnancy. American Journal of Clinical Nutrition, 71, 1295S–1303S.

Scott, J., Rebeille, F., & Fletcher, J. (2000). Review—folic acid and folates: the feasibility for nutritional enhancement in plant foods. Journal of the Science of Food and Agriculture, 80, 795–824.

Stevanovic, M., Radulovic, A., Jordovic, B., & Uskokovic, D. (2008). Poly(dl-lactide-co-glycolide) nanospheres for the sustained release of folic acid. Journal of Biomedical Nanotechnology, 4, 1–10.

Vahteristo, L. T., Lehikoinen, K. E., Ollilainen, V., Koivistoinen, P. E., & Varo, P. (1998). Oven-baking and frozen storage affect folate vitamer retention. LWT- Food Science and Technology, 31, 329–333.

Wigertz, K., Svensson, U. K., & Jagerstad, M. (1997). Folate and folate binding protein content in dairy products. The Journal of Dairy Research, 64, 239–252.

Williams, P. G., Ross, H., & Miller, J. C. B. (1995). Ascorbic acid and 5-methyltetrahydrofolate losses in vegetables with cook/chill or cook/hot-hold food service systems. Journal of Food Science, 60, 541–546.

Witthoft, C. M., Forssen, K., Johannesson, L., & Jagerstad, M. (1999). Folates—food sources, analyses, retention and bioavailability. Scandanavian Journal of Nutrition, 43, 138–146.

Yoo, H. S., & Park, T. G. (2004). Folate receptor targeted biodegradable polymeric doxorubicin micelles. Journal of Controlled Release, 96, 273–283.

Zhang, J., Rana, S., Srivastava, R. S., & Misra, R. D. K. (2008). On the chemical synthesis and drug delivery response of folate receptor-activated, polyethylene glycol-functionalized magnetite nanoparticles. Acta Biomaterialia, 4, 40–48.

Acknowledgements

The authors would like to thank the Archaeology Department at University College London for use of their electron microscope. The authors wish to acknowledge the Engineering & Physical Sciences Research Council (Platform grant EP/E045839/1) of the UK for funding their research. We also gratefully acknowledge funding from The Leverhulme Trust (grant F/07 134/DG) for supporting the contribution by Dr. Nangrejo.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bakhshi, P.K., Nangrejo, M.R., Stride, E. et al. Application of Electrohydrodynamic Technology for Folic Acid Encapsulation. Food Bioprocess Technol 6, 1837–1846 (2013). https://doi.org/10.1007/s11947-012-0843-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0843-4