Abstract

Mixture design was used to investigate the effects of four different gums (xanthan gum, guar gum, alginate and locust bean gum) and their combinations on the rheological properties of a prebiotic model instant hot chocolate beverage (including 3.5% inulin) and to determine their interactions in the model beverage. Simplex centroid mixture design was applied to predict the physicochemical (soluble solids, pH, colour properties) and rheological parameters (consistency index (K), flow behaviour index (n) and apparent viscosity (η 50)) of the samples. In the model, the optimum gum combination was found by simplex centroid mixture design as 59% xanthan gum and 41% locust bean gum, and the highest K value was 33.56 Pa sn. The increase of guar gum and alginate in the gum mixture caused a decrease in the K value of the sample.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Instant foods ranging from liquids or semisolids are convenient products that require very little effort or time to reconstitute or cook before consumption (Shittu and Lawal 2007). Instant hot chocolate drinks are one of the most popular dairy products throughout the world and are prepared by adding powdered ingredients to water or to milk (Da Silva et al. 2008). The ingredients of instant hot chocolate drinks are sugar, cocoa powder, skimmed milk powder, whey powder, starch, flavour, salt and hydrocolloids which are used in food products for different purposes such as thickeners, stabilizers, gelling agents and texture modifiers (Dogan et al. 2007) and to improve consistency and to prevent sedimentation of the cocoa particles. These ingredients provide nutritional and sensory characteristics to the beverage, which are crucial factors for product consumption by different consumer groups like children, adults and elderly people.

In addition to the nutritional and sensory properties of the product, functionality of the product is another important factor affecting consumer preference. Throughout the world, demand for health-promoting foods is growing due to the increased awareness of consumers in matters of diet and health (Fagan et al. 2006). For that reason, one of the aims of this study is to increase the functionality of the hot chocolate by adding inulin to its formulation. Due to its nutritional and technological properties, inulin is used as a prebiotic dietary fibre in the formulation of food products (Franck 2002). In addition to its beneficial effects on health, inulin is a low calorie sweetener, fat substitute and texture modifier (Tungland and Meyer 2002). Some authors have analysed the effect of adding inulin on the rheological and sensory characteristics of ice creams (El-Nagar et al. 2002; Schaller-Povolny and Smith 1999, 2001), yoghurts (Brennan and Tudorica 2007; Dello Staffolo et al. 2004; El-Nagar et al. 2002; Guven et al. 2005), fresh cheese (Henelly et al. 2006; Koca and Metin 2004) and dairy desserts (Cardarelli et al. 2008; Tárrega and Costell 2006). However, there was a scarce study in the literature about the use of fibres in instant beverages like hot chocolate (Rodriguez Furlán et al. 2011; Sutinium et al. 2008).

Although the demand may be increasing for functional foods, their acceptability by the consumer is still based on satisfactory textural and sensory attributes (Fagan et al. 2006). Rheological properties, which are provided by hydrocolloids found in the formulation of the product, are an indicator of product quality (Marcotte et al. 2001) especially for hot chocolate and salep drink (Kayacier and Dogan 2006). The addition of two or more gums to the formulations of food products is very widespread in the food industry for the synergistic effect of combined use (Kayacier and Dogan 2006). The use of two or more gums leads to an improvement in product quality and economic benefit as they can provide better rheological properties to the product, which may also reduce costs during production (Walkenström et al. 2003; Khouryieh et al. 2006). For this reason, the optimization of the gum combination in the product is important. Mixture experimental designs are used for the optimization of ingredients of products that involve more than one ingredient or ingredients that possess an alternative substance, since the ratio of the components in the mixture and their levels are dependent on each other (Lop et al. 1999; Dutcosky et al. 2006). This design provides a predictive mathematical representation of the relationship between mixture factor and responses (Flores et al. 2010). This method can be preferred to observe the effects of the ingredients on foods, and it determines the importance of ingredient interactions (Arteaga et al. 1993; Karaman et al. 2011). The aims of this study are to investigate the effect of the interaction between xanthan, guar, alginate and locust bean gums on the rheological properties of a model prebiotic hot chocolate drink using the mixture design approach and to determine which gum or gum combination is the optimum for the product in terms of rheology.

Material and Methods

Materials

Sugar, skimmed milk powder (Pinar Food Co, Turkey), whey powder (Ova Food Co, Turkey), cacao (Ulker, Gold type from Turkey), potato and modified corn starch (Bayrak Food Co, Turkey), inulin (short chain, soluble in water type, Orafti Group, Artısan Food, Turkey), chocolate powder and chocolate flavouring (Aromsa Food Co, Turkey), salt, guar gum (GG), sodium alginate (Alg.), xanthan gum (XG) and locust bean gum (LBG) were obtained from a firm manufacturing instant beverages in Kayseri, Turkey.

The Preparation of the Model Hot Chocolate Beverage Samples

Twelve grams sucrose, 7.46 g inulin, 3 g skimmed milk powder, 2 g whey powder, 6 g cacao, 0.25 g potato starch, 0.25 g modified corn starch, 0.25 g powdered chocolate, 0.1 g chocolate flavouring, 0.025 g salt and 2 g gum were mixed. Fifteen powder mixtures including different gums were prepared. Of these 11 samples included, two different gums and their amounts were equal to 1 g (type of gum used in the hot chocolate formulations is shown in Table 1). To prepare the hot chocolate beverage, 180 ml of distilled water was heated to 80 °C on a hot plate (Yellowline, Germany), and the powder mixture was added slowly to water to prevent agglomeration and stirred constantly under closed conditions to prevent evaporation with a magnetic stirrer at 80 °C for 15 min. Then the hot chocolate drink was cooled to 60 °C in a water bath with a temperature of 25 °C. During analyses, the temperature of the sample was kept at 60 °C in a water bath temperature of 60 °C, to obtain drinkable temperature (Brown and Diller 2008).

Wetting Time

Wetting time or wettability was modified from the method which was described by Schubert (1987a, b). Wet ability was defined as the time (seconds) required for all the ingredients to sink down and penetrate the surface of the water. Forty millilitres of water with a temperature of 80 °C was poured into the cylindrical container diameter of which was 50 mm. Four grams of sample was poured into the cylindrical container. After pouring, they started to wet and sink down into the liquid. The wetting time, i.e. the time necessary for all the powder particles to disappear, was recorded. Analysis was done for S1, S2, S3 and S4 samples.

Solubility

Solubility was modified from the method described by Takashi and Seibi (1988). Solubility of the samples S1, S2, S3 and S4 were determined. Four grams of the samples was added to the water which was at 80 °C in the centrifuge tube. The mixture was stirred intermittently for 30 min and centrifuged at 9,000 rpm for 10 min. About 15 g of the supernatant was drained into an evaporating dish and dried to stable weight at 105 °C. The weight after drying was used to calculate the water solubility. Analyses were performed in duplicate for each of two repetitions.

Bulk Density

The bulk density (BD) was determined following the method of Okaka and Potter (1979). Each sample was poured into a measuring cylinder and tapped ten times on a flat platform. The volume occupied by the sample was recorded. The mass of the empty and filled part of the measuring cylinder and the sample volume poured into the cylinder for each sample were noted. Analysis was performed in duplicate.

Soluble Solids and pH

The soluble solids (brix) of the samples were determined in an automatic refractometer (Reichert AR 700, USA) at room temperature, and the results were expressed as degrees Brix at 20 °C. The pH values were determined using a pH meter (WTW-Inolab Level 3 Terminal, Weilheim, Germany) at room temperature. Both measurements were done in triplicate for each of two repetitions.

Measurement of Colour

The colour of the samples was measured in a colourimeter (Lovibond Reflectance Tintometer 962, Canada). The L*, a* and b* values of each sample were measured at room temperature (L* brightness, a* redness, b* yellowness). Each measurement was done in triplicate for each of two repetitions.

Rheological Measurements

The rheological properties of the hot chocolate samples were determined using a strain/stress controlled rheometer (Thermo-Haake, Rheo Stress 1, Germany) equipped with a temperature-control unit (Thermo-Haake, Karlsruhe K15 Germany) and with a cone-plate configuration with a cone radius of 35 mm and a gap of 1.00 mm between the cone and plate. Measurements were carried out in the shear rate range of 1–300 s−1 at a constant temperature (60 °C). A total of 25 data points were recorded at 10-s intervals during the shearing. Each measurement was replicated five times on the same sample with two repetitions. The apparent viscosity was determined as the function of the shear rate. Apparent viscosity at a shear rate of 50 s−1 was obtained from this graph. The flow curve, shear stress versus shear rate, was plotted by increasing the shear rate. According to obtained data, the Ostwald de Waele model was the most fitted to the flow behaviours of the samples.

where σ is the shear stress (pascal), K is the consistency index (pascal (second)n), γ is the shear rate (per second) and n is the flow behaviour index (dimensionless) (Rao 1999).

Experimental Design and Statistical Analysis

In this study, the simplex centroid mixture design was performed by JMP package software (Version 5.0.1a, SAS Institute, Inc., Cary, NC, USA) to observe the effect of alginate (X 1), xanthan gum (X 2), locust bean gum (X 3) and guar gum (X 4) on the rheological, physical and chemical characteristics of the prebiotic hot chocolate beverage (PHCB) samples. In mixture experiment design, the total amount of gum is held constant, and the measured property of the PHCB changes when the proportions of the gums are changed. Therefore, the aim of this methodology was to verify how the interested properties were affected by the variation in mixture components (Nardi et al. 2004). The proportional levels of the gums were set at 0–1 (0–100%). Fifteen combinations of the four gums are given in Table 1. The 15 points were four single-ingredient, six two-ingredient mixtures, four three-ingredient mixtures and one four-ingredient mixture.

The following quadratic equation was fitted to data obtained from the experimental point. The following polynomial equation was used:

where Y is the predicted response (ºBrix, pH, L*, a*, b*, K, n and η 50); β1, β2, β3, β4, β12, β13, β14, β23, β24 and β34 are the linear and non-linear constants for each term and X is the gum concentration used in the PHCB samples (X 1 alginate; X 2 xanthan gum, X 3 locust bean gum and X 4 guar gum). The predicted equations were obtained by JMP package software (Version 5.0.1a, SAS Institute, Inc., Cary, NC, USA) for each response. Ternary plots were generated by Statistica. Significant differences between the samples and the correlation between the parameters were determined using SPSS 17.0.1

Results and Discussion

Wetting Time, Solubility and Bulk Density of the PHCB Samples Containing Different Gums

Figure 1 shows the solubility, wetting time and bulk density values of the S1, S2, S3 and S4 samples. Solubility is an instant property that affects the consumption characteristics and sensory attributes of instant hot chocolate. There is a close relationship between the particle size of the ingredients and solubility. The percent solubility of the PHCB samples ranged from 7.8% to 8.7%. It is seen from Fig. 1 that the solubility of the four PHCB samples were very close to each other since the most important factor affecting the solubility of hot chocolate drinks is sugar content which is the major component of the products.

BD is a measure of the packing characteristics of particulate solids. The BD of the instant hot chocolates ranged concerning 0.6 and 0.7 g/l. In previous studies, some important linear correlations were reported between BD which increased with increase in moisture contents (Rameshbabu et al. 1996; Suthar and Das 1996). However, Oje (1994) and Carman (1996) reported negative linear correlations between them. Therefore, there was a contradictory result about the relationship between the BD and moisture content of the product.

Wetting time (or wettability) has a close relation with particle size especially in the ingredients which have big particles such as sugar and salt. The wetting time of the samples ranged between 3.48 and 5.45 s. As is seen from Fig. 1, the magnitudes of the solubility, BD and wetting time of the S1, S2, S3 and S4 samples were very close to each other. This result is to be expected because the only difference between these four samples was the type of gum, which made up only a very small amount of PHCB formulation when compared to the other ingredients like sugar, cacao and skimmed milk powder. The slight differences between the samples may have resulted from the particle size of the gums and their water absorption capacity.

Physicochemical Properties of the PHCB Samples

The brix values (total solid content) of the studied samples varied between 13.04 and 13.89 ºBrix, being the highest for the S8 and S14 and lowest for the S1 samples (Table 2). The pH values of the samples were in the range of 8.06 and 8.33. The maximum pH value was observed for the S12 sample (Table 2). The observed pH and brix values were slightly different from those of the previous studies (Yanes et al. 2002a; Dogan et al. 2011). It is known that the formulations of such beverages differ from each other based on country or region. These different formulations cause a variation in the pH and brix values. L* (brightness), a* (redness) and b* (yellowness) values for the PHCB samples are also given in Table 2. The L*, a* and b* values changed between 7.44–13.30, 8.05–10.88 and 7.10–12.95, respectively. These values were different from the previous studies due to the results mentioned above.

Rheological Properties of the PHCB Samples

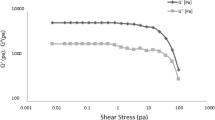

The flow behaviours of the PHCB samples are presented in Fig. 2. Experimental data for the shear stress (σ) and shear rate (γ) for the PHCB samples (except for S8) with different gums or gum combinations were well fitted to the power law model with high determination coefficients (R 2 = 0.962–1.000), as shown in Table 3. The consistency coefficient (K) and flow behaviour index values (n) for each flow curve are also shown in Table 3. The flow behaviour values of the samples were in the range of 0.10–0.69. This value range (less than unity) showed that all the samples exhibited shear-thinning (pseudoplastic) behaviour, and the apparent viscosity values decreased with an increase in shear rate. The K values of the samples varied between 0.81 and 32.97 Pa sn. While the PHCB sample including XG and LBG (1:1) had the highest K, the sample containing alginate had the lowest K value. It is also seen from Table 3 that there were significant differences between the K and n values of the samples (P < 0.05). Similar results were reported in the literature in which chocolate milk beverages exhibited shear-thinning behaviour (Dogan et al. 2011; Toker et al. 2011) and K values ranging between 3.24–65.61 mPa sn at 25 °C and 3.69–126.90 mPa sn at 5 °C (Yanes et al. 2002b). In another study, the K values changed between 6.5 and 144.8 mPa sn (Yanes et al. 2002b). Their results were very low when compared to the results obtained in this study due to the formulation of the samples, especially the difference in gum concentration. We increased the gum concentration in the formulation to observe the effect of different gums or combinations of them on the rheological behaviour of the prebiotic hot chocolate beverage more clearly. The apparent viscosity values (η 50) of the samples at 50 s−1, accepted as the shear rate in mouth (Bourne 2002), are also presented in Table 3. As is seen from the table, η 50 varied between 0.230 and 0.813 Pa s. Among the samples analysed in this study, S14 had the highest η 50 value.

Effect of the Interaction Between the Gums on the Physicochemical and Rheological Parameters

The mixture design was applied to determine the significance of the interaction between the gums. Table 4 shows the predicted models, significance of regression coefficients and the R 2 values for eight different parameters (K, n, η 50, brix, pH, L, a, b) of the PHCB samples. The p values were used to identify the significance of the coefficients. The higher the magnitude of p, the less significant the corresponding coefficient is. If the p values are less than 0.05 or 0.01 (based on significance level), the model terms are accepted as significant.

Effect of the Interaction Between the Gums on the Physicochemical Properties of the PHCB Samples

Table 4 shows the predicted models, significance of regression coefficients and the R 2 values for the brix, pH, L, a and b values of the PHCB samples. These values were important to determine the significance of the equations or models developed from the design (Karaman et al. 2011). It is seen from Table 4 that except for the pH parameter, the R 2 values of the models were higher than 0.75, indicating that these equations may be used for prediction of the parameters (Henika 1982).

Brix values refer to the total soluble solid in the mixture, related to the water absorption capacity of the gums. The R 2 value of the predicted model for the brix value was close to unity, indicating this equation may be used for the prediction of the brix values of the samples based on different gum combinations. Interpreting from the regression coefficients of the linear terms of the predicted model equations, all the gums caused to increase in brix values of the PHCB samples at a nearly equal rate. As seen in the table, all of the linear terms were significant (P < 0.01), and the interaction between the Alg./XG and XG/LBG combinations was also found to be significant. Both of them exerted a synergistic effect on the brix values of the samples. The samples containing XG and LBG (S8) had the highest brix values of 13.89. The variation in the brix values of the samples may have resulted from the water content of the gums, water absorption capacity of the gums and interaction between the gums.

The predicted models for the L*, a* and b* values of the samples are also shown in Table 4. All the linear terms in all three predicted models were significant, and all of them increased these three values (P < 0.01). The XG had the highest increasing effect on the L*, a* and b* values. While there were no significant non-linear terms for the prediction of L* value, the combination of Alg./XG had an antagonistic effect on the a* and b* values. The S8 sample had the highest L* value and S2 sample had the highest a* and b* values. It is seen from the Table 4 that generally the magnitudes of the L*, a* and b* values were similarly affected by gum. This is to be expected because there is a correlation between these values (Table 5). As is seen from Table 4, the colour properties of the samples, which play a major role in quality evaluation and in the decisions of the consumer (Antonelli et al. 2004), were predicted satisfactorily by the mixture design approach.

The pH value was not predicted by using this mixture design approach since the determination coefficient was too low. It is known that pH refers to H+ concentration in the solution, which is affected differently by the amount of water in the solutions, the molecular structure of the gums and the interaction between the gums. Therefore, these complex phenomena resulted in modelling the pH value of the samples poorly.

Effect of the Interaction Between the Gums on the Rheological Properties of the PHCB Samples

The rheological properties of the PHCB samples are shown in Table 3. The K and η 50 values of XG had the highest K value among all the gums, and samples including GG were much higher than those including Alg. and LBG (P < 0.05). XG had the highest effect on the K values of the samples as seen in Table 4. While both of the XG and GG were significant (P < 0.05) in the predicted model equation of K value, the other two gums were not significant. This may have resulted from the fact that the sample containing GG or XG had a much higher K value than the sample including Alg. or LBG. In other words, the GG and XG disenabled the other gums. However, although there was a positive correlation between the K and η 50 values (Table 5), all of the linear terms were significant (P < 0.05) for predicted model of η 50. When the interval between the K (0.81–32.97 Pa sn) and η 50 (0.230–0.813 Pa s) values was investigated, it was seen that the changes in the magnitudes of the K values of the samples were a lot higher than those of the η 50 values. The low change in the magnitudes of the η 50 values between the samples made all linear terms significant in the predicted model equation.

The K values of the LBG/XG and XG/GG were higher than the samples including XG, LBG or GG, indicating that there were synergic interactions between the XG/LBG or XG/GG combinations. It was also observed in the predicted models that XG and LBG had a synergic interaction (P < 0.05). However, the synergic interaction between XG and GG was not found as significant (P > 0.05), which may be resulted from that the K values of XG/GG including sample were very small compared to that of the sample including XG/LBG. The interaction of XG with galactomannans to form high viscosity at low-total-polysaccharide concentrations has been reported in previous studies (Tako et al. 1984; Wielinga 2000). This interaction is more pronounced in LBG than in any other galactomannan (Dea et al. 1977; Higiro et al. 2006). These results supported our findings. There are a considerable number of studies on the mechanisms of the interaction between XG and LBG (Cairns et al. 1986; Cairns et al. 1987; Tako et al. 1984; Wang et al. 2002; Williams et al. 1991). Tako et al. (1984) reported that the interaction between xanthan side chains and the LBG backbone interacted with each other as in the lock-and-key model, in which one xanthan chain could associate with one, two or more LBG molecules.

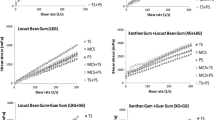

Figures 3 and 4 show the effects of the interaction between the gums on the K and η 50 values of the samples. It is seen from these figures that the increase in Alg. causes a decrease in these two values. In addition, for the mixture containing XG/LBG/GG, the increase in GG concentration results in a decrease in both of the K and η 50 values. It could be said that the use of a XG and LBG combination provides the highest K and η 50 values for the PHCB samples. Instead of the using of LBG or XG in the formulation of the PHCB or similar products, the use of both LBG and XG may be more convenient.

The n values of the samples were satisfactorily explained by the model equation with a high determination coefficient value (R 2 = 0.9788). As is seen from Table 4, all of the linear terms were significant (P < 0.01). XG and LBG interaction had an antagonistic effect on the n values (P < 0.01). It can be concluded that there was no correlation between the K and n values (Table 5). Similar results were obtained by several researchers (Sopade and Filibus 1995; Hassan and Hobani 1998; Togrul and Arslan 2004; Yılmaz et al. 2011).

Figure 5 shows the prediction profiles of the different gum effects on the parameters of the PHCB samples. As is seen in the figure the brix, K and η 50 values showed similar attitudes as expected in this figure. Positive correlations between these three parameters are also seen in Table 5. The a* and b* values also showed a similar trend, which resulted from the correlation between these values with high determination coefficients (R 2 = 0.869).

Optimization of the Gum Combination Based on the Rheological Parameters

Our aim was to optimize the gum combination used in the PHCB sample based on the rheological parameters to minimize the gum concentration in the formulation of the product. The consistency index value (K) is accepted as the major criteria for the optimization of the gum combination. The sample containing 59% XG and 41% LBG combination had the highest K value of 33.56 Pa sn. The usage of Alg. and GG led to a decrease in the K values of the samples. The magnitudes of the n, η 50, brix, pH, L, a and b values of the sample containing 59% XG and 41% LBG were found to be 0.009, 0.82 Pa s, 13.93, 8.17, 13.44, 10.06 and 11.26, respectively.

Conclusion

The rheological properties of the samples are very important for the consumer acceptability of products such as hot chocolate. In prebiotic hot chocolate beverage, these properties are mainly affected by the amount or type of the gum used. The determination of the optimum gum or gum combination for the product provides economic benefits by decreasing the gum concentration in the formulation. In this study, mixture design was applied to obtain the optimum gum combination for the prebiotic hot chocolate beverage. The optimum gum combination was found to be 59% XG and 41% LBG. The use of the GG and Alg. resulted in a decrease in the K values of the samples. As a result of this study, it may be concluded that these types of models may be used in industry to optimize the formulation of products, to minimize product costs and to ensure consumer acceptability of the product.

Abbreviations

- K :

-

Consistency index (Pa sn)

- n :

-

Flow behaviour index

- η 50 :

-

Apparent viscosity at 50 s−1 (Pa s)

- L*:

-

Brightness

- a*:

-

Redness

- b*:

-

Yellowness

- SCMD:

-

Simplex centroid mixture design

- X 1 :

-

Alginate concentration

- X 2 :

-

Xanthan gum concentration

- X 3 :

-

Locust bean gum concentration

- X 4 :

-

Guar gum concentration

- Alg.:

-

Alginate

- GG:

-

Guar gum

- XG:

-

Xanthan gum

- LBG:

-

Locust bean gum

- σ :

-

Shear stress (Pa)

- γ :

-

Shear rate (s−1)

- PHCB:

-

Prebiotic hot chocolate beverage

- β 1 β 2 :

-

Linear and non-linear constants

- BD:

-

Bulk density (g/l)

- °C:

-

Degree centigrade

References

Antonelli, A., Cocchi, M., Fava, P., Foca, G., Franchini, G. C., Manzini, D., & Ulrici, A. (2004). Automated evaluation of food colour by means of multivariate image analysis coupled to wavelet-based classification algorithm. Analytica Chimica Acta, 515, 3–13.

Arteaga, G. E., Li-Chan, E., Nakai, S., Confrades, S., & Jimenez-Colmenero, F. (1993). Ingredient interaction effects on protein functionality: Mixture design approach. Journal of Food Science, 58(3), 656–662.

Bourne, M. C. (2002). Physics and texture. Chapter 3 Food texture and viscosity. 558 concept and measurement (pp. 59–106). London: Academic.

Brennan, C. S., & Tudorica, C. M. (2007). Fresh pasta quality as affected by enrichment of nonstarch polysaccharides. Journal of Food Science, 72, 659–665.

Brown, F., & Diller, R. K. (2008). Calculating the optimum temperature for serving hot beverages. Burns, 34(5), 648–654.

Cairns, P., Miles, M. J., & Morris, V. J. (1986). Intermolecular bonding of xanthan gum and carob gum. Nature, 322, 89–90.

Cairns, P., Miles, M. J., Morris, V. J., & Brownsey, G. J. (1987). X-ray fibre-diffraction studies of synergistic, binary polysaccharide gels. Carbohydrate Research, 160, 411–423.

Cardarelli, H. R., Buriti, F. C. A., Castro, I. A., & Saad, S. M. I. (2008). Inulin and oligofructose improve sensory quality and increase the probiotic viable count in potentially symbiotic petit-suisse cheese. LWT—Food Science and Technology, 41(6), 1037–1046.

Carman, K. (1996). Physical properties of lentil seeds. Journal of Agricultural Engineering Research, 63, 87–92.

Da Silva Lannes, S. C., & Medeiros, M. L. (2008). Rheological properties of chocolate drink from cupuassu. International Journal of food engineering, 4(1), 1–11.

Dea, I. C. M., Morris, E. D., Rees, D. A., & Welsh, E. J. (1977). Associations of like and unlike polysaccharides: mechanism and specificity in galactomannans, interacting bacterial polysaccharides, and related systems. Carbohydrate Research, 57, 249–272.

Dello Staffolo, M., Bertola, N., Martino, M., & Bevilacqua, A. (2004). Influence of dietary fiber addition on sensory and rheological properties of yogurt. International Dairy Journal, 14, 783–789.

Dogan, M., Kayacier, A., & Ic, E. (2007). Rheological characteristics of some food hydrocolloids processed with gamma irradiation. Food Hydrocolloids, 21(3), 392–396.

Dogan, M., Toker, O. S., & Goksel, M. (2011). Rheological behaviour of instant hot chocolate beverage: Part 1. Optimization of the effect of different starches and gums. Food Biophysics, 6, 512–518

Dutcosky, S. D., Grossmann, V. M. E., Silva, R. S. S. F., & Welsch, A. K. (2006). Combined sensory optimization of a prebiotic cereal product using multicomponent mixture experiments. Food Chemistry, 98(4), 630–638.

El-Nagar, G., Clowes, G., Tudorica, C. M., Kuri, V., & Brennan, C. (2002). Rheological quality and stability of yog-ice cream with added inulin. International Journal of Dairy Technology, 55(2), 89–93.

Fagan, C. C., O’Donnel, C. P., Cullen, P. J., & Brennan, C. S. (2006). The effect of dietary fibre inclusion on milk coagulation kinetics. Journal of Food Engineering, 77, 261–268.

Flores, S. K., Costa, D., Yamashita, F., Gerschenson, L. N., & Grossmann, M. V. (2010). Mixture design for evaluation of potassium sorbate and xanthan gum effect on properties of tapioca starch films obtained by extrusion. Materials Science and Engineering: C, 30, 196–202.

Franck, A. (2002). Technological functionality of inulin and oligofructose. British Journal of Nutrition, 87, 287–291.

Guven, M., Yasar, K., Karaca, O. B., & Hayaloglu, A. A. (2005). The effect of inulin as a fat replacer on the quality of set-type low-fat yogurt manufacture. International Journal of Dairy Technology, 58(3), 180–184.

Hassan, B. H., & Hobani, A. I. (1998). Flow properties of Roselle (Hibiscus sabdariffa L.) extract. Journal of Food Engineering, 35, 459–470.

Henelly, P. J., Dunne, P. G., O’Sullivan, M., & O’Riordan, E. D. (2006). Textural, rheological and microstructural properties of imitation cheese containing inulin. Journal of Food Engineering, 75, 388–395.

Henika, R. G. (1982). Use of response surface methodology in sensory evaluation. Food Technology-Chic, 36, 96–101.

Higiro, J., Herald, T. J., & Alavi, S. (2006). Rheological study of xanthan and locust bean interaction in dilute solution. Food Research International, 39, 165–175.

Karaman, S., Yilmaz, M. T., & Kayacier, A. (2011). Simplex lattice design approach on the rheological behaviour of glucomannan based salep–honey drink mixtures: An optimization study based on the sensory properties. Food Hydrocolloids, 25(5), 1319–1326.

Kayacier, A., & Dogan, M. (2006). Rheological properties of some gums-salep mixed solutions. Journal of Food Engineering, 72, 261–265.

Khouryieh, H. A., Herald, T. J., Aramouni, F., & Alavi, S. (2006). Influence of mixing temperature on xanthan conformation and interaction xanthan-guar gum in dilute aqueous solutions. Food Research International, 39, 964–973.

Koca, N., & Metin, M. (2004). Textural, melting and sensory properties of low-fat fresh kashar cheeses produced by using fat replacers. International Dairy Journal, 14, 365–373.

Lop, S. C. F., Silva, R. S. F., & Beleia, A. P. (1999). Formulation and evaluation of dry dessert mix containing sweetener combinations using mixture response methodology. Food Chemistry, 66(2), 167–171.

Marcotte, M., Hoshahili, A. R. T., & Ramaswamy, H. S. (2001). Rheological properties of selected hydrocolloids as a function of concentration and temperature. Food Research International, 34, 695–703.

Nardi, J. V., Acchar, W., & Hotza, D. (2004). Enhancing the properties of ceramic products through mixture design and response surface analysis. Journal of the European Ceramic Society, 24, 375.

Oje, K. (1994). Moisture dependence of some physical properties of cowpea. Ife Journal of Technology, 4, 23–27.

Okaka, J. E., & Potter, N. N. (1979). Physicochemical and functional properties of soybean powders processed to reduce flavor. Journal of Food Science, 44, 1235–1240.

Rameshbabu, M., Jayas, D. S., Muir, W. E., White, N. D. G., & Mills, J. T. (1996). Bulk and handling properties of hull-less barley. Canadian Agricultural Engineering, 38, 31–35.

Rao, M. A. (1999). Rheology of fluid and semisolid foods (pp. 371–372). Gaithersburg: Aspen.

Rodriguez Furlán LT, Pérez Padilla A, Campderros M (2011). Development of a functional beverage formulation with high protein content, inulin and Stevia. International Journal of Food Engineering, 7(3), Art. No. 1.

Schaller-Povolny, L. A., & Smith, D. E. (1999). Sensory attributes and storage life of reduced fat ice cream as related to inulin content. Journal of Food Science, 64(3), 555–559.

Schaller-Povolny, L. A., & Smith, D. E. (2001). Viscosity and freezing point of a reduced fat ice cream mix as related to inulin content. Milchwissenschaft-Milk Science International, 56(1), 25–29.

Schubert, H. (1987a). Process and properties of instant powdered foods. In P. Link, Y. Milky, J. Lockup, & J. Laminar (Eds.), Food processing engineering (pp. 657–684). London: Elsevier Applied Science.

Schubert, H. (1987b). Food particle technology. Part I: Properties of particles and particulate food systems. Journal of Food Engineering, 6, 1–32.

Shittu, T. A., & Lawal, M. O. (2007). Factors affecting instant properties of powdered cocoa beverages. Food Chemistry, 100, 91–98.

Sopade, P. A., & Filibus, T. E. (1995). The influence of solid and sugar contents on rheological characteristics of akamu, a semi-liquid maize food. Journal of Food Engineering, 24(2), 197–211.

Suthar, S. H., & Das, S. K. (1996). Some physical properties of Karingda [Citrus lanatus (thumb) mansf] grains. Journal of Agricultural Engineering Research, 65, 15–22.

Sutinium, D., Haruthaithasan, V., & Chompreeda, P. (2008). Development of instant nutritious beverage from germinated jasmine brown rice for elderly consumers. Kasetsart Journal—Natural Science, 42(1), 88–98.

Takashi, S., & Seibi, P. A. (1988). Paste and gel properties of prime corn and wheat starches with and without nitric liquids. Cereal Chemistry, 65, 474.

Tako, M., Asato, A., & Nakamura, S. (1984). Rheological aspects of the intermolecular interaction between xanthan and locust bean gum in aqueous media. Agricultural and Biological Chemistry, 48(12), 2995–3000.

Tárrega, A., & Costell, E. (2006). Effect of inulin addition on rheological and sensory properties of fat-free starch-based dairy desserts. International Dairy Journal, 16(9), 1104–1112.

Togrul, H., & Arslan, N. (2004). Mathematical model for prediction of apparent viscosity of molasses. Journal of Food Engineering, 62, 281–289.

Toker, Ö. S., Doğan, M., & Göksel, M. (2011). Prediction of rheological parameters of model instant hot chocolate beverage by adaptive neuro fuzzy inference system. Milchwissenchaft-Milk Science International, In press.

Tungland, B. C., & Meyer, D. (2002). Non digestible oligo-and polysaccharides (dietary fiber): Their physiology and role in human health and food. Comprehensive Reviews in Food Science and Food Safety, 1, 73–92.

Walkenström, P., Kidman, S., Hermansson, A., Rasmussen, P. B., & Hoegh, L. (2003). Microstructure and rheological behaviour of xanthan/pectin mixed gels. Food Hydrocolloids, 17, 593–603.

Wang, F., Wang, Y. J., & Sun, Z. (2002). Conformational role of xanthan in its interaction with locust bean gum. Journal of Food Science, 67(7), 2609–2614.

Williams, P. A., Clegg, S. M., Day, D. H., Phillips, G. O., & Nishinari, K. (1991). Mixed gels formed with konjac mannan and xanthan gum. In E. Dickinson (Ed.), Food polymers, gels and colloids (pp. 339–348). Cambridge: Royal Society of Chemistry.

Wielinga, W. C. (2000). Galactomannans. In G. O. Philips & P. A. Williams (Eds.), Handbook of hydrocolloids. Cambridge: Woodhead.

Yanes, M., Durán, L., & Costell, E. (2002a). Effect of hydrocolloid type and concentration on flow behaviour and sensory properties of milk beverages model systems. Food Hydrocolloids, 16, 605–611.

Yanes, M., Durán, L., & Costell, E. (2002b). Rheological and optical properties of commercial chocolate milk beverages. Journal of Food Engineering, 51, 229–234.

Yılmaz, M. T., Karaman, S., Cankurt, H., Kayacier, A., & Sagdic, O. (2011). Steady and dynamic oscillatory shear rheological properties of ketchup-processed cheese mixtures: Effect of temperature and concentration. Journal of Food Engineering, 103, 197–210.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dogan, M., Toker, O.S., Aktar, T. et al. Optimization of Gum Combination in Prebiotic Instant Hot Chocolate Beverage Model System in Terms of Rheological Aspect: Mixture Design Approach. Food Bioprocess Technol 6, 783–794 (2013). https://doi.org/10.1007/s11947-011-0736-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0736-y